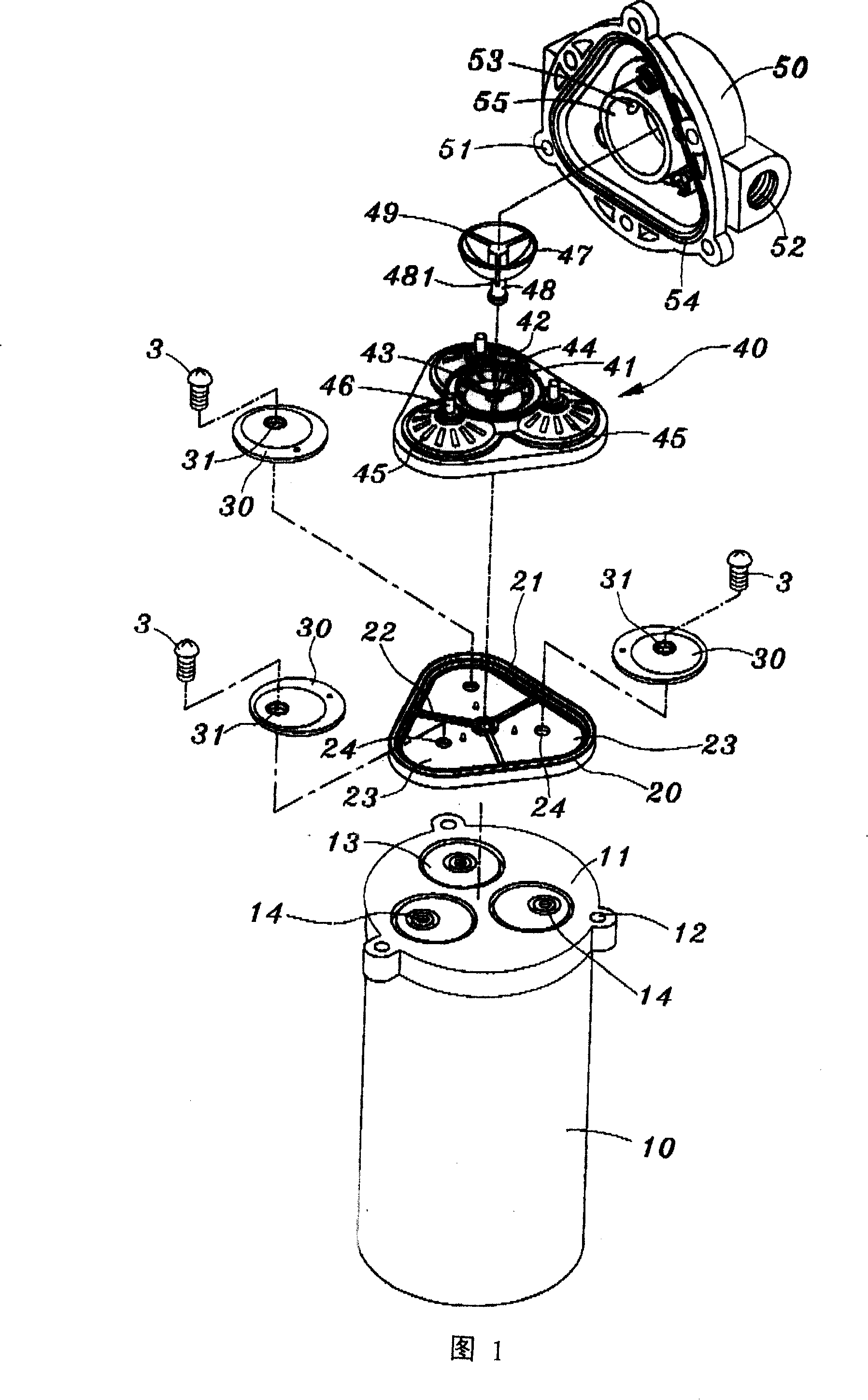

Method and construction for preventing water leakage in diaphragm type compression pump

A pressure pump and diaphragm technology, applied in the field of pressure pumps, can solve the problems of diaphragm pressure pump damage, reduced boosting efficiency, pressure loss and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

