Falling testing system and test method

A test system and test method technology, which is applied in the direction of optical instrument test, machine/structural component test, measuring device, etc., can solve the problems of height error, test speed and test efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

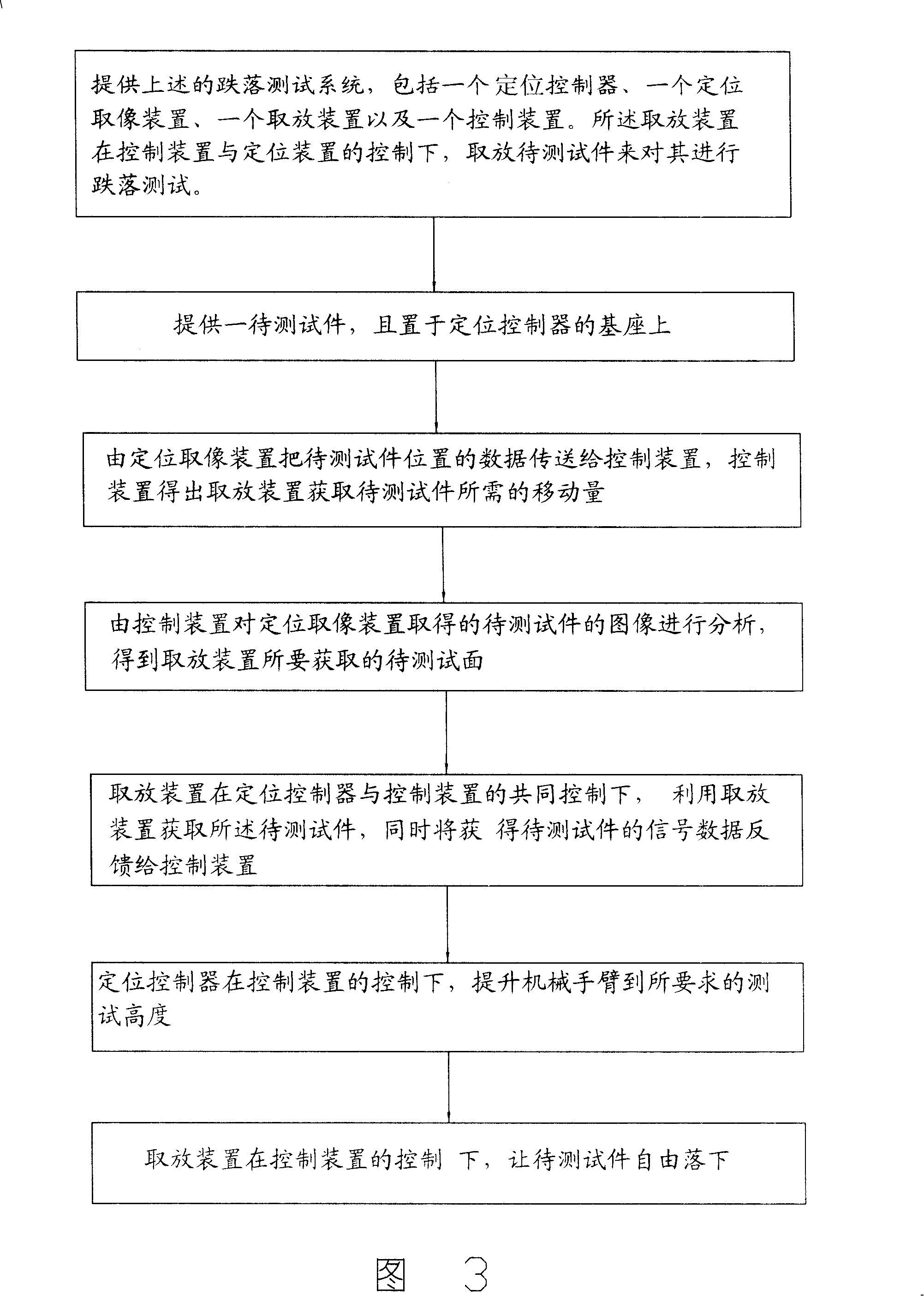

[0023] In order to further illustrate the present invention, a preferred embodiment is given and described in detail below with accompanying drawings.

