Drainage system estuary pier bar swirl chamber composite energy dissipation method

A drainage system and vortex chamber technology, applied in dams, coastline protection, dikes, etc., can solve problems such as uneven distribution of water flowing out of diffusion pools, increase drainage system investment, increase drainage pipe diameter, etc., and achieve obvious energy dissipation effect and design Simple, construction investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

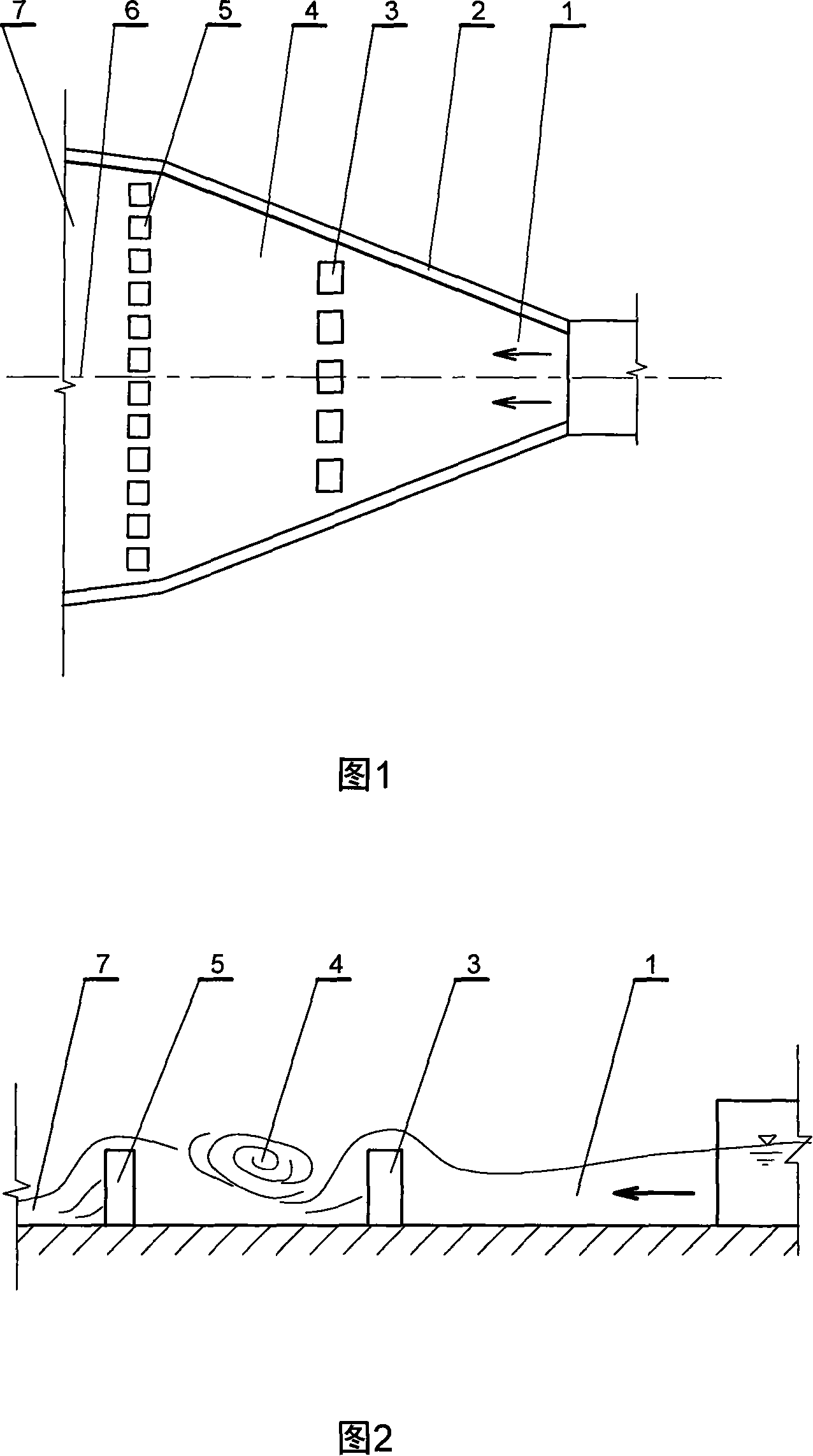

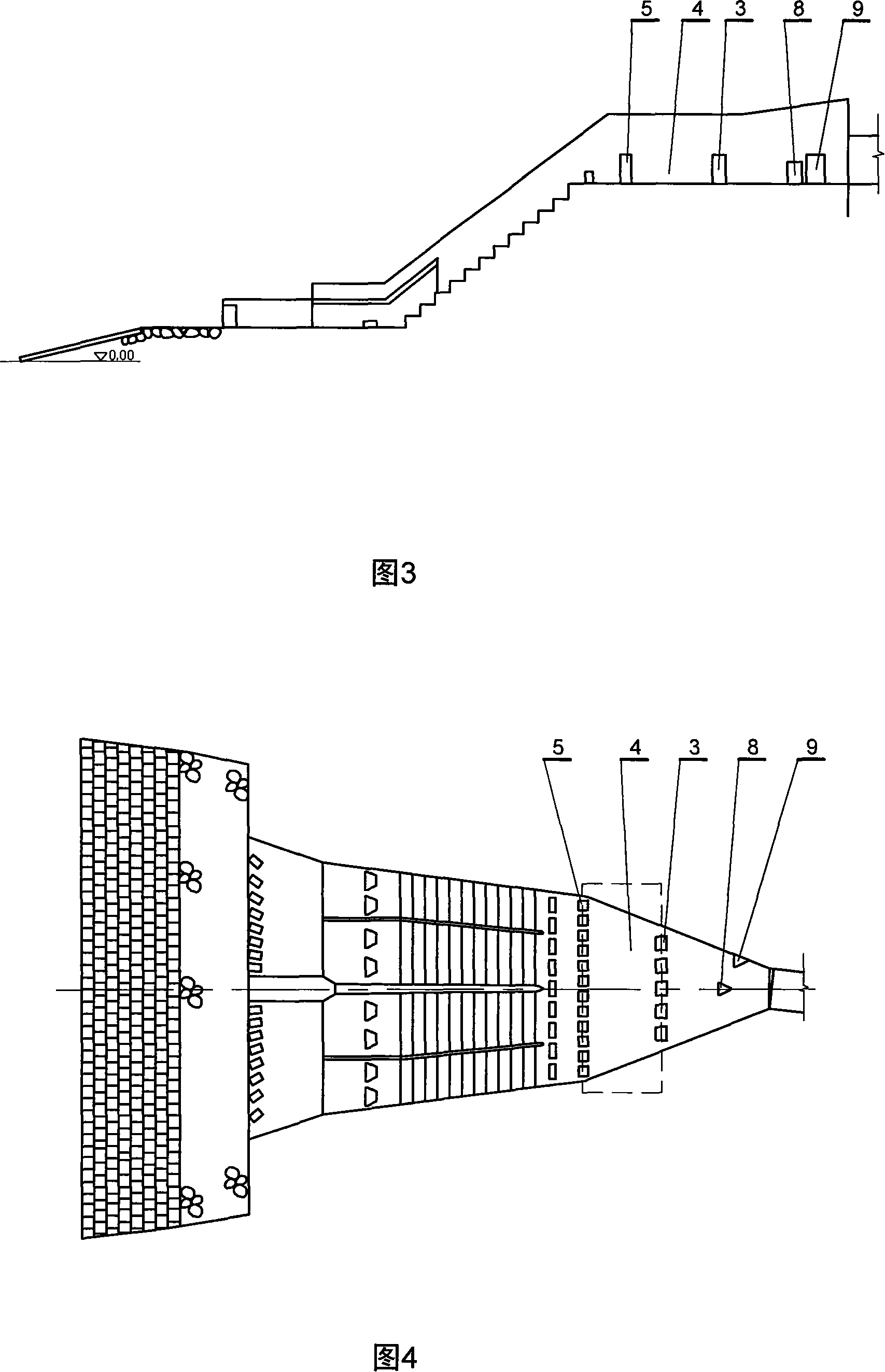

[0025] This embodiment is a composite energy dissipation method for the pier grid vortex chamber at the sea inlet of the drainage system, as shown in FIG. 1 . This example includes:

[0026] Water inlet 1: The water inlet can be connected with the outlet of the rainwater drainage culvert or the outlet of other hydraulic engineering.

