Patents

Literature

31 results about "Procedure requested" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

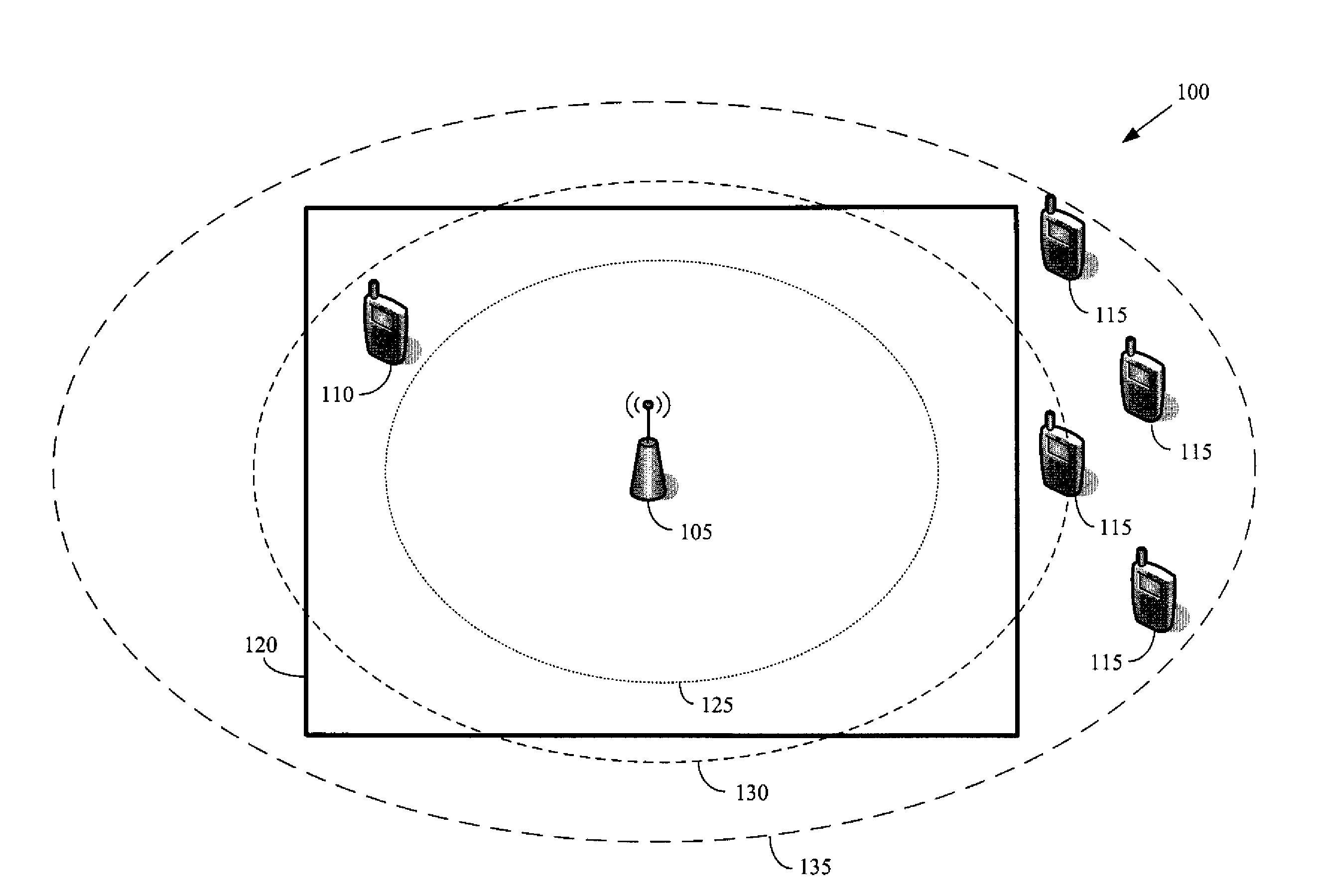

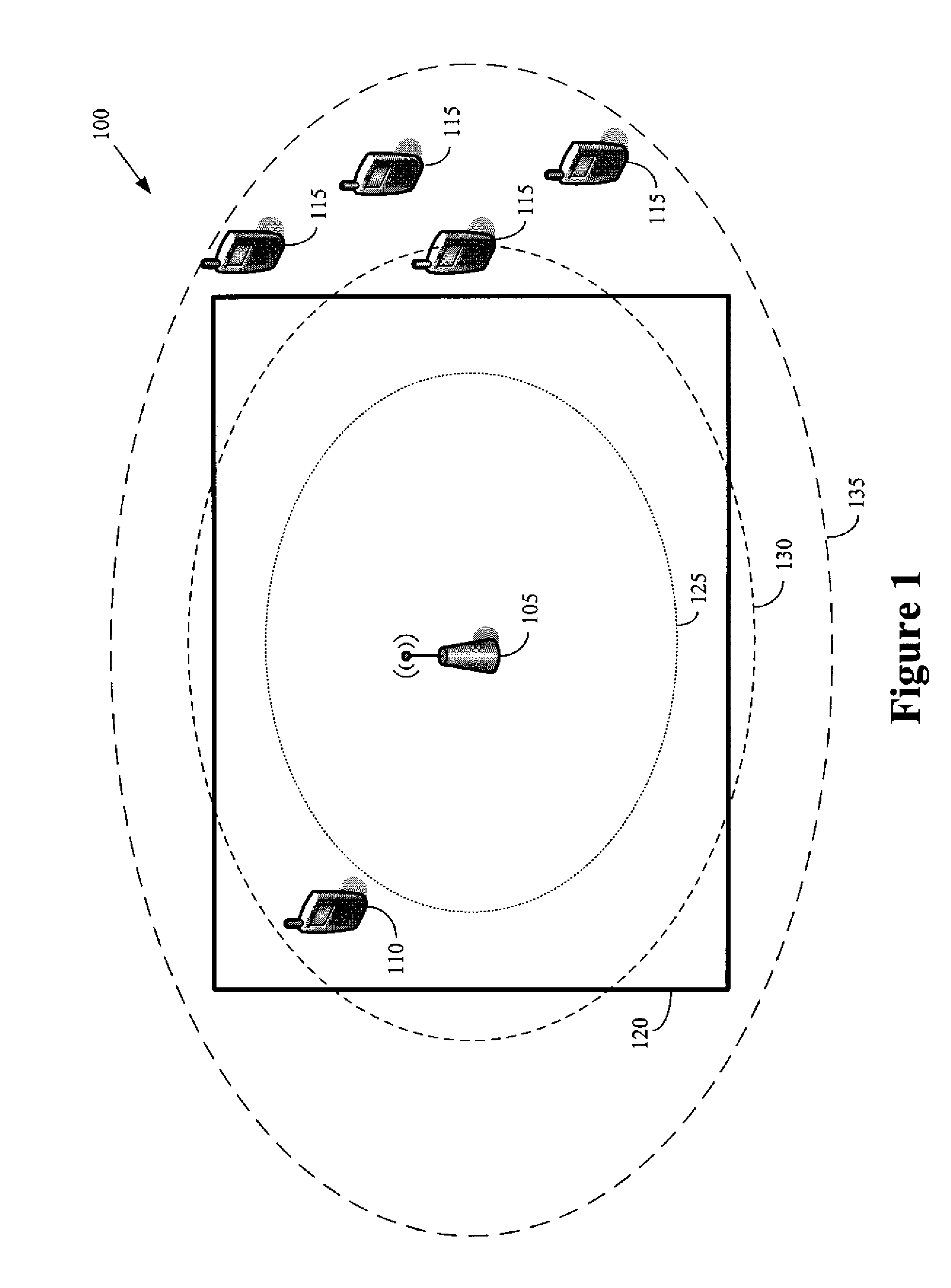

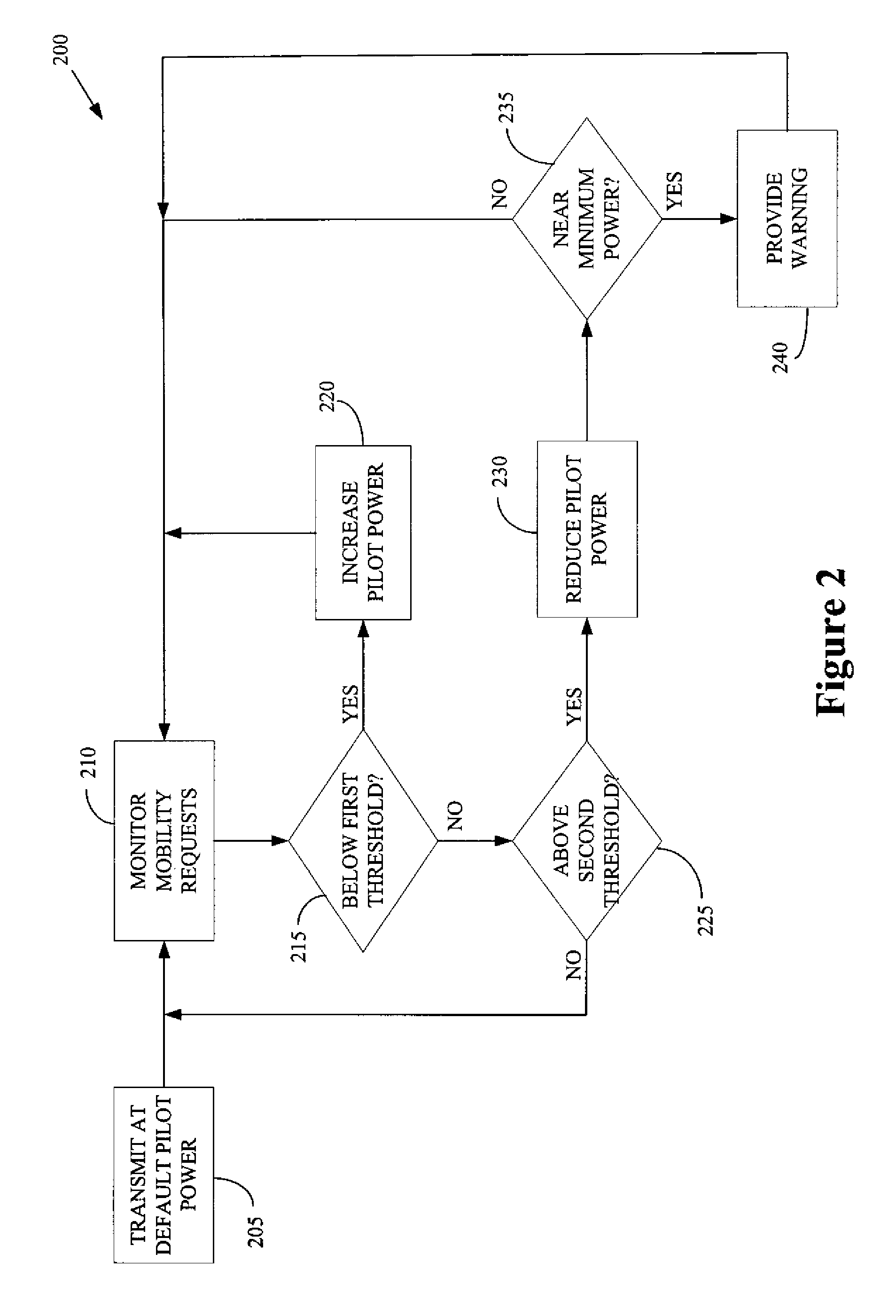

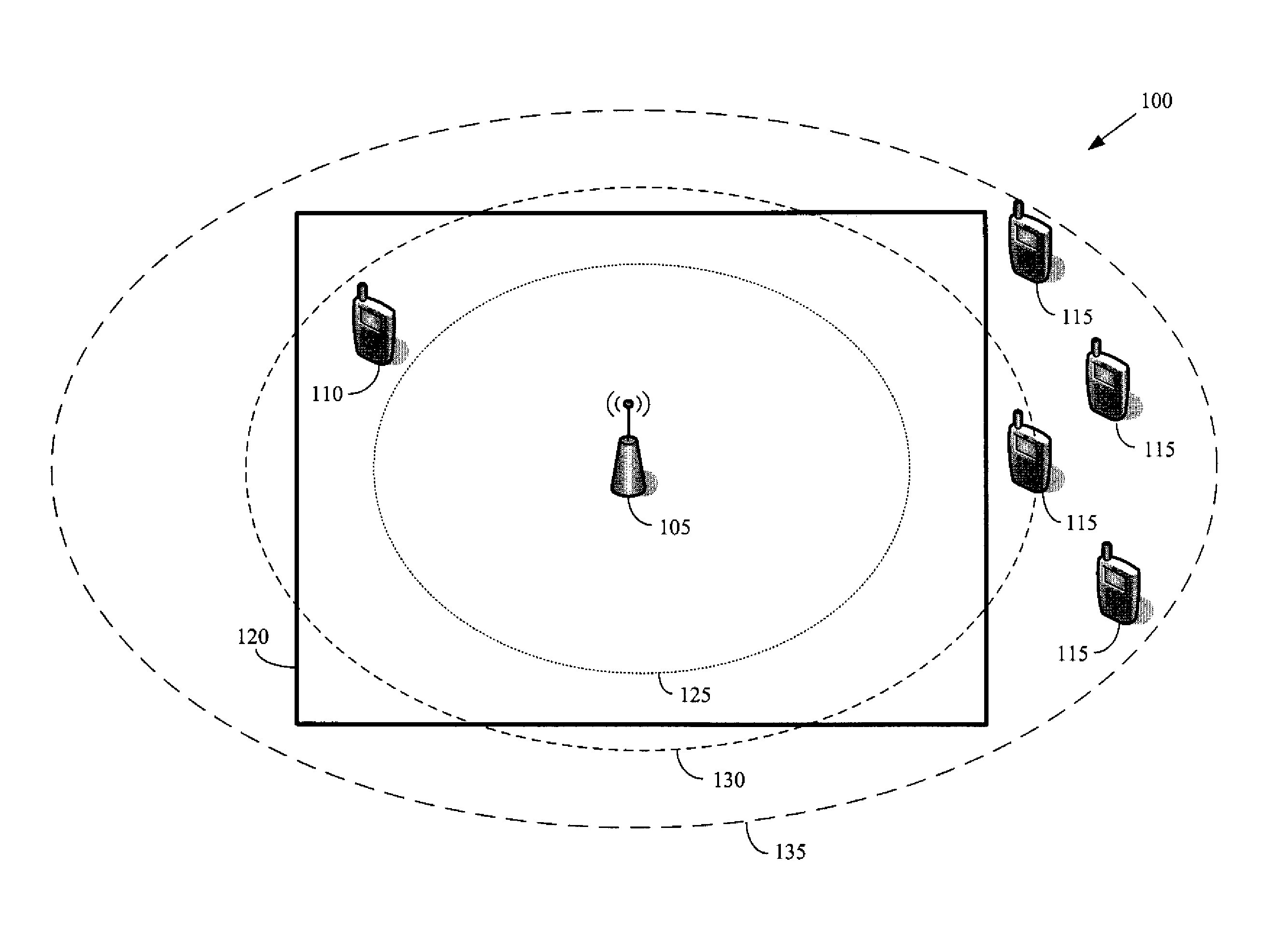

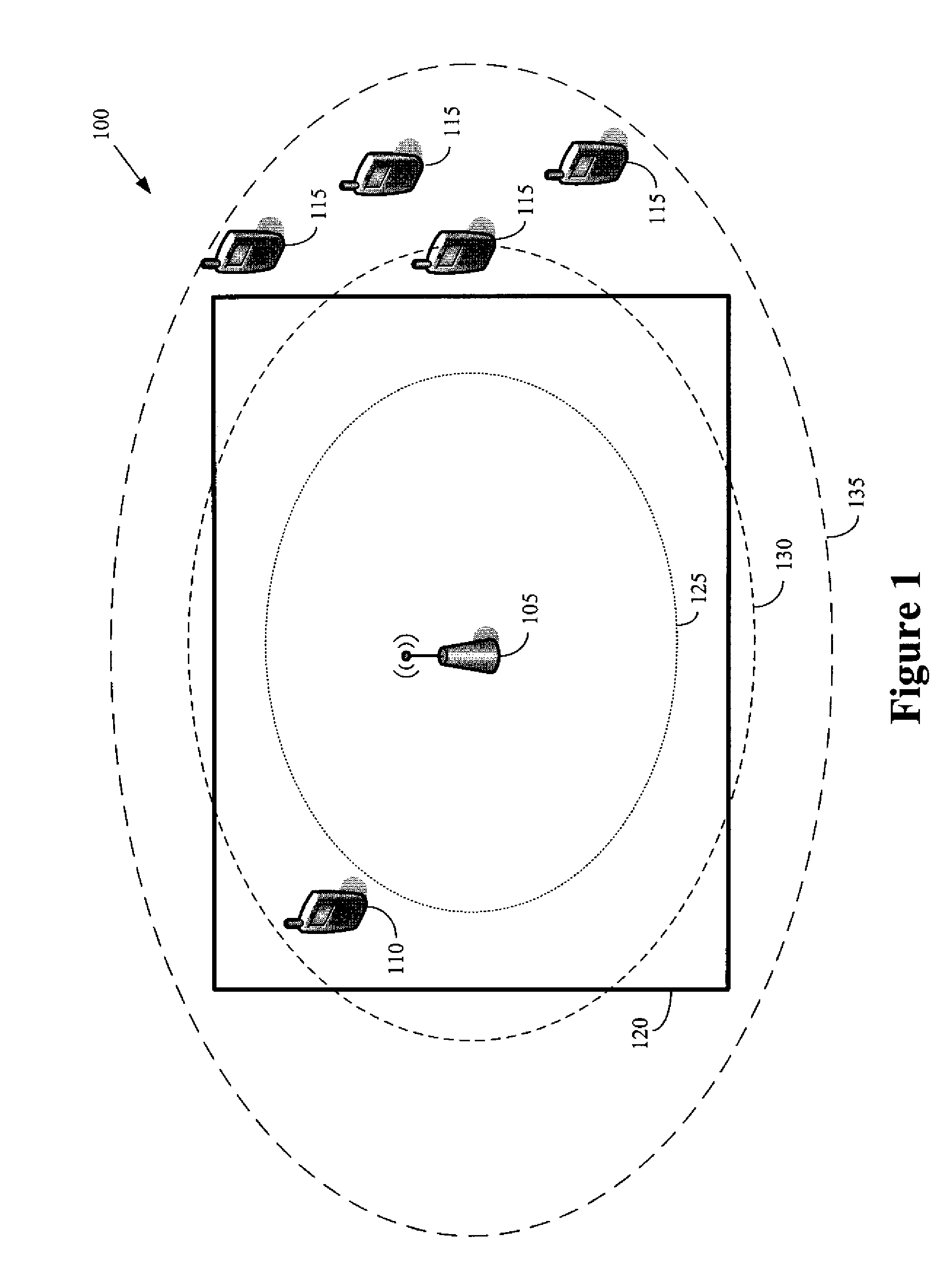

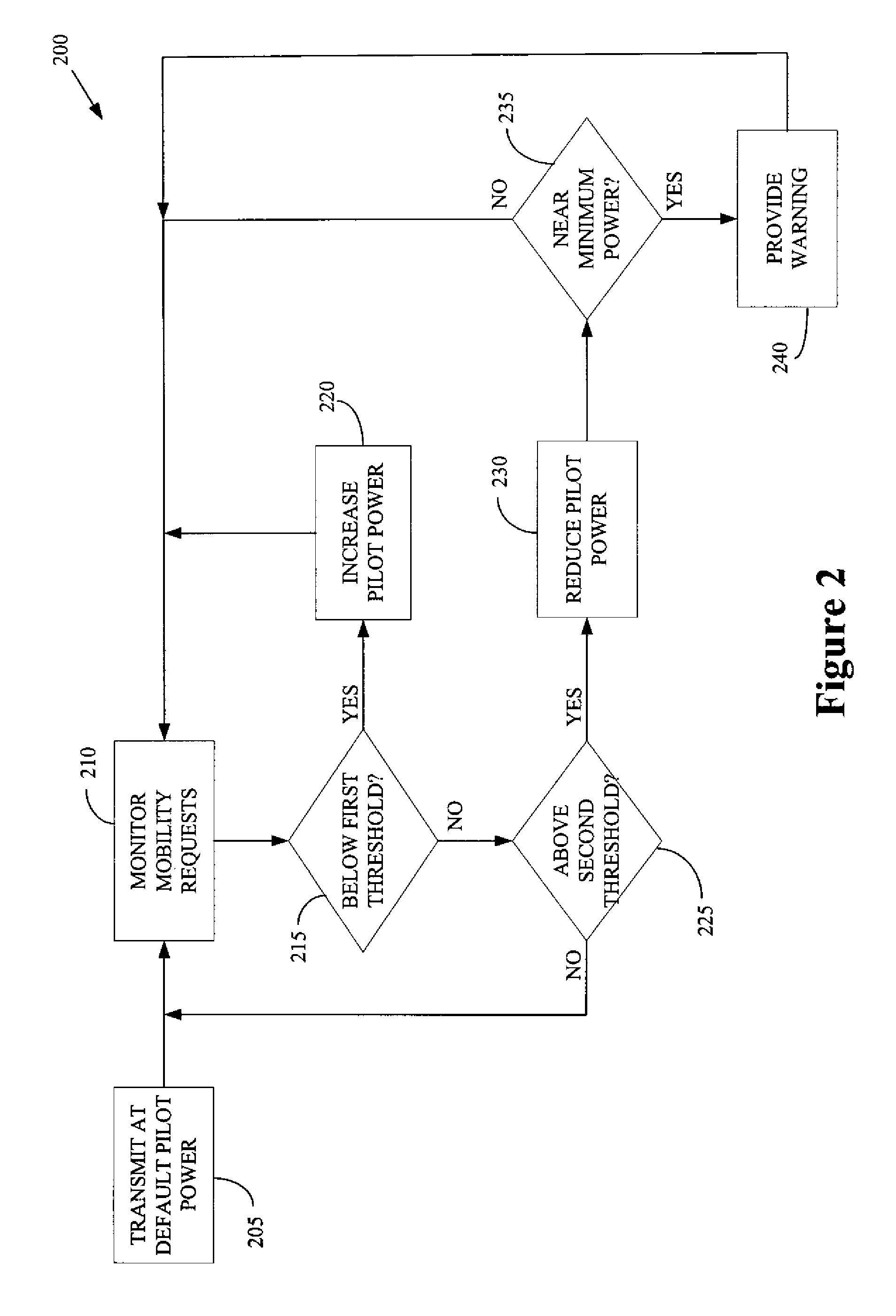

Method of automatically configuring a home base station router

The present invention provides a method of automatically configuring a base station router. The method includes modifying a transmission power for a pilot signal transmitted by the base station router. The modification of the transmission power is determined based upon a frequency of mobility-related procedure requests received by the base station router.

Owner:ALCATEL-LUCENT USA INC

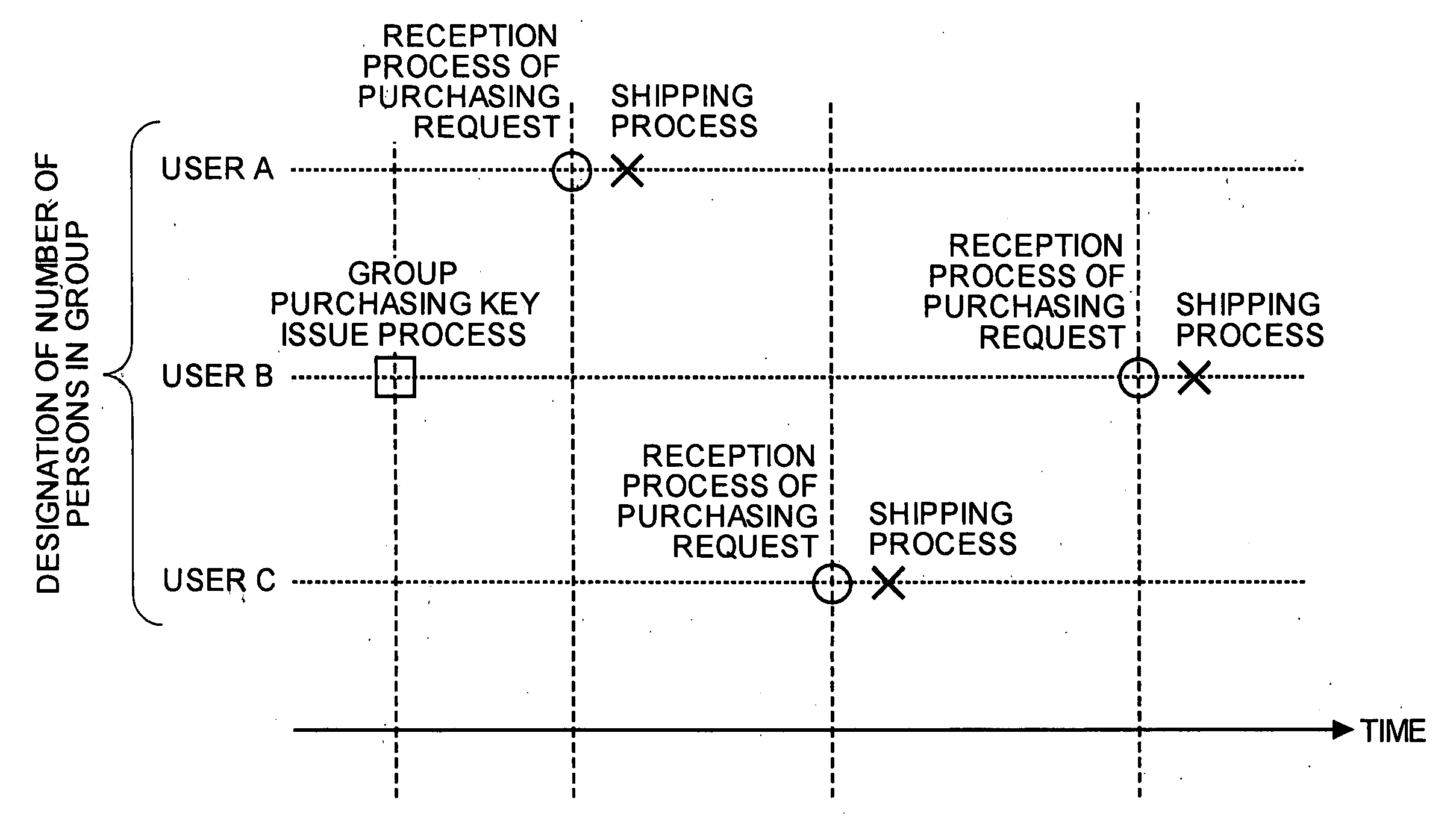

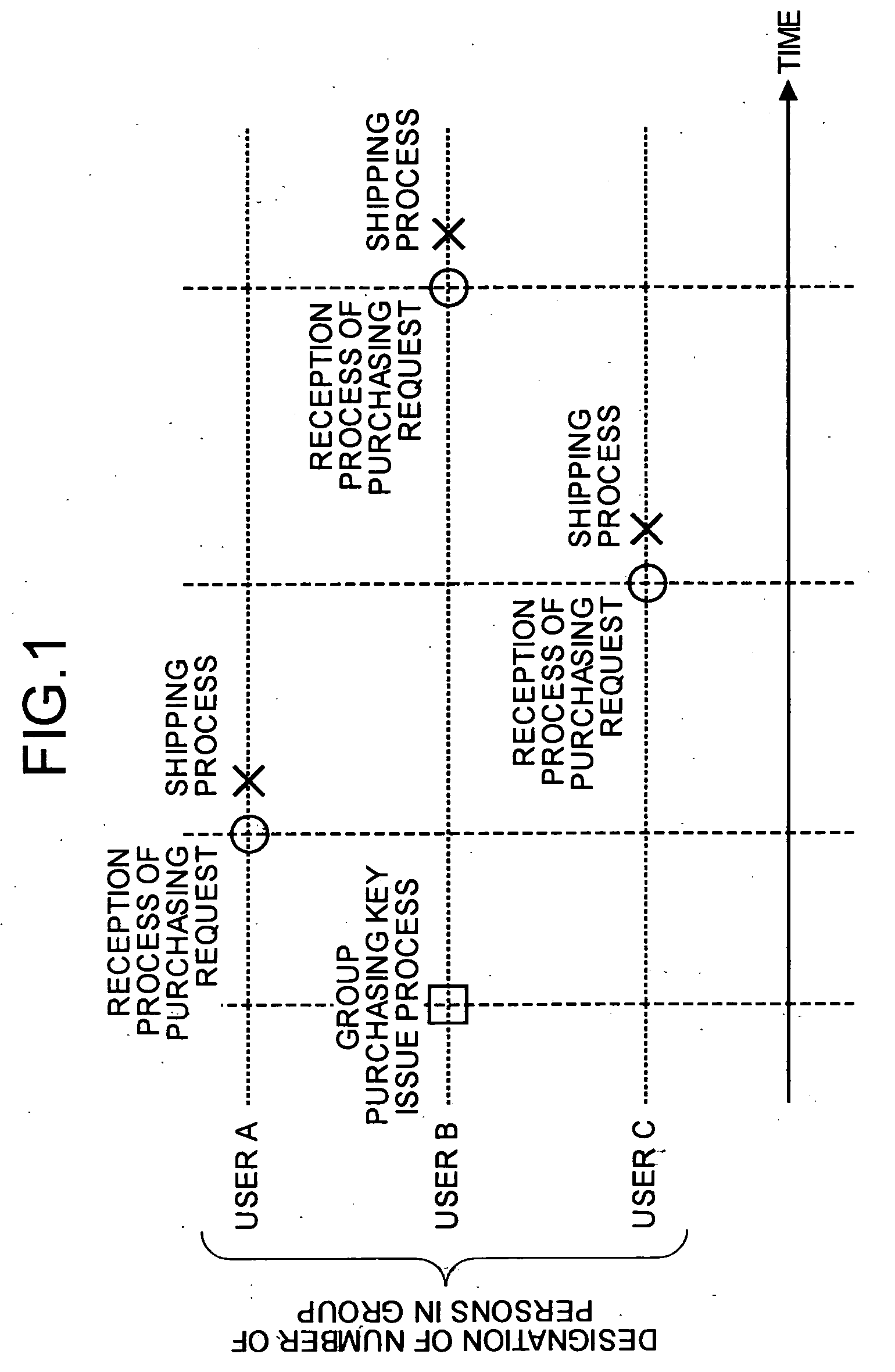

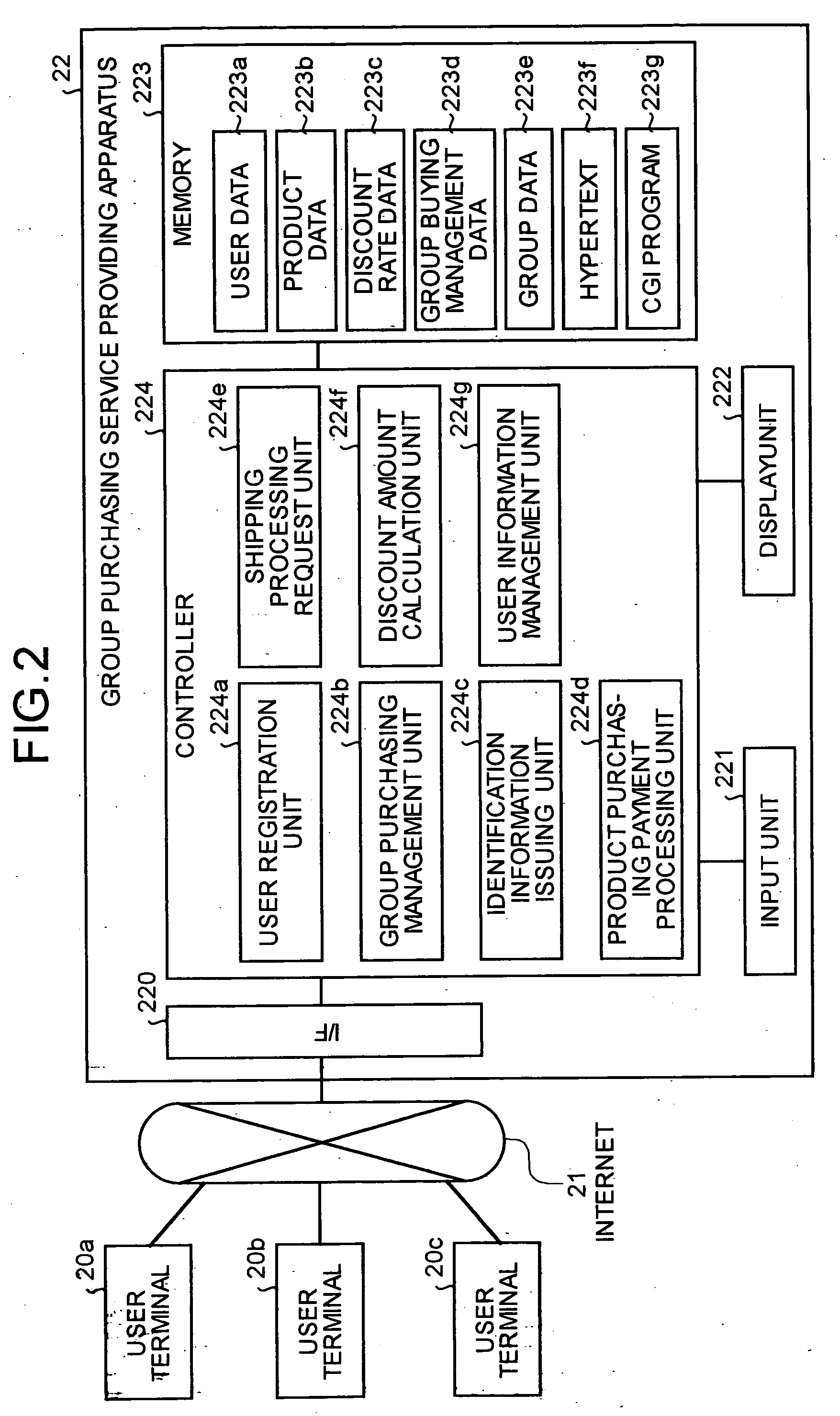

Method of and apparatus for providing group purchasing service, and computer product

InactiveUS20040186789A1Payment architectureBuying/selling/leasing transactionsPaymentGroup Purchasing

When a group purchasing application according to a group of a predetermined number of persons is received, a group purchasing key that identifies the group is issued. When a product purchasing procedure request having the group purchasing key is received from a user, a payment processing is carried out at a normal price without a discount, and a product shipping processing is carried out. After the purchasing procedure processing for all users in the group is completed, a discount amount according to the group purchasing is calculated, and a discount amount payback processing is carried out.

