Method for washing shrinkable textiles and a washing machine for carrying out said method

A washing machine and washing technology, which is applied to other washing machines, washing devices, textiles, and papermaking, etc., can solve the problems of not getting water or washing liquid to be fully wetted, and cleaning is not fully and thoroughly rinsed, etc. Duration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

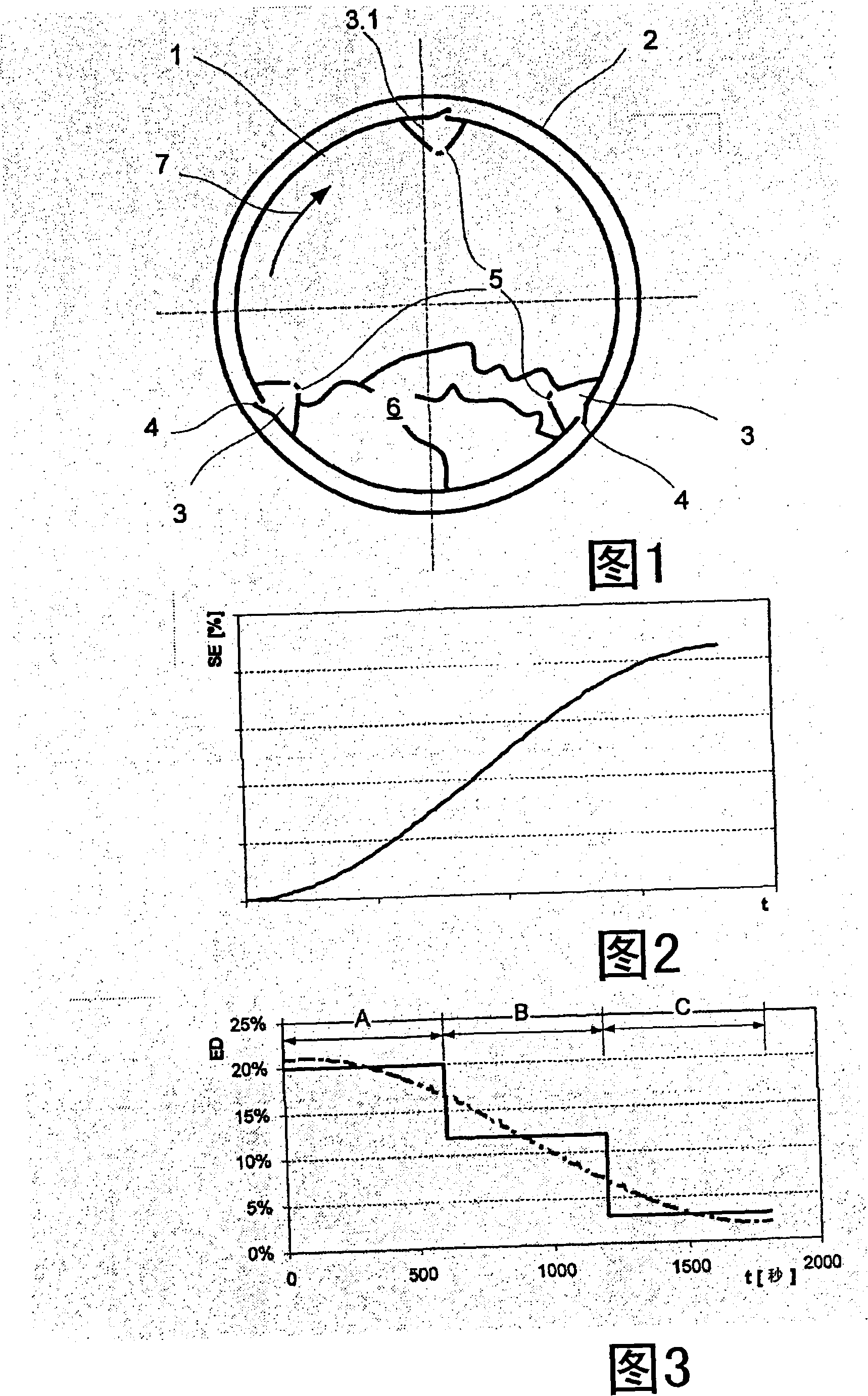

[0024] The washing machine has a washing drum 1 shown in FIG. 1 that is rotatably installed in a washing liquid container 2, and a motor that drives the washing drum 1, not shown. Three washing baffles 3 are installed on the inner side of the shell of the washing drum 1, which make the washing items in a batch of washing 6 rise from the bottom of the washing drum 1 when the washing drum 1 rotates, and after being lifted, due to gravity Fall again. The washing process required for cleaning is thus applied to the wash items. The degree of motion exerted on the wash items or the degree of the washing process depends on the geometry of the wash drum 1 and the baffle 3 and also on the rotational speed of the wash drum 1 . In a preferred embodiment the diameter of the drum of the washing machine is 50 cm. Other drum diameters are also possible, but the rotational speed of the drum must therefore be particularly adapted accordingly to the drum diameter in question.

