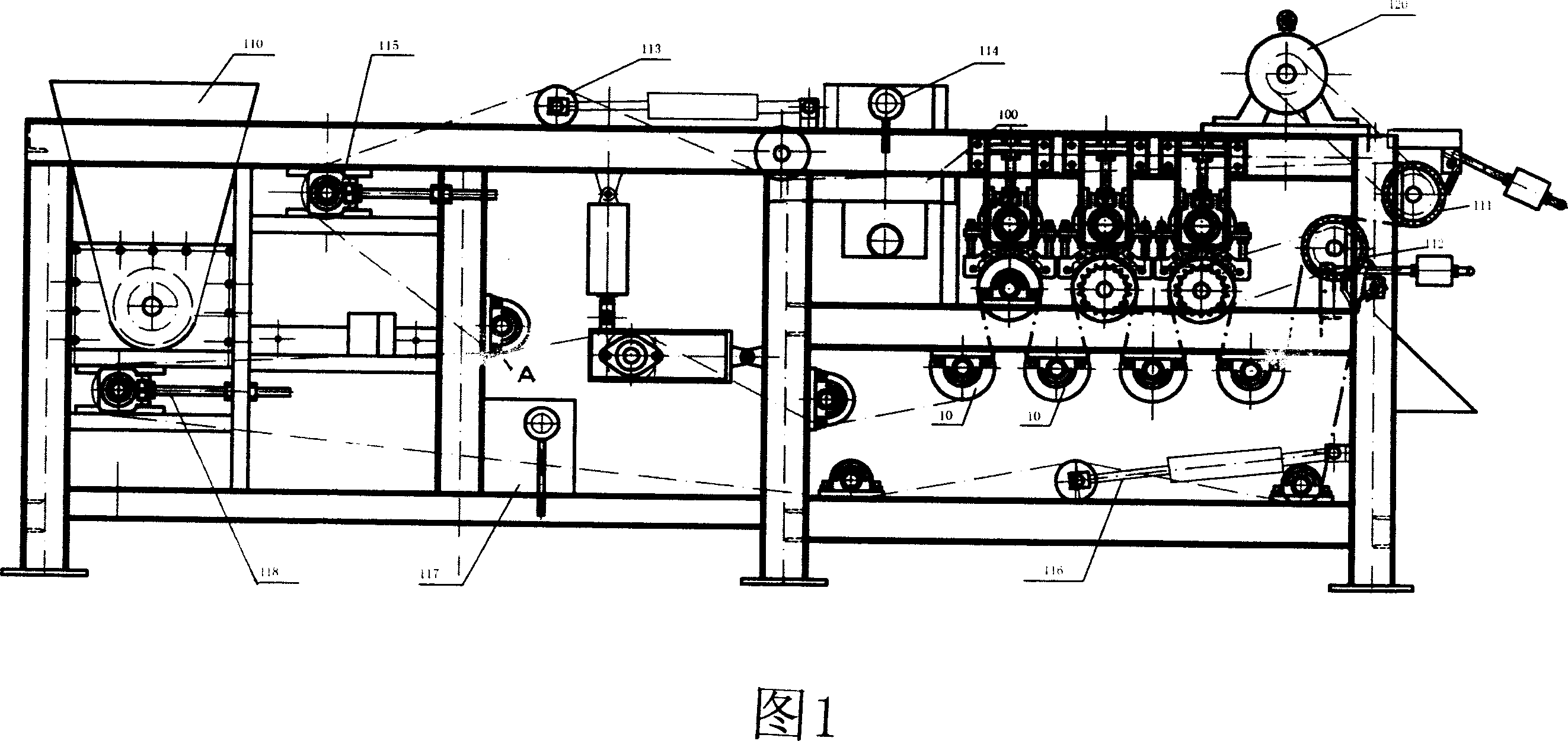

Belt type strong force squeezing dewatering machine

A technology for pressing and dehydrating and dehydrating machines, which is used in presses, drying solid materials, manufacturing tools, etc., and can solve problems such as pollution, mosquito breeding environment, and inability to landfill operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