Owner:FUJITSU LTD

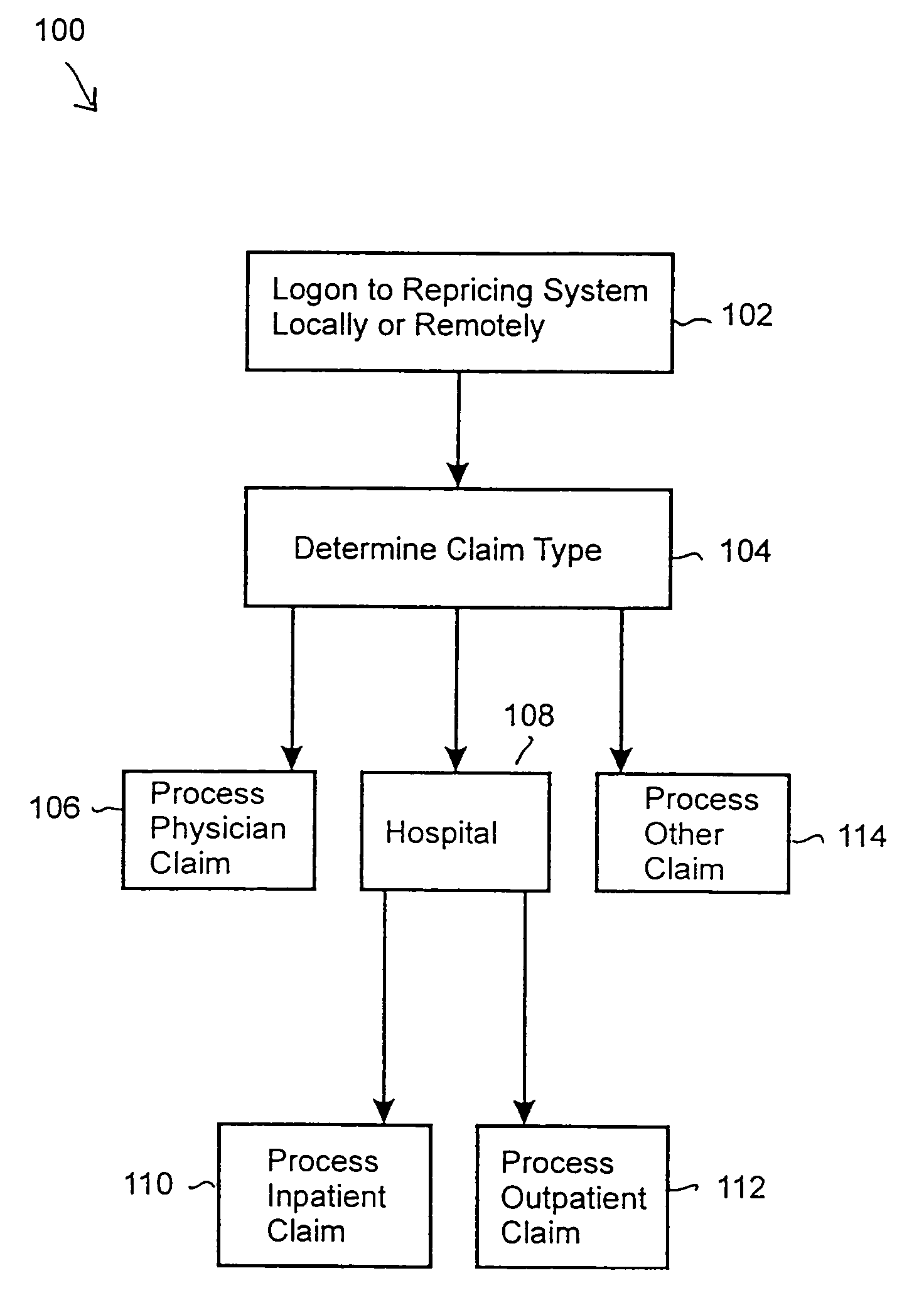

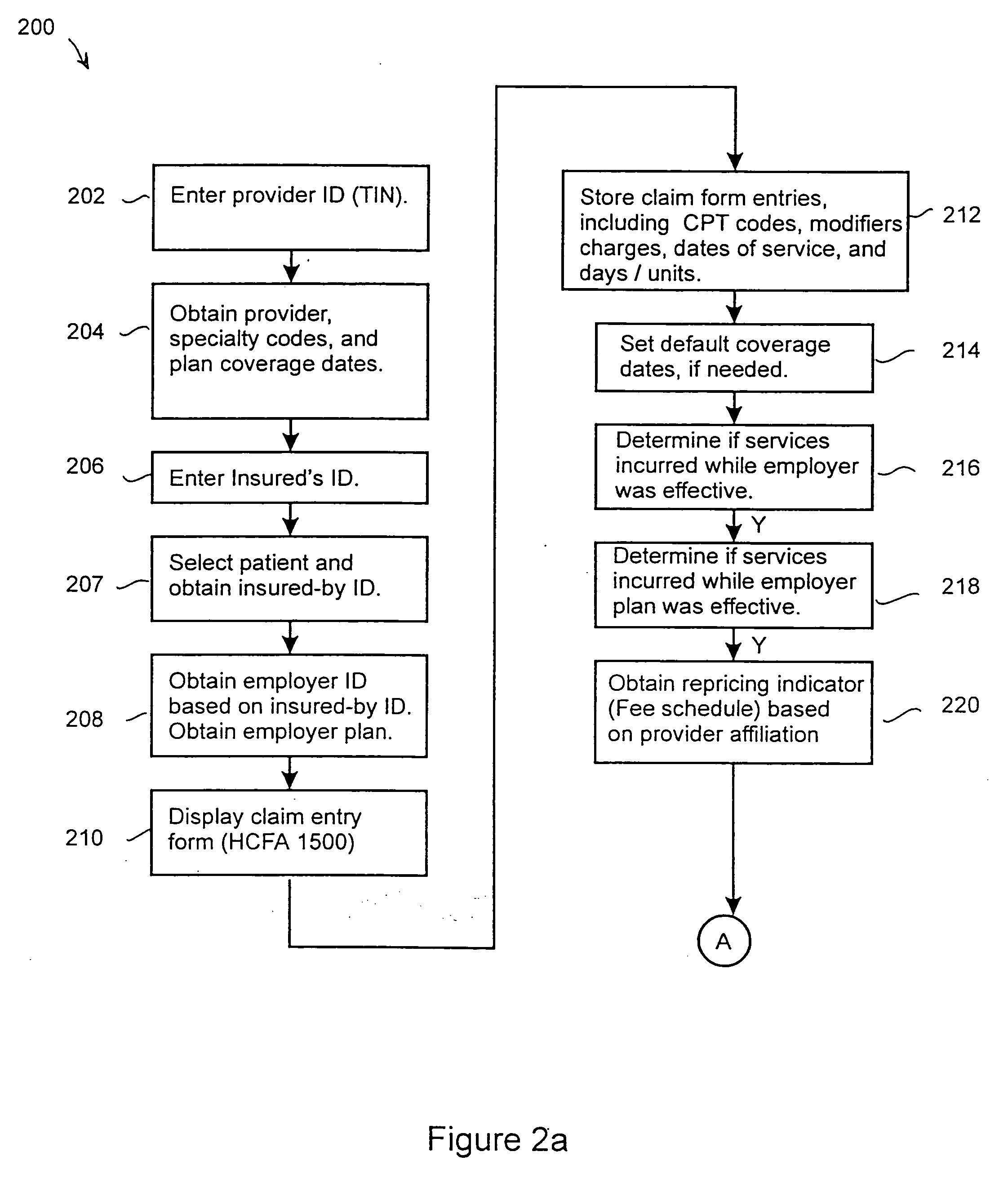

Automated claim repricing system

InactiveUS20050033612A1Quickly and accurately and reliable repriceQuick and efficientFinanceOffice automationEffective dateProgram instruction

The present claim repricing system generally includes a processor and a program and data memory coupled to the processor. The memory stores the requisite database tables, as well as program instructions for repricing several different types of claims, including physician, inpatient, and outpatient claims. The claim repricing system includes instructions for determining availability of insurance plan coverage to the patient based on an effective date of the employer insurance plan, as well as determining the availability of the physician or provider based on an effective provider date. The claim repricing system further handles specialty codes and exceptions. For example, the claim repricing system includes instructions for determining the presence of anesthesia specialty codes, and for determining the correct number of anesthesia units and an anesthesia repricing indicator. The anesthesia repricing indicator may be a percentage discount, for example, or a rate. Furthermore, the claim repricing system may operate in a batch processing mode to quickly, accurately, and reliable reprice large amounts of claims.

Owner:DONOVAN EDWARD JOSEPH +2

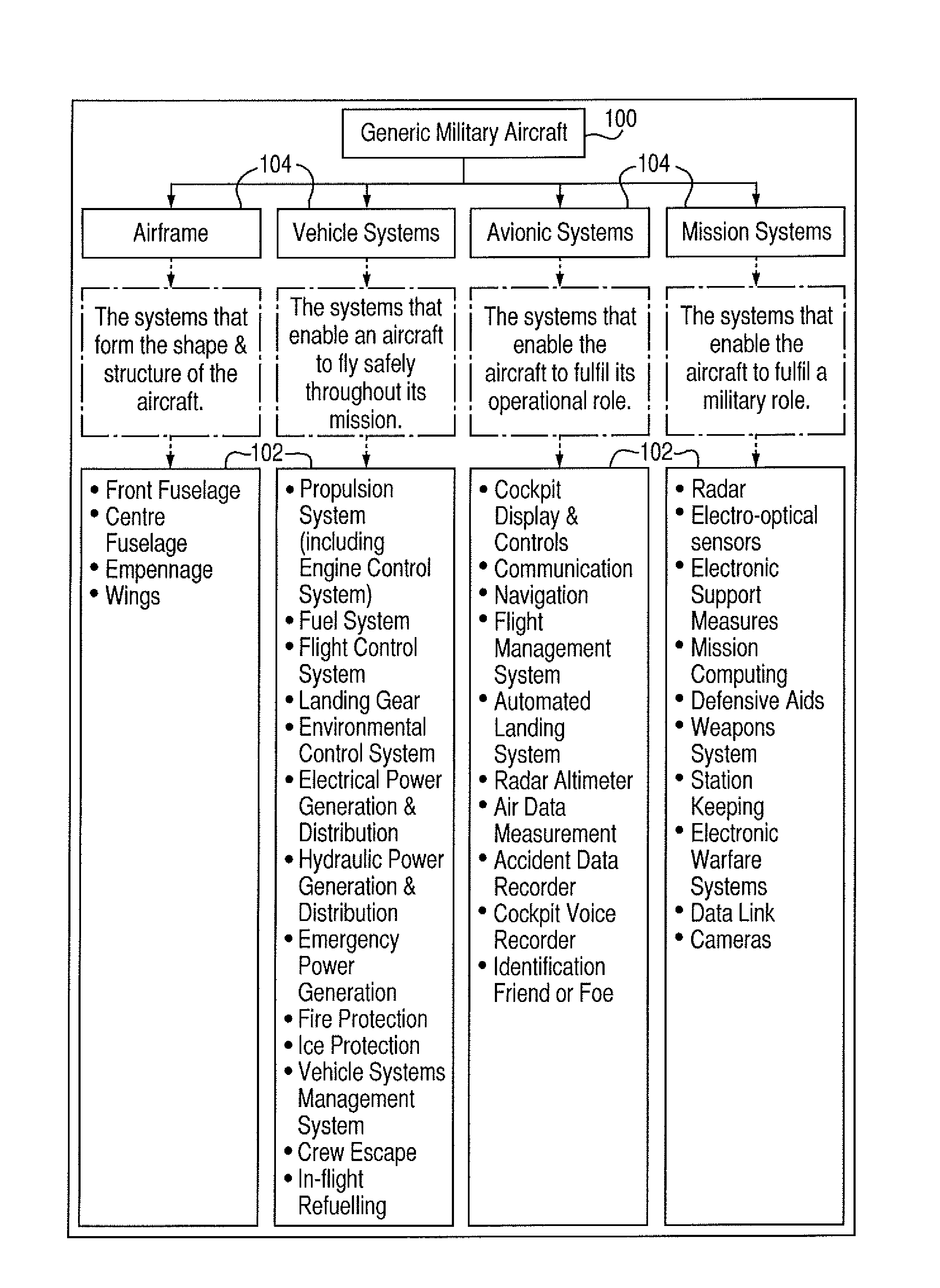

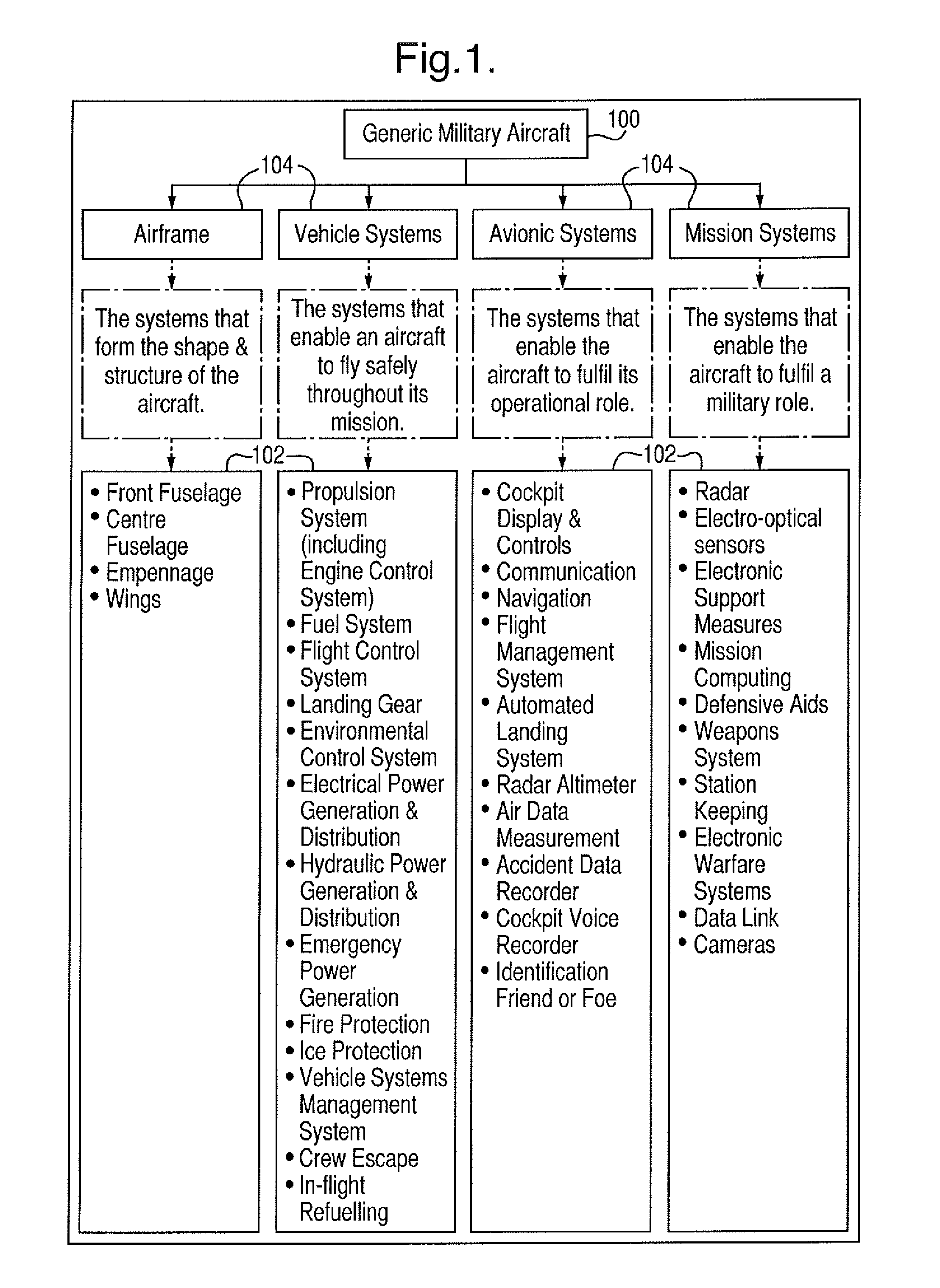

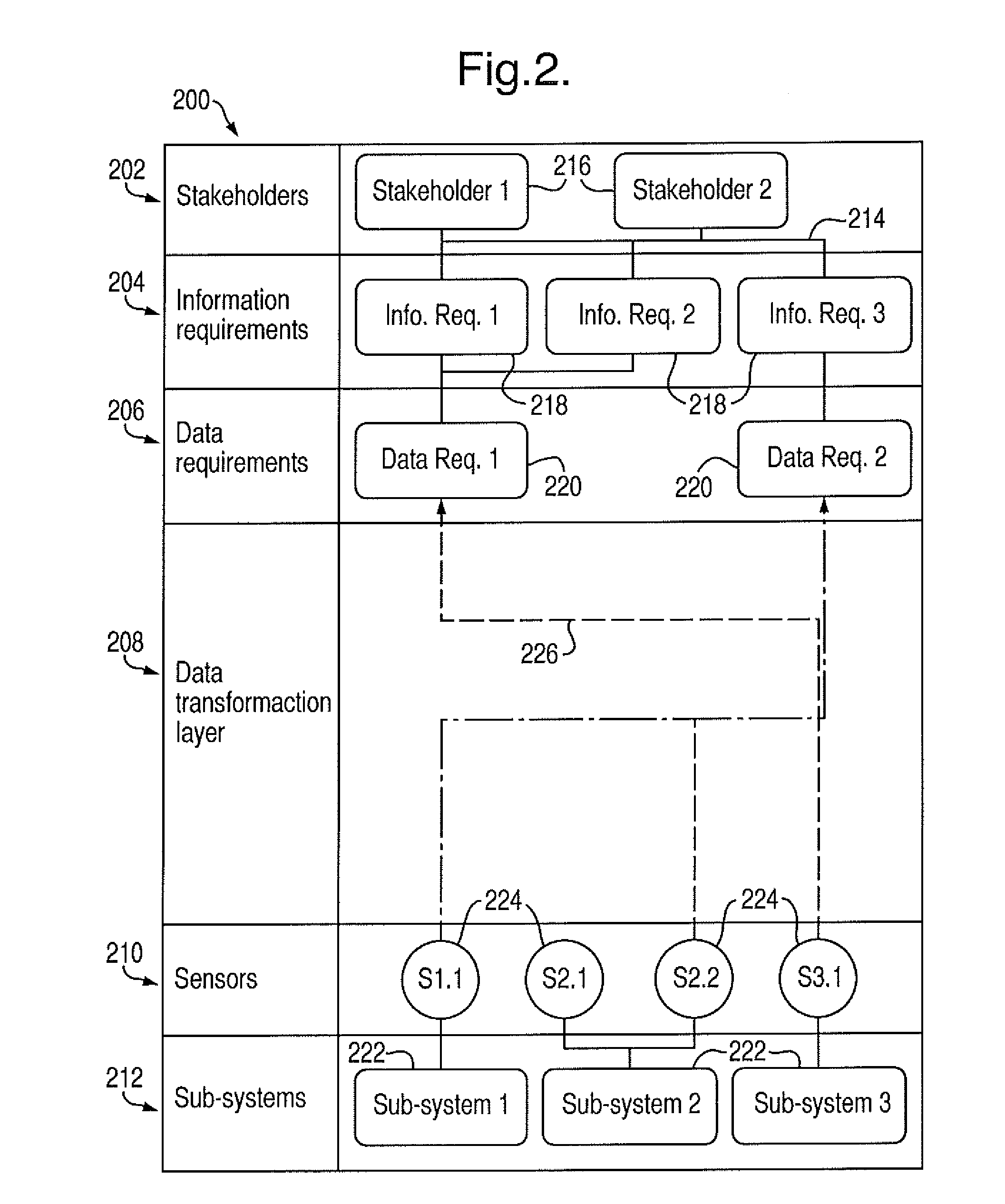

Monitoring system

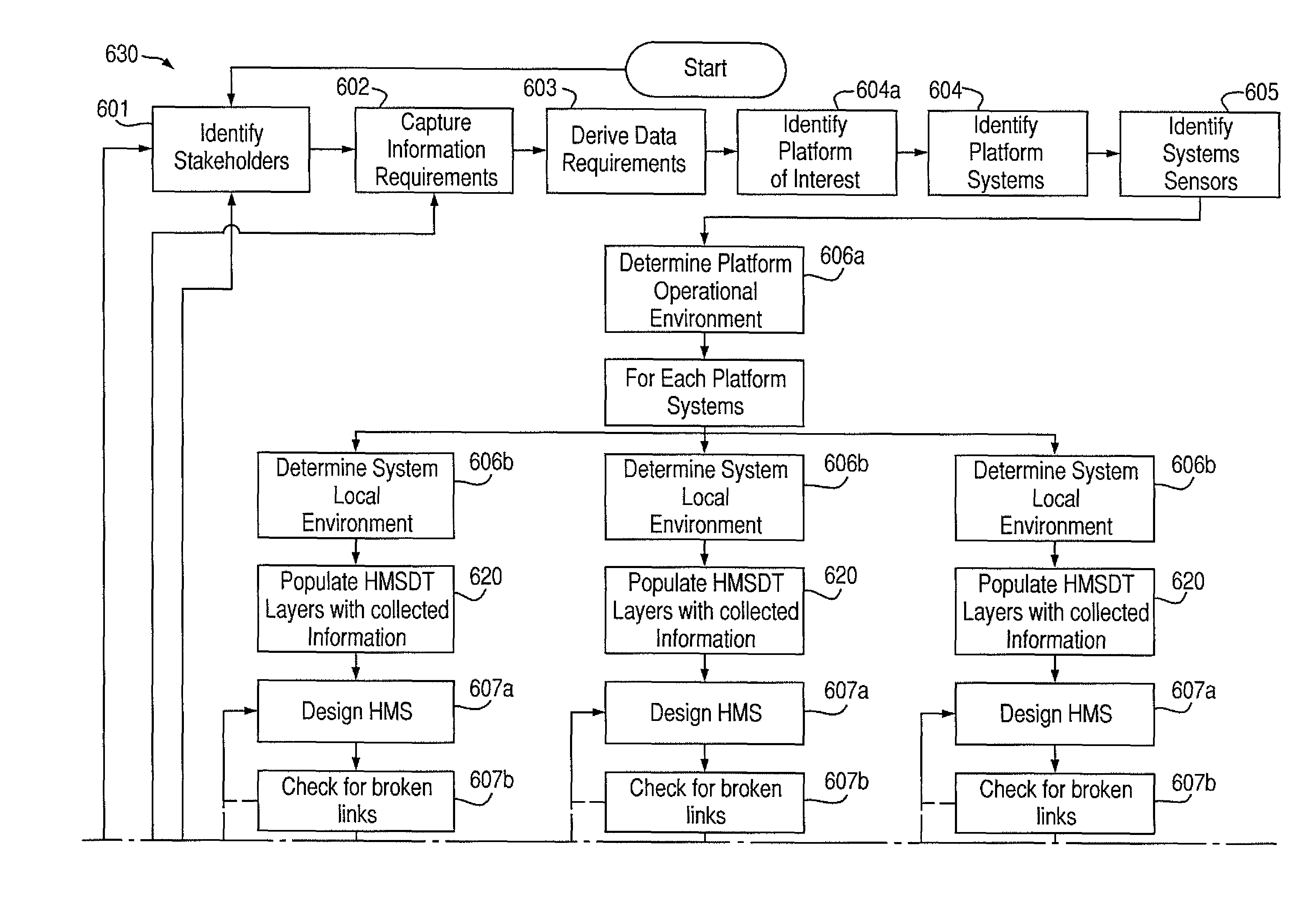

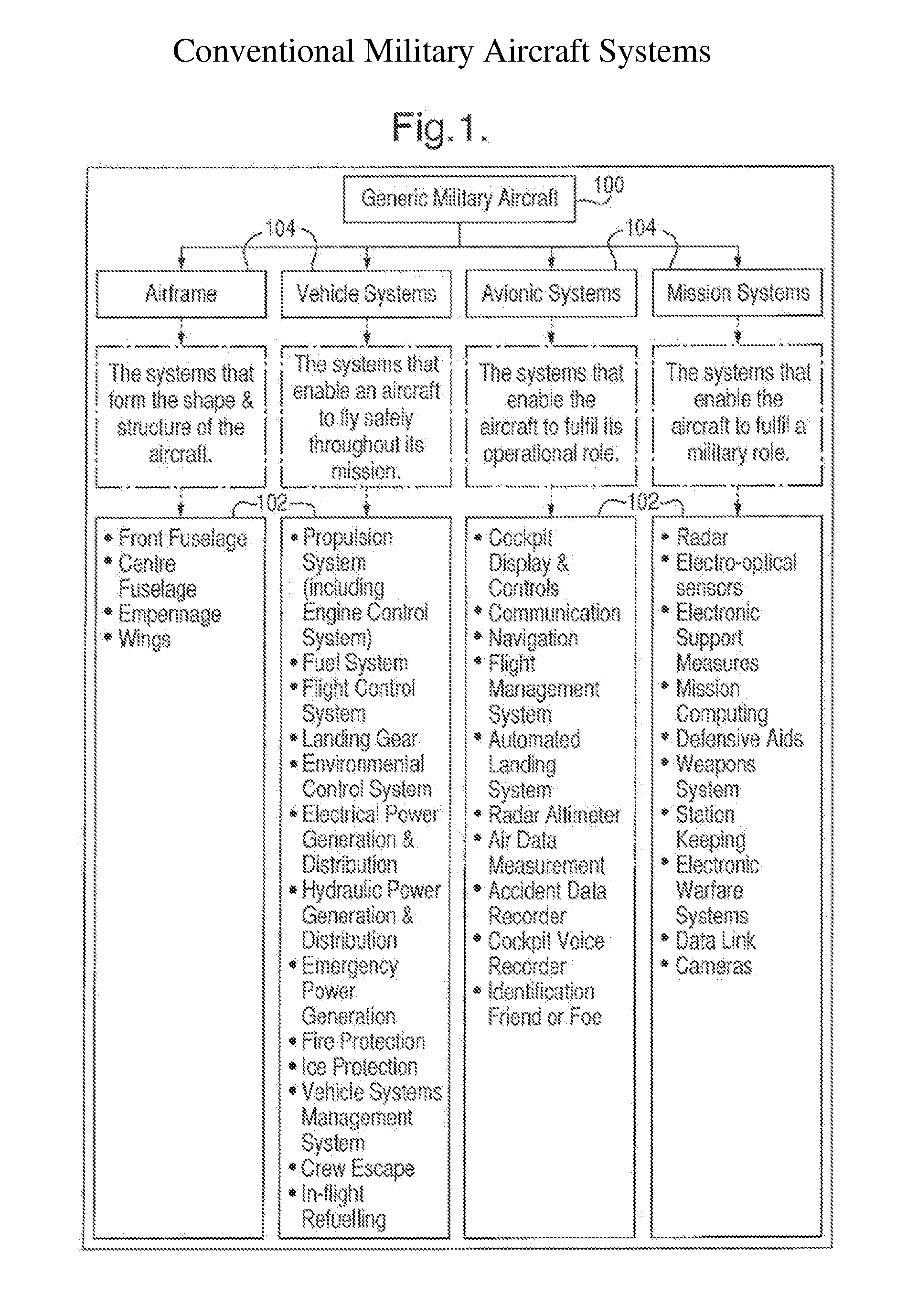

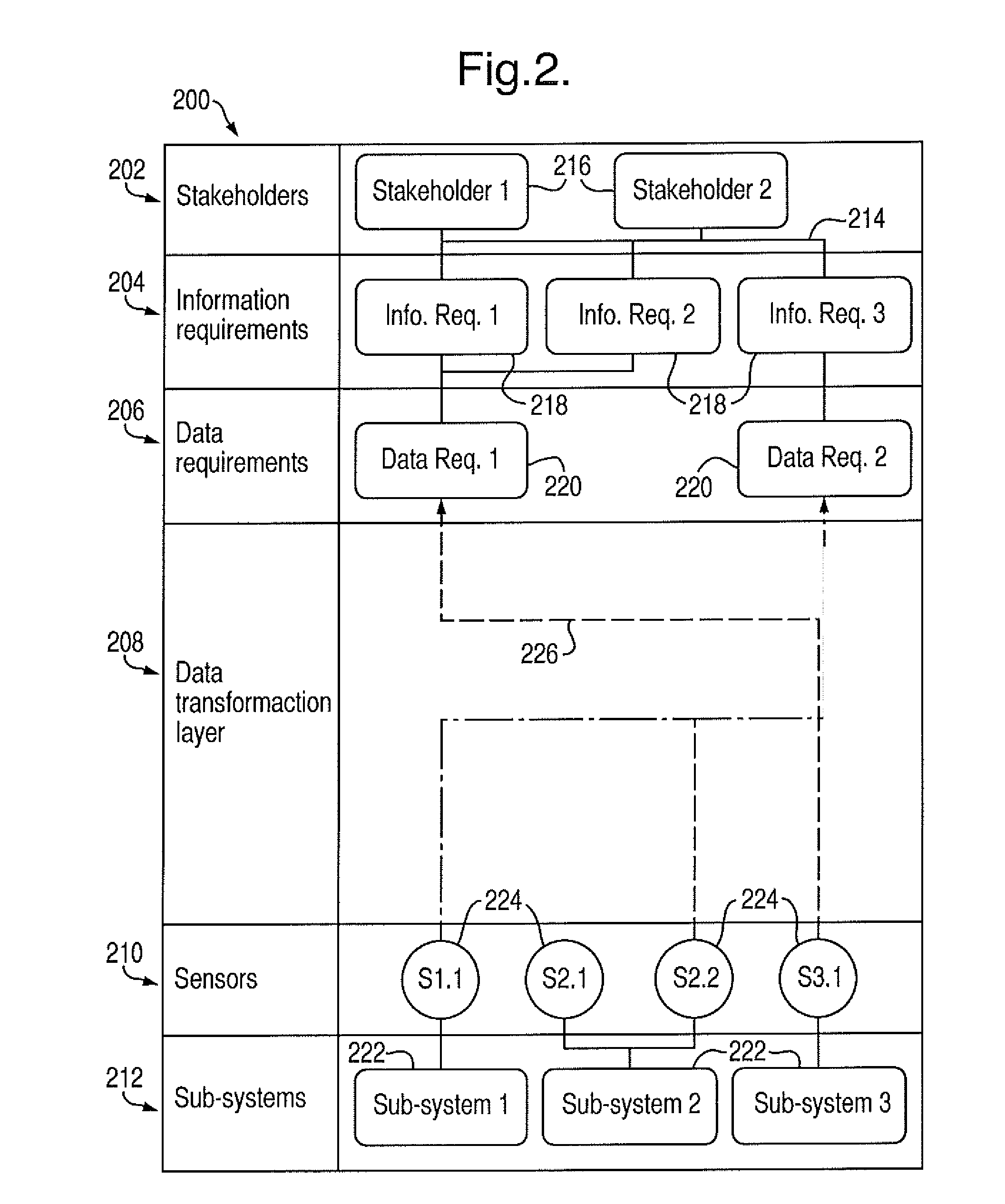

ActiveUS20120130701A1Convenient to accommodateSimple designProgramme controlSimulator controlSensor arrayProcedure requested

A method for designing a secondary sub-system for monitoring the condition of a platform is disclosed. The platform can include one or more primary sub-systems. The method can include identifying stakeholders of the platform, capturing information requirements of the stakeholders, determining data requirements corresponding to the information requirements, defining a sensor array comprising sensors suitable for providing output signals relating to condition characteristics of the one or more primary sub-systems, and defining procedures for converting the output signals from the sensor array to the data requirements, thereby to fulfil the information requirements of the stakeholders. The method can be implemented using a design tool having a graphical user interface with a hierarchical layer structure.

