One-way clutch life test machine

A one-way clutch, life test technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of restricting the research and development of one-way clutch products, the inability to obtain scientific and accurate test data, and the lack of technical support for one-way clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

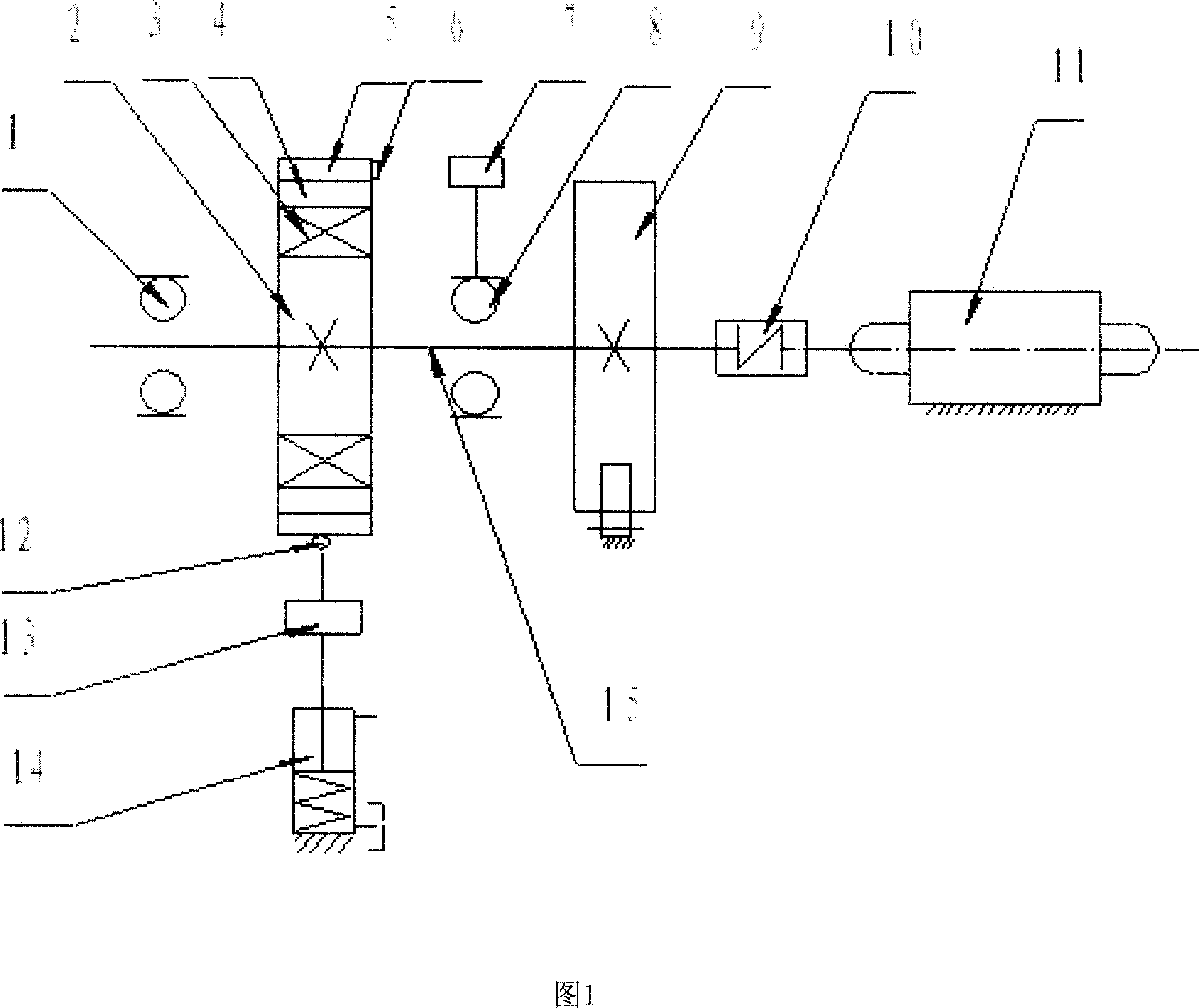

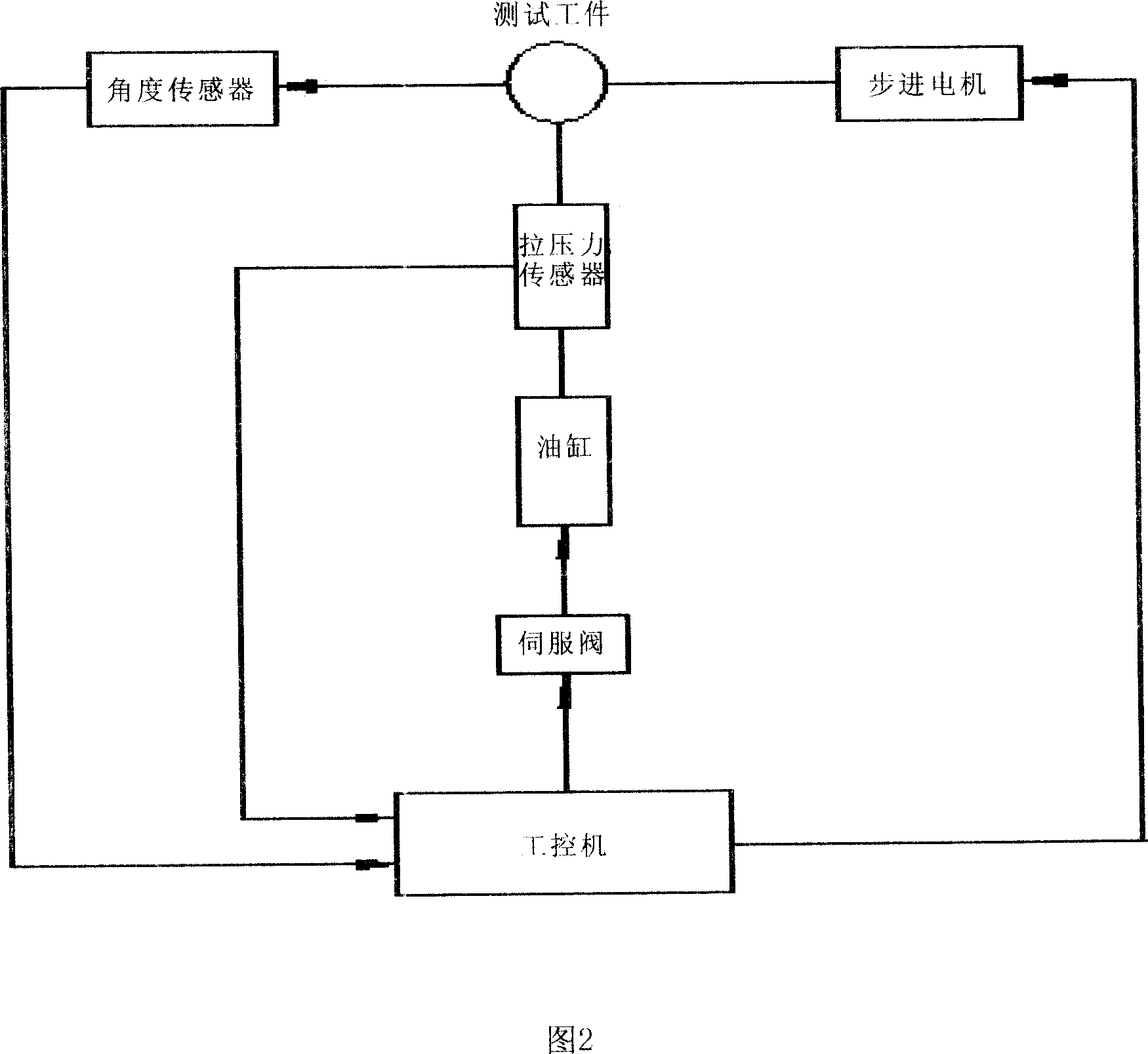

[0012] As shown in Figures 1 and 2: this one-way clutch life testing machine has a control system, a transmission system, a loading system and a data acquisition system; its device consists of a stepping motor (11) through a shaft coupling (10) and a main shaft ( 15) are connected; the main shaft (15) passes through the ratchet (9), the bearing seat (8), the inner sleeve (2) and the detachable bearing seat (1); the ratchet (9) is keyed to the main shaft (15), and the ratchet The claw (9) is fixed on the machine base; the angle sensor (7) is fixed on the bearing seat (8); the test piece (3) is installed between the inner sleeve (2) and the outer sleeve (4), and the inner sleeve ( 2) It is connected with the main shaft (15) by a key, and the outer casing (4) is provided with a casing (5), which is connected by a key; the end surface of the casing (5) is provided with a distributed magnetic patch (6), and the casing (5) ) is provided with a fixed hinge (12) to link to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com