Bathroom decoration construction method

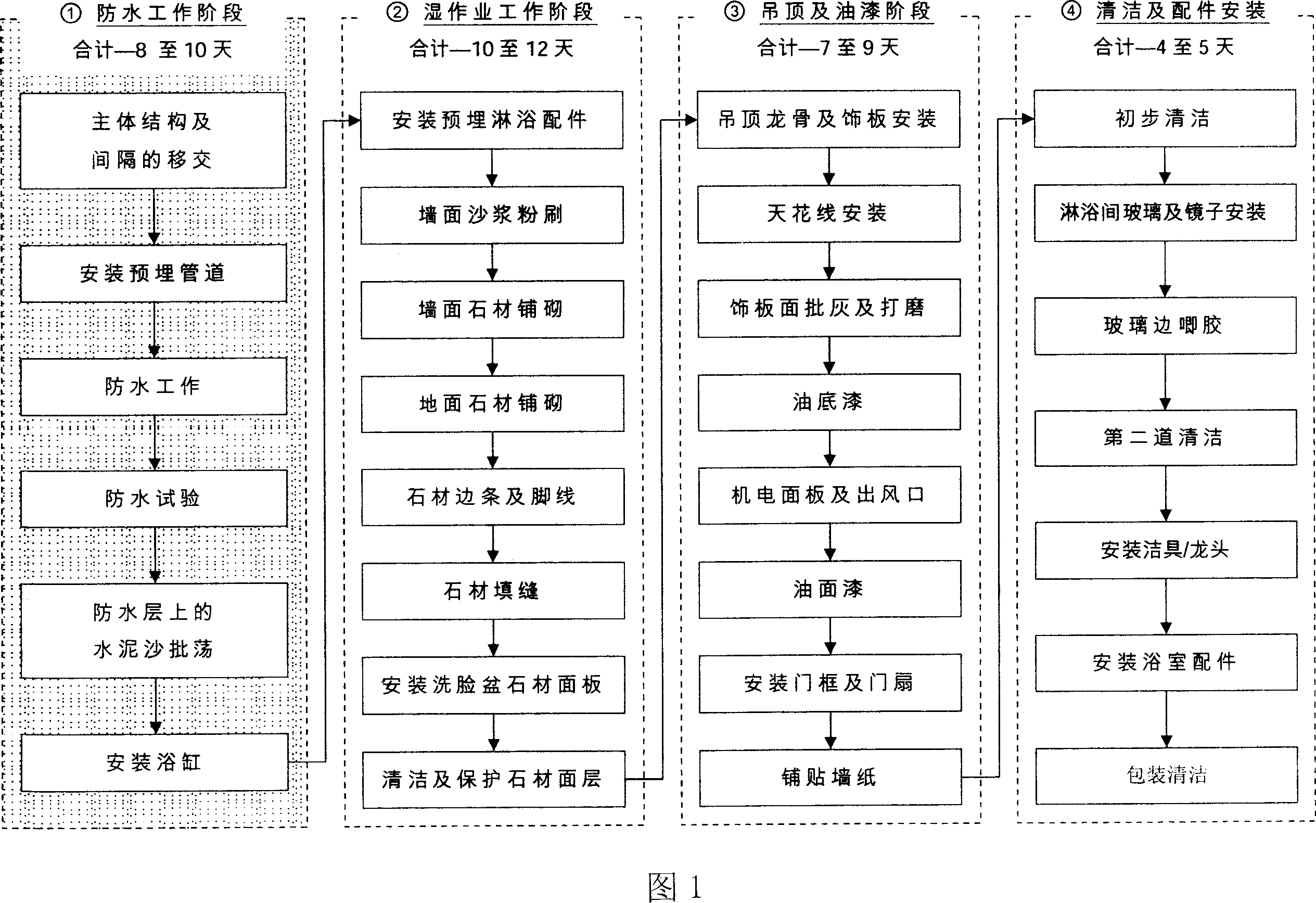

A decoration construction and bathroom technology, which is applied in the field of decoration and construction of bathrooms in high-end hotels, can solve problems such as difficult quality assurance, slow construction progress, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