Owner:BAE SYSTEMS PLC

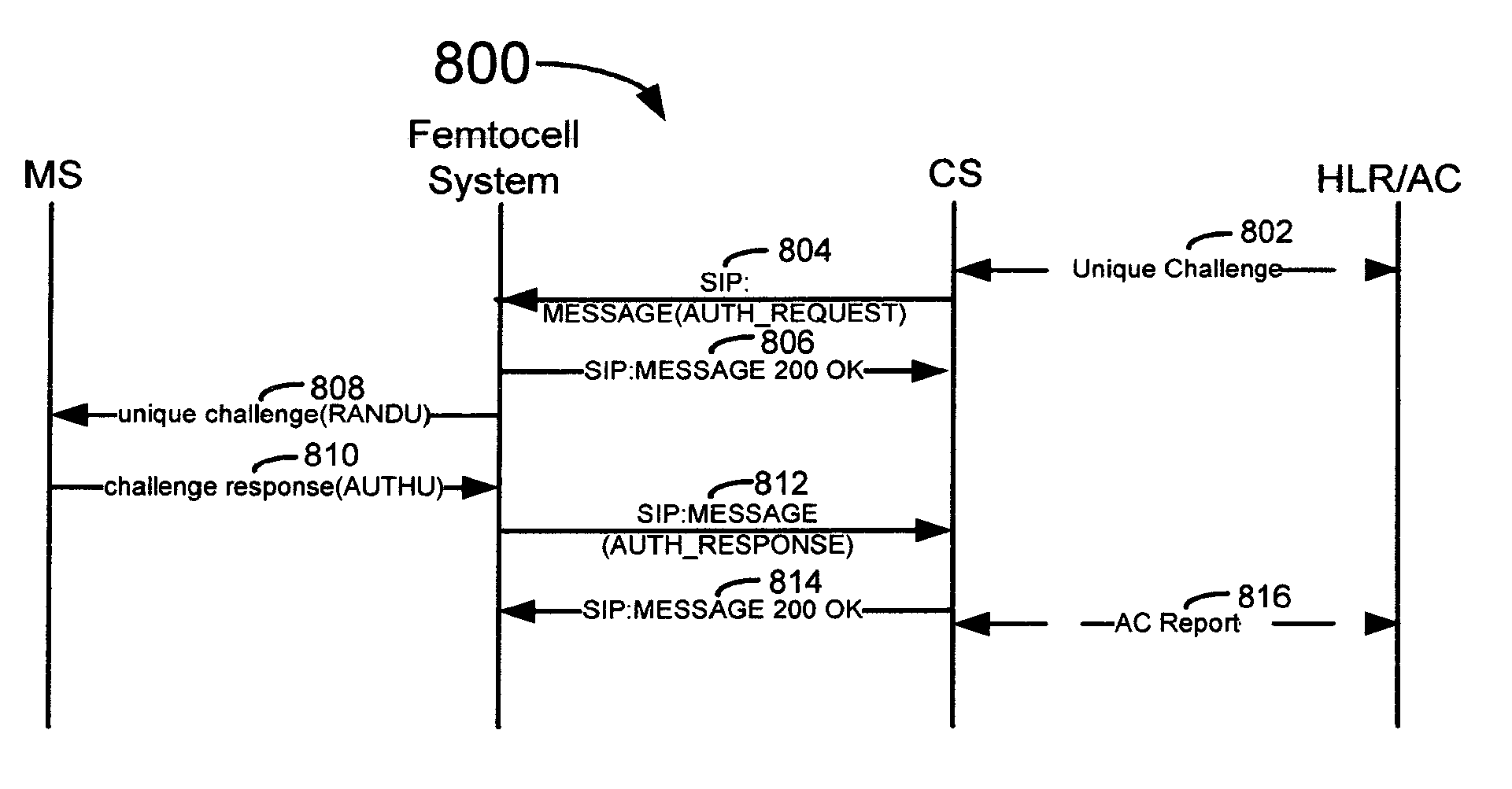

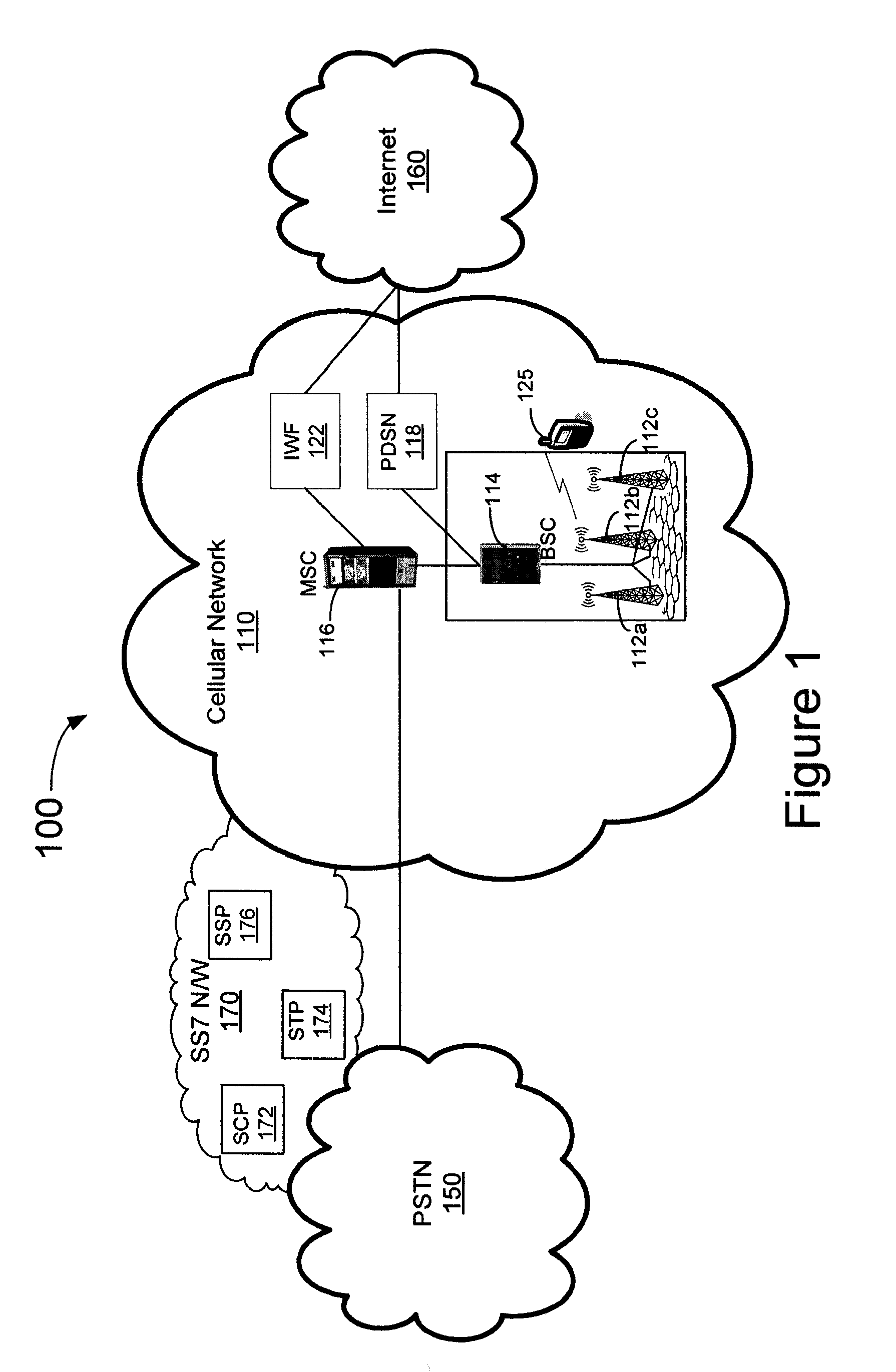

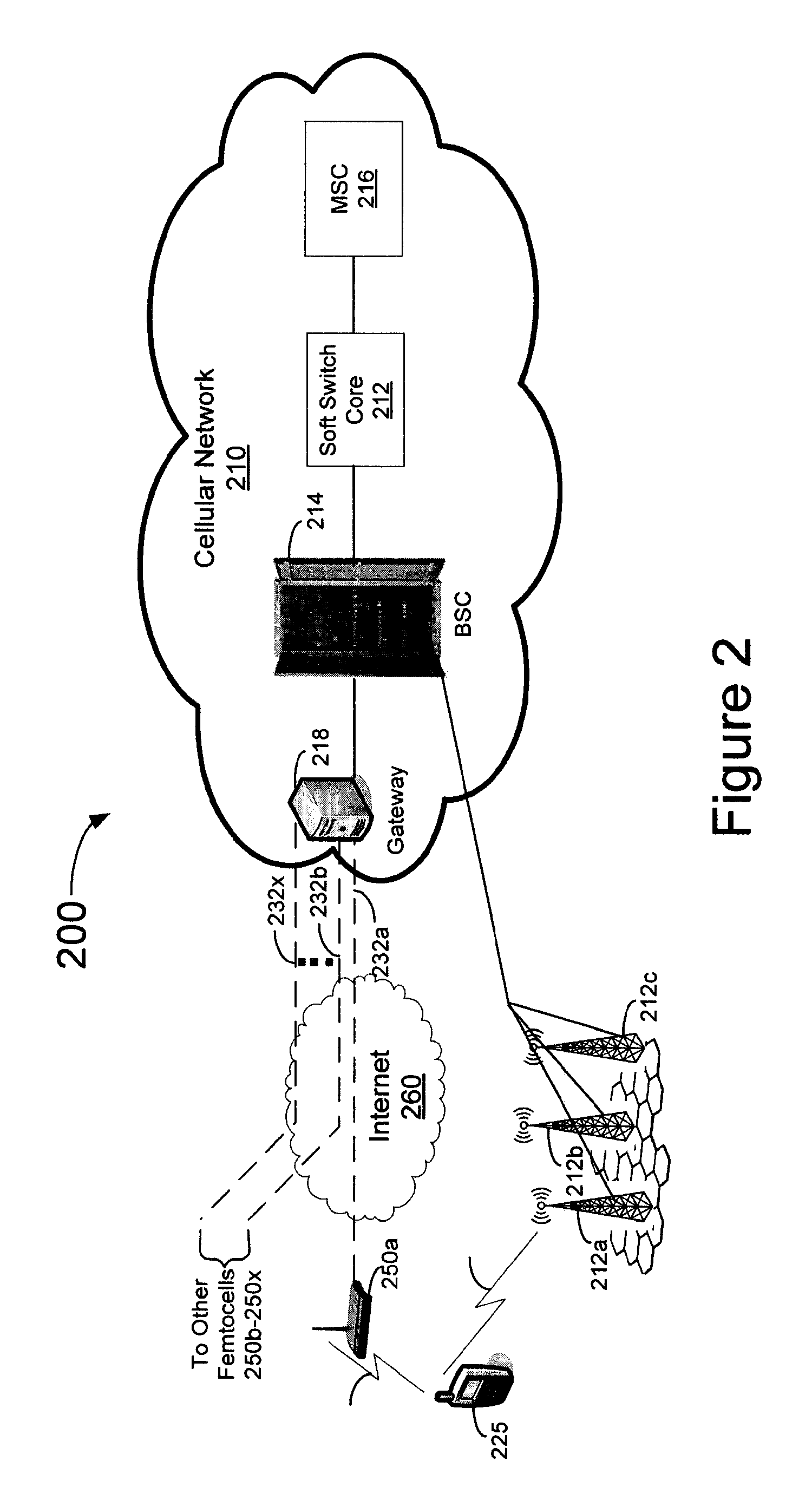

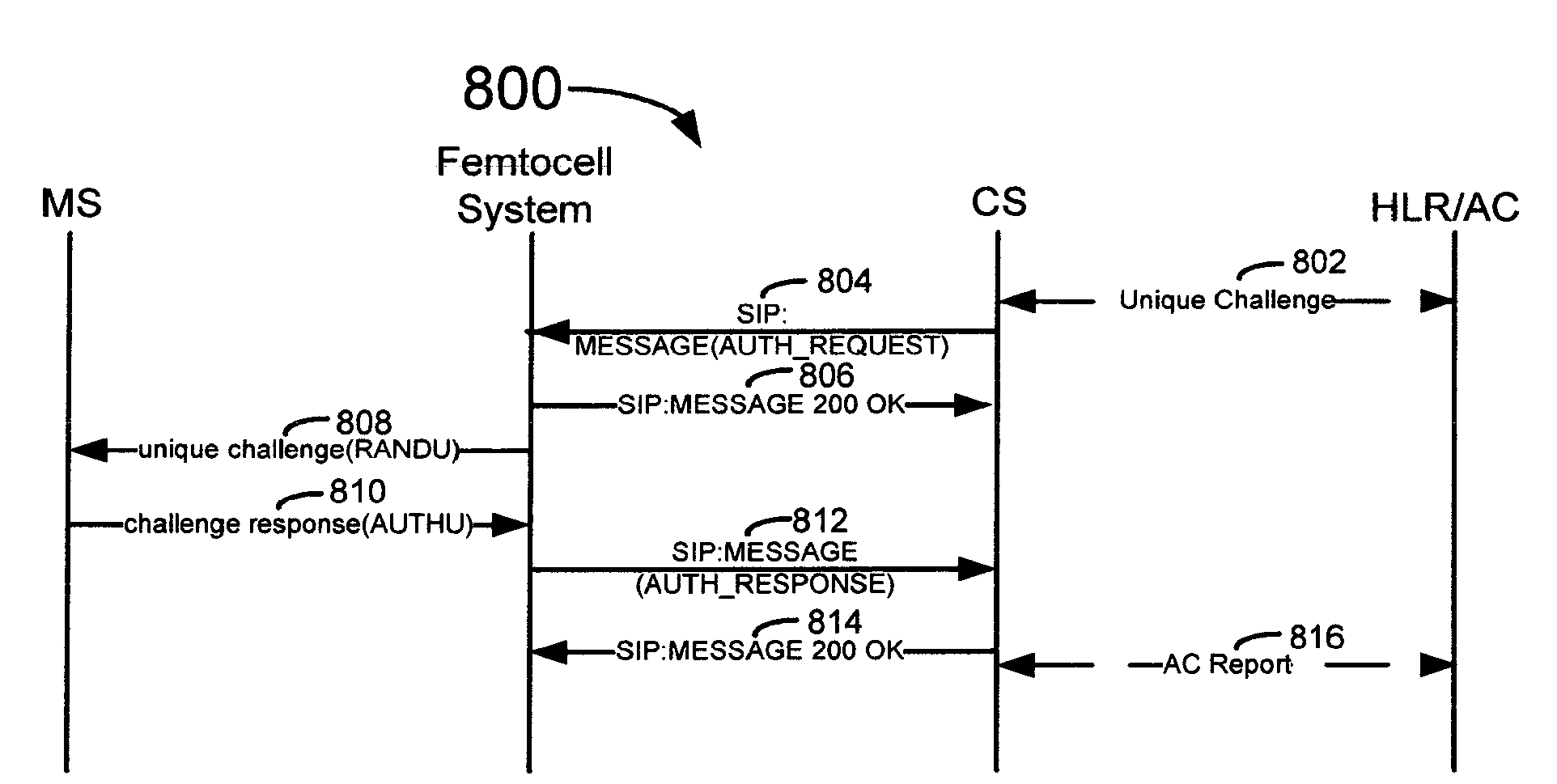

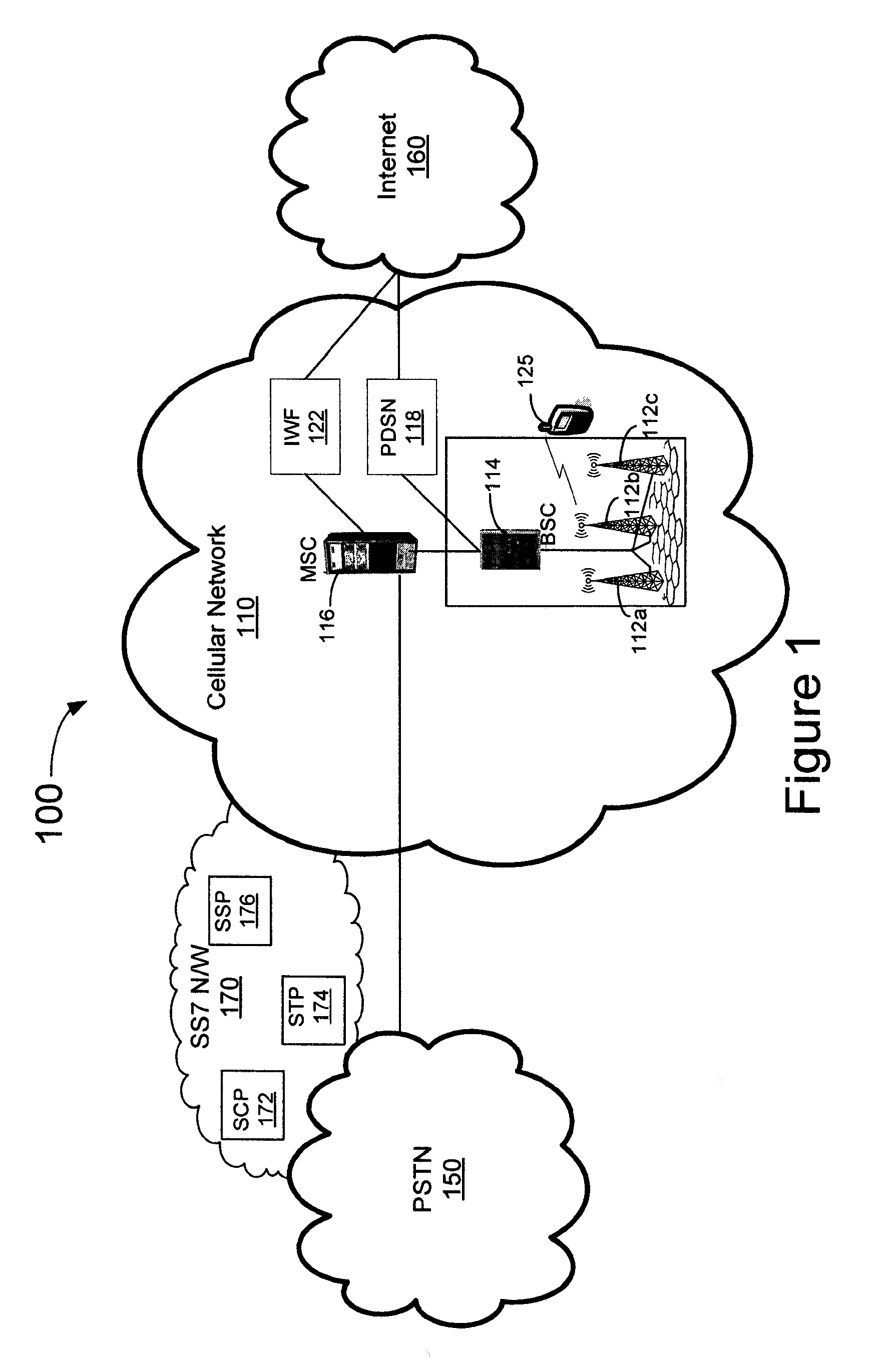

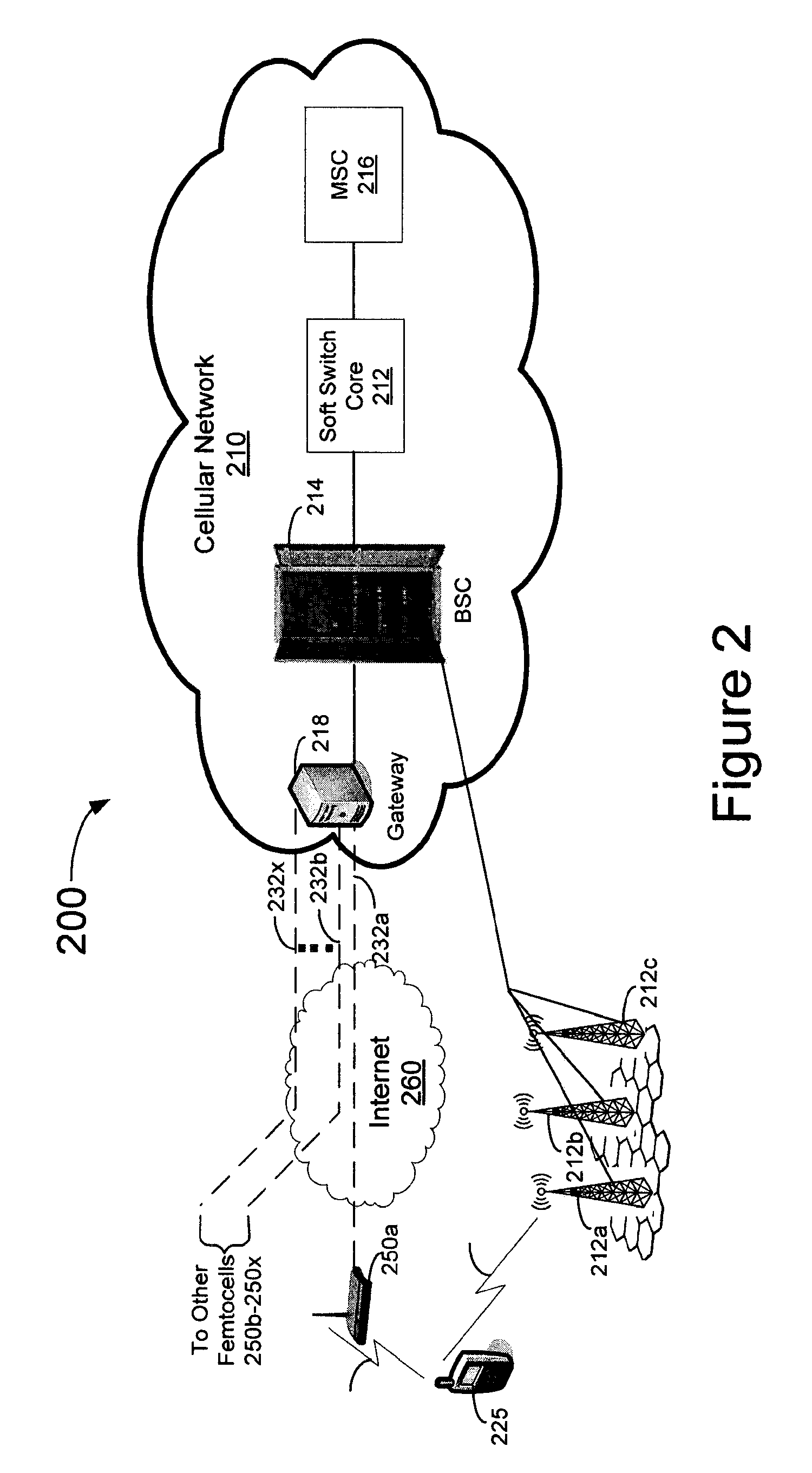

System, method, and computer-readable medium for authentication center-initiated authentication procedures for a mobile station attached with an ip-femtocell system

ActiveUS20100048175A1Easy procedureError preventionFrequency-division multiplex detailsProcedure requestedMobile station

A system, method, and computer readable medium that facilitate authentication center-initiated authentication procedures for a mobile station attached with a femtocell system are provided. A femtocell system may generate a registration identification of a mobile station from one or more mobile station authentication parameters. A convergence server located in a core network receives an authentication procedure request from an authentication center for the mobile station attached with the femtocell system and generates an authentication procedure request message that includes the registration identification assigned to the mobile station. The convergence server then transmits the authentication procedure request message to the femtocell system and receives a response to the authentication procedure request message from the femtocell system. The authentication procedure request may comprise a unique challenge, a shared secret data update procedure, or a call history count update procedure.