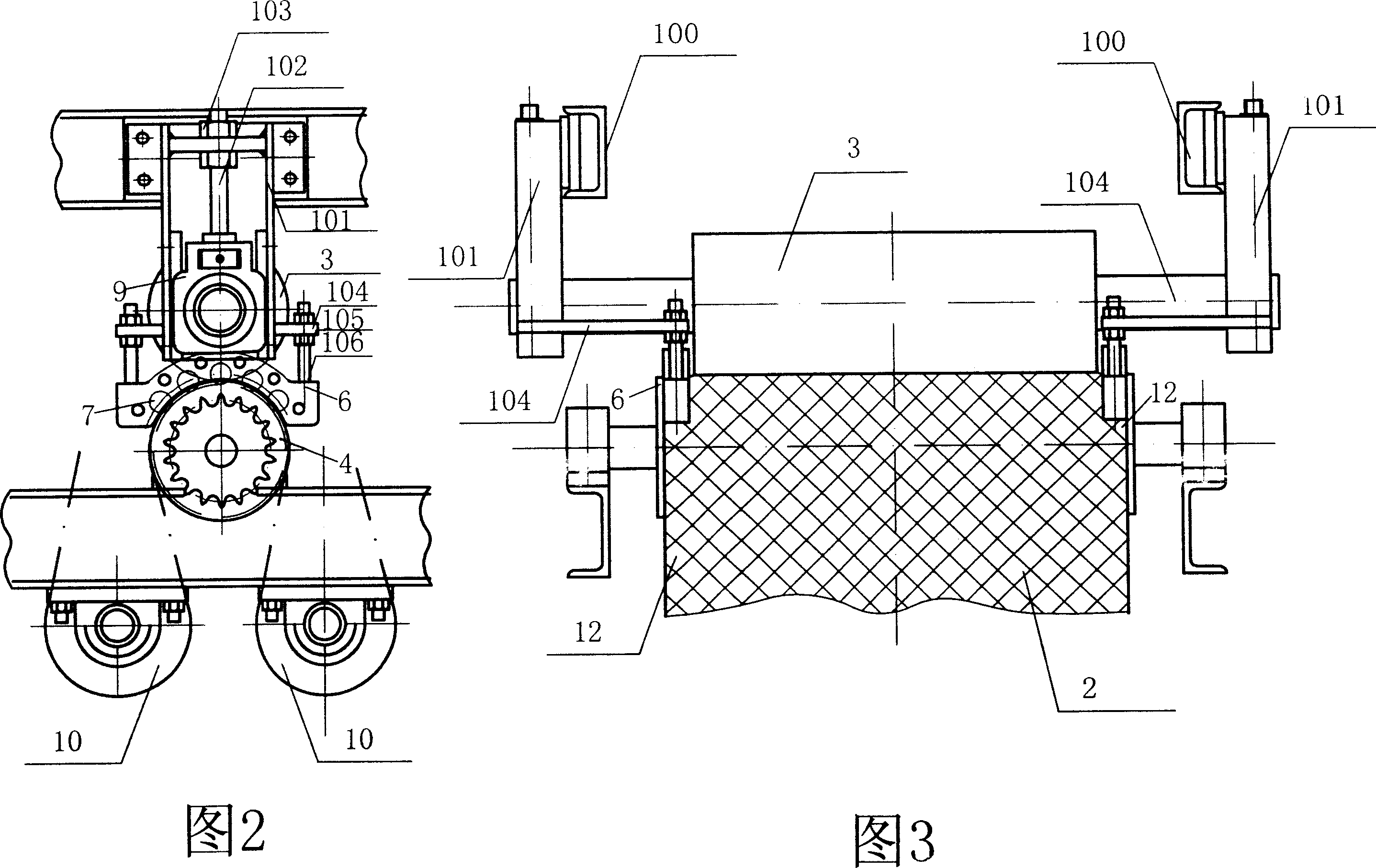

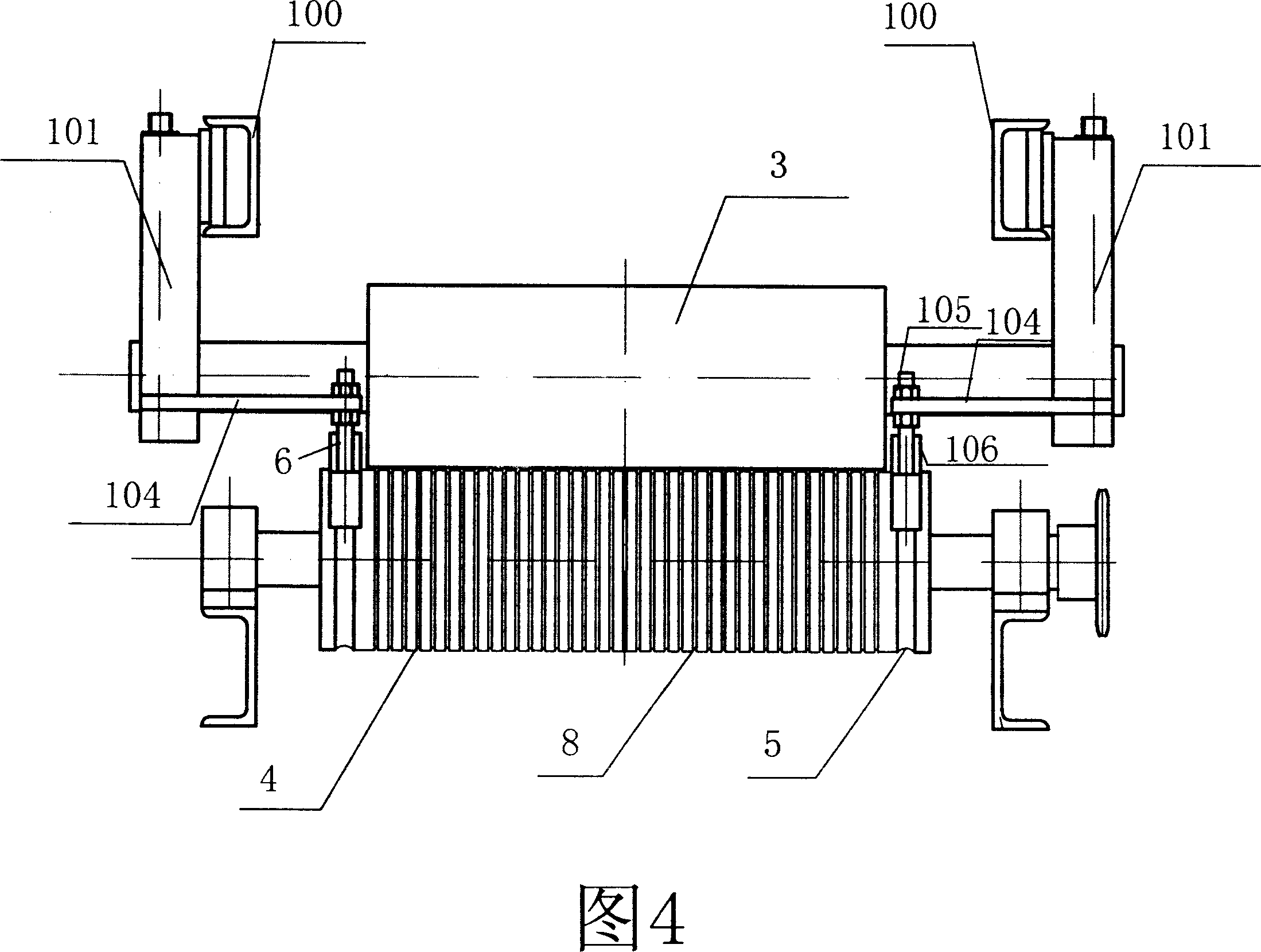

[0009] Refer to attached picture. The present invention includes upper and lower circulating conveying mesh belts 2 and 1. The dehydrator includes several sets of powerful pressure roller groups, and the powerful pressing roller groups include pressure rollers 3 and bearing rollers 4 that bear the pressure of the pressure rollers. The belt passes between the pressure roller 3 and the pressure roller 4; the pressure roller is provided with an annular groove 5 near its two sides, and the two sides of the upper and lower circulation conveying mesh belt extend to the annular groove, The dehydrator is provided with a device for bending the upper and lower circulation conveying mesh belts 12 at the annular groove in cooperation with the annular groove.

[0010] The sludge is sandwiched between the upper and lower circulation conveying mesh belts 2 and 1, and the upper and lower circulating conveying mesh belts are both conveyor belts and filter screens during pressing. Pressure rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com