Slag-free orbit reinforced concrete pile net structure roadbed and construction method thereof

A reinforced concrete, ballastless track technology, applied in roads, tracks, buildings, etc., can solve the problems affecting the development speed of high-speed railway, large-scale construction of high-speed railway, complex regional geological conditions, etc., to improve maintenance and repair operation conditions, reduce The effect of reducing construction cost and reducing the intensity of maintenance and repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

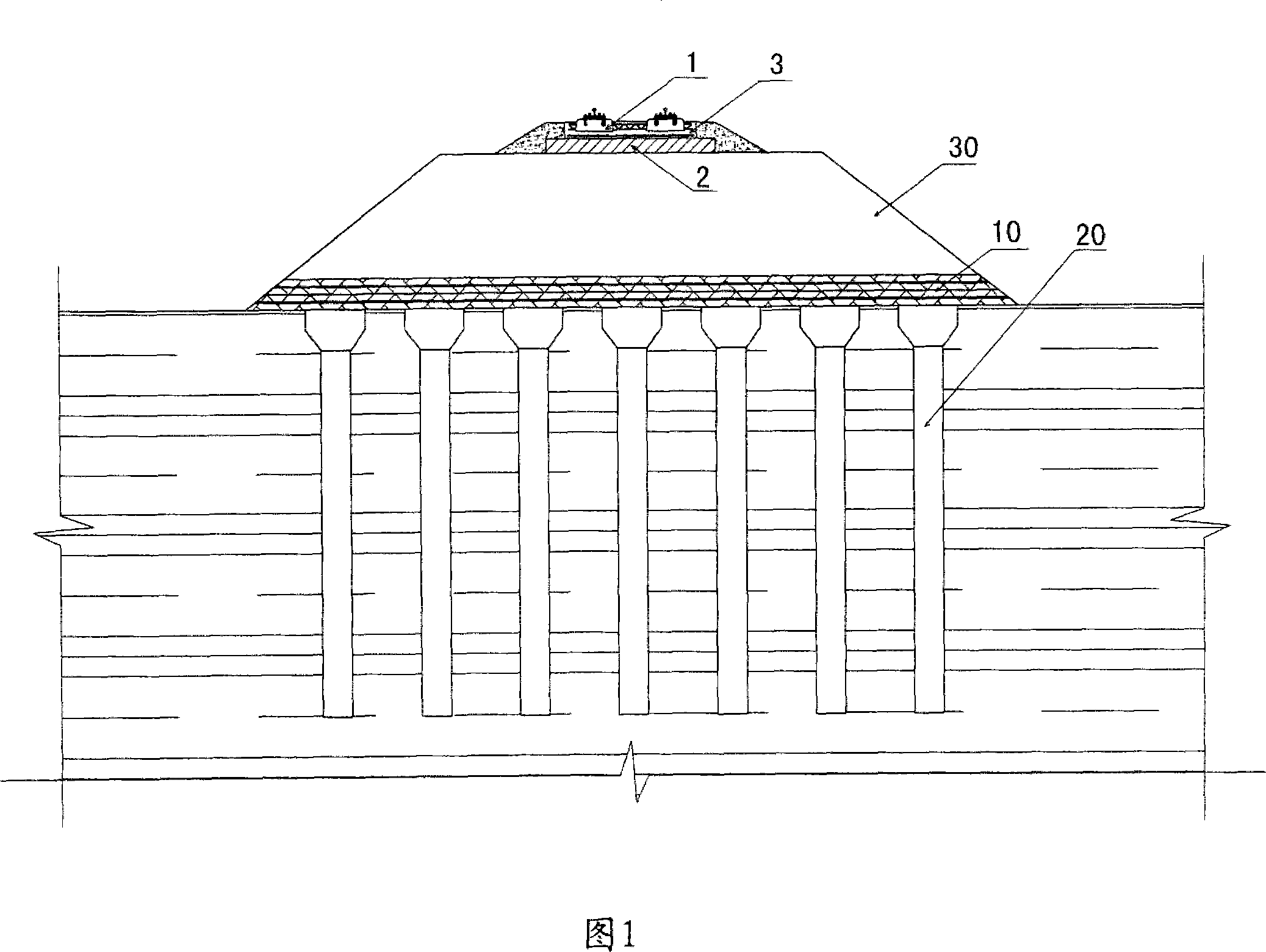

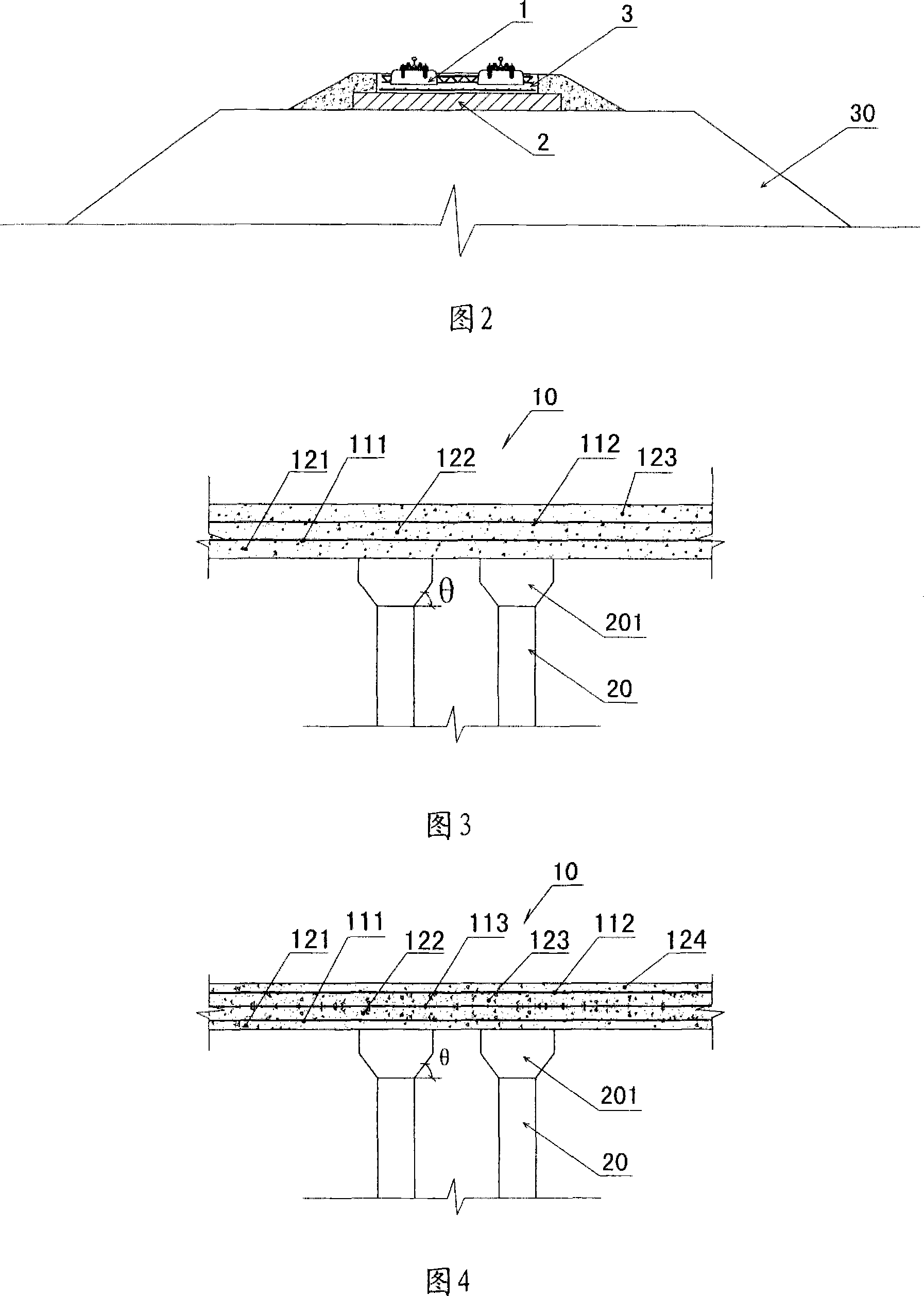

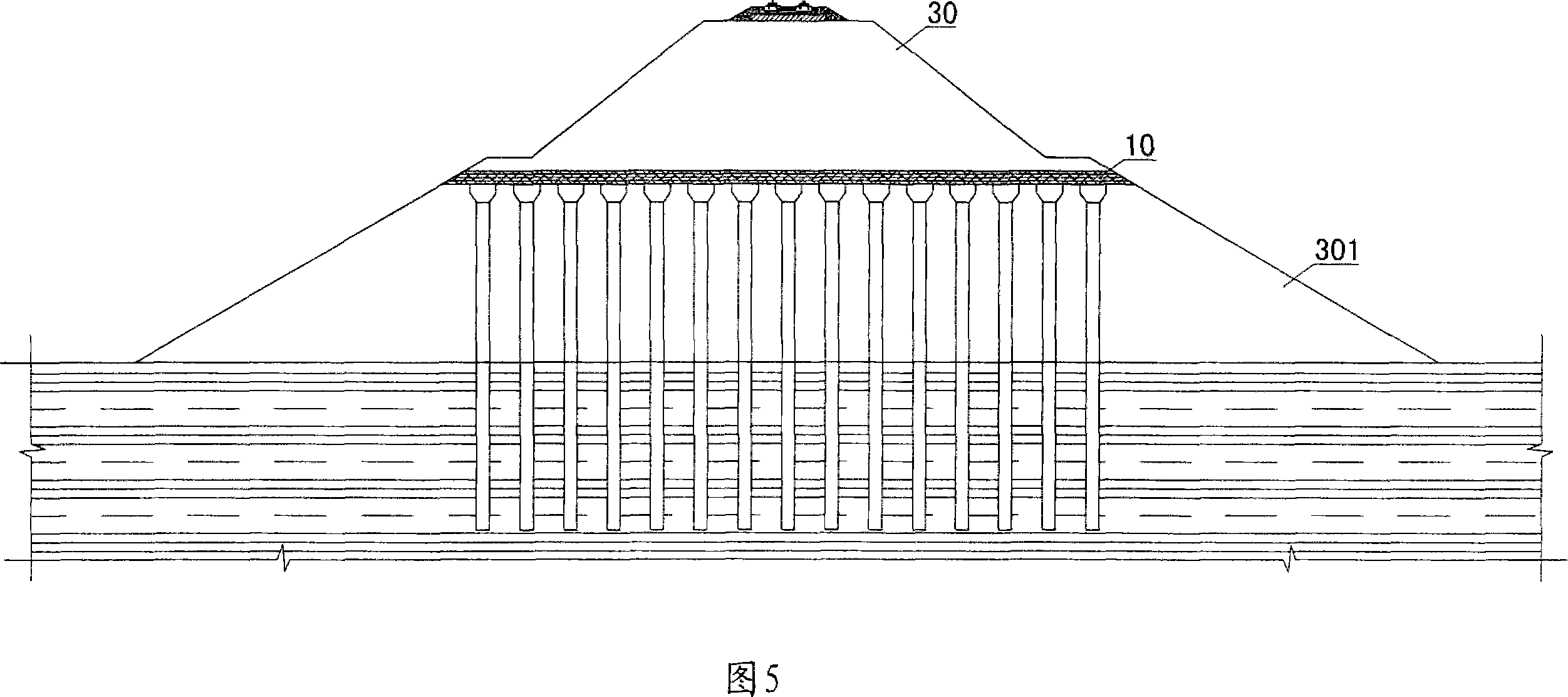

[0022] With reference to Fig. 1, the reinforced concrete pile net structure roadbed of ballastless track of the present invention, it comprises: reinforced concrete pile 20, longitudinally, laterally spaced arrangement along roadbed; 30, filling on the reinforced cushion 10.

[0023] The ballastless track reinforced concrete pile network structure subgrade of the present invention combines the respective characteristics of the double-block sleeper embedded ballastless track, the slab ballastless track and the composite foundation structure, and makes full use of the joint action principle of pile-net-soil It meets the strength and settlement deformation requirements of the ballastless track, overcomes the shortcomings of high embankment structure settlement and differential settlement and low embankment structure dynamic influence degree, and has strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com