Multi-fruit wine and method of producing the same

A manufacturing method and technology for fruit wine, applied in the field of fruit wine, can solve the problems of many process equipment, changing quality and nutrients, and high process cost, and achieve the effects of low process cost, diversified taste and short process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

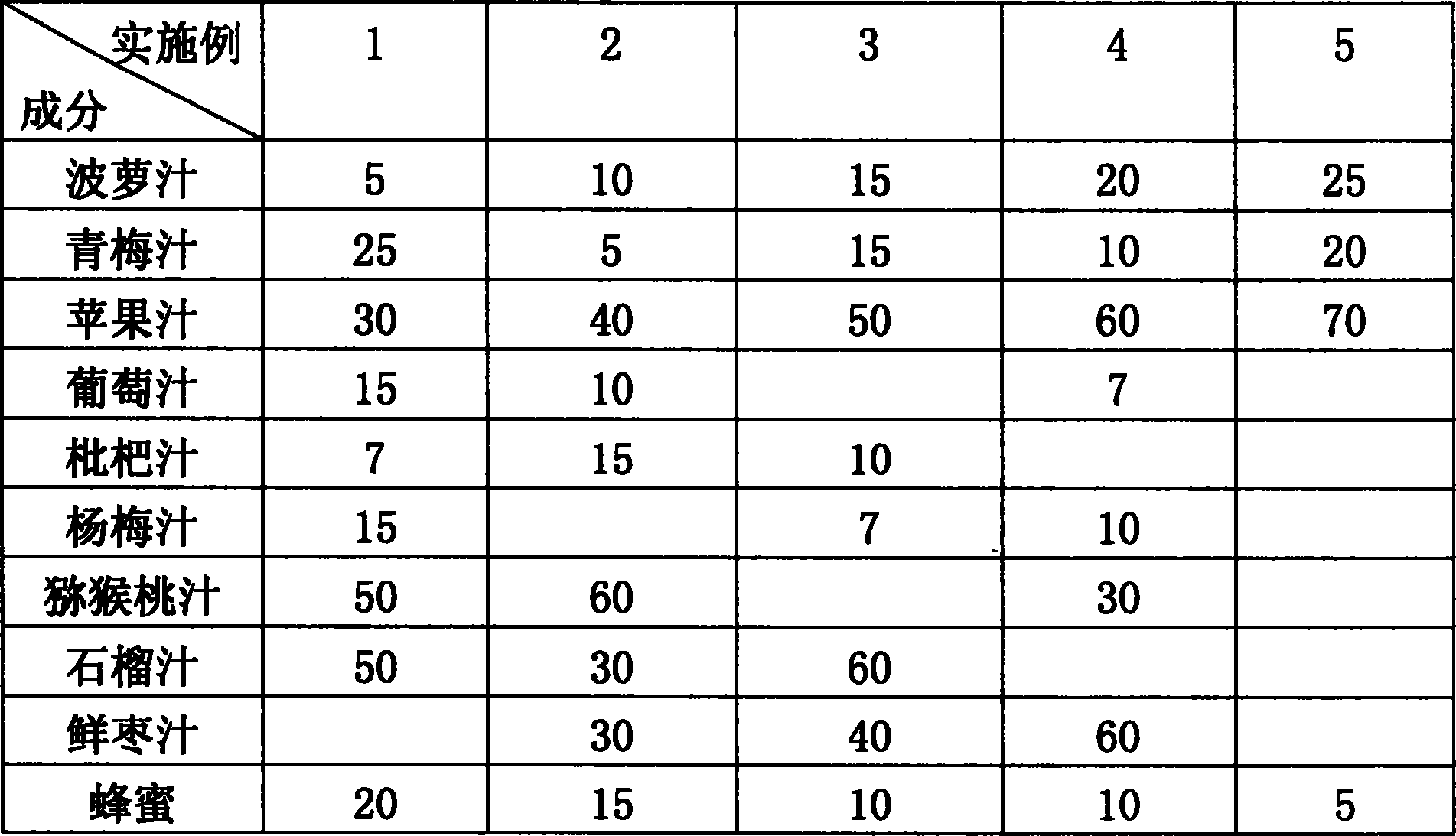

Embodiment 1

[0039] 1. Preparation of fruit juice

[0040] (1), the manufacturing process of apple juice:

[0041] Choose apples that are more than 70 years old and wash them with a towel and toothbrush without peeling or scraping the pedicles, and keep the natural yeast for cleaning. After soaking in tap water for 10 minutes, pick up and drain the water, and put them in a sealed bucket to be squeezed. Apples are crushed with a stainless steel grinder to a fineness of about 3 mm, and the crushed apples are squeezed with a stainless steel juicer, and put into a sterilized container after the juice is squeezed. The container disinfection process Soak in tap water with 0.6ppm of bleaching powder for 15 minutes; the capacity of the juice in the container should not exceed 80%, and carry out natural fermentation for 3 months under dark and room temperature conditions, until the alcohol concentration of the supernatant is about Stop the fermentation after reaching 2%, and get the supernatant fo...

Embodiment 2

[0053] 1. Preparation of fruit juice

[0054] (1), the manufacturing process of apple juice:

[0055] Choose apples that are more than seven ripe and wash them with a towel and toothbrush. Do not peel or scrape the stems, and keep the natural yeast for cleaning. After soaking in tap water for 12 minutes, pick up and drain the water, and put them in a sealed bucket to be squeezed. The raw juice is made of stainless steel. The grinder grinds the apples to a fineness of about 5 mm, and the crushed apples are squeezed with a stainless steel juicer, and put into a sterilized container after the juice is squeezed. The disinfection process of the container is as follows: Soak in tap water with 0.4ppm of bleaching powder for 25 minutes; the capacity of the juice in the container should not exceed 80%, and carry out natural fermentation for 5 months under dark and room temperature conditions, until the alcohol concentration of the supernatant is about 3 %, stop the fermentation and ta...

Embodiment 3

[0067] 1. Preparation of fruit juice

[0068] (1), the manufacturing process of apple juice:

[0069] Choose apples that are more than seven ripe and wash them with a towel and toothbrush. Do not peel or scrape the stems, and keep the natural yeast for cleaning. After soaking in tap water for 15 minutes, pick up and drain the water, and put them in a sealed bucket to be squeezed. The raw juice is made of stainless steel. The pulverizer crushes the apples until the fineness is about 7 mm, and the crushed apples are squeezed with a stainless steel juicer, and put into a sterilized container after the juice is squeezed. The disinfection process of the container is as follows: Soak in tap water with 0.3ppm of bleaching powder for 30 minutes; the capacity of the juice in the container is not more than 80%, and it is naturally fermented for 6 months under the condition of dark and room temperature, and the alcohol concentration of the supernatant is about 6 %, stop the fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com