Transfer loading device

A transfer device and transfer technology, applied in storage devices, transportation and packaging, claw arms, etc., can solve the problems of longer transfer distance and increased transfer weight, so as to reduce the movement load and shorten the action time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, embodiments (examples) of the present invention will be described with reference to the drawings.

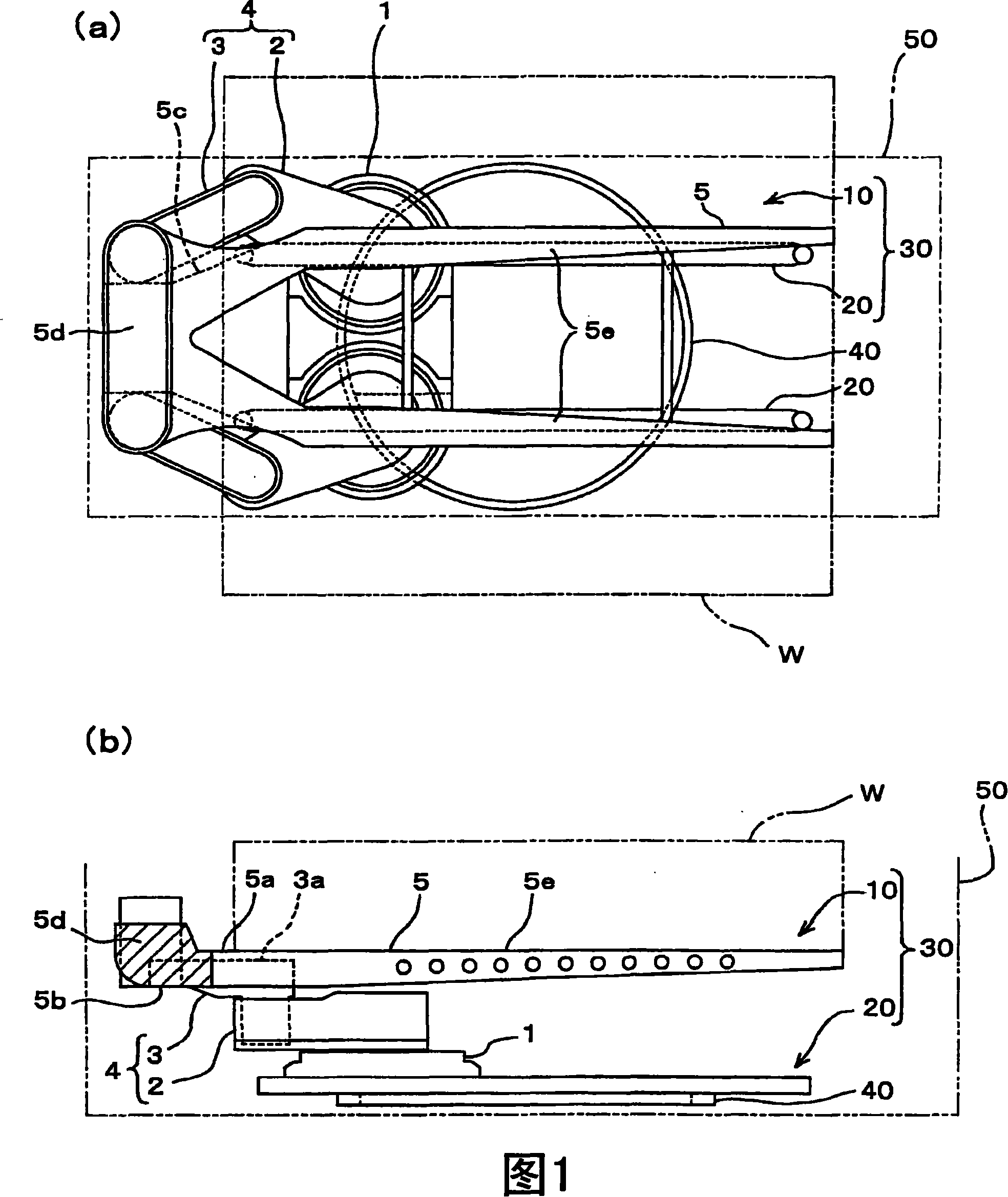

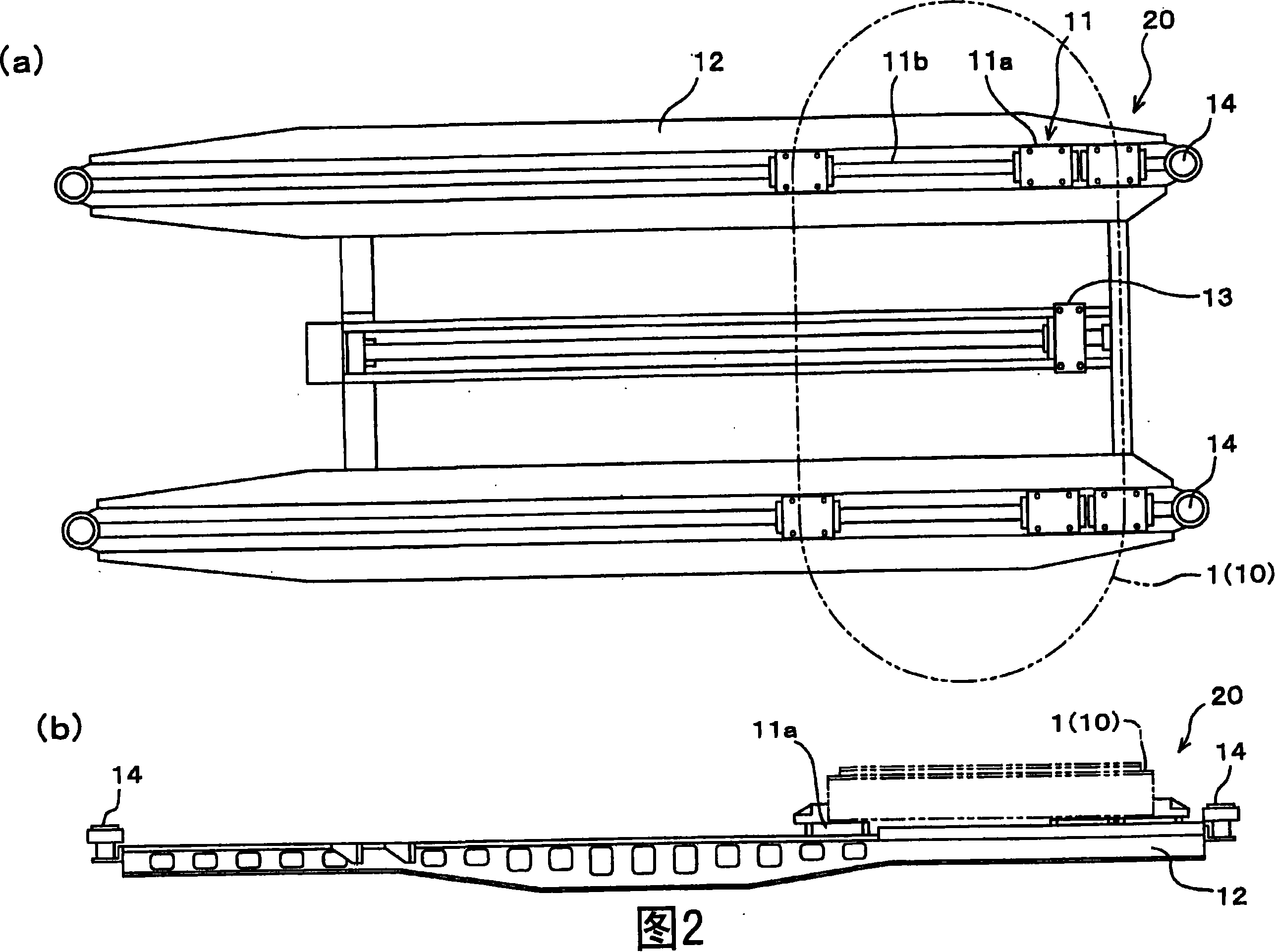

[0033] FIG. 1( a ) is a front view showing an example of the transfer device of the present invention, and FIG. 1( b ) is a side view of FIG. 1( a ).

[0034] This transfer device 30 is in a factory that manufactures semiconductor substrates or liquid crystal display panels, etc., in order to perform various processing treatments on its flat blanks (semiconductor wafers or glass plates) in a clean room, and each accommodates one piece of the flat blank (semiconductor wafer or glass plate). The blank pallet is used as a device for transferring the workpiece W, which is the object to be conveyed, in a stacked state of one or more stages.

[0035] In addition, here, as an example where the transfer device is suitably used, the case where the tray containing the flat blanks is conveyed in the clean room is shown, but the transfer device of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com