Special-shaped cavity flow meter

A flowmeter and special-shaped cavity technology, which is applied in fixed measurement chambers and other directions, can solve the problems of strong measurable medium restriction, easy noise generation, poor safety, etc., and achieves low production and maintenance costs, reliable work, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

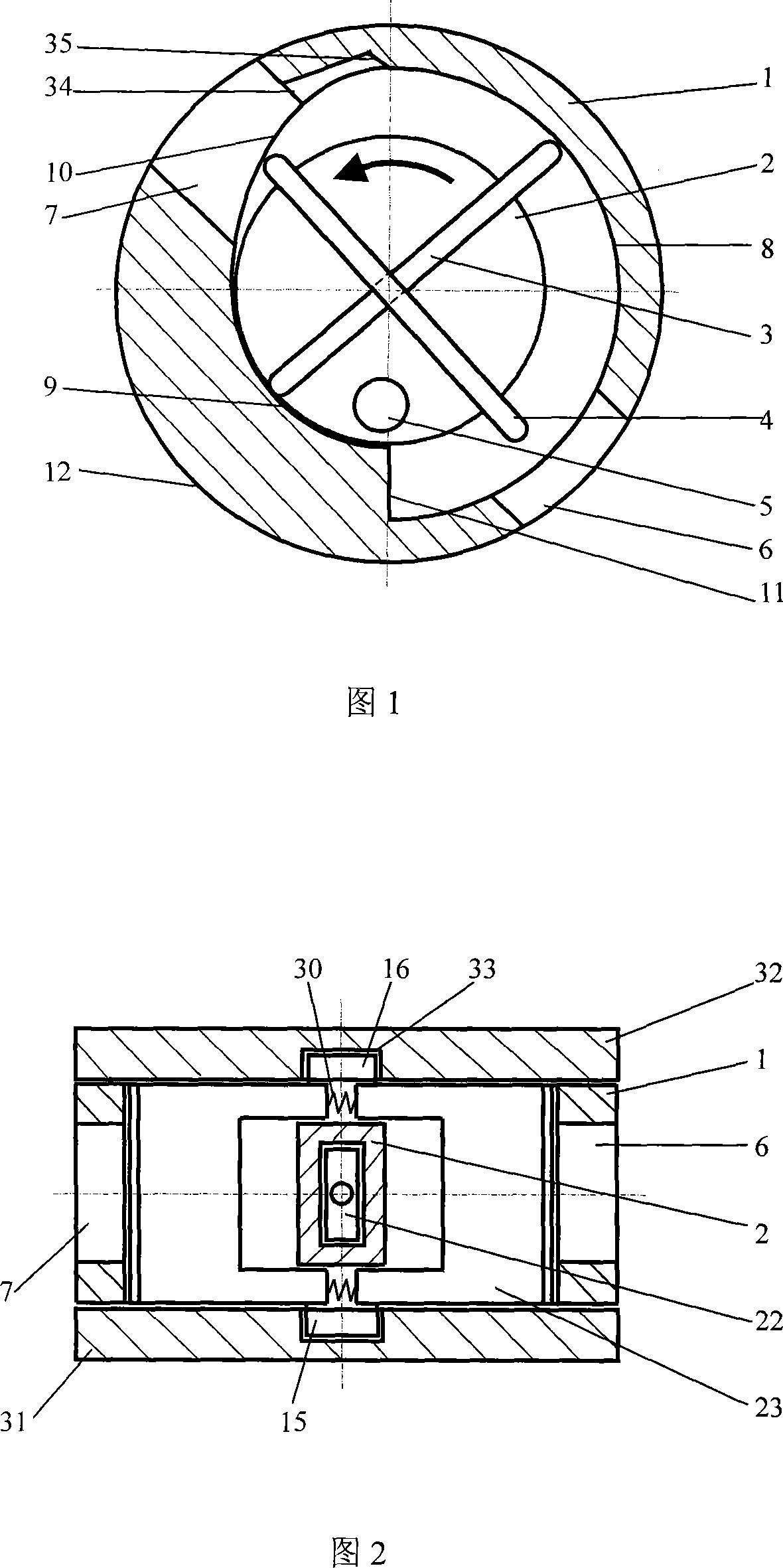

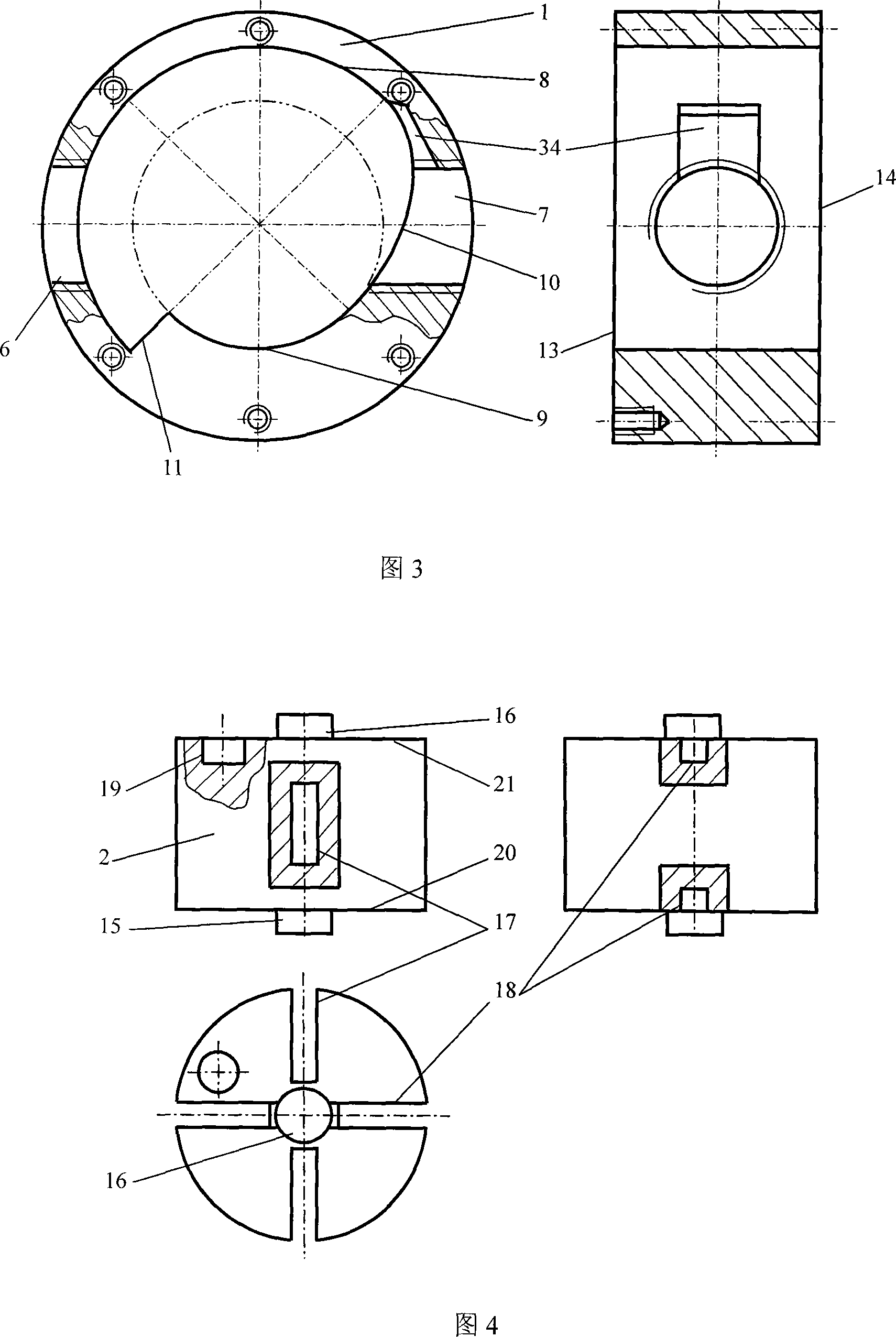

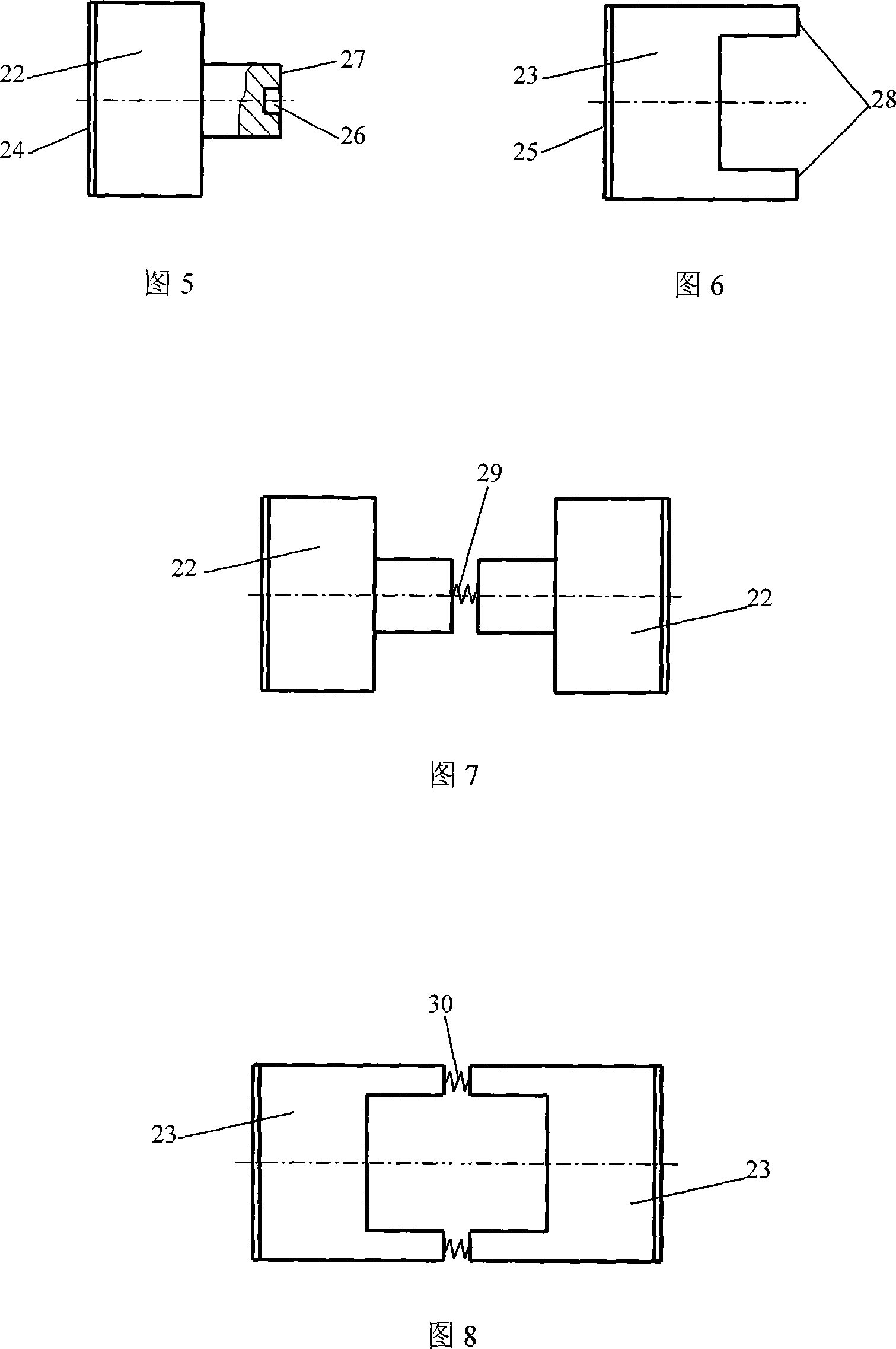

[0020] Refer to Figures 1 to 9. The special-shaped cavity flowmeter provided by the present invention includes a cavity body 1 with a special-shaped cylindrical inner cavity, an inlet 6, an outlet 7 and a diversion groove 34, and a lower cover plate 31 and an upper cover installed on both ends of the cavity body 1. The sealed cavity formed by the plate 32 is installed with a rotor assembly in the sealed cavity. The rotor assembly is composed of a cylindrical rotor 2 with a cross guide groove and a first combined slide plate 3, a second combined slide plate 4 and a permanent magnet 5; The assembly cooperates with the bearing holes 33 on the upper and lower cover plates through the lower centering shaft 15 and the upper centering shaft 16 on the rotor, and the upper and lower centering shafts of the rotor are coaxial with the cylindrical body of the rotor, (see Fig. 1 and Figure 2). The special-shaped cylindrical inner cavity of the cavity 1 is composed of a semicircular arc su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com