Owner:RED HAT

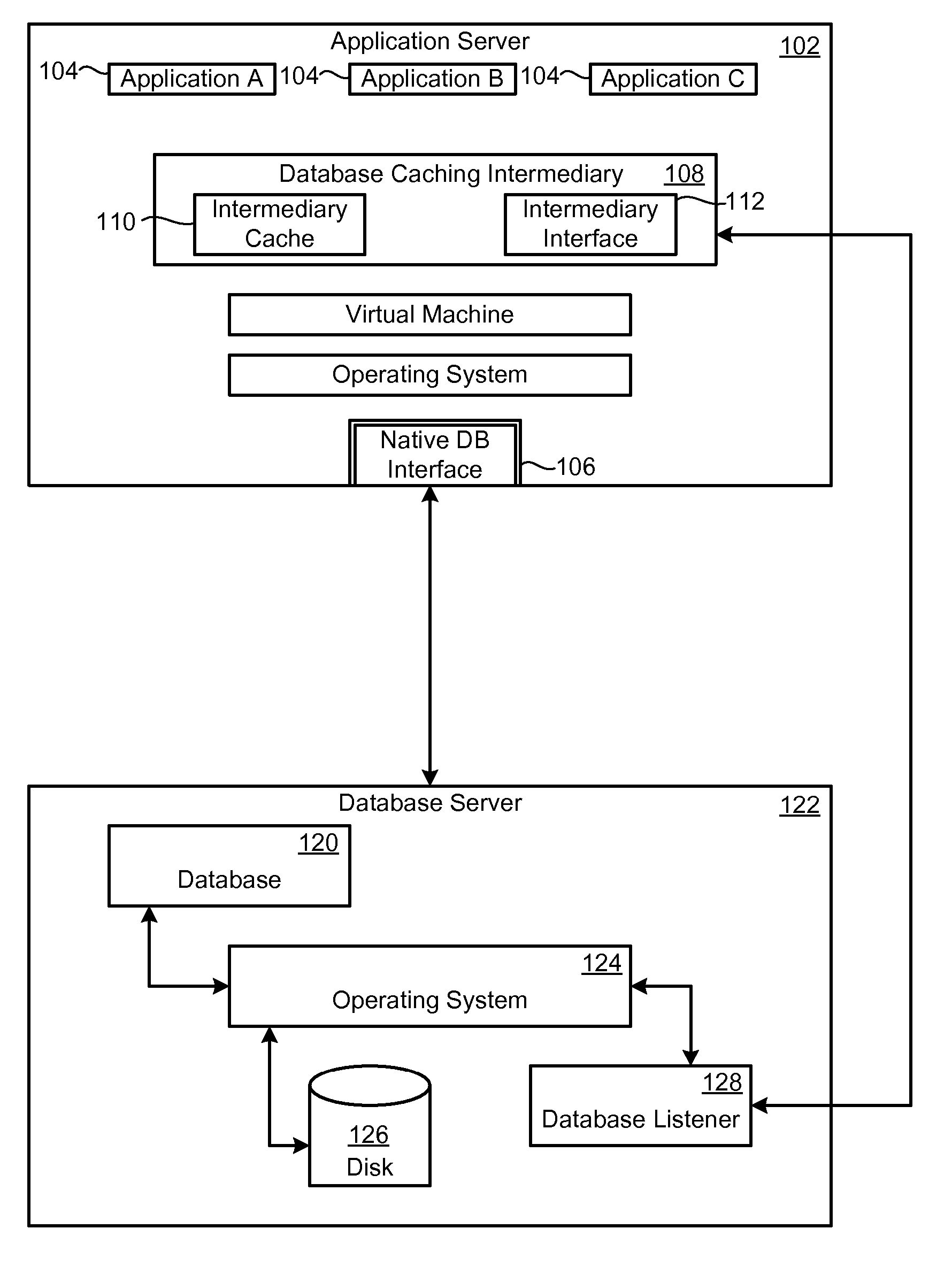

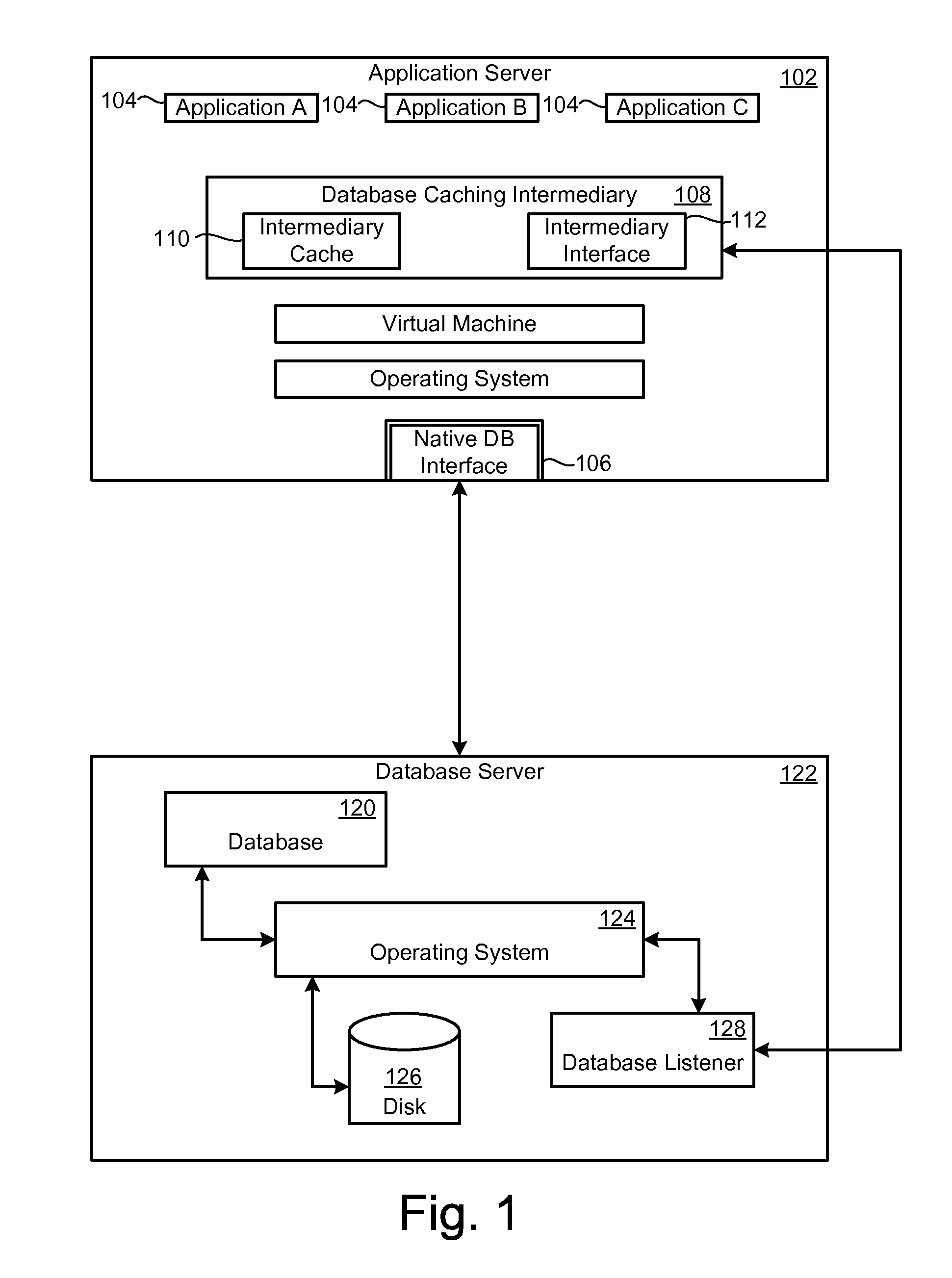

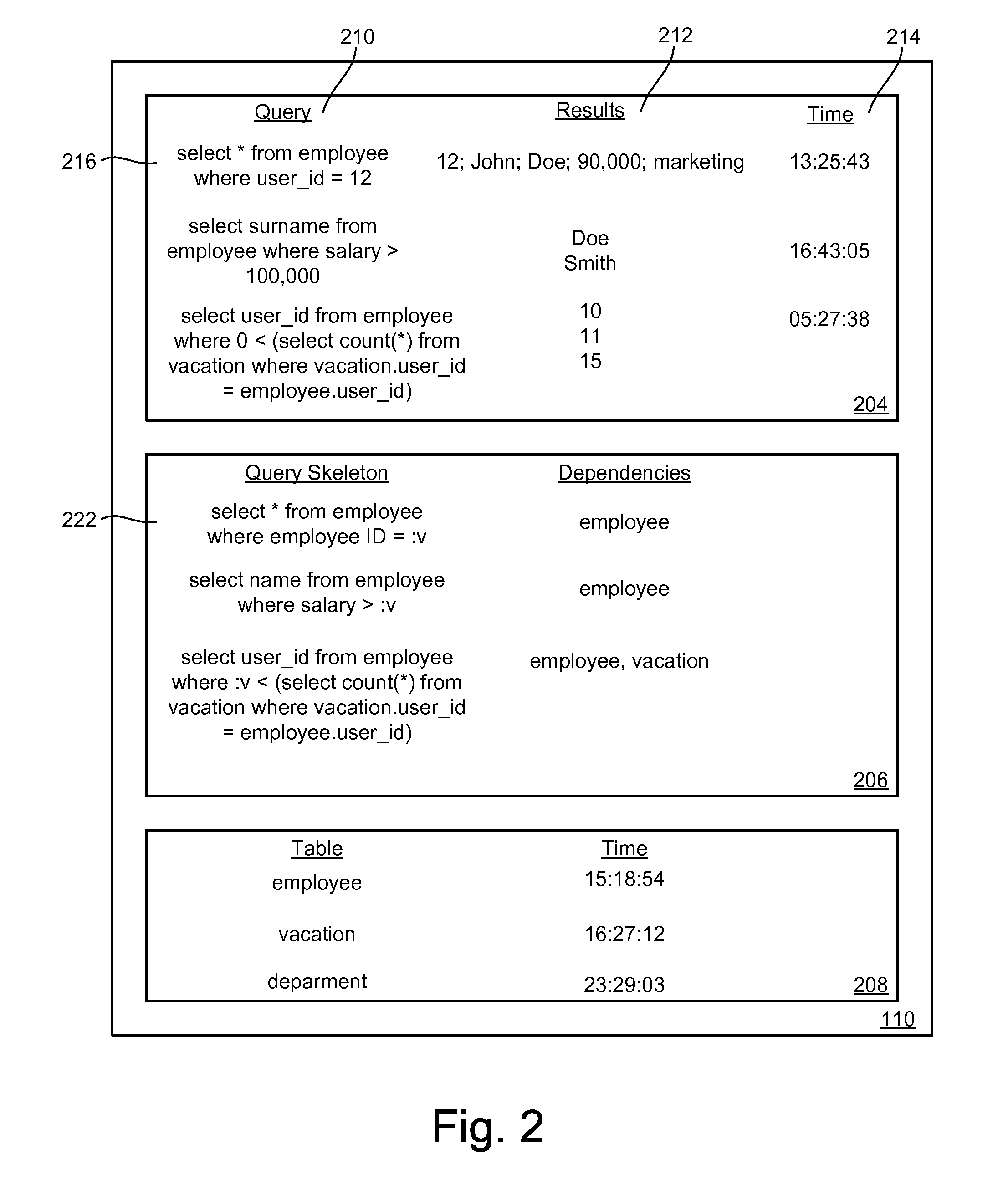

Database Caching and Invalidation for Stored Procedures

InactiveUS20060271511A1Sure easyDigital data information retrievalProgram synchronisationProcedure requestedStored procedure

Database data is maintained reliably and invalidated based on actual changes to data in the database. Updates or changes to data are detected without parsing queries submitted to the database. Requests for stored procedures and their results can be cached without pre-existing knowledge of the stored procedure's operation. A caching system can open a session at the database instructing the database to monitor and log its processes. The caching system can pass the stored procedure request and access the log to determine how the stored procedure is processed and the queries executed as part of the stored procedure. The dependencies of a query can be determined by submitting a version of the received query to the database through a native facility provided by the database to analyze how query structures are processed. The results of the stored procedure can be cached the results of the query dependency analysis can be cached for subsequent request processing and invalidation.

Owner:TERRACOTTA

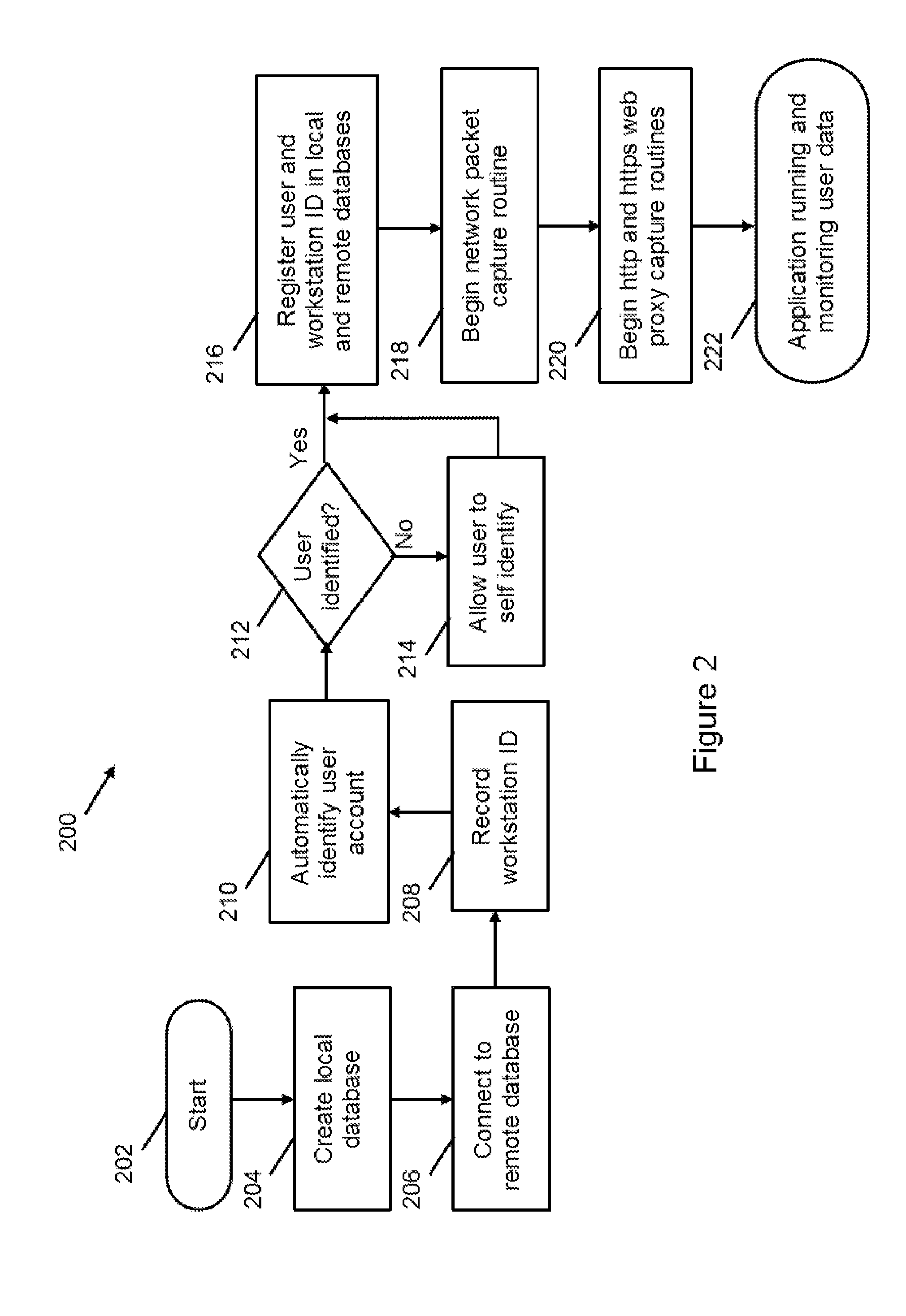

Relative value unit monitoring system and method

InactiveUS20140142972A1Office automationHealthcare resources and facilitiesMonitoring systemProcedure requested

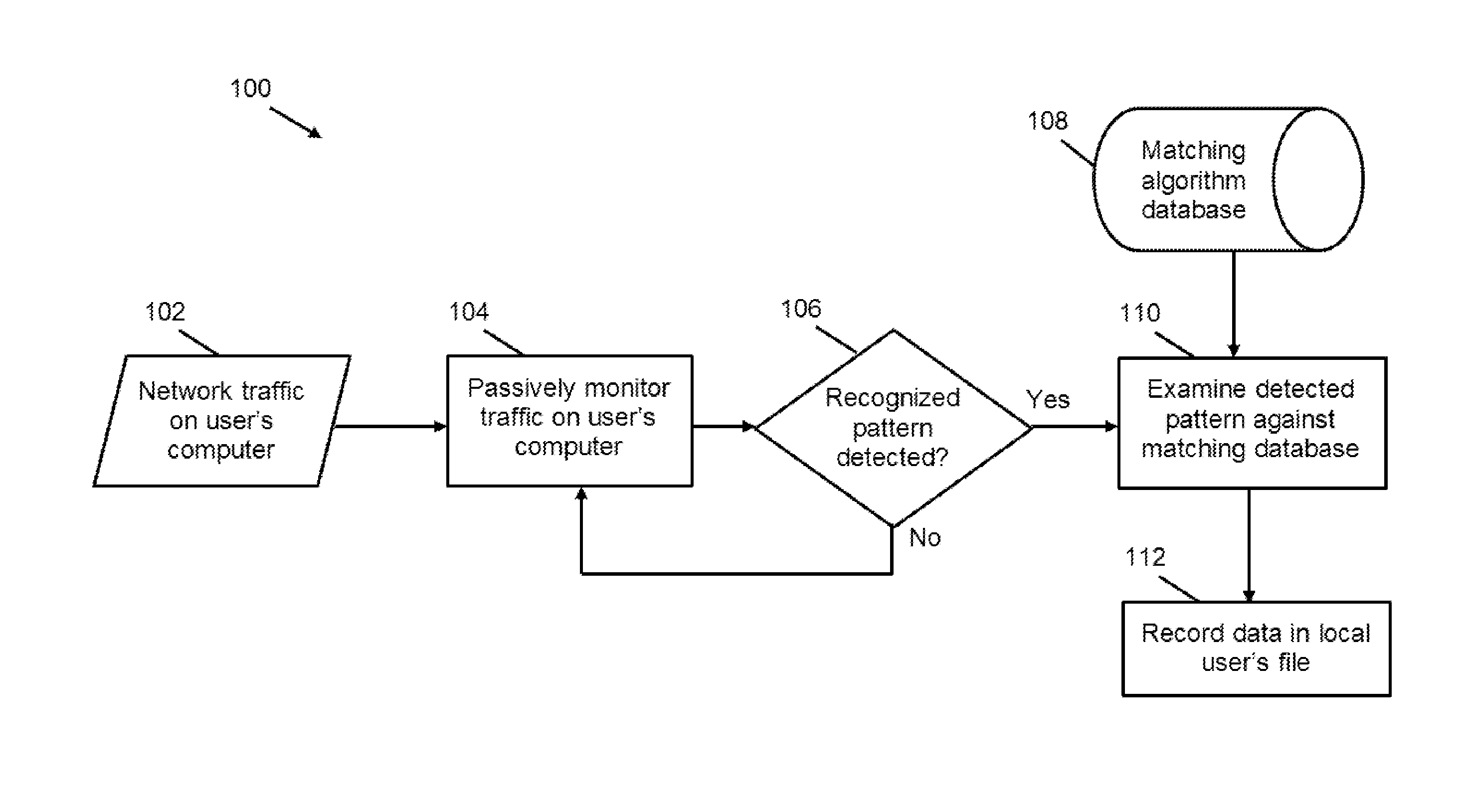

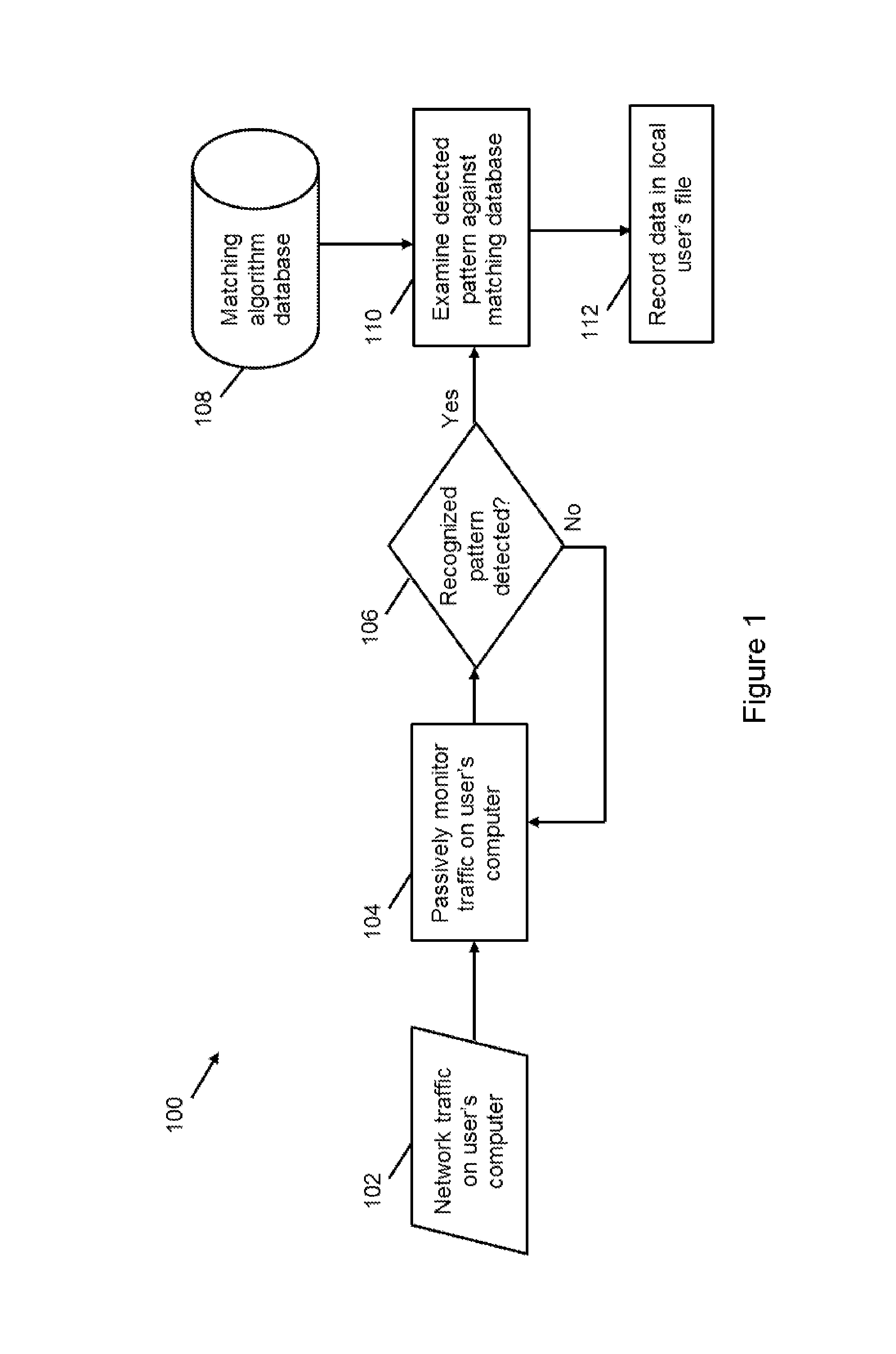

A Relative Value Unit (RVU) monitoring method and system is disclosed that includes passively monitoring network traffic; examining the monitored traffic for recognized patterns in a matching database; deriving detected RVU values from the matching recognized patterns; and updating an RVU tracking database with the detected RVU values. The matching database stores a plurality of recognized patterns and RVU values, and associates the recognized patterns and RVU values. The method can also include notifying the user of detected CPT codes and RVU values. The method can also include determining procedures requested by received medical orders; tracking fulfillment of the requested procedures; and notifying the user when requested procedures remain to be fulfilled. The method can include analyzing data associated with detected patterns to determine if it's a new or previously observed procedure. The method can simultaneously run on multiple computers; and update a common RVU tracking database.

Owner:LUCID RADIOLOGY SOLUTIONS

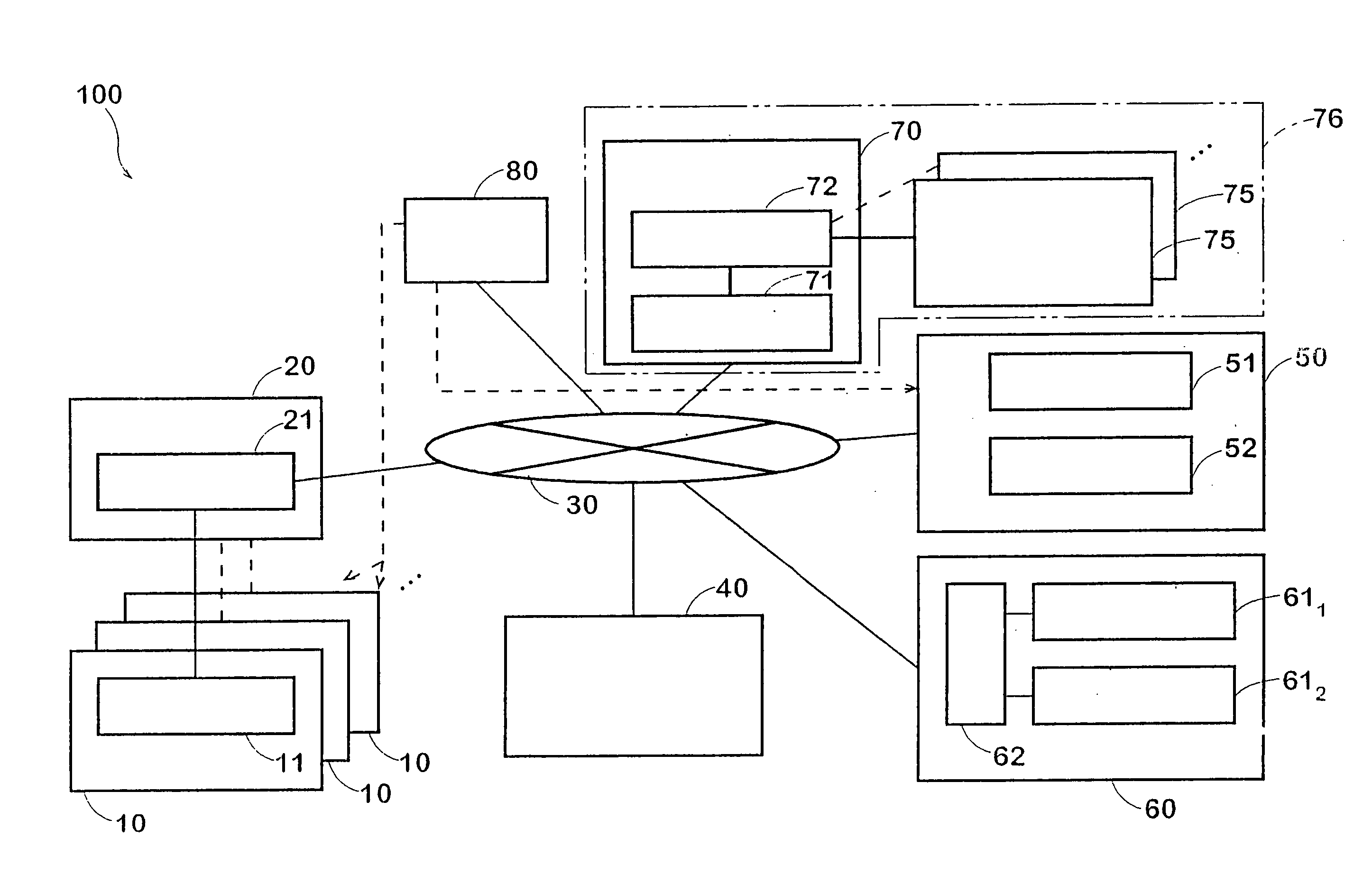

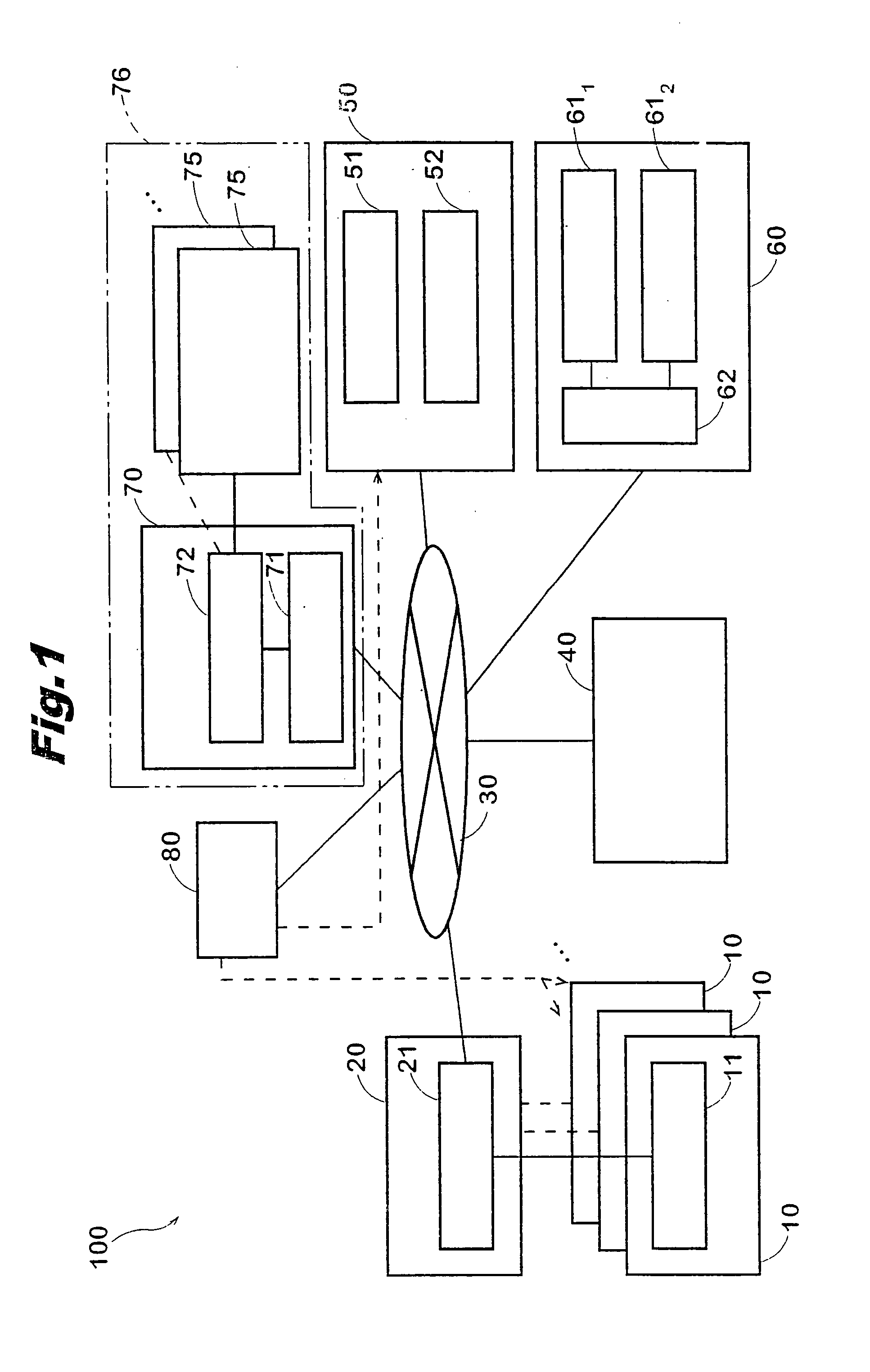

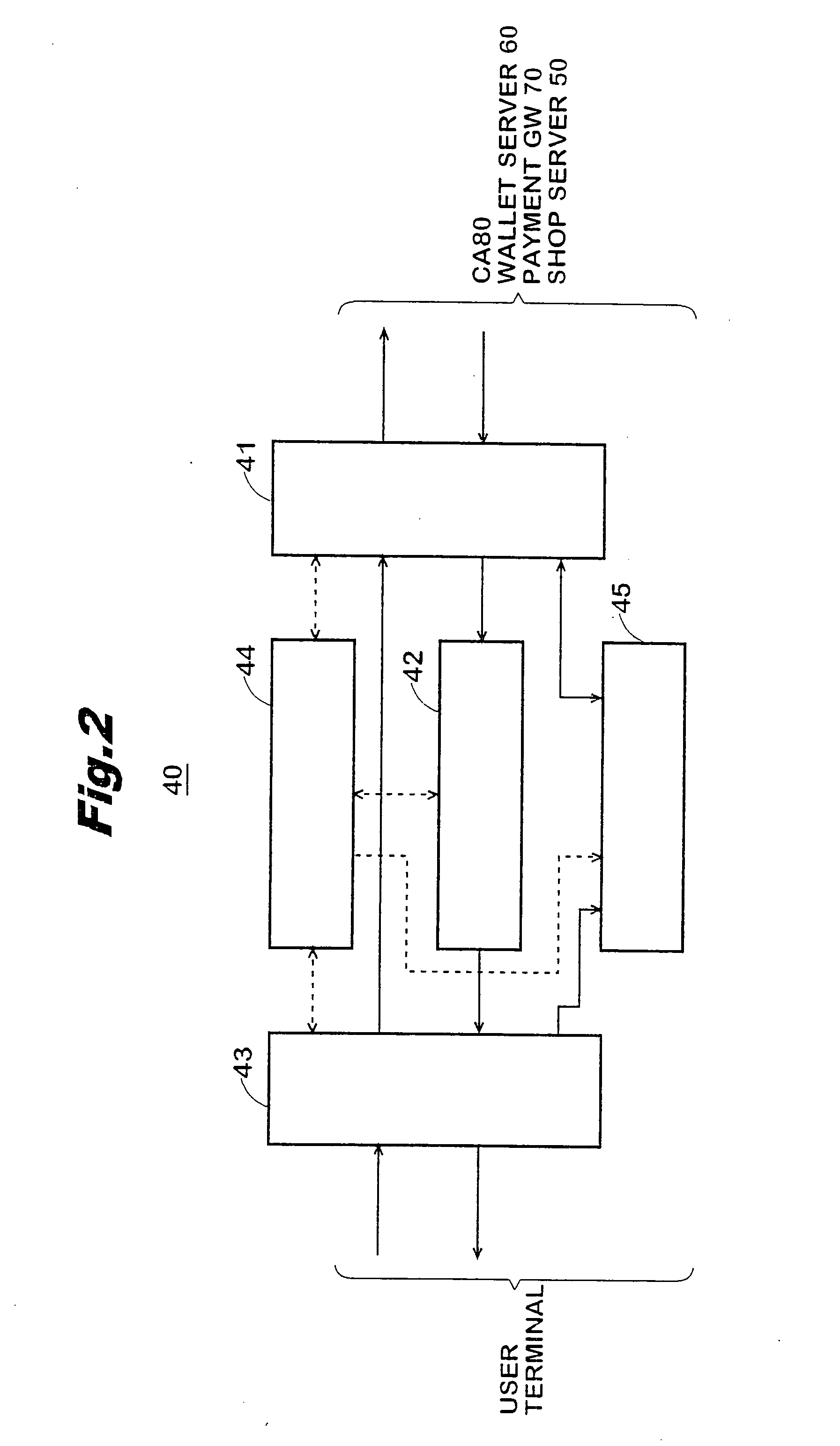

Relay server, relaying method and payment system

InactiveUS20070162386A1Limited display capabilityImprove securityComplete banking machinesFinanceProcedure requestedPayment order

A relay server to be installed in a payment system which is suitably used in a specially designed terminal having limited communication functions such as a portable telephone. The relay server is provided in the payment system including a user terminal to take payment procedures through a network, a shop server to produce payment information containing amounts to be paid by a user, a payment server to perform payment processing through the network and a wallet server to maintain authentication information of the user and to request the payment server to take payment procedures. The relay server has a redirecting section used to transfer, when receiving procedure request information from the terminal, the information to the shop server and, when receiving the payment information from the shop server having acquired the request information, to transfer the payment information to the wallet server.