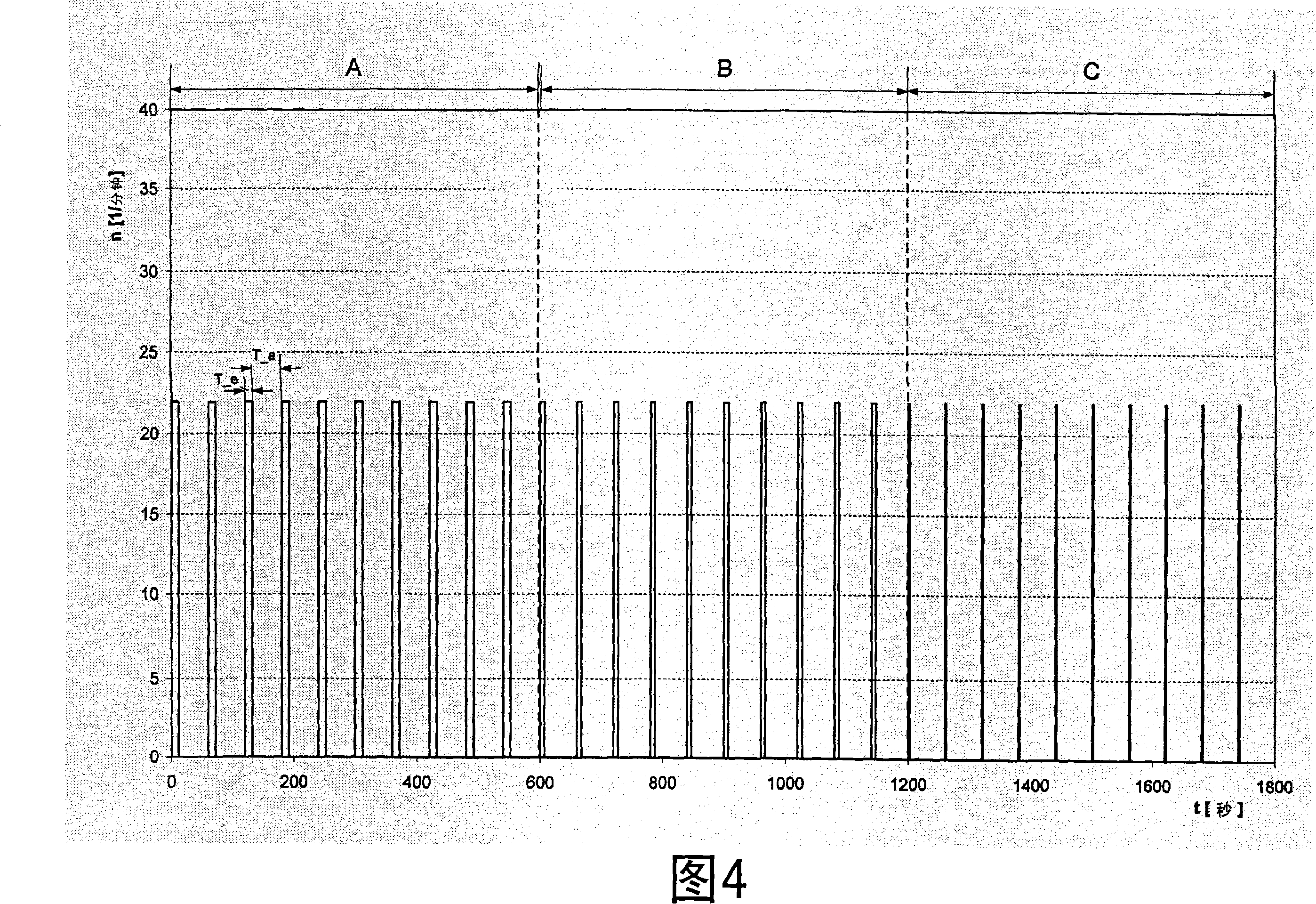

[0025] FIG. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com