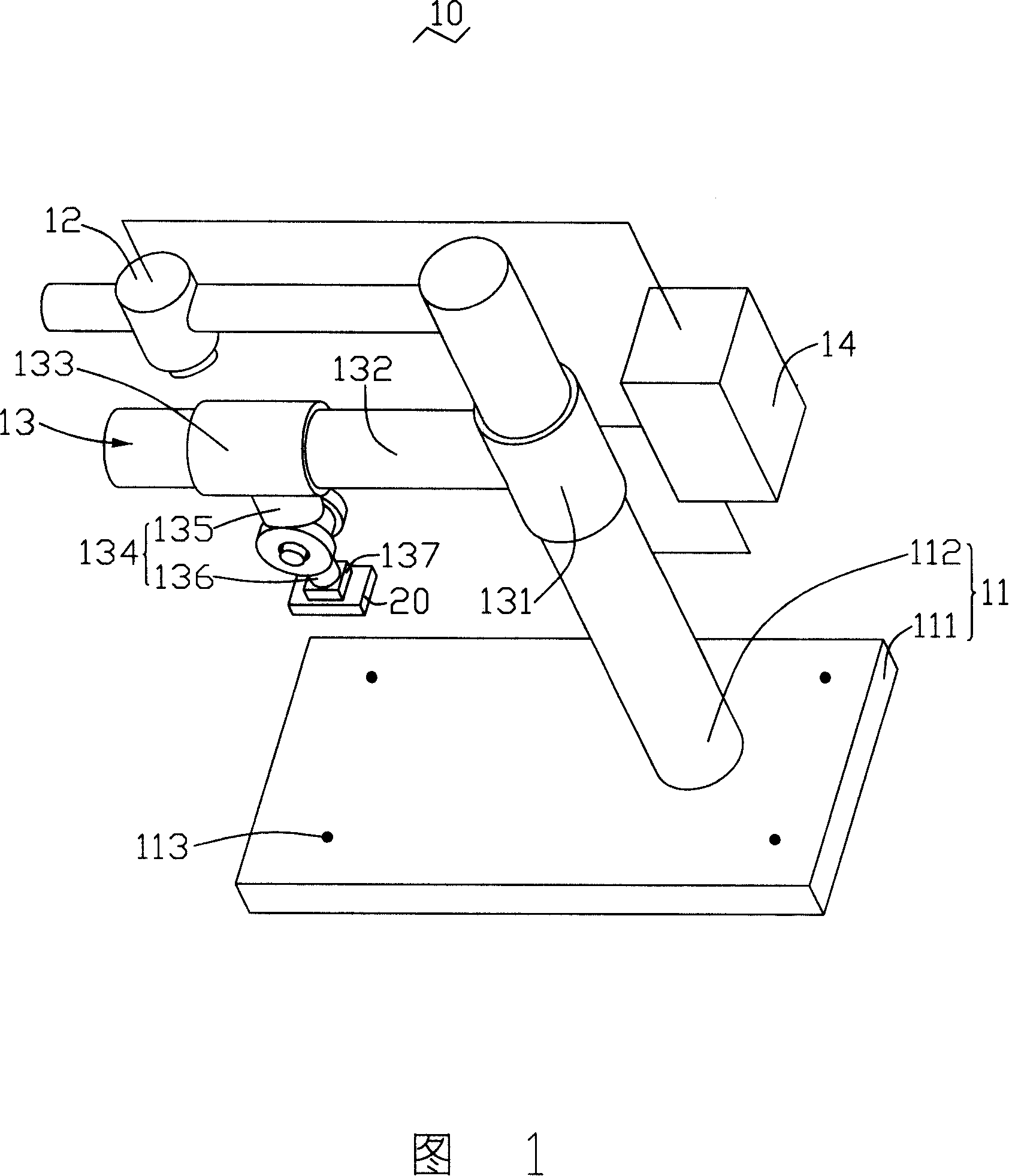

[0024] Referring to Fig. 1, the drop test system 10 of the embodiment of the present invention includes a positioning controller 11, an image taking and positioning device 12 for measuring the position of the test piece 20 and taking an image of the test piece 20, A pick-and-place device 13 for picking and placing the piece to be tested 20 and a control device 14 that controls the pick-and-place device 13 according to the measurement and image-taking results of the image-taking and positioning device 12, and the control device 14 is connected with the image-taking and positioning device respectively. The device 12, the positioning controller 11 and the pick-and-place device 13 are electrically connected.

[0025] The positioning controller 11 may be a three-axis controller, including a base 111 and a positioning control arm 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com