Owner:OKI ELECTRIC IND CO LTD

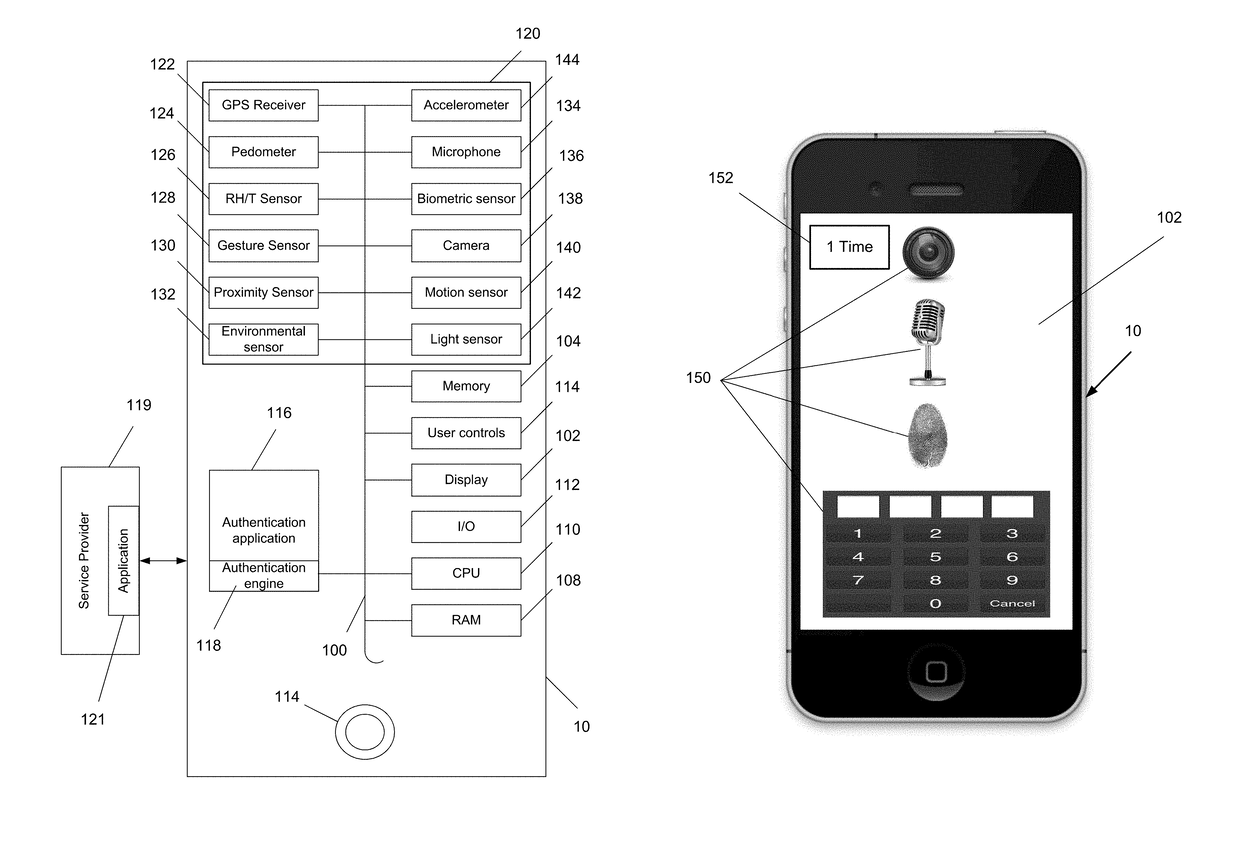

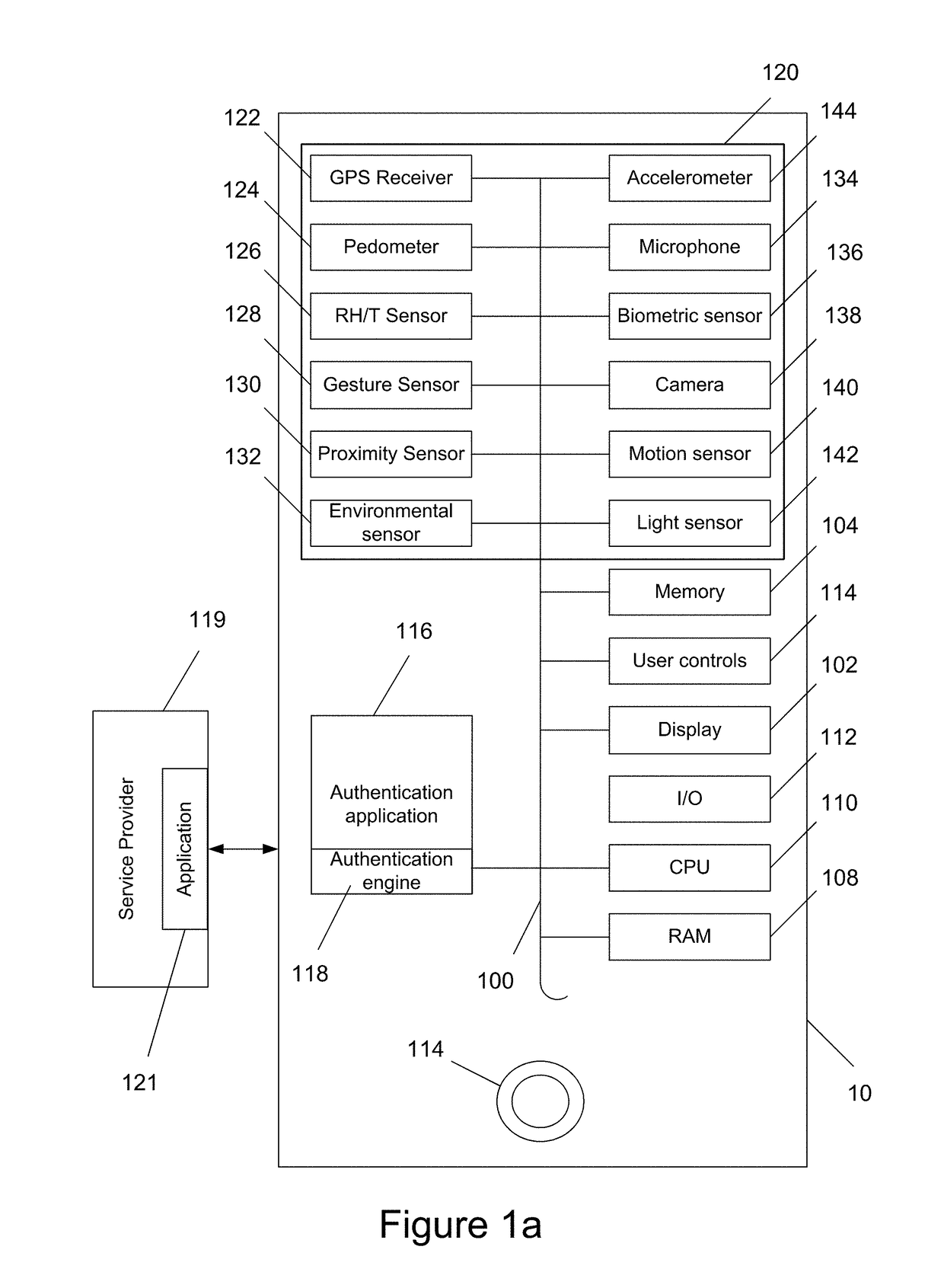

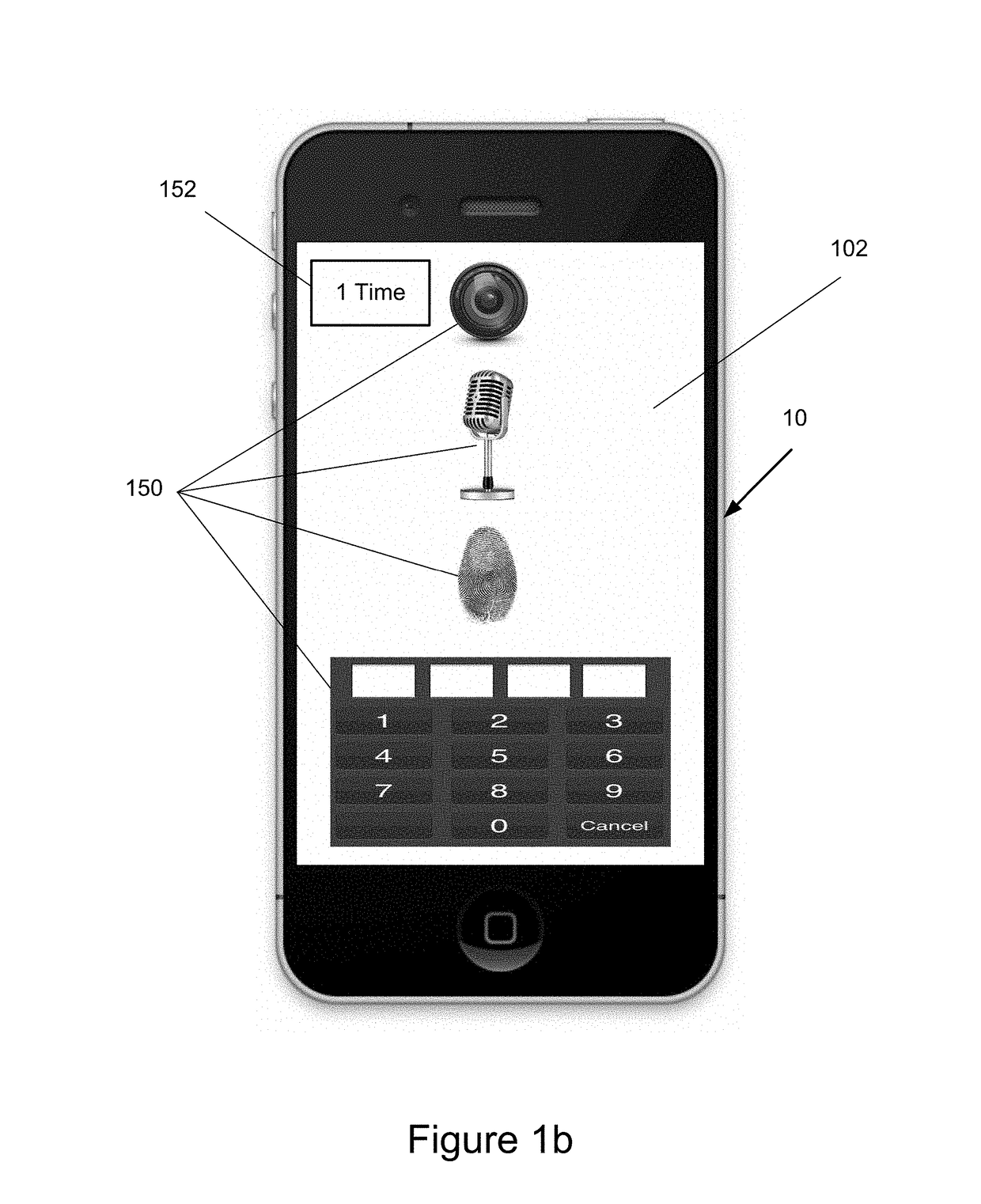

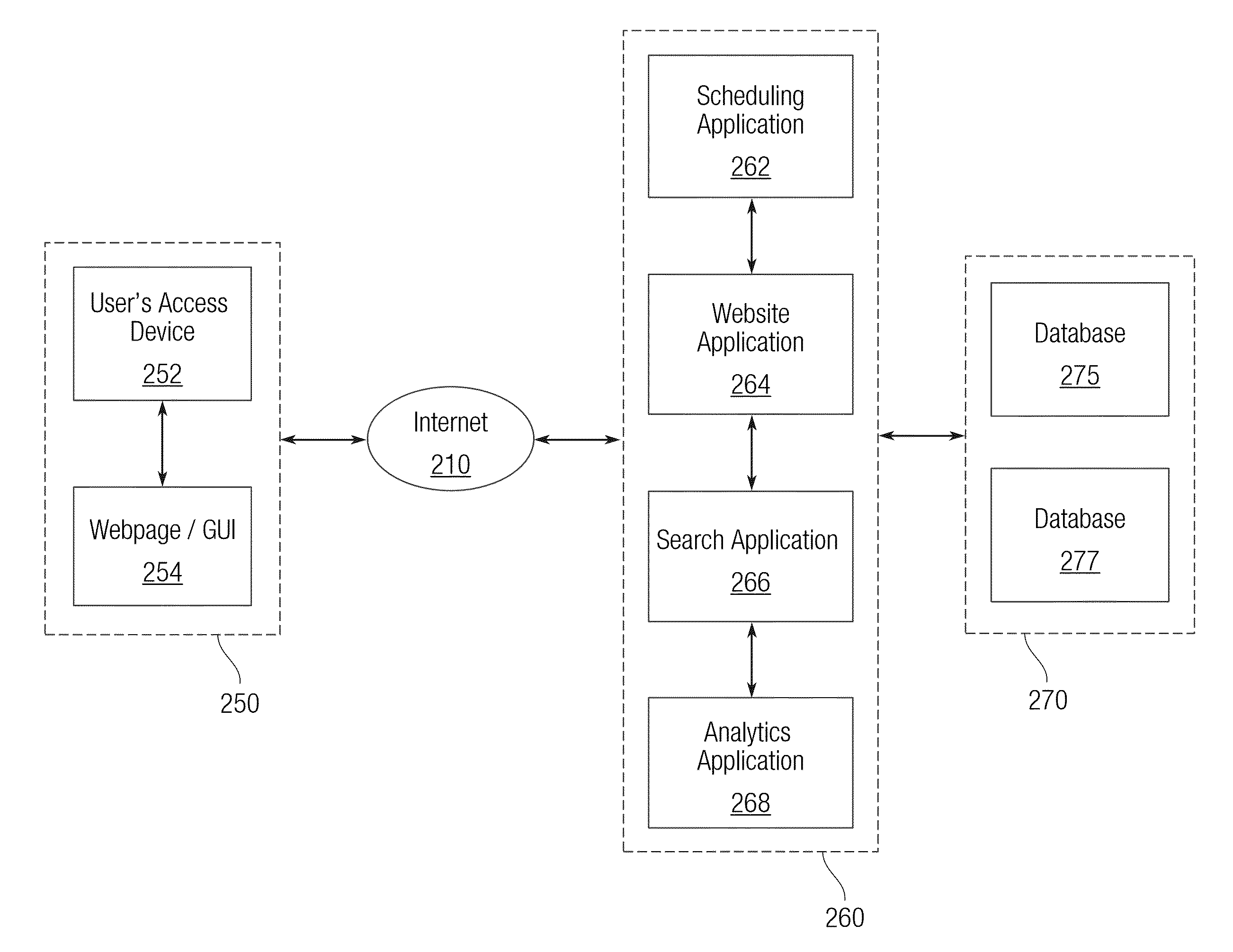

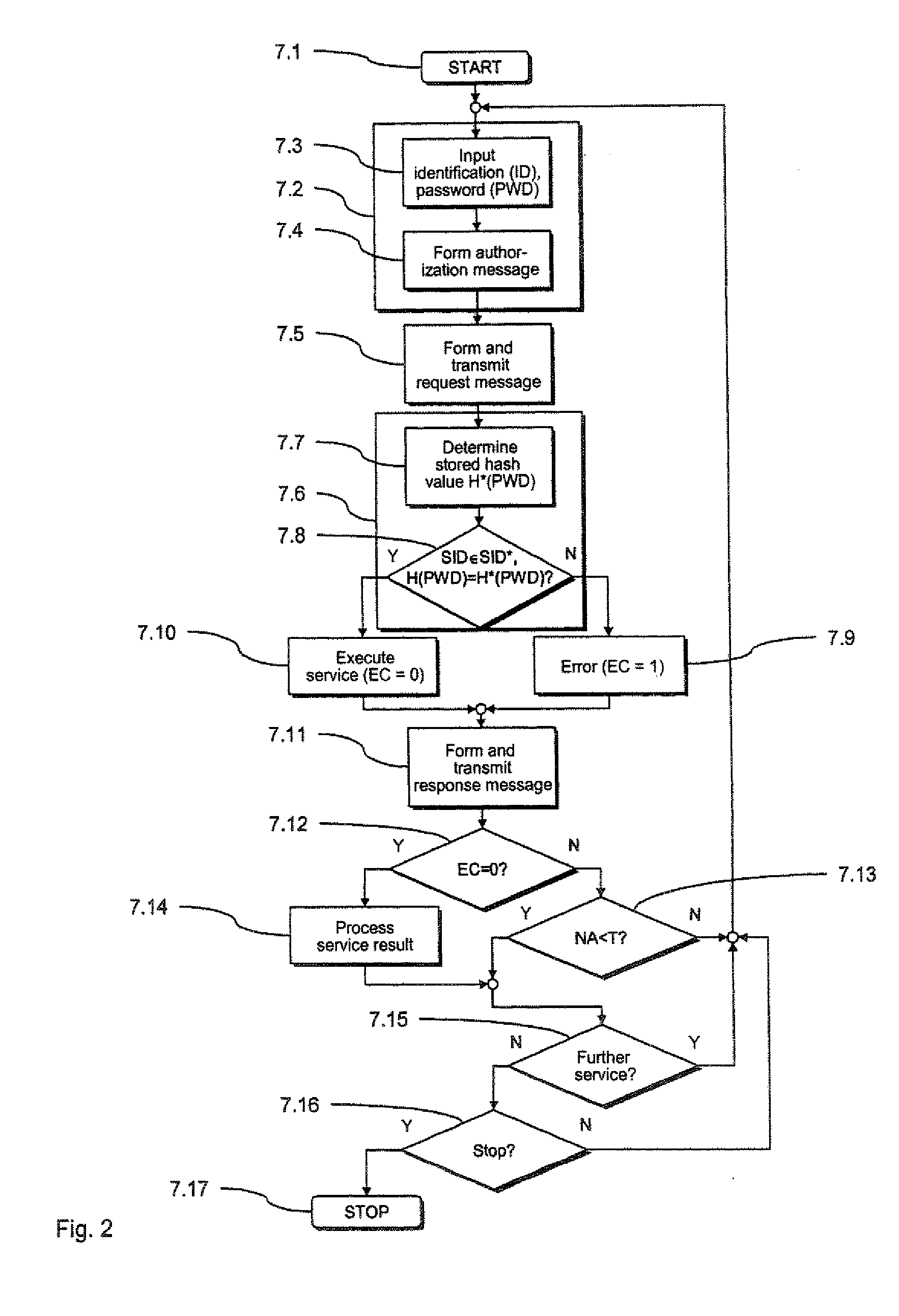

Method for effecting an authentication procedure associated with a service provider or an application

ActiveUS20180007062A1Easy to optimizeImproves mobile paymentsDigital data authenticationTransmissionService provisionProcedure requested

A computer device for effecting an authentication procedure associated with a service provider or an application, including a plurality of sensors; and one or more processors in communication with the sensors and non-transitory data storage including, stored thereon, a plurality of instructions which, when executed, cause the one or more processors to perform the steps of (a) receiving an authentication procedure request; (b) determining a hierarchy of authentication processes for the authentication procedure; (c) selecting an authentication process from the hierarchy of authentication processes; and (d) executing the authentication process.

Owner:MASTERCARD ASIA PACIFIC

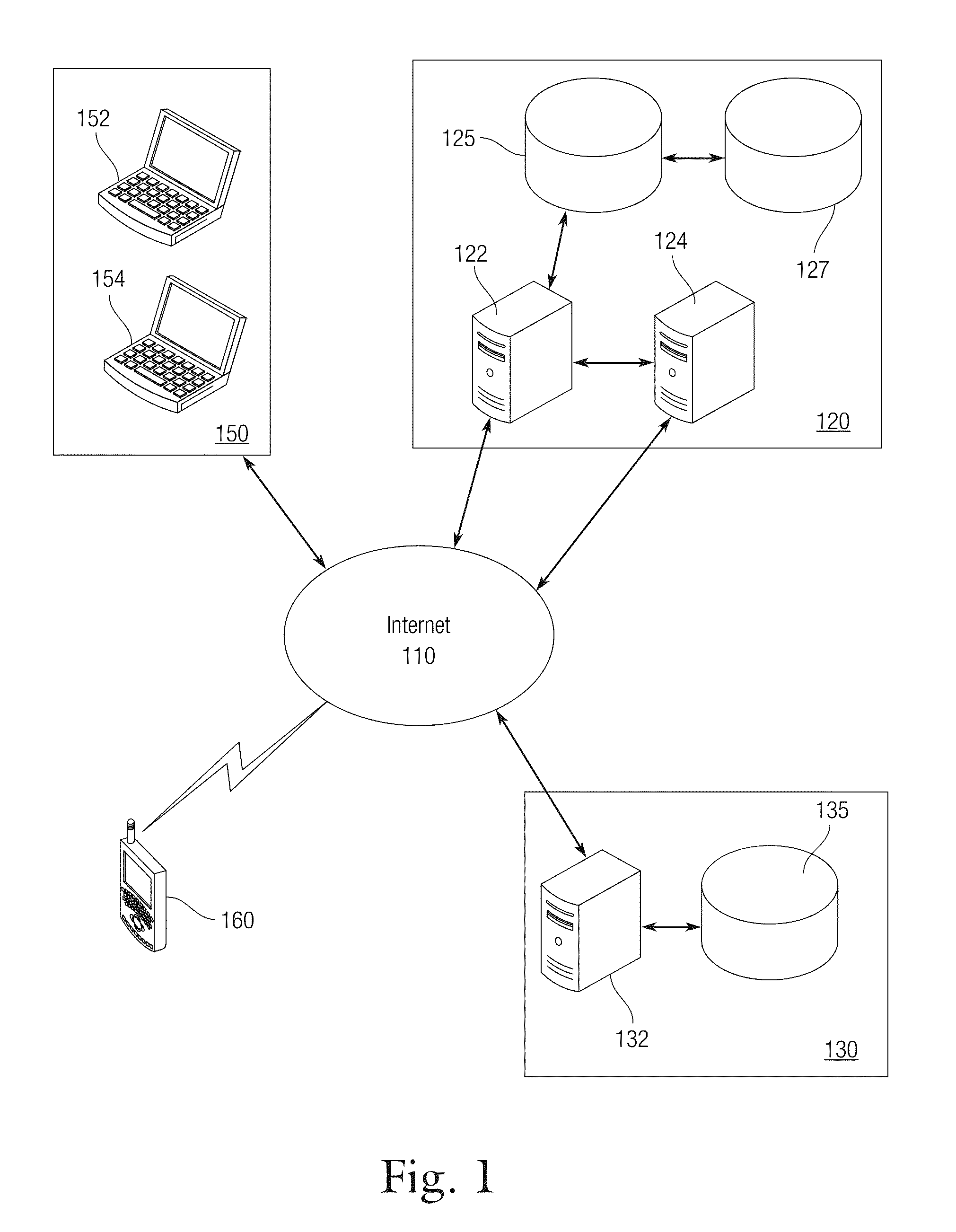

System and Methods for Managing Patients and Services

A system and methods for monitoring compliance with at least one time based rule for treating individuals with health related procedure requests. The system includes a server which periodically receives information on individuals within a group, a request procedure type, and a request date for the individuals that requested a health related procedure. The system then tracks the lapsed time of each health related request to monitor compliance with the time based rule. The system can also rank the individuals for scheduling of the health related procedure based on the procedure type, lapsed time, and the time based rule. The server also identifies individuals which have changed facilities while maintaining their original request date and then updates the rankings for each facility. The system is especially useful for handling dental procedures and requests for individuals at correctional institutions, military bases, and campuses.