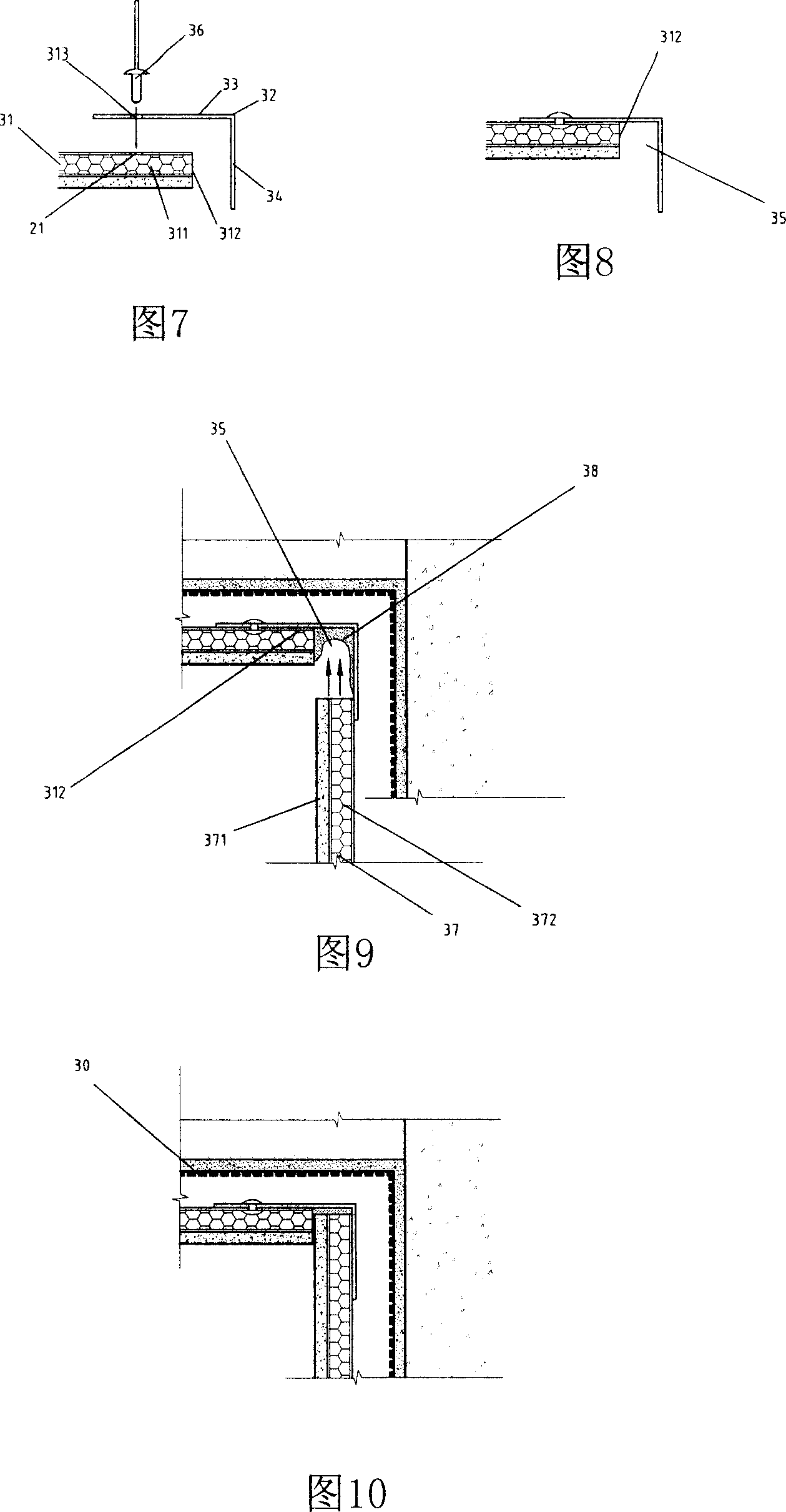

[0050] Below, according to FIG. 2 to FIG. 16 , a preferred embodiment of the present invention is given and described in detail, so as to better understand the functions and characteristics of the present invention.

