n-type Cu2Sn3S7-based medium-high temperature thermoelectric semiconductor and mechanical alloying preparation technique thereof

A thermoelectric semiconductor and mechanical alloying technology, applied in the field of new materials, can solve the problems of complex preparation process, insufficient performance, and high difficulty of thermoelectric semiconductors, and achieve the effects of rich content, long life and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

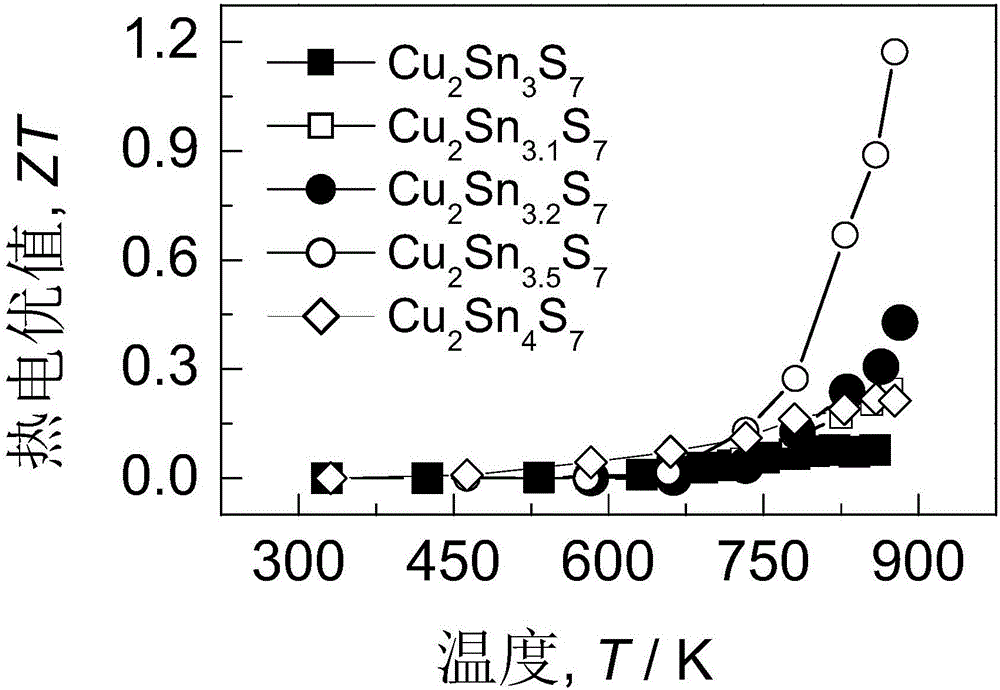

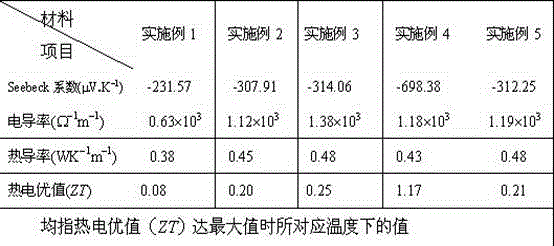

[0013] According to the chemical formula Cu 2 sn 3 S 7 Weigh Cu, Sn, and S three-element particles with a purity greater than 99.999wt.%, and then place them directly in a vacuum ball mill jar for ball milling for 2 hours. The ball-milled powder was placed in a vacuum quartz tube and heated to 700°C for 48 hours for annealing. The annealed powder is formed by spark plasma sintering in a short period of time. The sintering time is 4 minutes, the sintering temperature is 700°C, and the sintering pressure is 60MPa. Cu 2 sn 3 S 7 thermoelectric semiconductors.

Embodiment 2

[0015] According to the chemical formula Cu 2 sn 3.1 S 7 Weigh Cu, Sn, and S three-element particles with a purity greater than 99.999wt.%, and then place them directly in a vacuum ball mill jar for ball milling for 2 hours. The ball-milled powder was placed in a vacuum quartz tube and heated to 700°C for 48 hours for annealing. The annealed powder is formed by spark plasma sintering in a short period of time. The sintering time is 4 minutes, the sintering temperature is 700°C, and the sintering pressure is 60MPa. Cu 2 sn 3.1 S 7 thermoelectric semiconductors.

Embodiment 3

[0017] According to the chemical formula Cu 2 sn 3.2 S 7 Weigh Cu, Sn, and S three-element particles with a purity greater than 99.999wt.%, and then place them directly in a vacuum ball mill jar for ball milling for 2 hours. The ball-milled powder was placed in a vacuum quartz tube and heated to 700°C for 48 hours for annealing. The annealed powder is formed by spark plasma sintering in a short period of time. The sintering time is 4 minutes, the sintering temperature is 700°C, and the sintering pressure is 60MPa. Cu 2 sn 3.2 S 7 thermoelectric semiconductors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com