Owner:SMALLWOOD WILLIAM

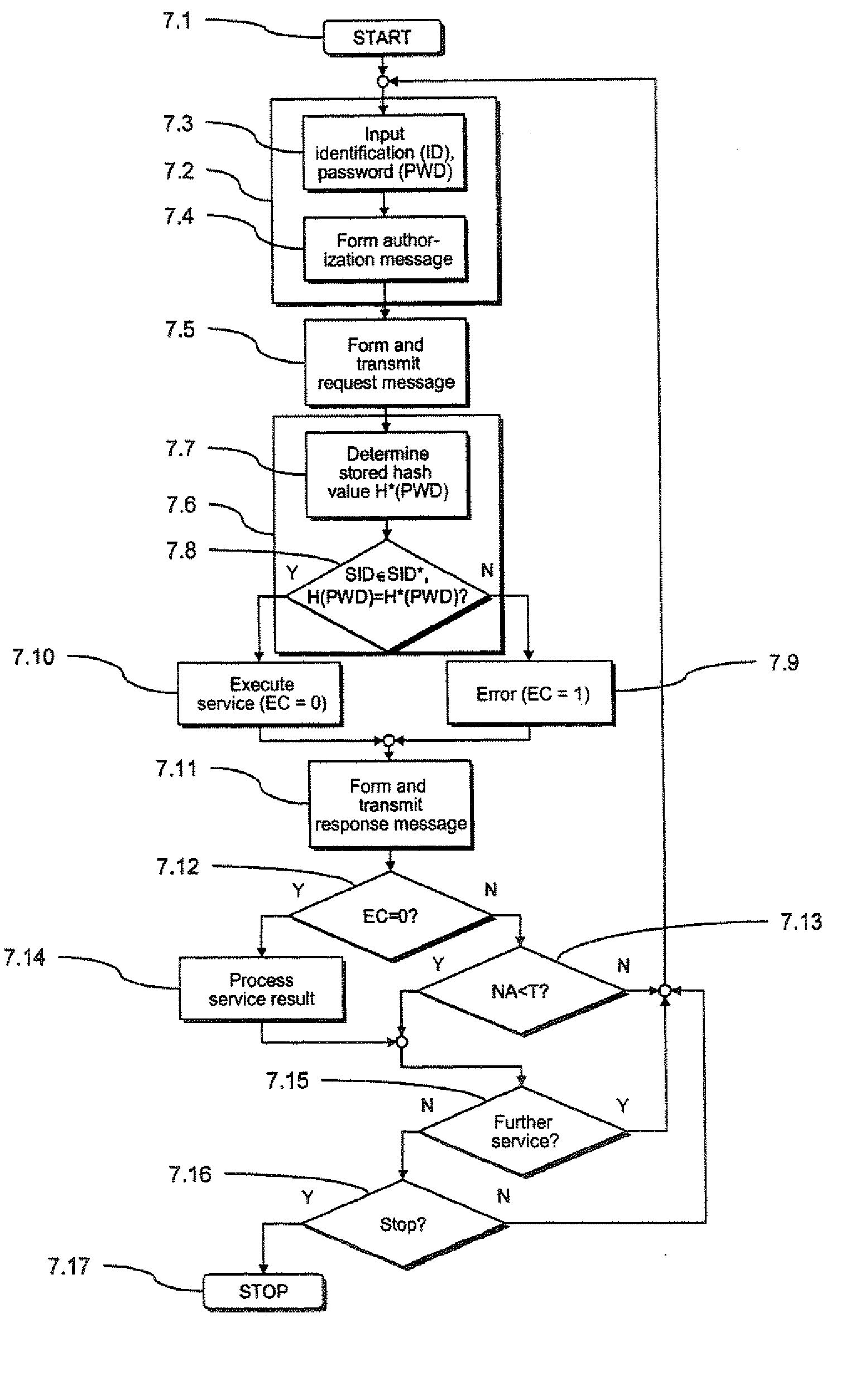

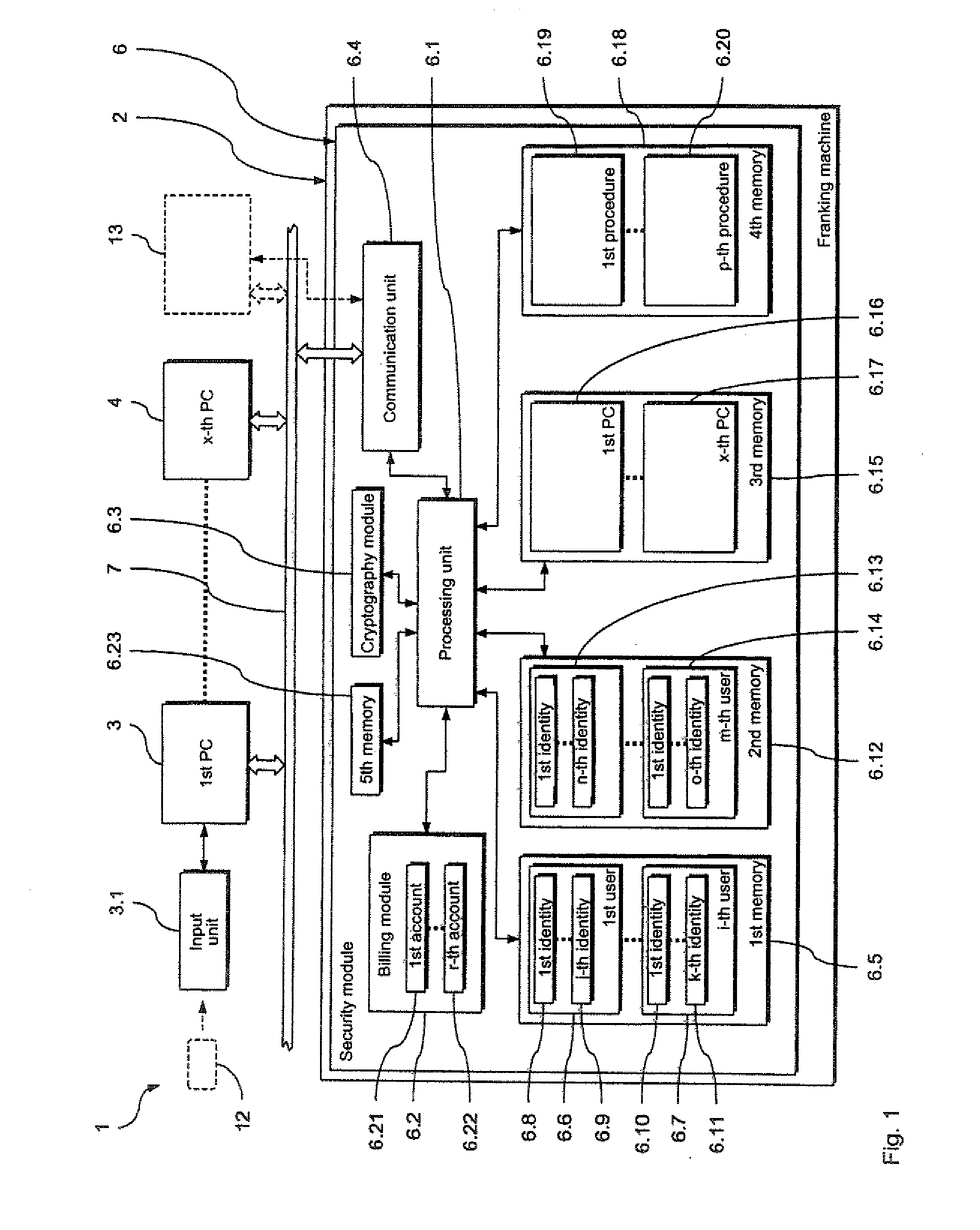

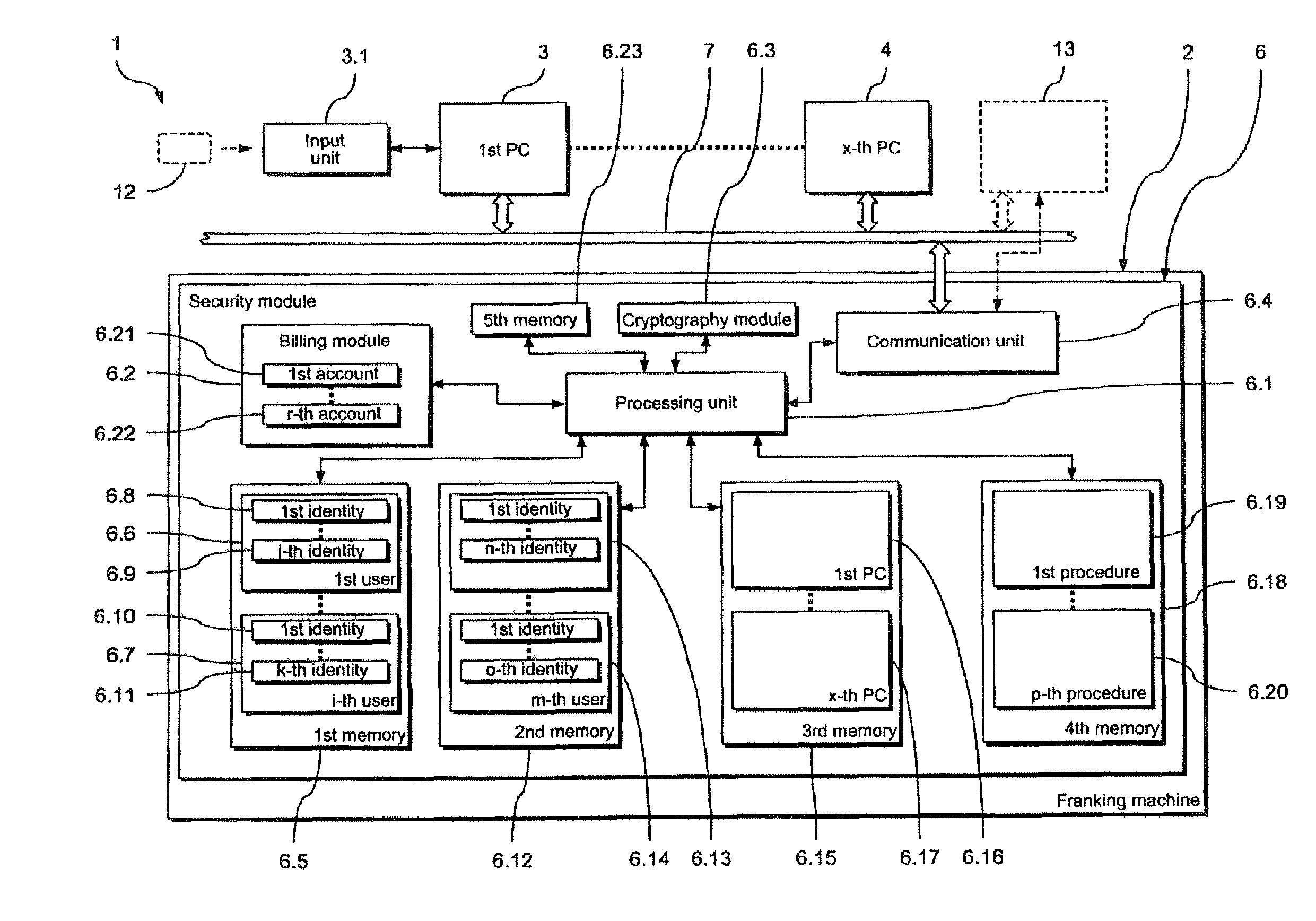

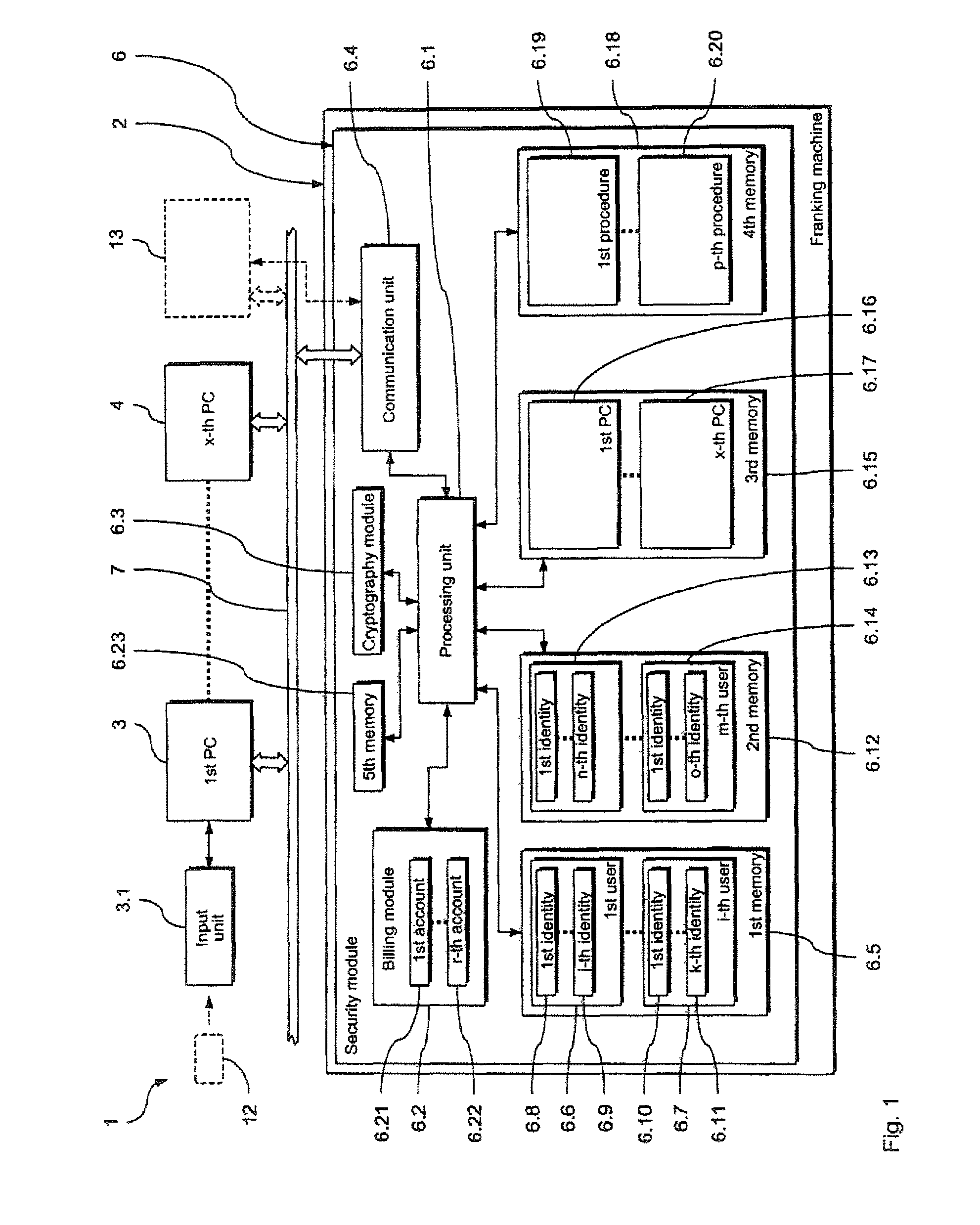

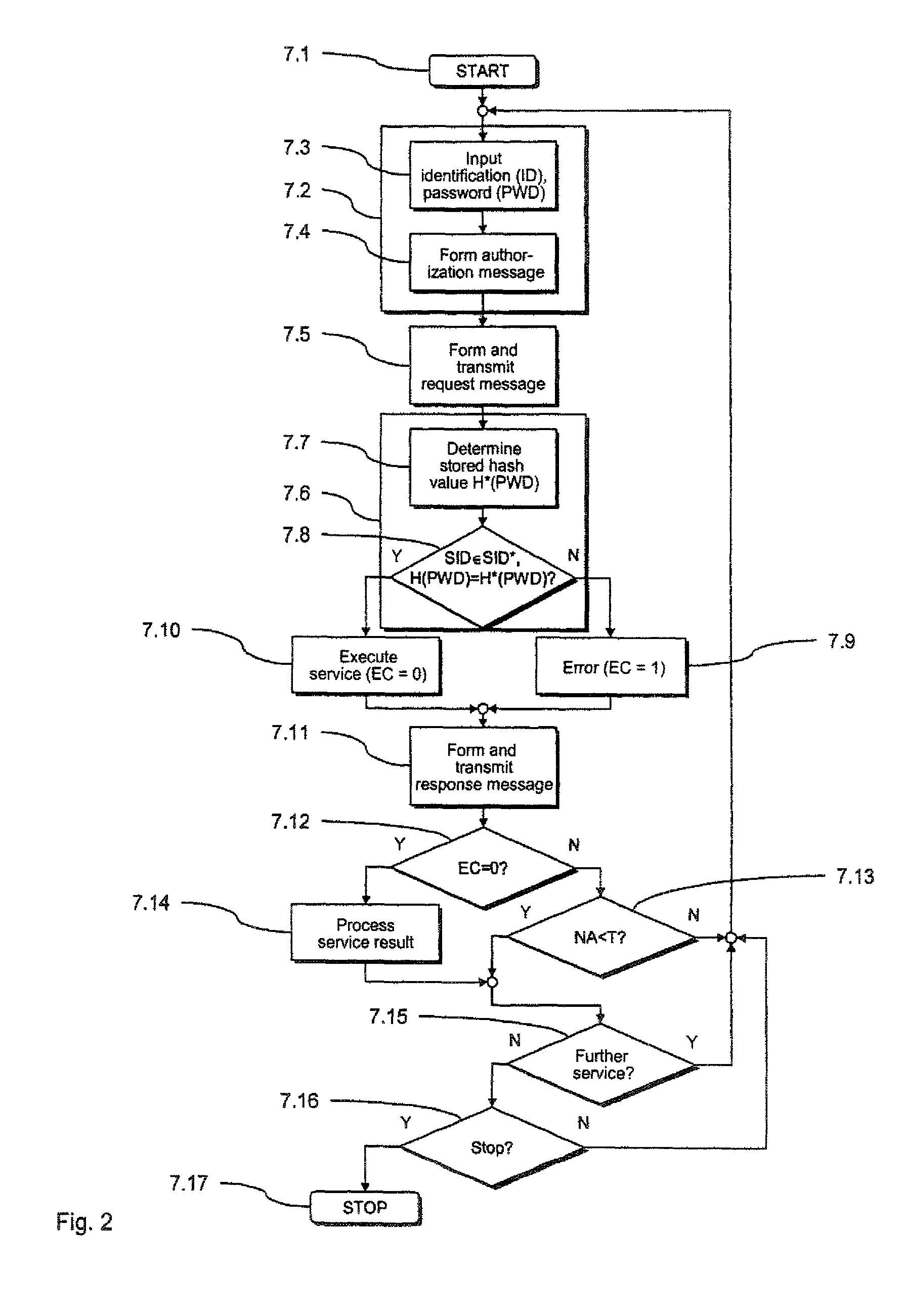

Method and arrangement for provision of security relevant services via a security module of a franking machine

ActiveUS20070156605A1Improve overall utilizationGood utilization of security-related (and therewith economical) possibilityDigital data protectionPayment protocolsProcedure requestedAuthorization

In a method and an arrangement for provision of at least one secured service via a security module of a franking machine for at least one procedure for data processing that is executed in a data processing device that can be connected with the franking machine, the procedure requests a secured first service from the security module in a request step; and the security module provides the first service in a provision step subsequent to the request step. The security module verifies an authorization to request the first service via the procedure in a verification step preceding the provision step

Owner:FRANCOTYP POSTALIA

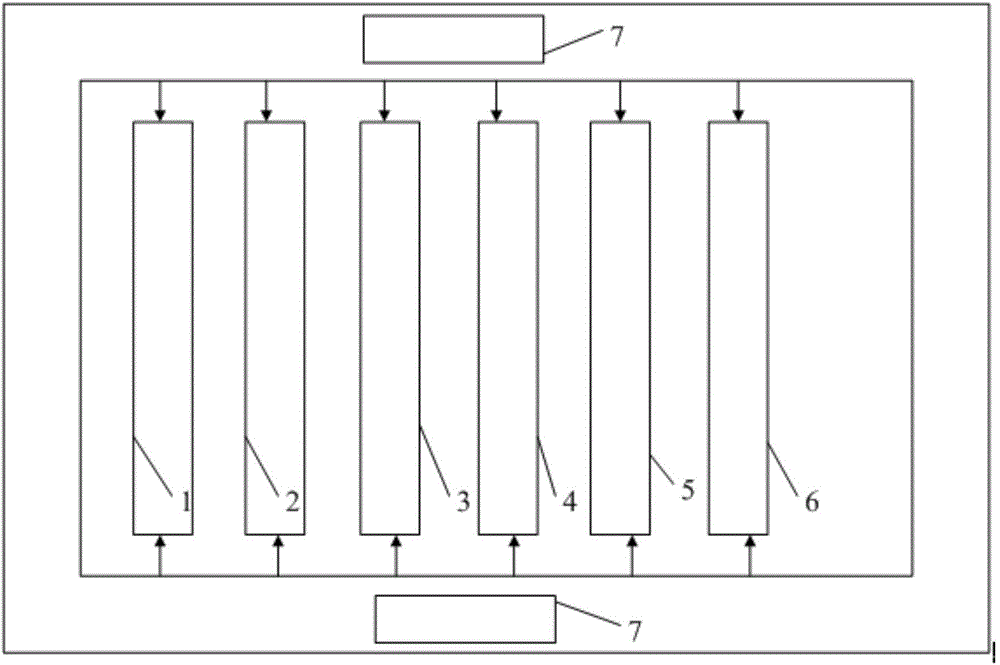

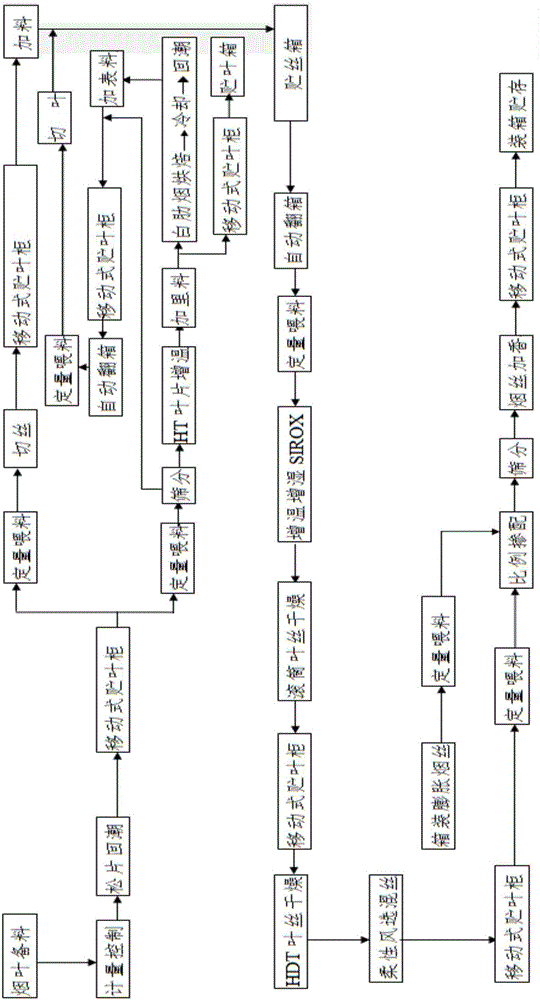

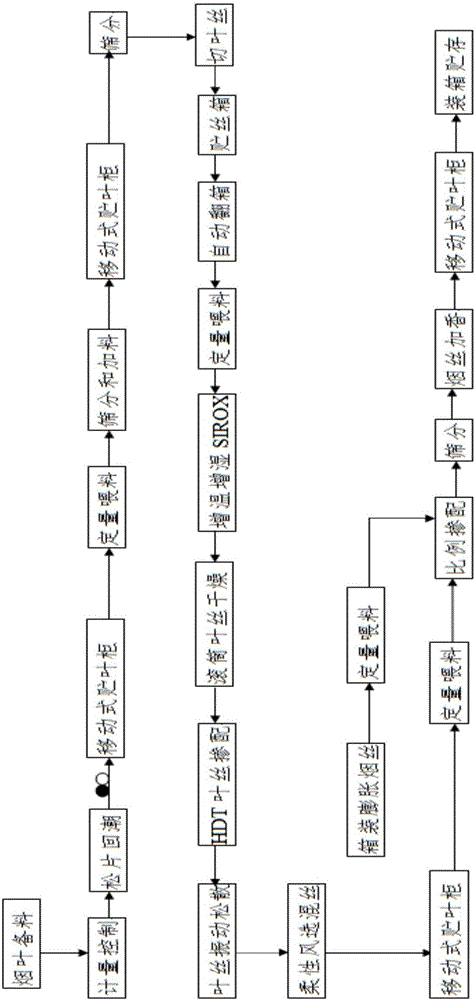

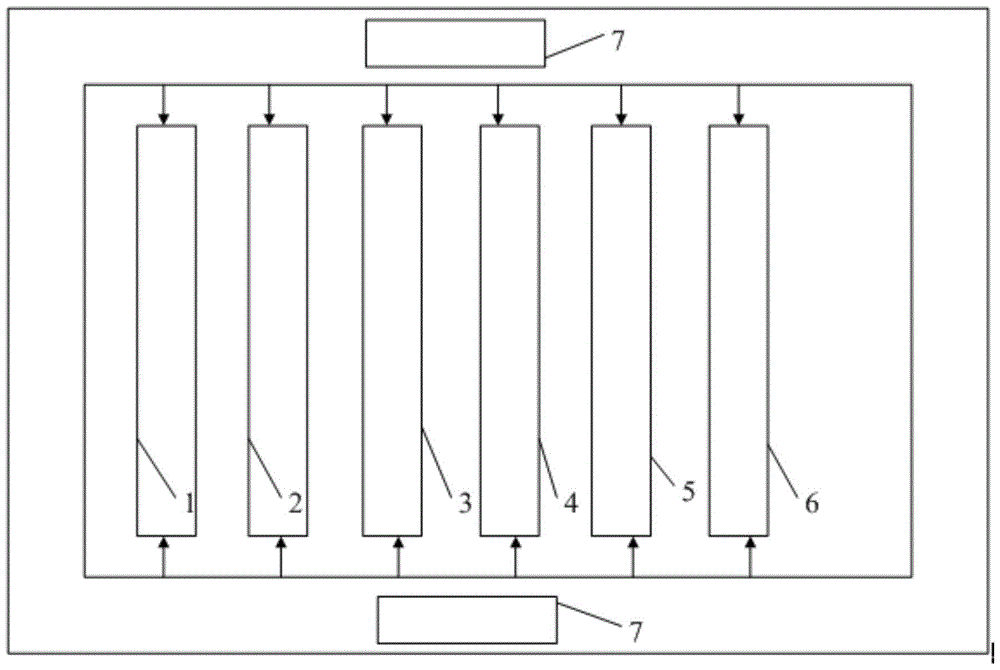

Tobacco processing production system and method

ActiveCN104921284AFix fixityAddress flexibilityTobacco preparationTobacco treatmentProcedure requestedComputer module

The invention relates to the technical field of tobacco, and discloses a tobacco processing production system. The tobacco processing production system comprises a loosening and conditioning processing module, a conditioning and charging processing module, a leaf tobacco cutting processing module, a cut leaf tobacco drying processing module, a blending and perfuming processing module, a burley tobacco processing module, and movable leaf storage cabinets. The movable leaf storage cabinets connected with the six processing modules freely to achieve arbitrary permutation and combination of the processing modules, wherein the loosening and conditioning module or the conditioning and charging processing module is arranged at the first place. The invention further provides a tobacco processing method. The movable leaf storage cabinets connected with the six processing modules arbitrarily, material supply, discharging and storage of each module are achieved through the movable leaf storage cabinets, the movable leaf storage cabinets can be pulled to any designated position as needed, and therefore whole-line flexible connection is achieved through the movable leaf storage cabinets. The processing modules do not need to be moved, flexible combination of production procedures can be achieved, and the requirement for manufacturing special cigarettes or some cigarettes with the special production procedure request can be met.