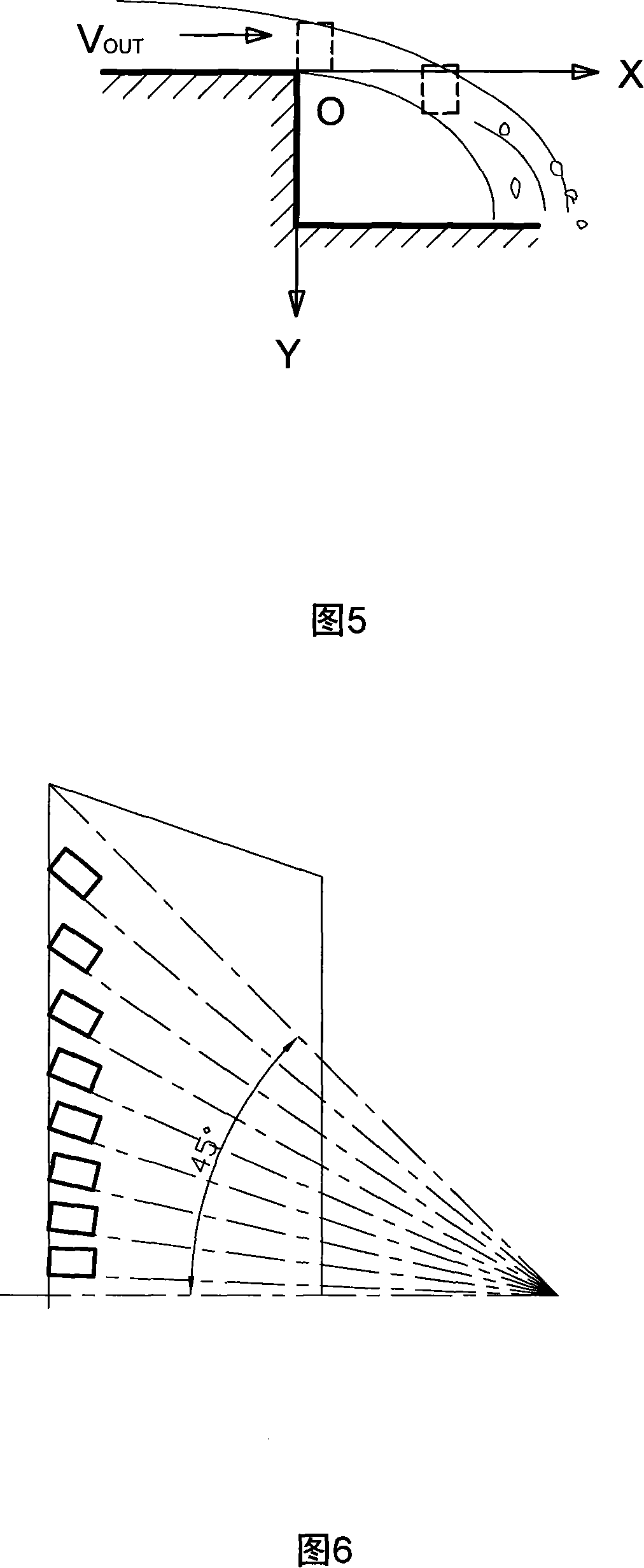

[0027] Two opposite side walls 2 of the symmetrical diffusion pool: The symmetrical diffusion pool described in this embodiment is actually a pool composed of two opposite side walls. The plan view of this pool is an isosceles trapezoid formed by two symmetrical hypotenuse walls , the water inlet and the water outlet form the two bases of the isosceles trapezoid, the short side of the trapezoid is the water inlet, and the long side of the trapezoid is the water outlet, the concentrated outflow of water spreads out in the isosceles trapezoid, and diffuses from the water outlet out, so it is called symmetrical diffusion type. The function of symm...

Embodiment 2

[0084] This embodiment is a hydraulic energy dissipation facility for implementing the method described in Embodiment 1, as shown in FIG. 1 . Including the water inlet 1, two opposite side walls 2 of the symmetrical diffusion pool, and the water outlet 7, in the direction perpendicular to the central axis 6 of the diffusion pool between the two opposite side walls of the water inlet of the diffusion pool, and in a direction that can induce the incoming water flow to generate a strong water flow The first row of piers 3 composed of stilling piers is arranged at the jump position, and the second row of piers 5 composed of stilling piers is arranged at the outlet of the diffusion pool. The two rows of piers are arranged in parallel. A vortex chamber 4 capable of generating a strong vortex is formed between the second row of pier grids.

[0085] This embodiment is the basic shape of the pier-grid vortex chamber composite energy dissipation facility. The principle of this embodimen...

Embodiment 3

[0087] This embodiment is a preferred solution of Embodiment 2, as shown in FIG. 1 . The first row of pier grids in this embodiment is composed of a row of rectangular stilling piers, one side of the rectangular cross section of the rectangular stilling piers is perpendicular to the central axis of the symmetrical diffusion pool and is the edge facing the water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com