Engine oil seal lip grease adding device

A filling device and grease technology, applied in the field of fixtures, can solve problems such as high labor intensity, low work efficiency, and poor safety, and achieve the effects of avoiding scratches, low labor intensity, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

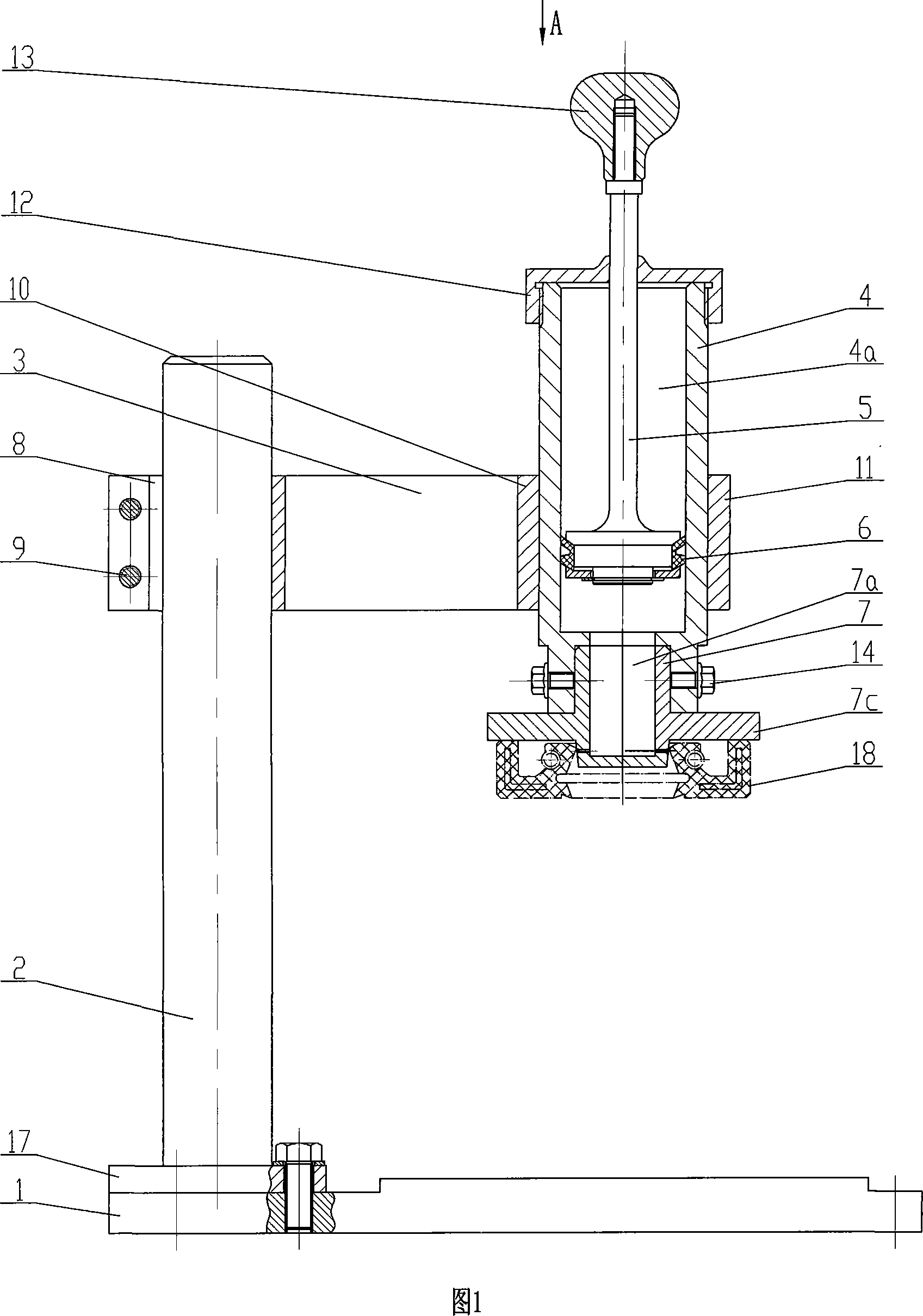

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

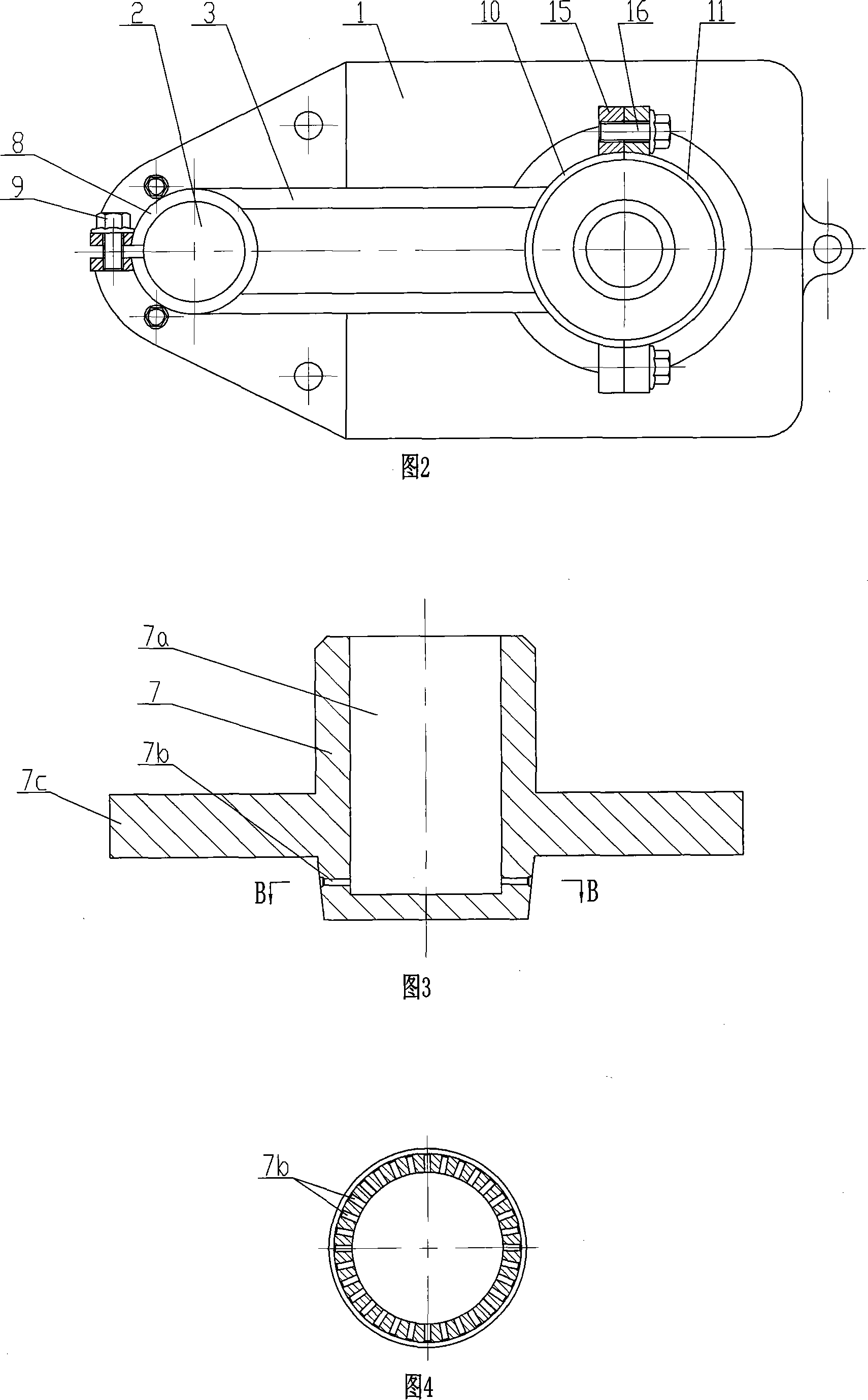

[0028] As shown in Figure 1 and Figure 2, the present invention consists of a base 1, a column 2, a support beam 3, an oil cylinder 4, a push rod 5, a piston 6, a positioning sleeve 7, a hoop 8, a fixed connecting plate 10, a movable connecting plate 11, Parts such as tail cover 12 and bolt constitute. Wherein the base 1 is a flat plate structure, the column 2 is positioned at the side above the base 1 and arranged vertically, the bottom end of the column 2 is a flange 17, and the flange 17 is fixedly connected with the base 1 by screws, and the base 1 can be fixed on work surface. The support beam 3 is horizontally arranged relative to the column 2, and one end of the support beam 3 is welded with a hoop 8, which is set on the upper body of the column 2 and locked by a bolt 9; the other end of the support beam 3 is a cantilever end, located at On the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com