Owner:CHINA TOBACCO GUANGDONG IND

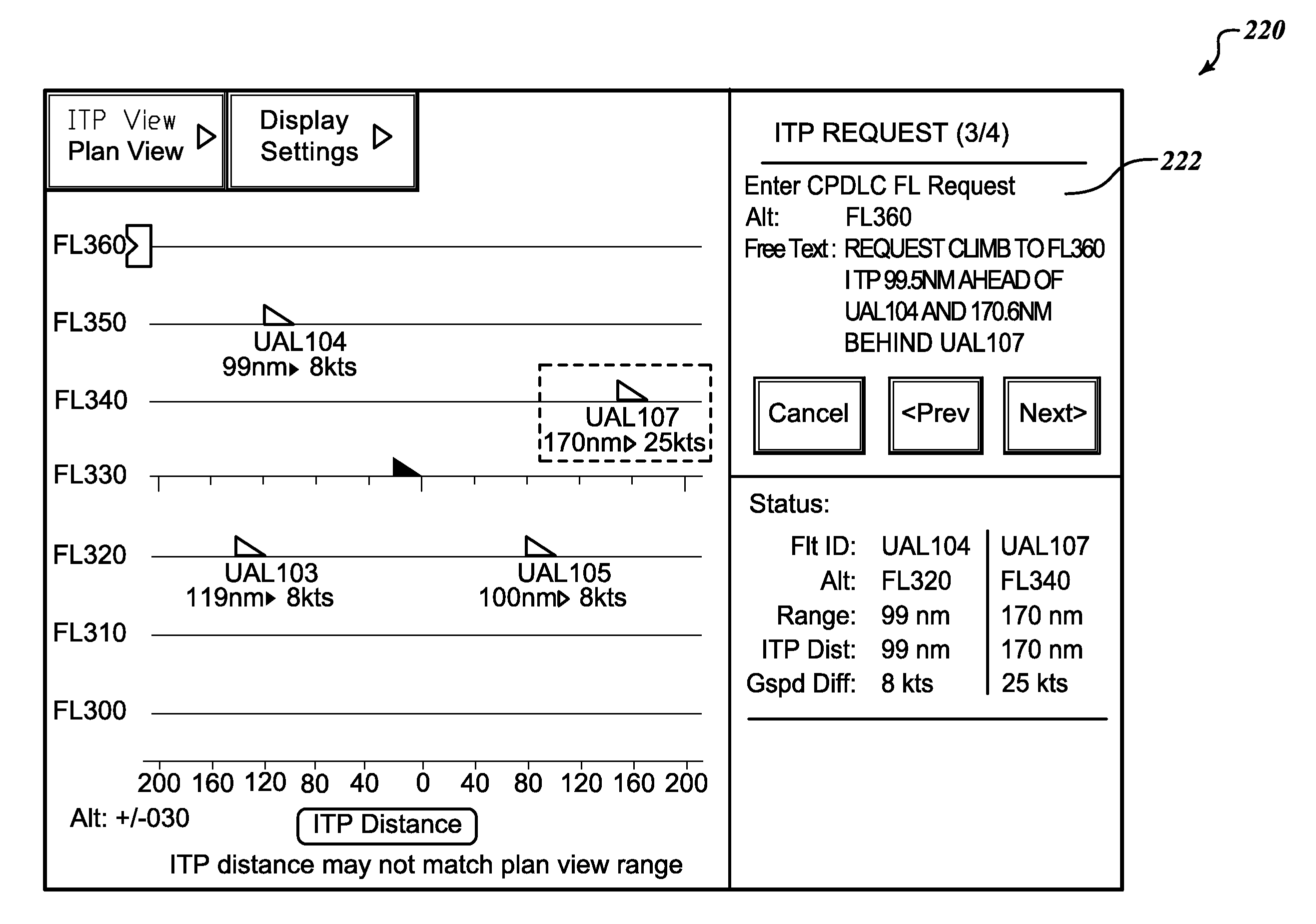

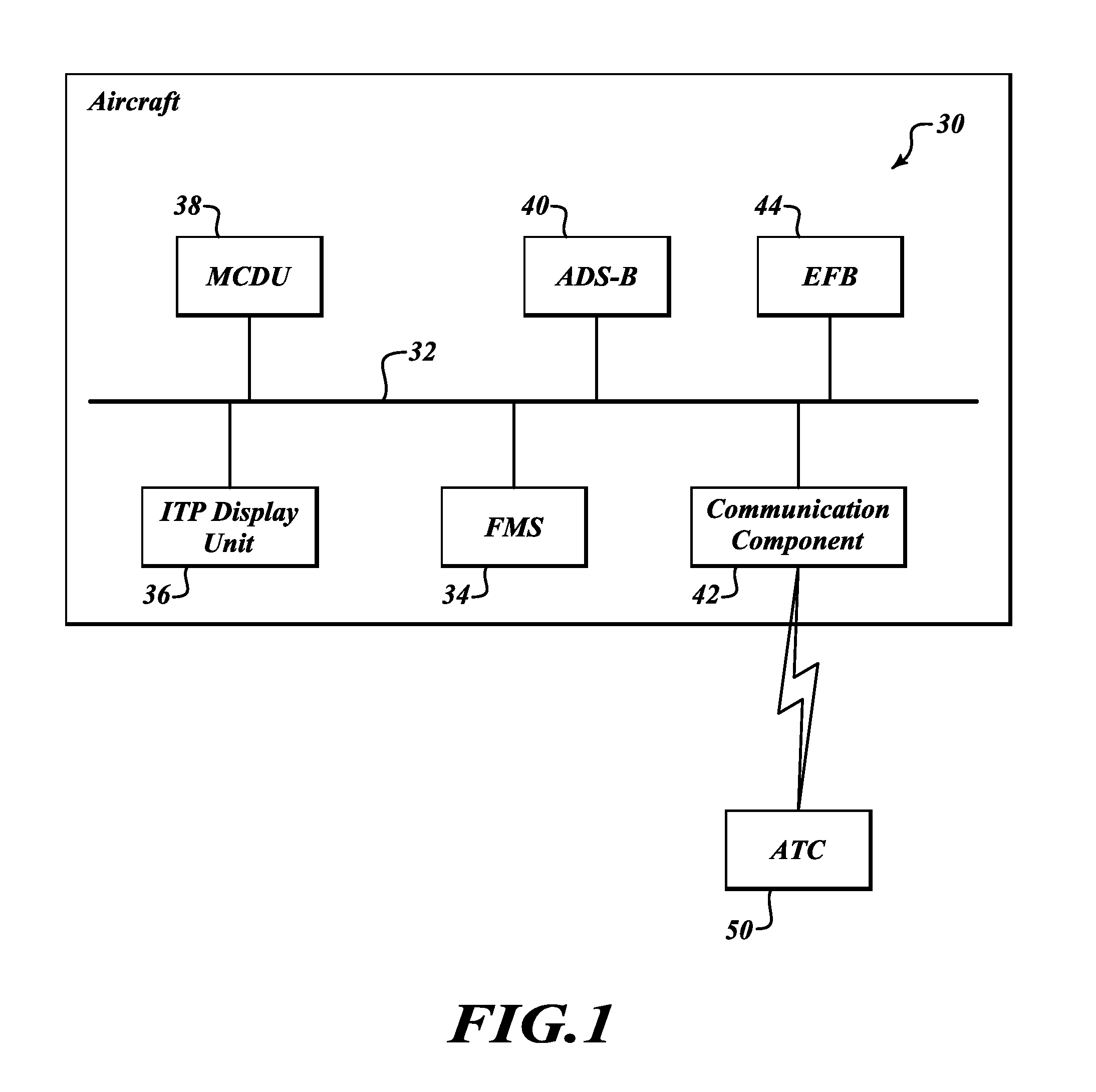

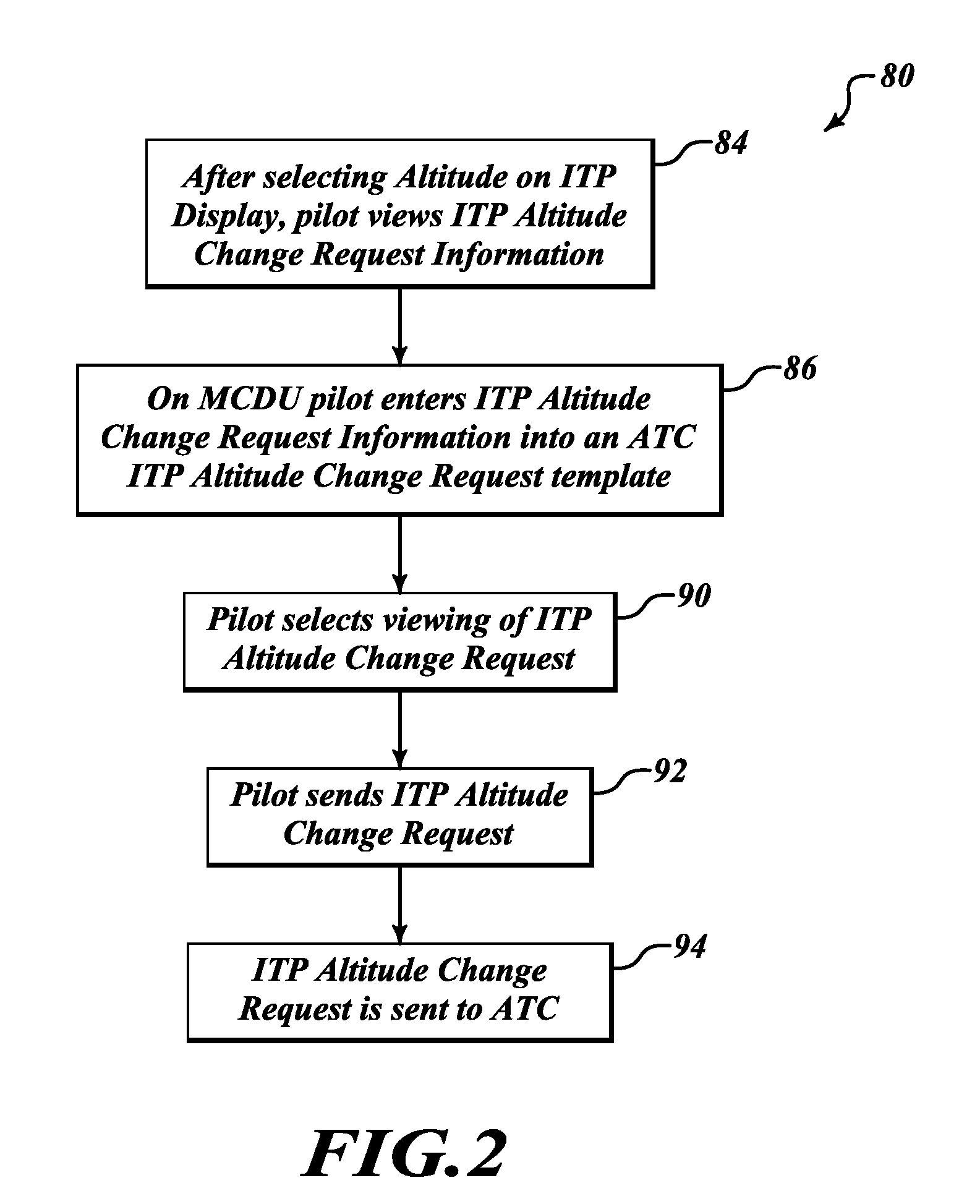

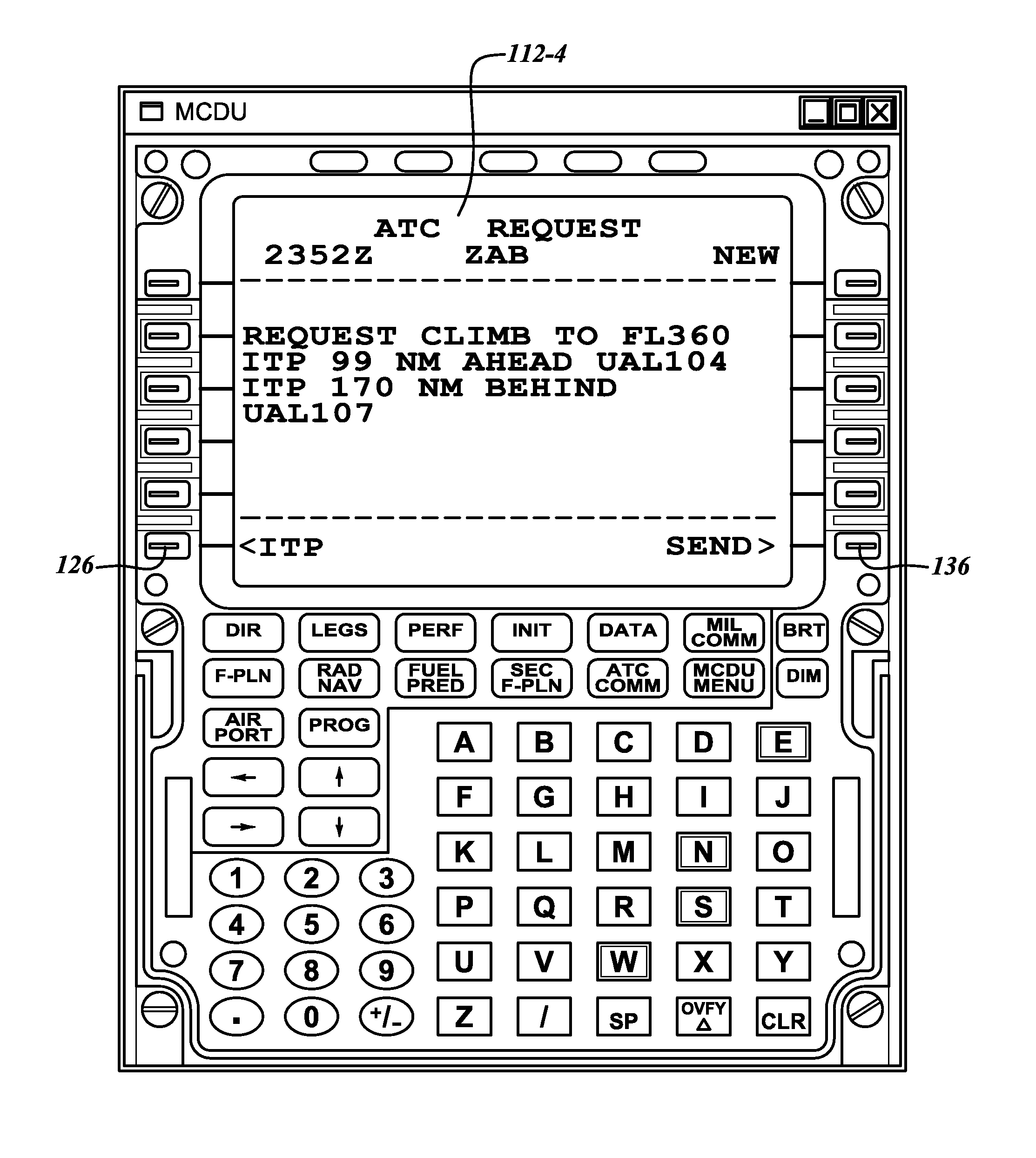

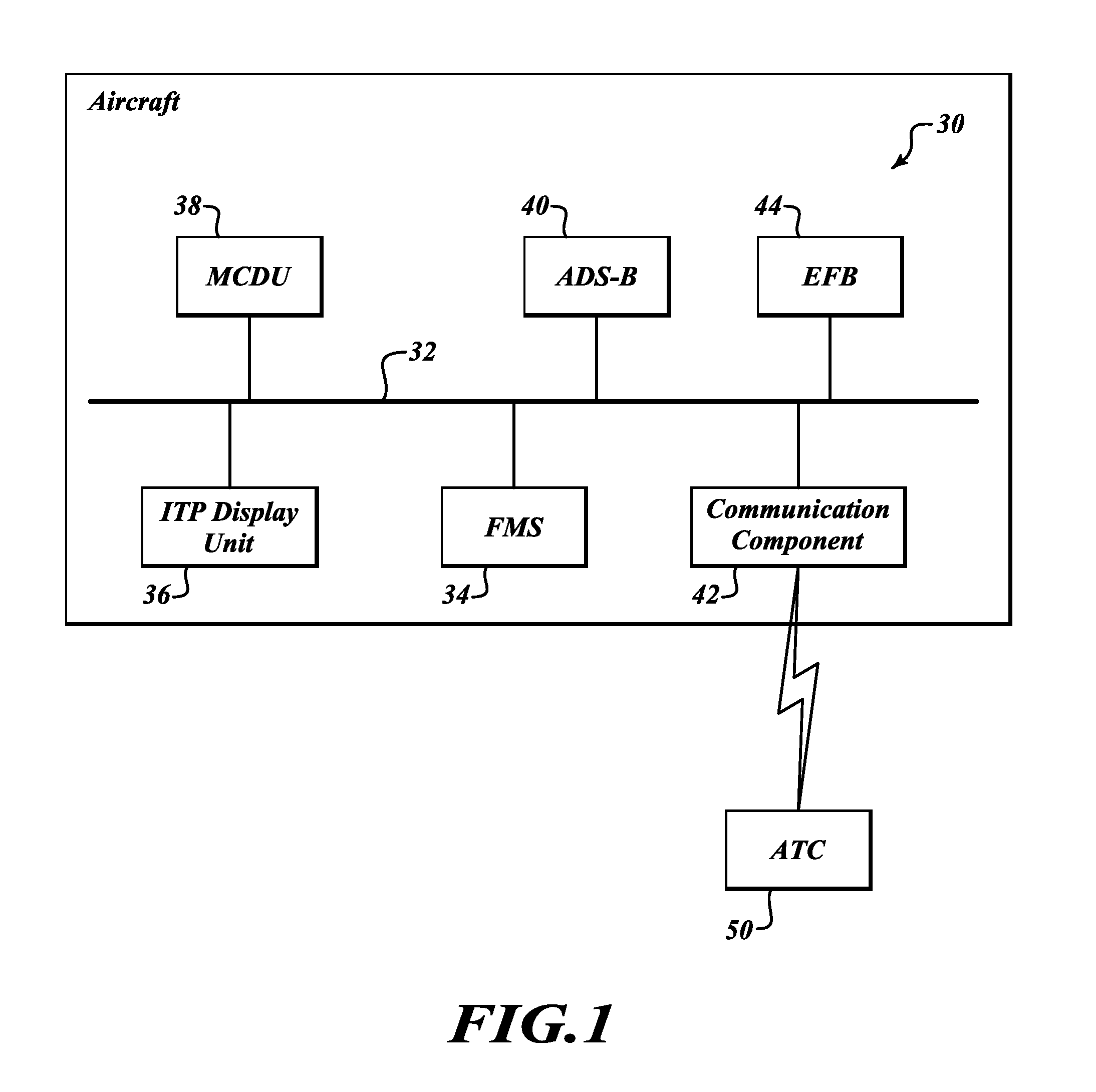

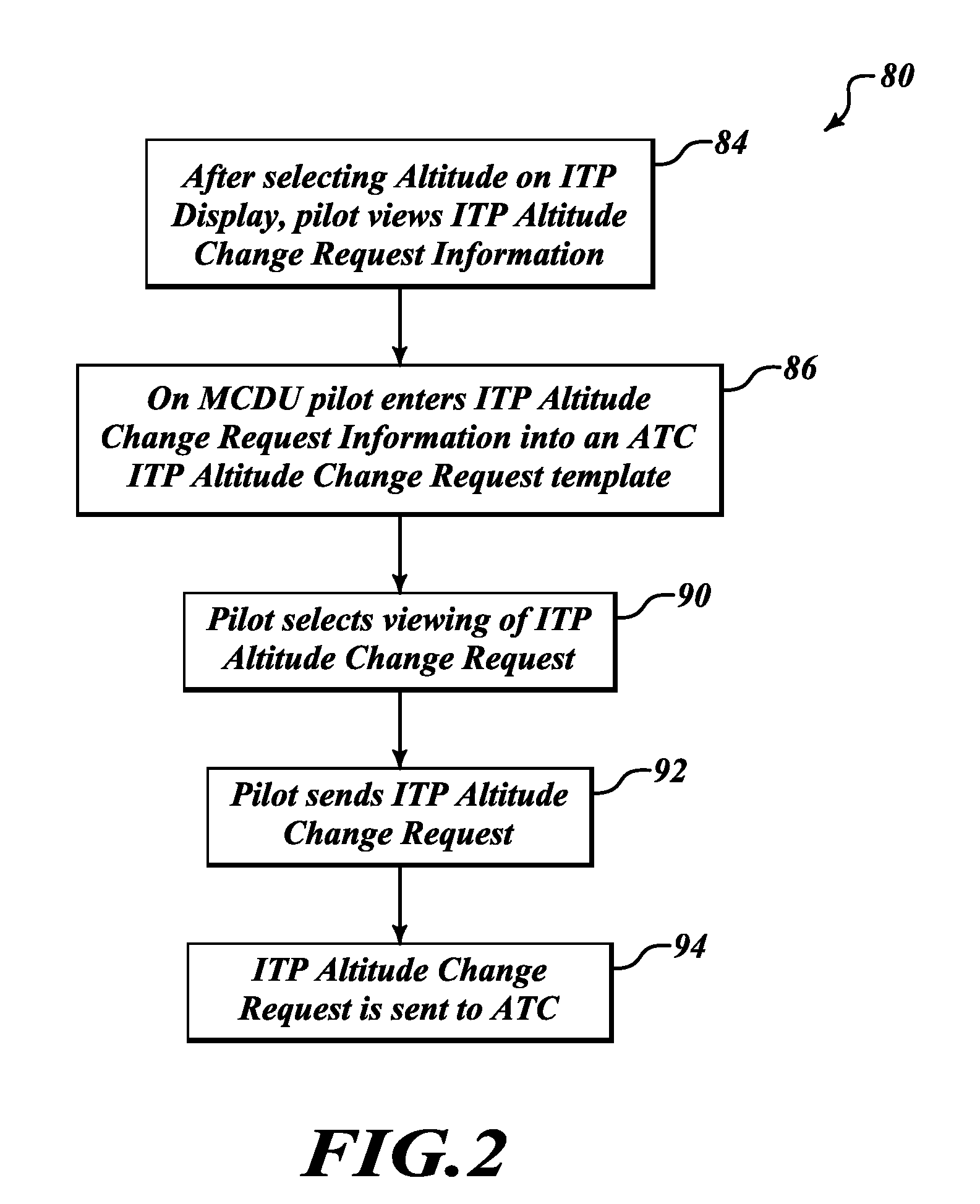

Systems and methods for improving an in-trail procedures request

ActiveUS20120102422A1Input/output processes for data processingAircraft traffic controlOn boardAir traffic control

Systems and methods for improving the reception and delivery of an In-Trail Procedures (ITP) altitude change request. An example system located on board a host aircraft includes a communication component, a display device and a processor unit that is in signal communication with the communication component and the display device. The processor unit presents a user interface on the display device. The user interface includes a plurality of fields for receiving In-Trail Procedures (ITP) altitude change request information. The processor sends the ITP altitude change request information received within the plurality of fields to an Air Traffic Control (ATC) facility via the communication component. An ITP unit having a display receives an altitude selection and presents ITP altitude change request information if the received altitude selection is determined to be valid.

Owner:HONEYWELL INT INC

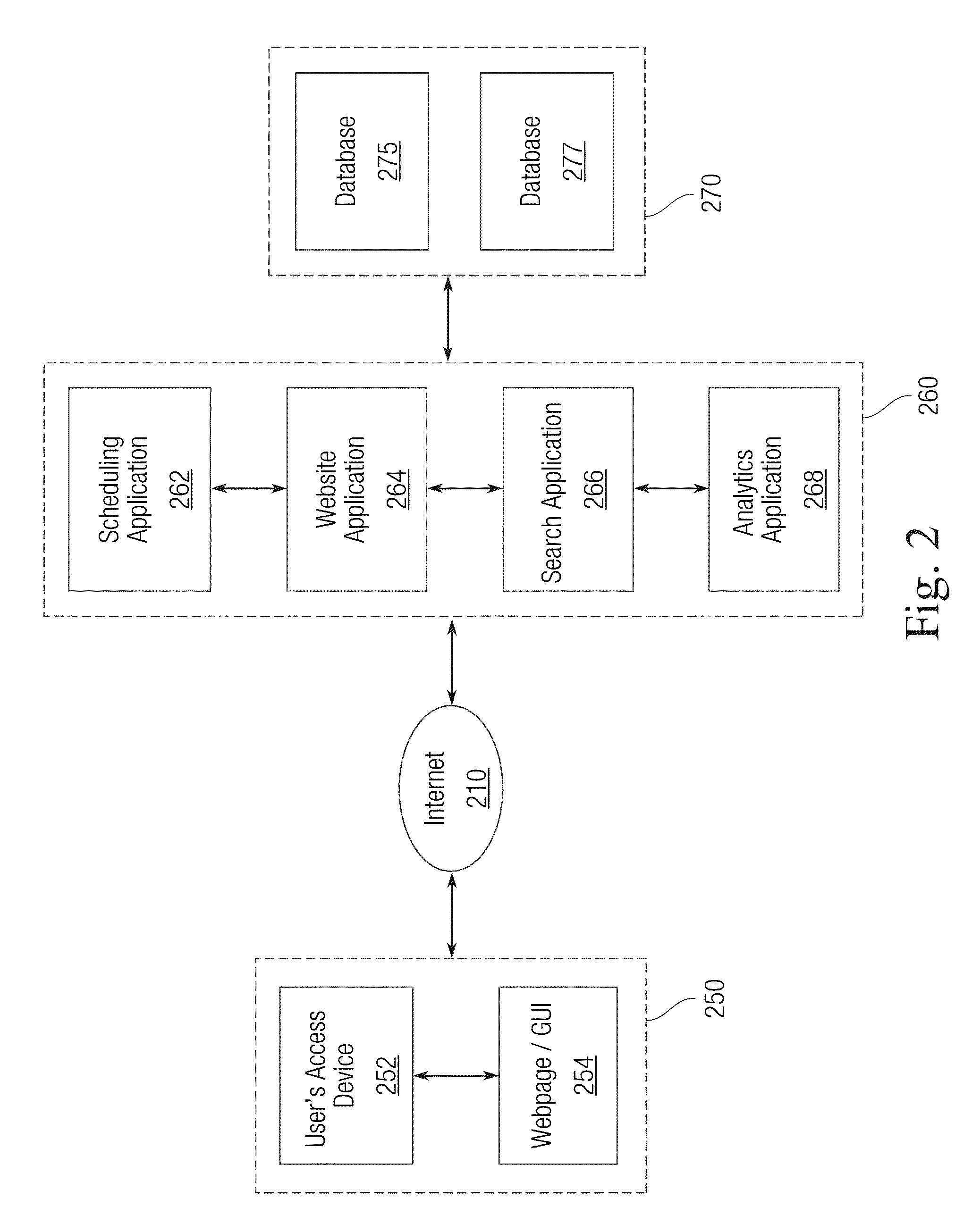

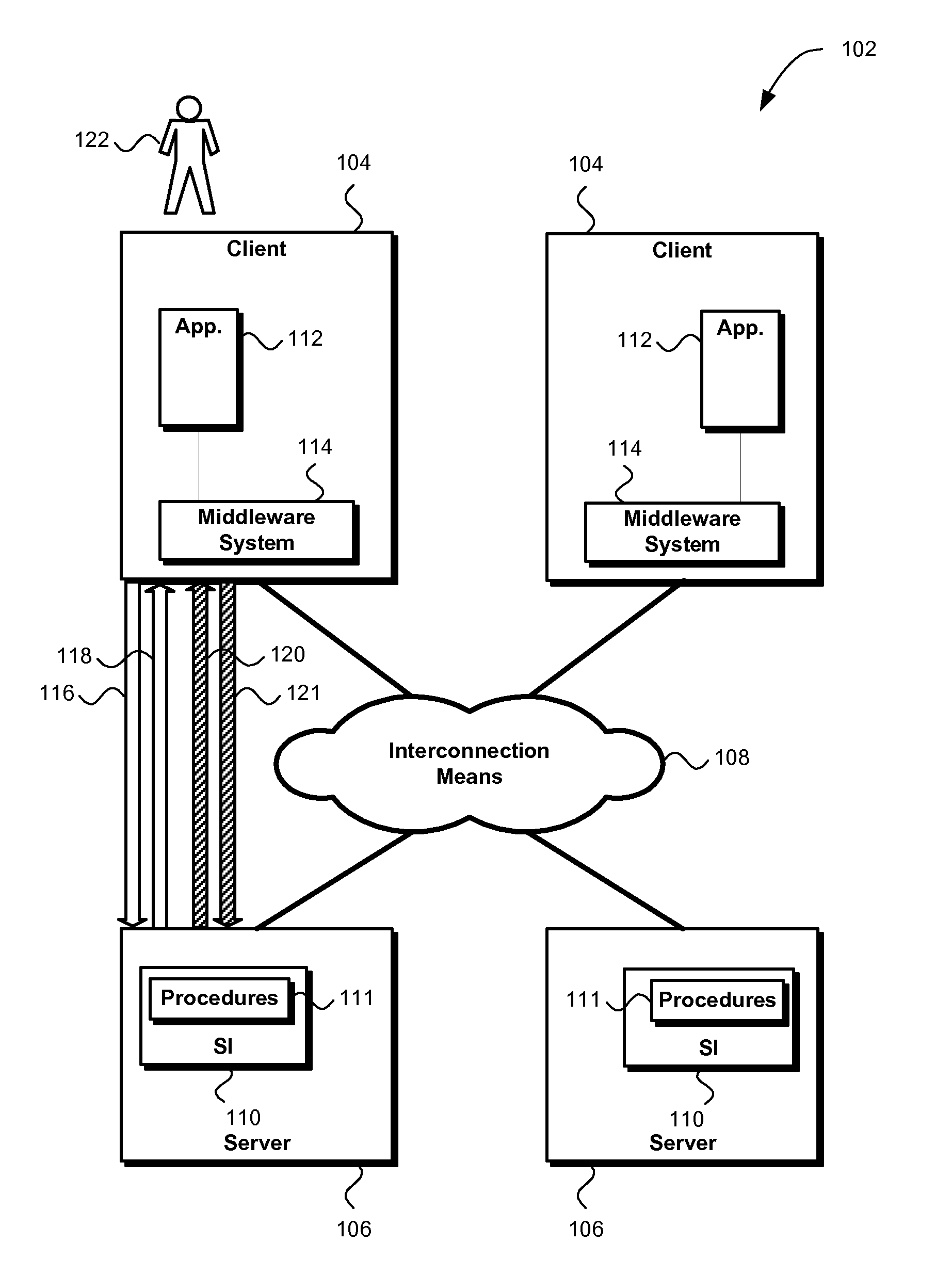

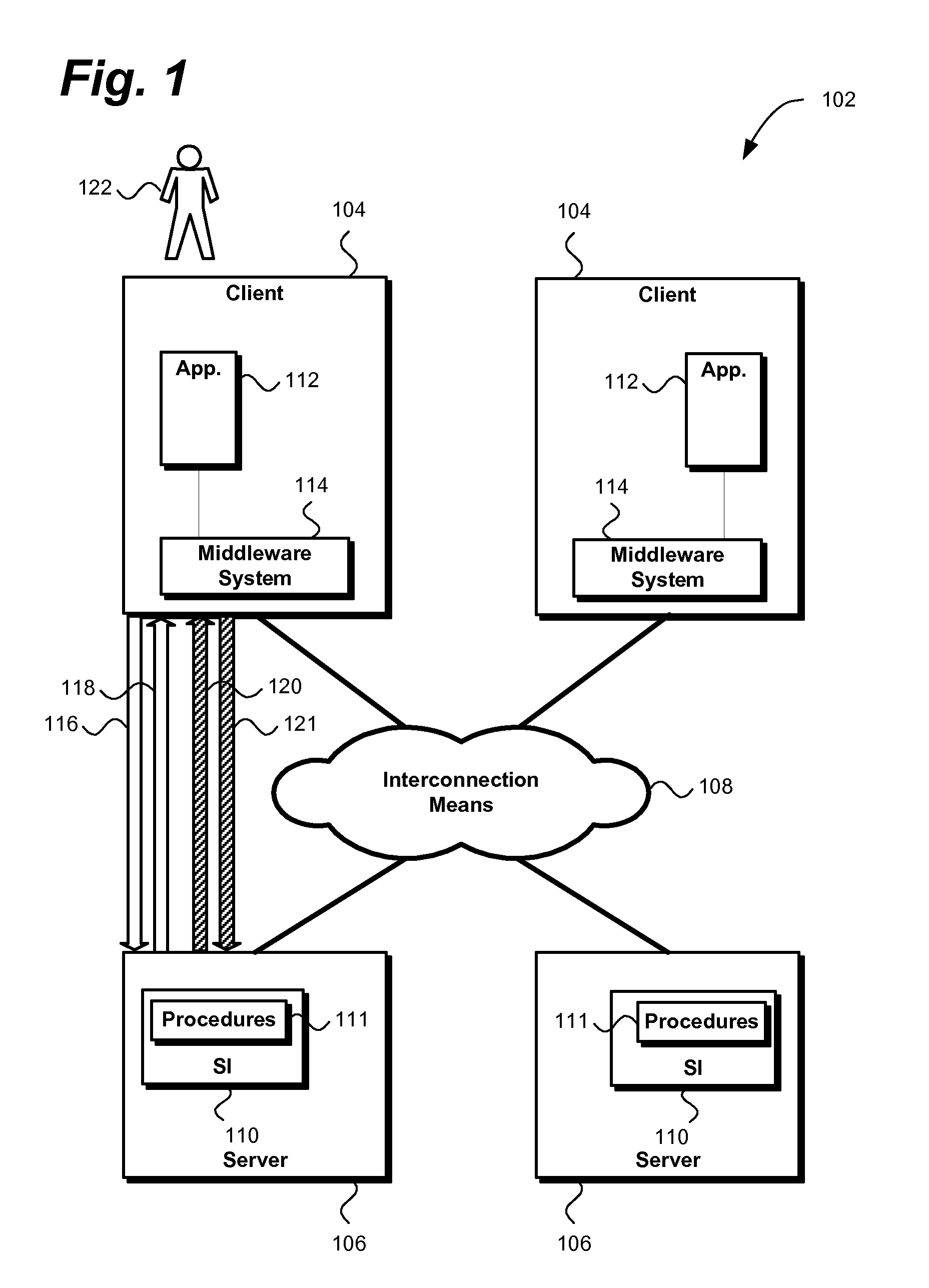

System and method for flexible and deferred service configuration

InactiveUS8561089B2Not easy to make mistakesSpecific program execution arrangementsProcedure requestedService configuration

