A method for preventing hard breaking of electrodes in the production of manganese-silicon alloys in submerged arc furnaces

A technology of manganese-silicon alloy and submerged arc furnace, which is applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems of unsuitable electrode protection and hard breaking of electrodes, so as to reduce the cost of smelting electricity, prevent hard breaking, and prevent electrode hard breaking. problem-solving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A method for preventing hard breaking of electrodes in submerged arc furnace peak avoidance production:

[0024] 1) First, press the electrode into the material surface after avoiding the peak, and lower the electrode by 200-300mm according to the length of the working end of the electrode;

[0025] 2) Secondly, before power transmission, return the electrode back by an appropriate amount of 100-150mm, control the power transmission current not to exceed 200A, and slowly increase the load at a lifting speed of 5-7A / min, subject to the shiny surface of the baked electrode, until it is fully charged. load;

[0026] 3) Add a stable layer at the root of the electrode. The stable layer includes manganese ore with high iron content. The stable layer can increase the specific resistance of the charge at the root of the electrode. After the iron oxide is melted and reduced in the middle and later stages of smelting, the high temperature in the electrode nest will ...

Embodiment 2

[0034] Example 2: Characterization:

[0035] The test method of hard break of the electrode: measure the length of the electrode with a measuring tool regularly every day, test continuously for one month, and use the hard break of the electrode to characterize the hard break of the electrode.

[0036] The amount of hard break of the electrode is expressed by the ratio of the hard break length of the electrode to the initial length of the electrode. The amount of electrode hard breaking is the average value during the 30-day test period; during the test period, the initial length of the electrode used every day is a fixed value.

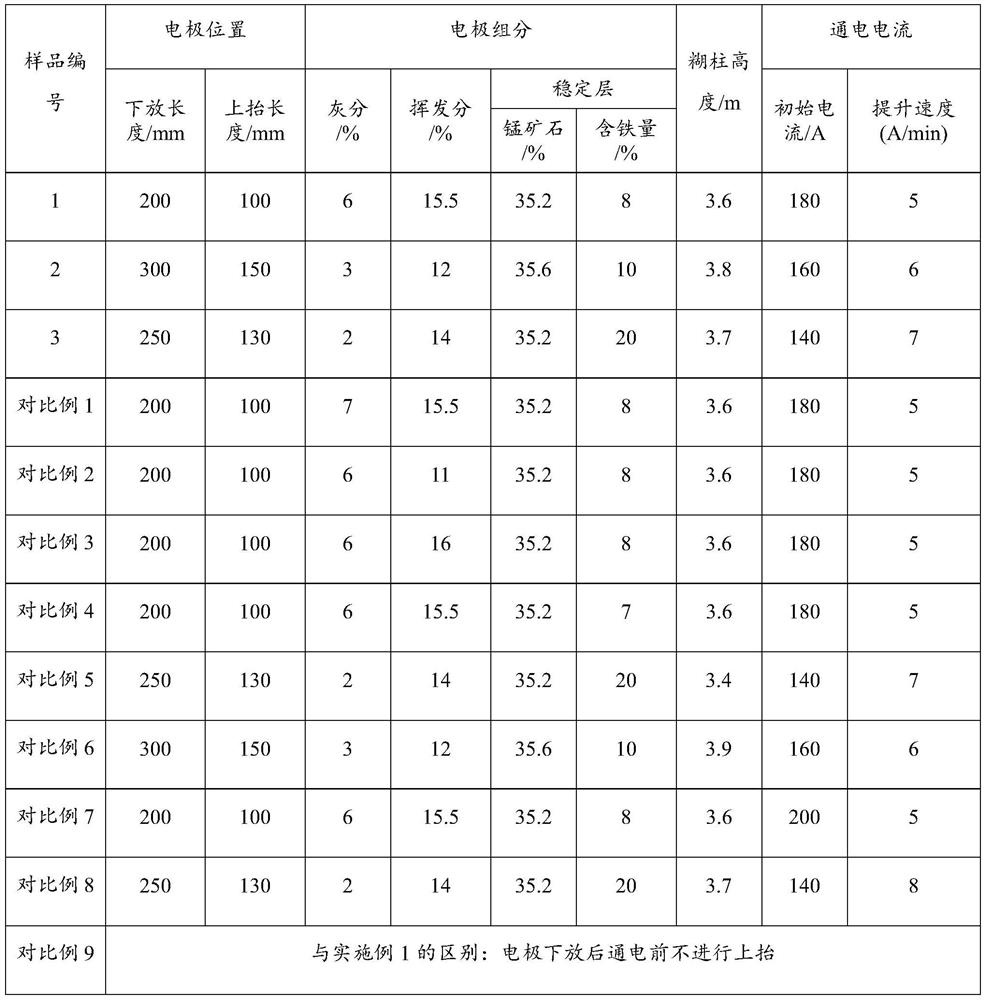

[0037] Table 2 Test results of electrode hard break

[0038] Sample serial number Electrode hard break / % 1 0 2 10 3 4 Comparative example 1 25 Comparative example 2 30 Comparative example 3 35 Comparative example 4 36 Comparative example 5 52 Comparative example 6 39 Comparative examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com