X-ray detector with in-pixel processing circuits

A technology of X-ray and detector, which is applied in the field of medical imaging equipment and the manufacture of this kind of X-ray detector, can solve the problems of damage and processing circuit X-ray interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

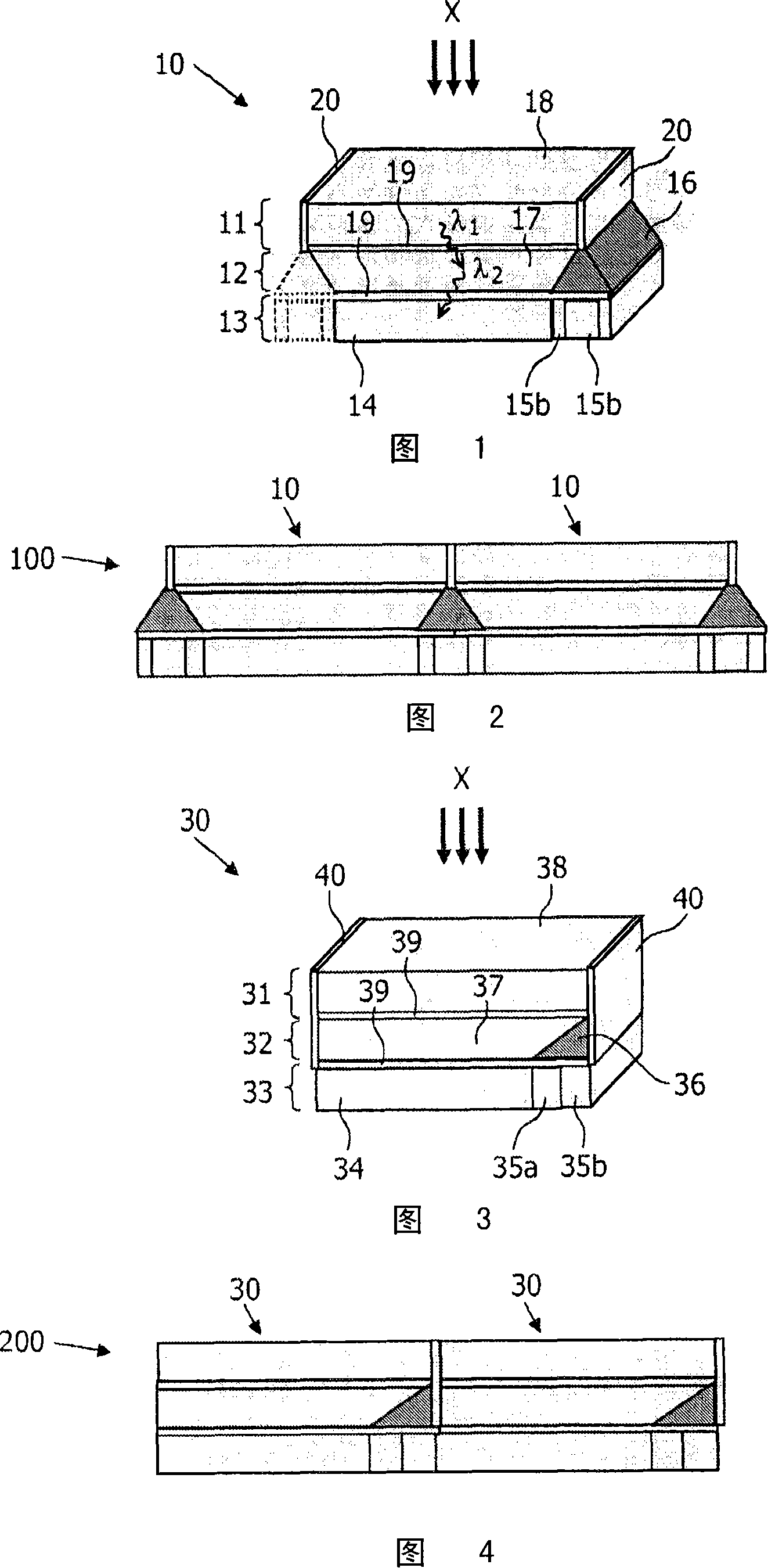

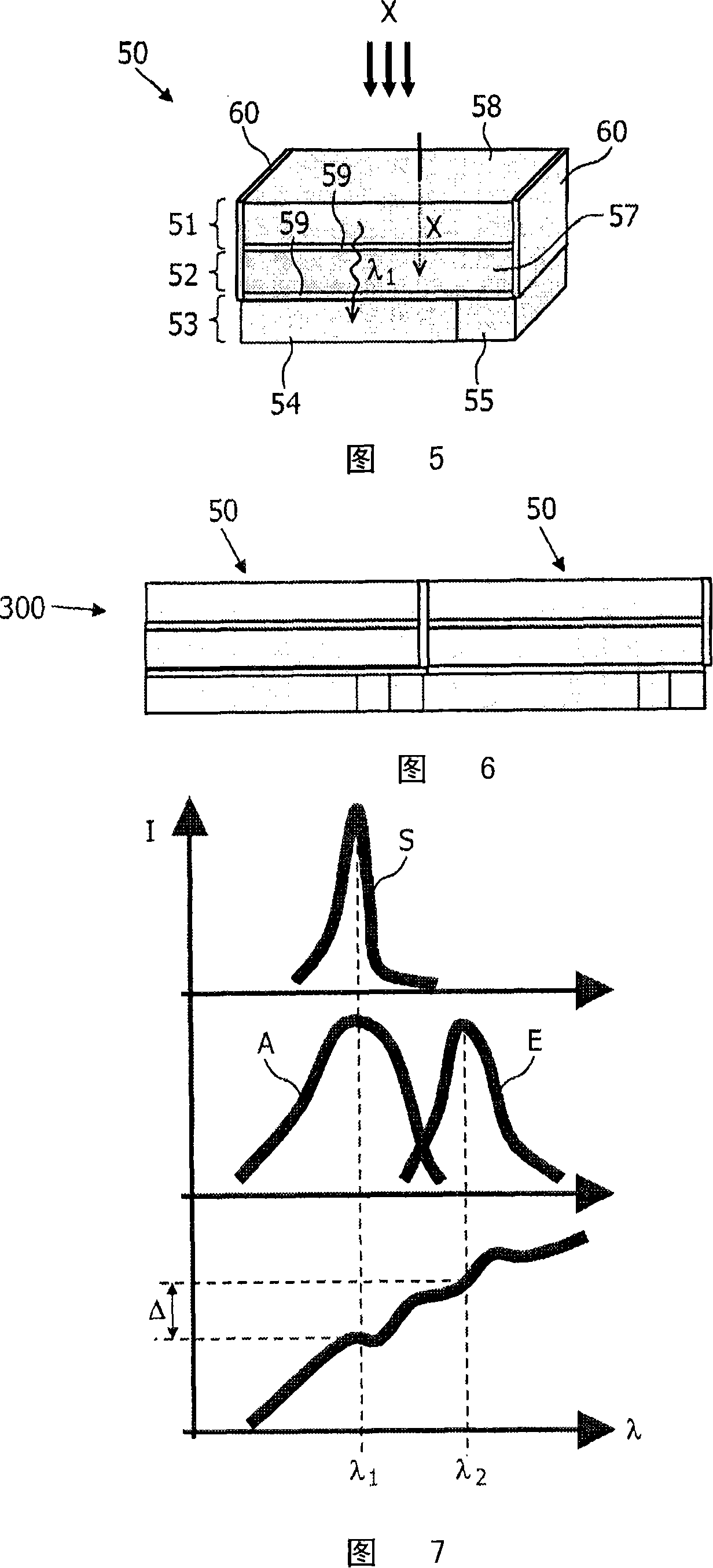

[0033]In prior art computed tomography (CT), scintillator pixel elements placed on Si photodiodes or on top of both CMOS photodiodes and integrated radiation-sensitive in-pixel electronics are used as X-ray detectors. Electronics are now protected from X-rays by lead spacers between adjacent scintillator elements. This technique is expensive to manufacture, construct and set up, and has the disadvantage of resulting in a sub-optimal DQE (Detection Quantum Efficiency). An alternative method of shielding the electronics is to employ the scintillator material itself. Since it must be thick enough to adequately absorb X-rays, it can adversely affect light output and efficiency due to reduced light transmission (also, thicker layers are also more expensive). If the thickness of the scintillator material is not sufficient for adequate shielding, a certain amount of X-ray radiation will pass through this material without any reaction and thus cause radiation damage to photodiodes, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com