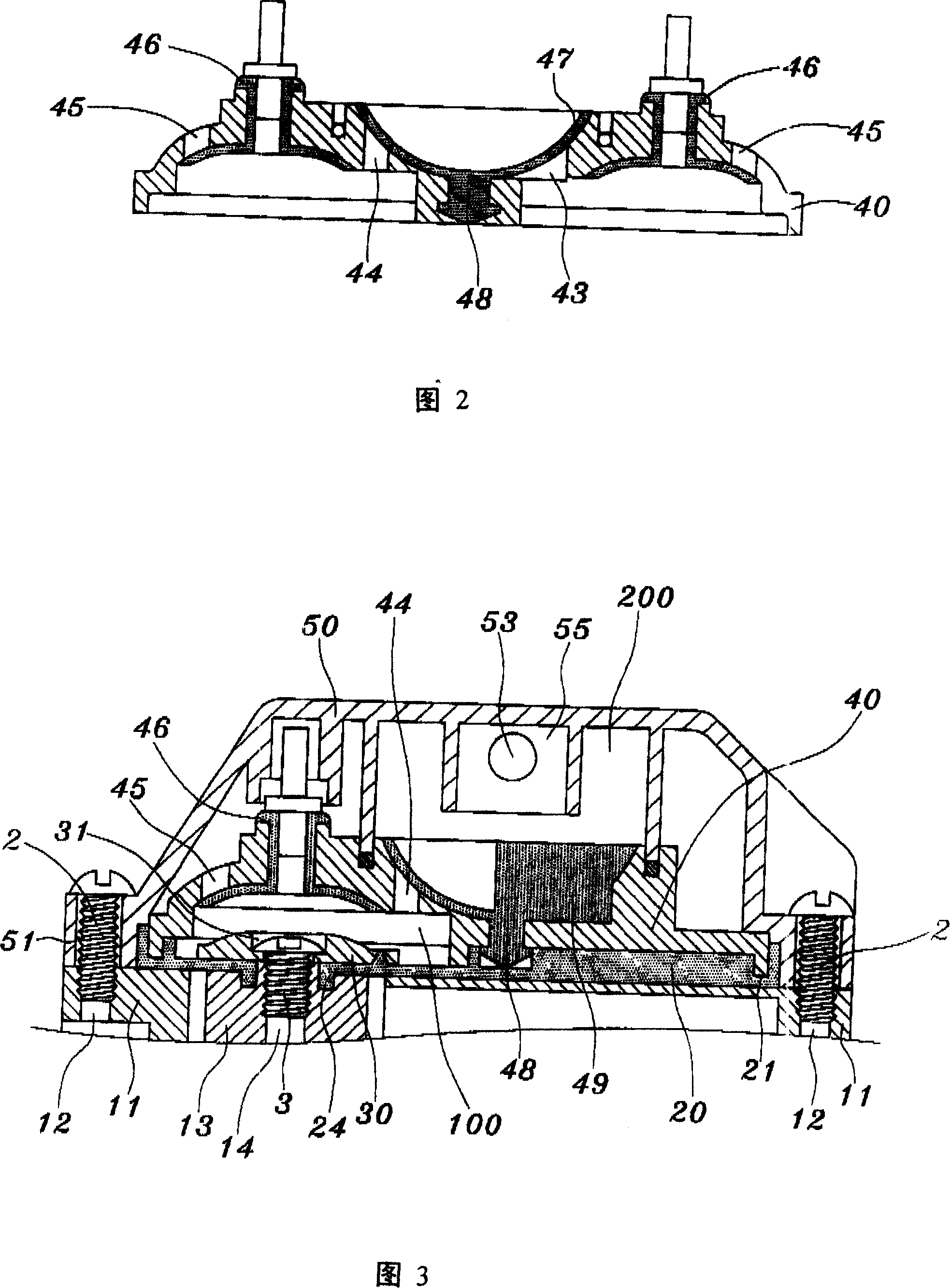

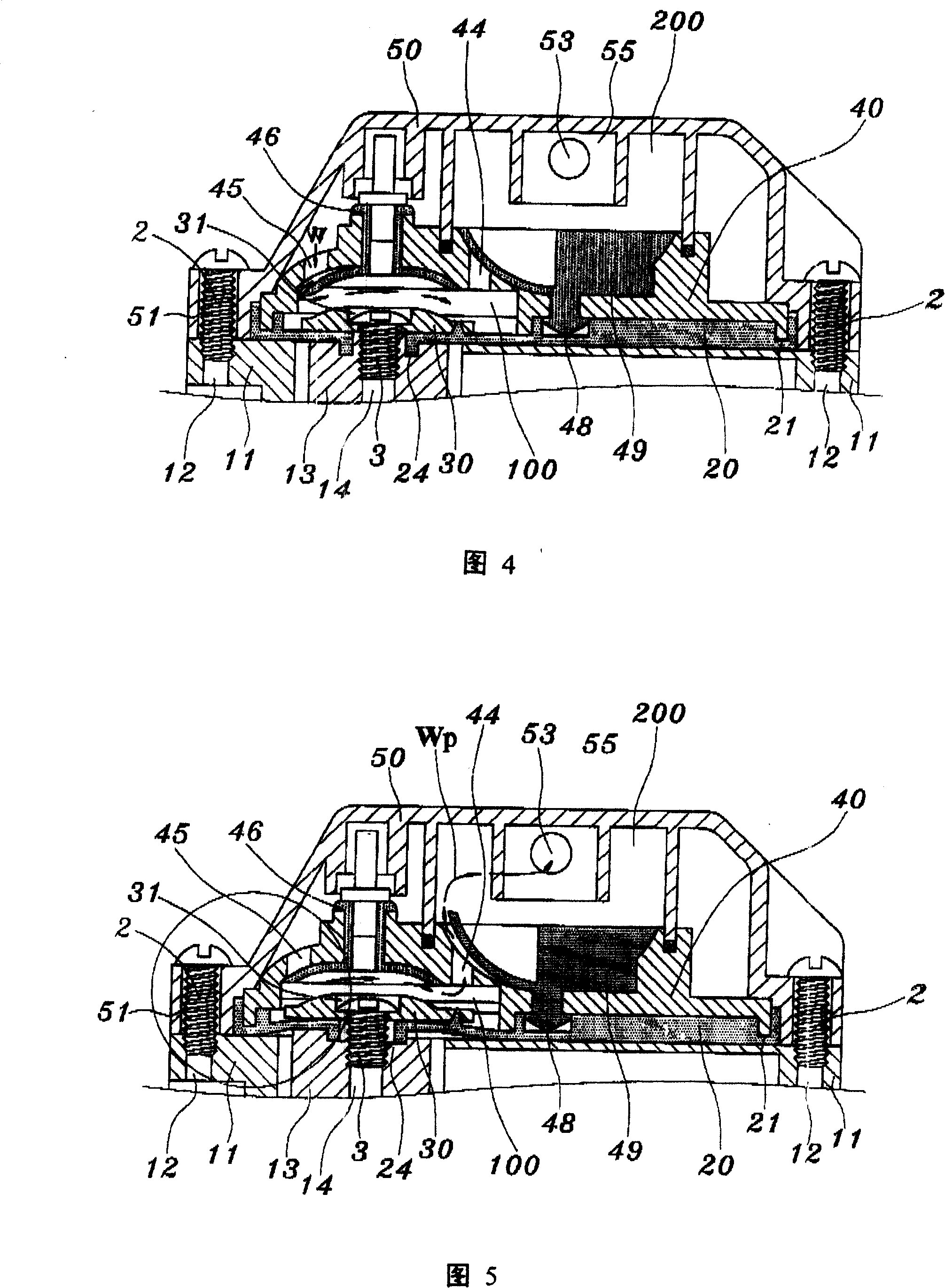

Embodiment Construction

[0061] As shown in Fig. 11 to Fig. 13, the method and structure thereof for preventing water leakage in a diaphragm type pressure pump of the present invention is to first set a screw hole on the top surface of each piston actuation area 63 of the diaphragm 60. A hollow cylinder 64 is formed, and the hollow cylinder 64 and the diaphragm 60 are integrally injection-molded with plastic material having the same elasticity (as shown in view A in FIG. 11 and FIG. 12 ), and its outer diameter is equal to or slightly smaller than The inner diameter of the stepped hole 31 in the piston push block 30, and then the stepped hole 31 of the piston push block 30 is placed on the outer edge of the hollow cylinder 64 (as shown in the view of B in Figure 12), and then threaded through the set screw 3 pass through the central hole of the hollow cylinder 64 (as shown in the view of C in FIG. 12 ), and apply force to lock the fixing screw 3 into the threaded hole 14 of the balance wheel 13. During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com