High-temperature and high-alkali flue gas ultra-clean treatment system

A processing system and ultra-clean technology, applied in the separation of dispersed particles, chemical instruments and methods, combined devices, etc., to achieve the effects of full reaction, reduced impact, and improved flue gas properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

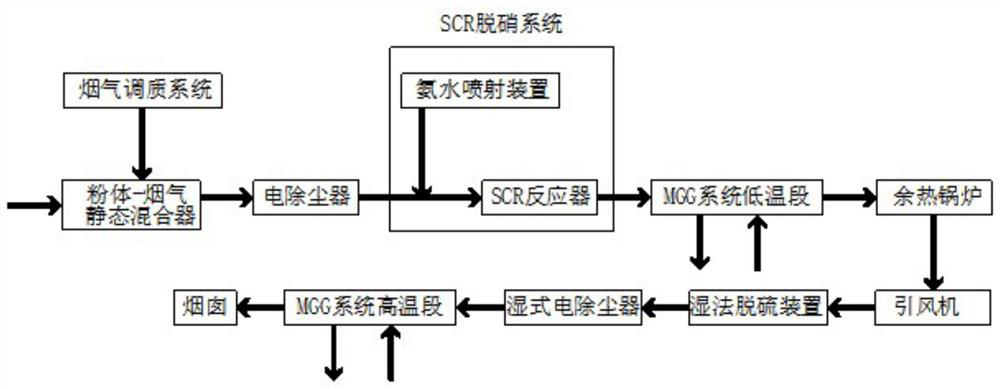

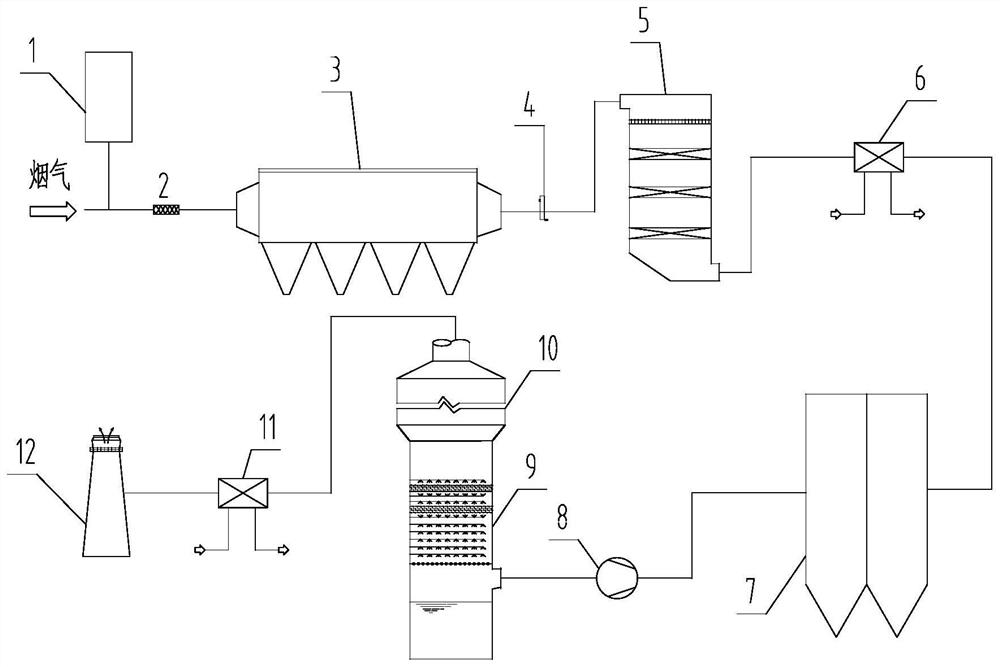

[0023] The present invention is an ultra-clean treatment system for high-temperature and high-alkali flue gas. The system includes that the high-temperature and high-alkali flue gas is sprayed by a flue gas conditioning system (1) and then mixed in a powder-flue gas static mixer (2). , and then enter the high-temperature electrostatic precipitator (3) to perform pre-dust removal treatment on the flue gas. Then the flue gas is sprayed with ammonia water by the ammonia water injection device (4) and then enters the SCR reactor (5) for denitrification treatment. The treated flue gas enters the high temperature section (6) of the MGGH system to cool down and then enters the waste heat boiler (7) to further utilize the waste heat of the flue gas. Enter the wet desulfurization device (9) through the induced draft fan (8), desulfurize the flue gas and then enter the wet electrostatic precipitator (10) at the top of the tower, and finally the flue gas enters the low temperature sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com