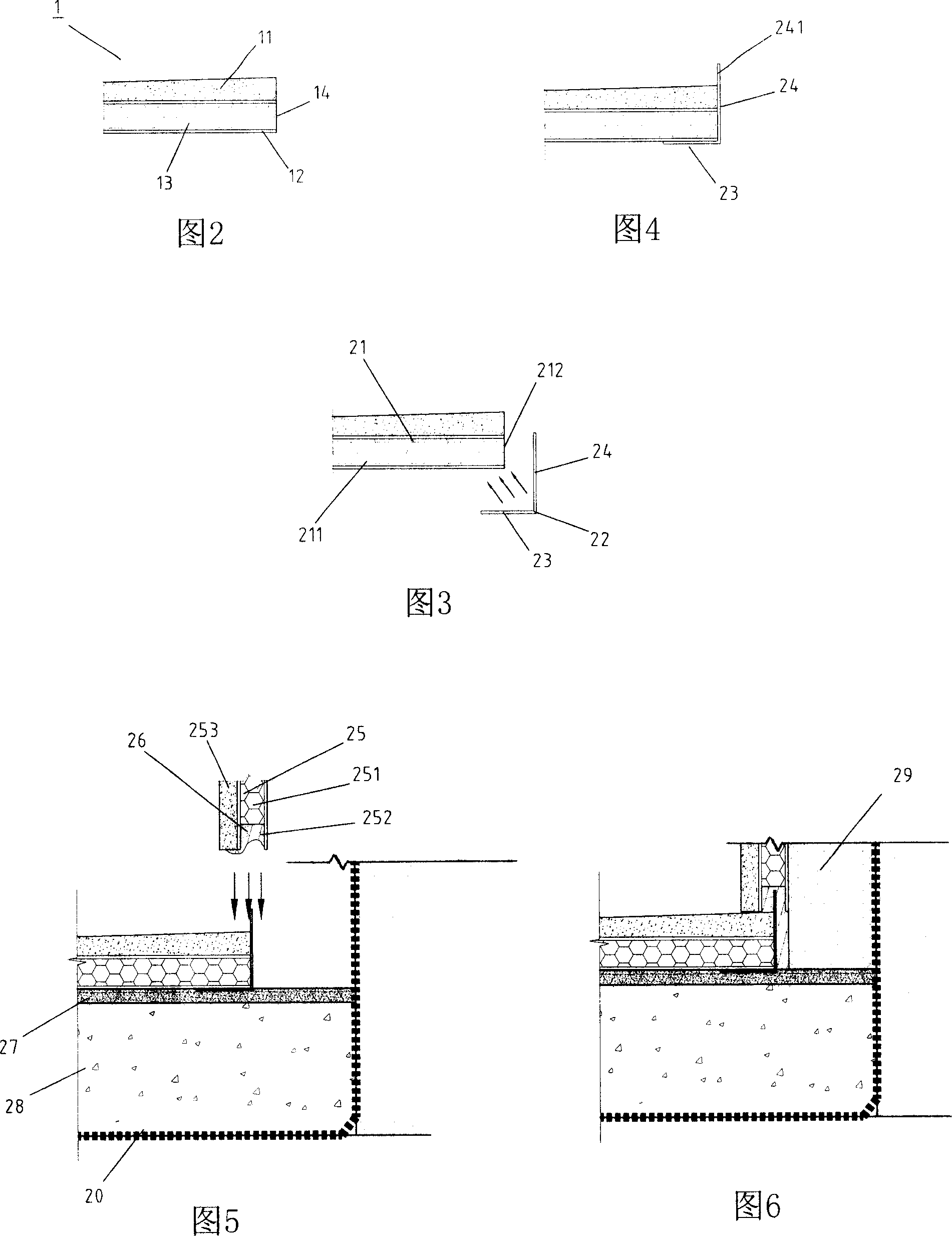

[0051] First, the present invention uses aluminum honeycomb composite stone panels as prefabricated standard parts. As shown in FIG. 2 , the aluminum honeycomb composite stone panel 1 of the present invention includes a 5mm marble thin panel 11 and an aluminum honeycomb panel 14 composed of an aluminum honeycomb 13 sandwiched by two layers of 1mm thick aluminum panels 12 . The marble thin plate 11 is pasted on the aluminum honeycomb panel 14 by vacuum sticking, as a subsequent wall veneer and floor veneer. The thickness of the aluminum honeycomb 13 is 8mm-12mm. Using such materials, the aesthetic feeling of natural stone can be retained, but the bending strength and impact strength are greatly enhanced. In addition, the weight is only one-third of the original ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com