Owner:INT BUSINESS MASCH CORP +1

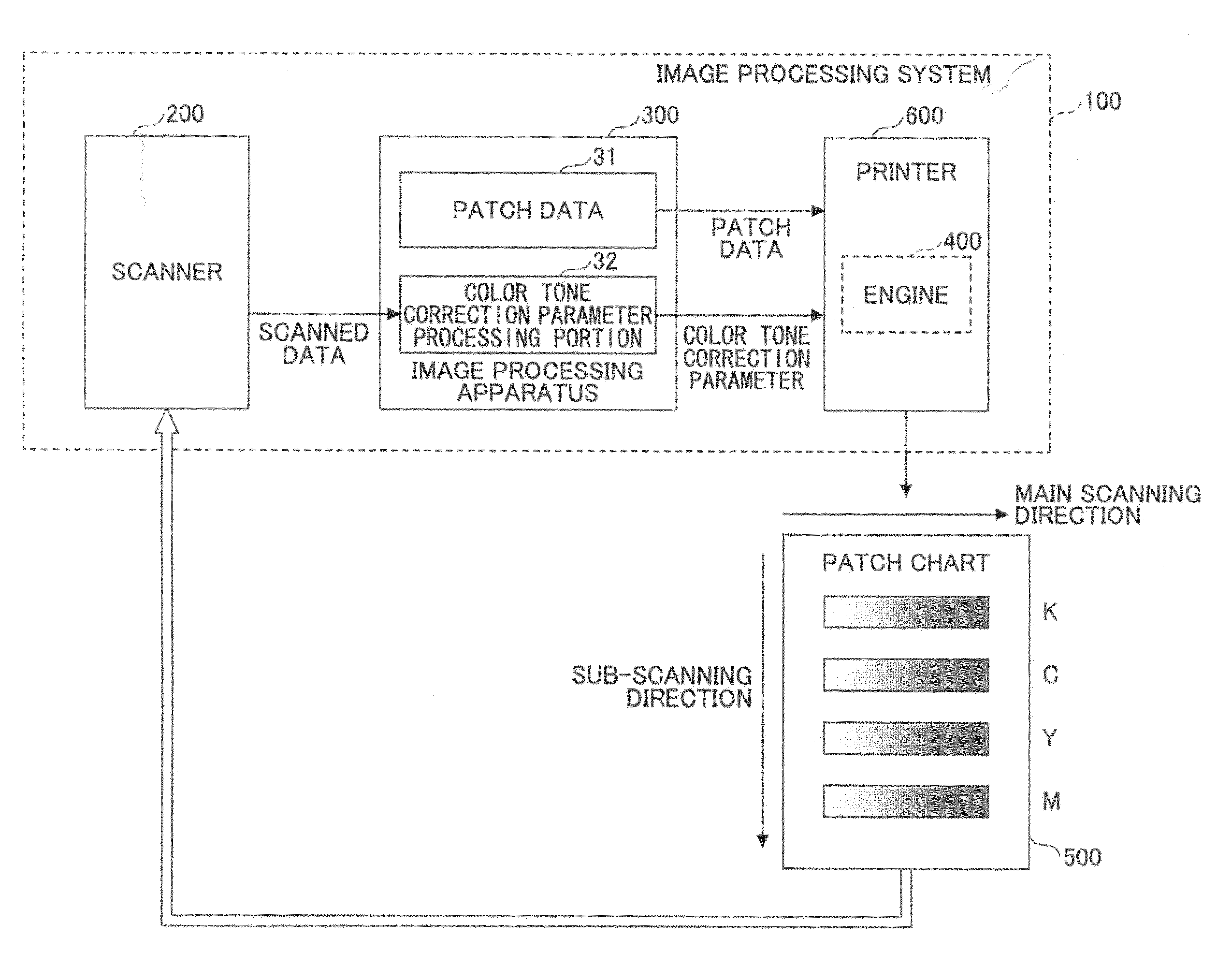

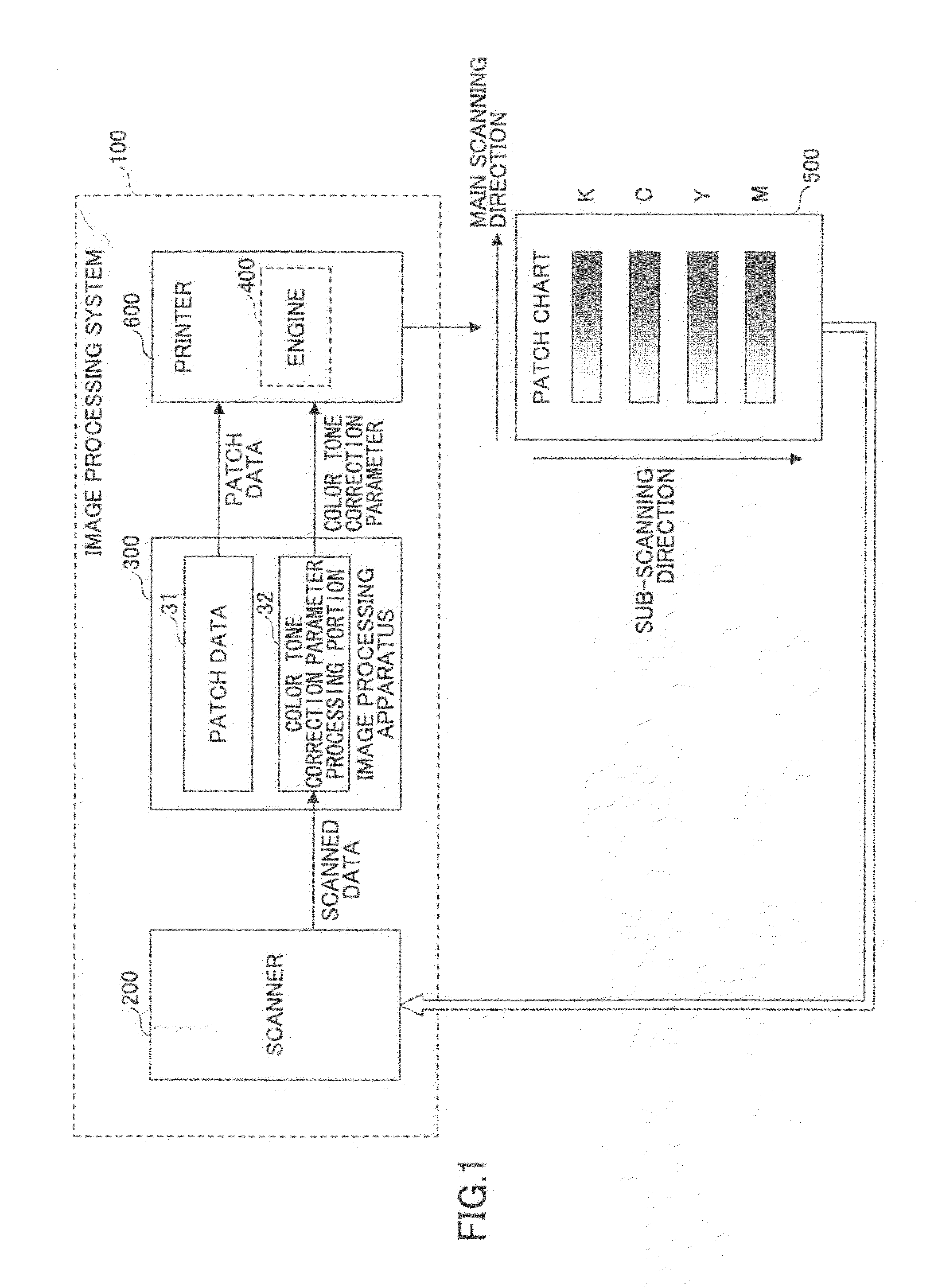

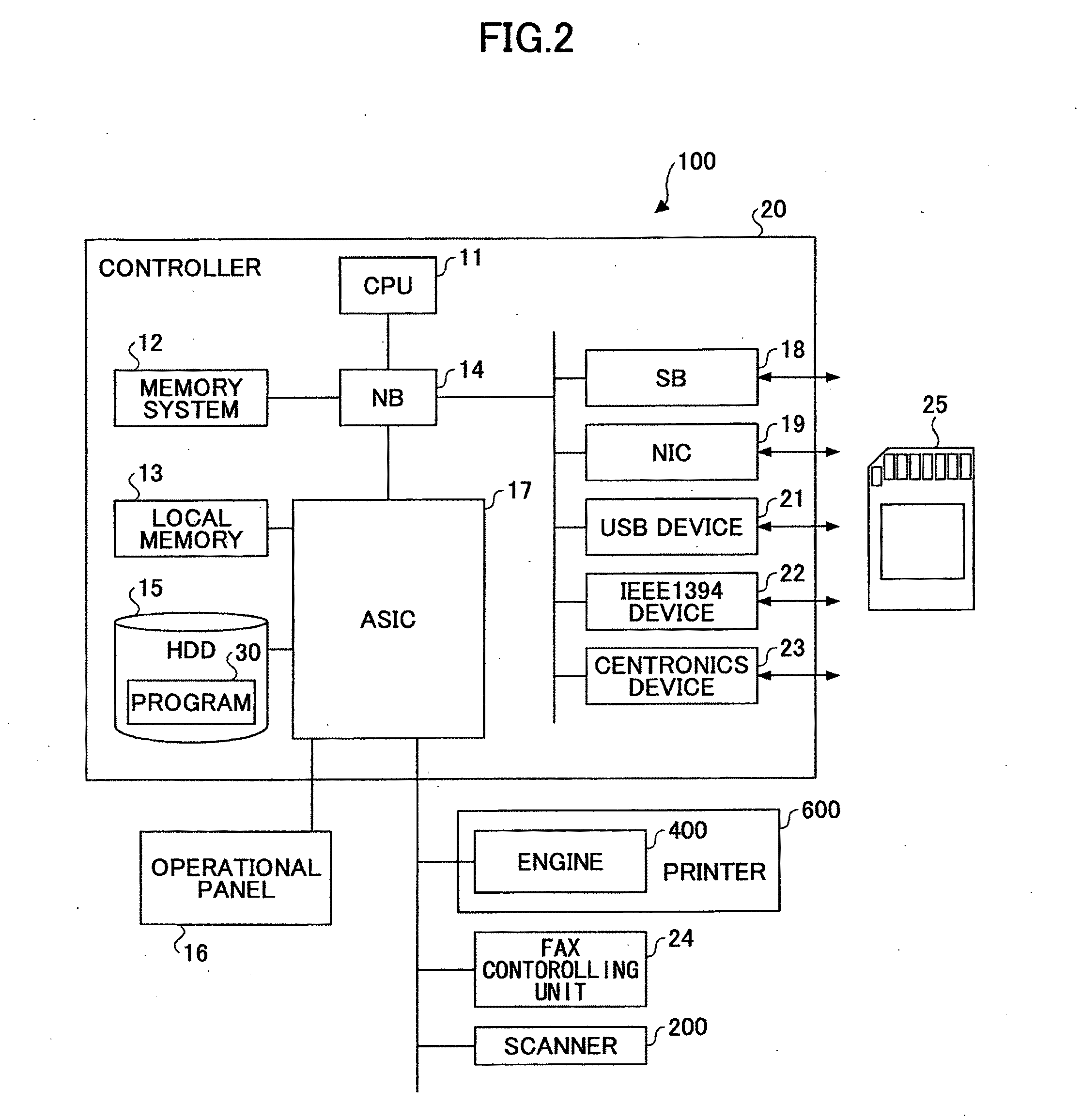

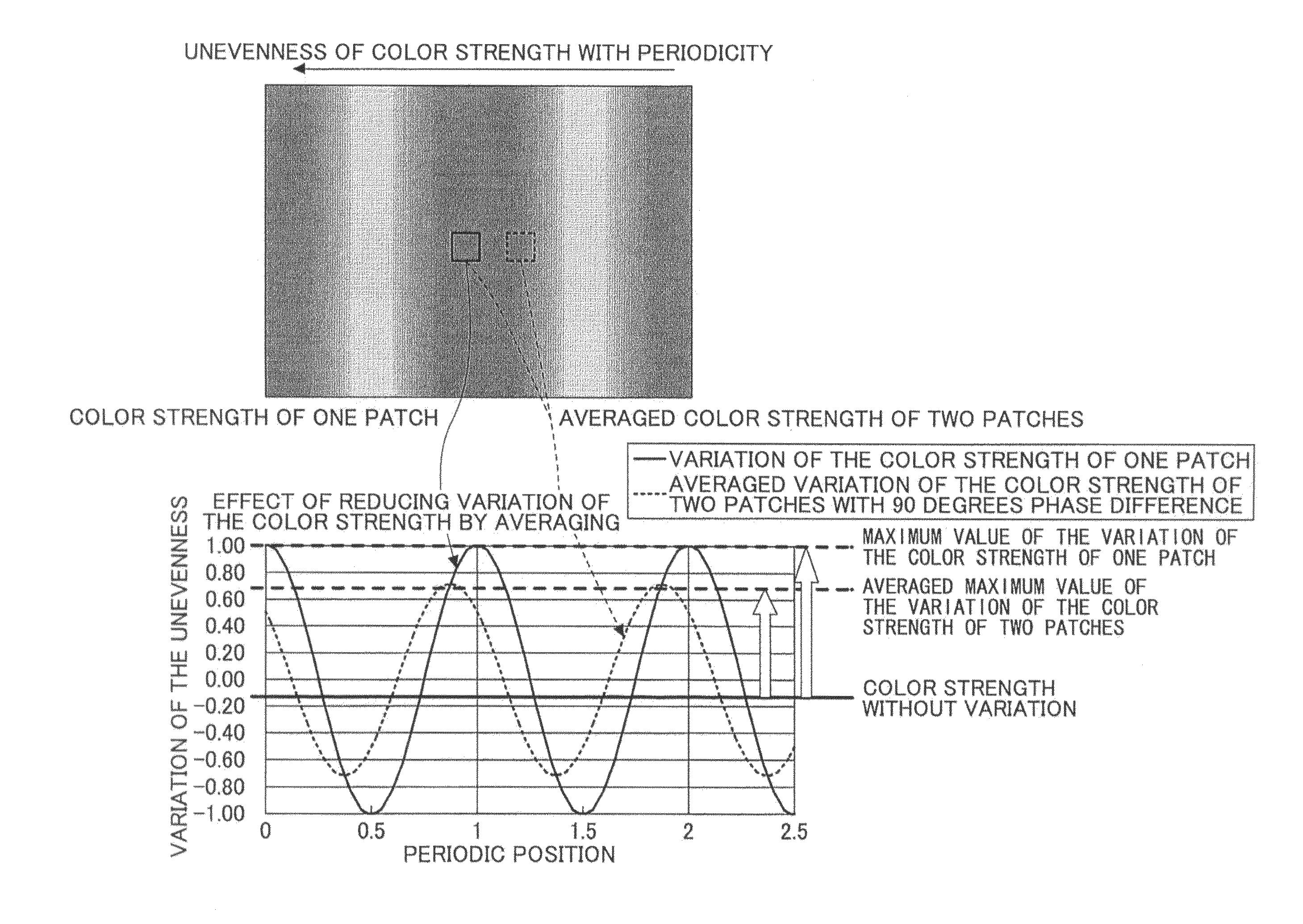

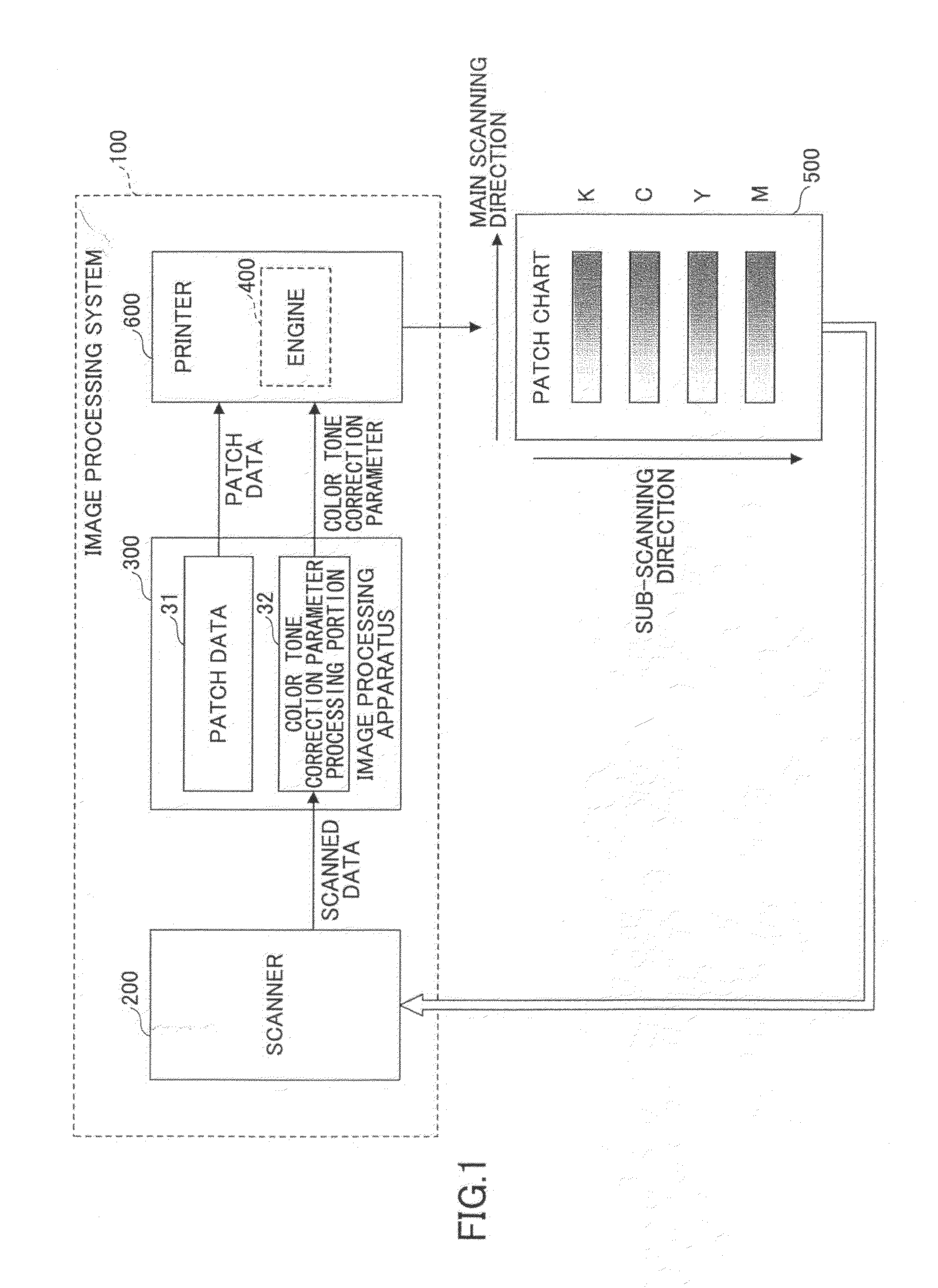

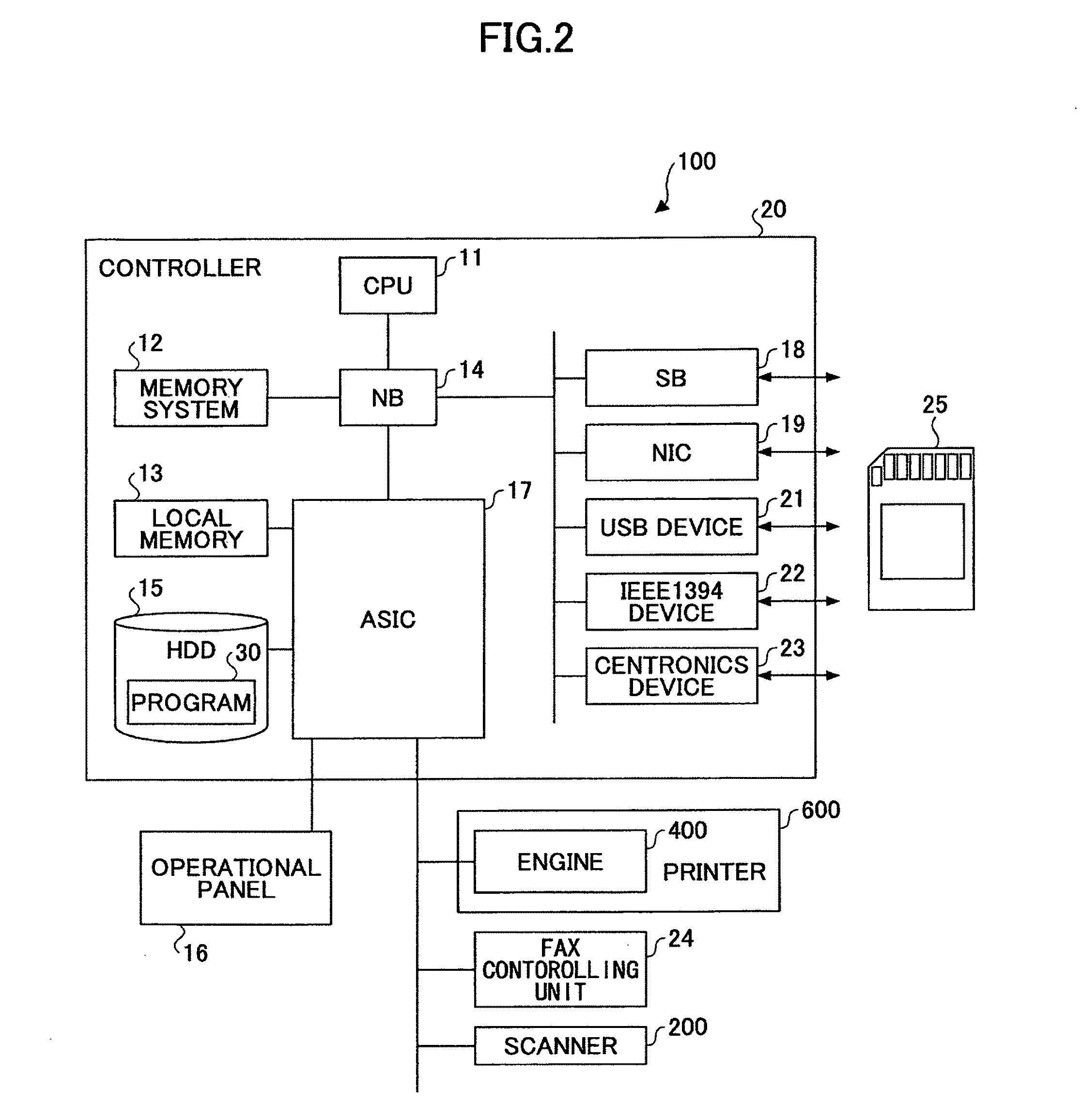

Image processing apparatus, image processing method, and computer- readable recording medium storing image processing program for generating color tone correction parameter

ActiveUS20100309498A1Reduce unevennessDigitally marking record carriersDigital computer detailsImaging processingProcedure requested

An image processing apparatus is disclosed that includes a printing procedure request portion configured to request printing of color tone image data in a state where a patch row is arranged in a direction almost parallel with a main scanning direction; an image data obtaining portion configured to obtain scanned color tone data, showing scanned value of the patch row, from a scanning portion configured to optically scan the patch row; and a parameter generating portion configured to generate a color tone correction parameter for correcting color tone value of photoconductive image data by comparing the scanned color tone data and the color tone image data.

Owner:RICOH KK

Monitoring system

ActiveUS8959007B2Convenient to accommodateSimple designProgramme controlSimulator controlSensor arrayProcedure requested

A method for designing a secondary sub-system for monitoring the condition of a platform is disclosed. The platform can include one or more primary sub-systems. The method can include identifying stakeholders of the platform, capturing information requirements of the stakeholders, determining data requirements corresponding to the information requirements, defining a sensor array comprising sensors suitable for providing output signals relating to condition characteristics of the one or more primary sub-systems, and defining procedures for converting the output signals from the sensor array to the data requirements, thereby to fulfil the information requirements of the stakeholders. The method can be implemented using a design tool having a graphical user interface with a hierarchical layer structure.

Owner:BAE SYSTEMS PLC

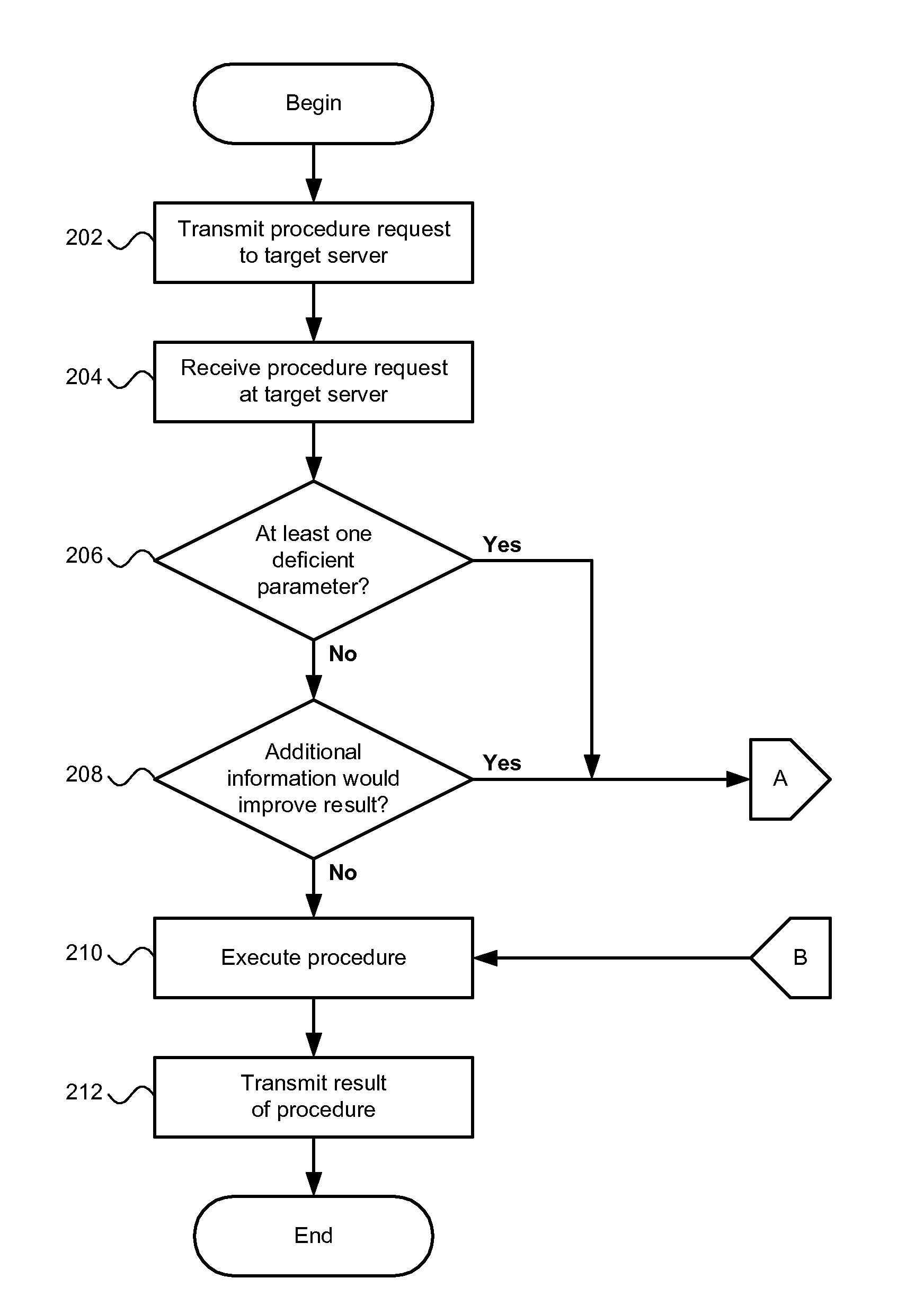

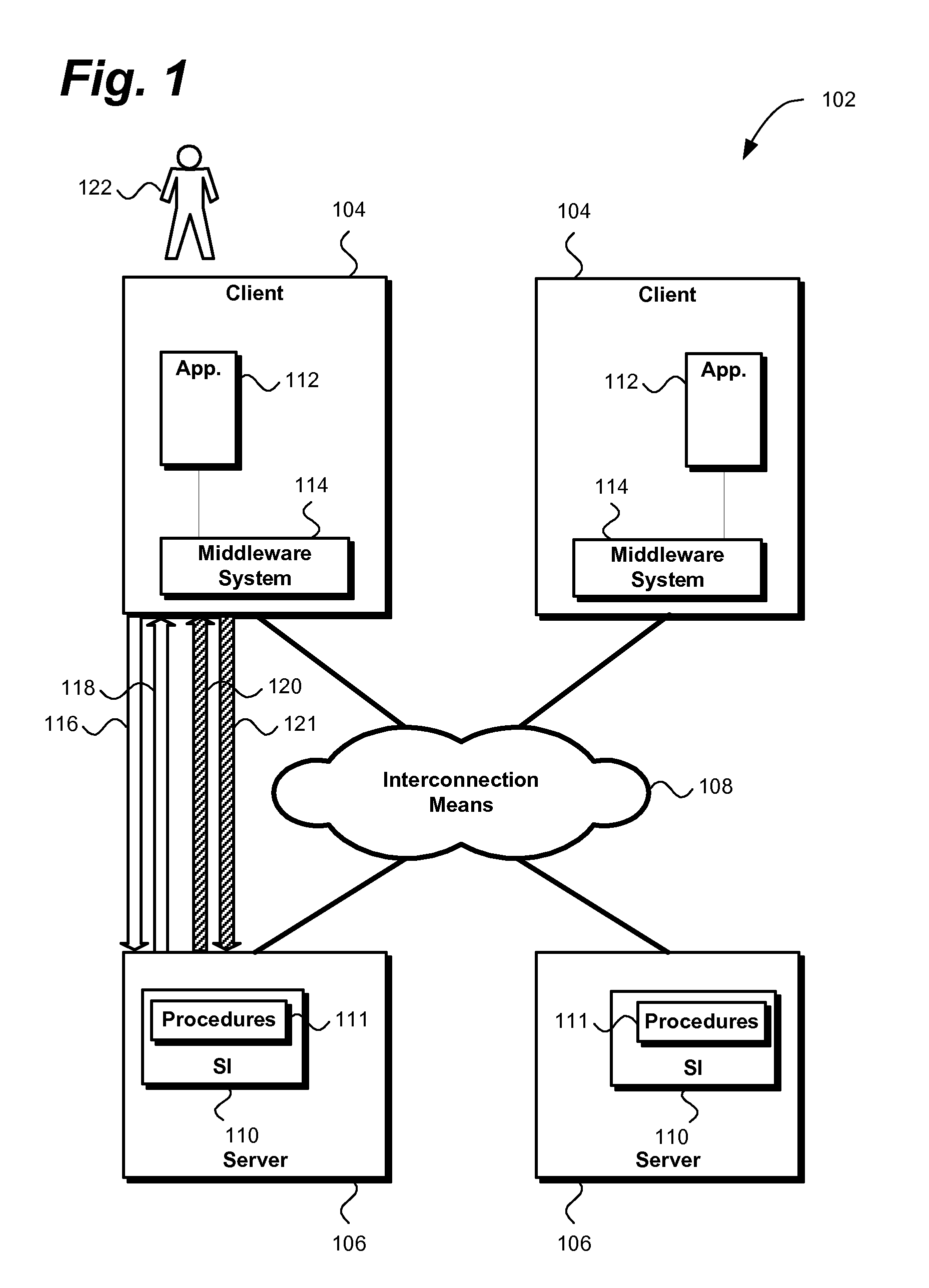

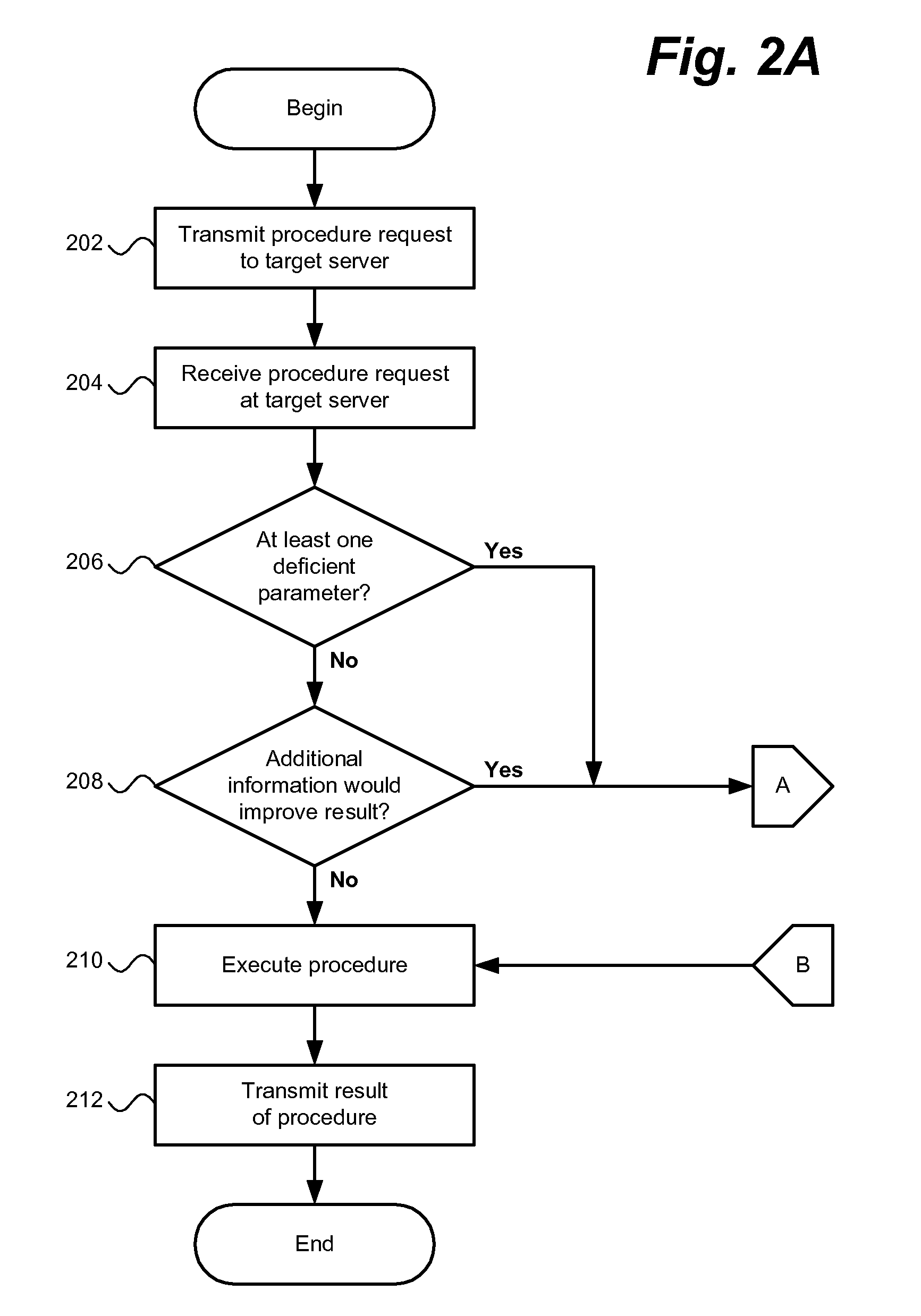

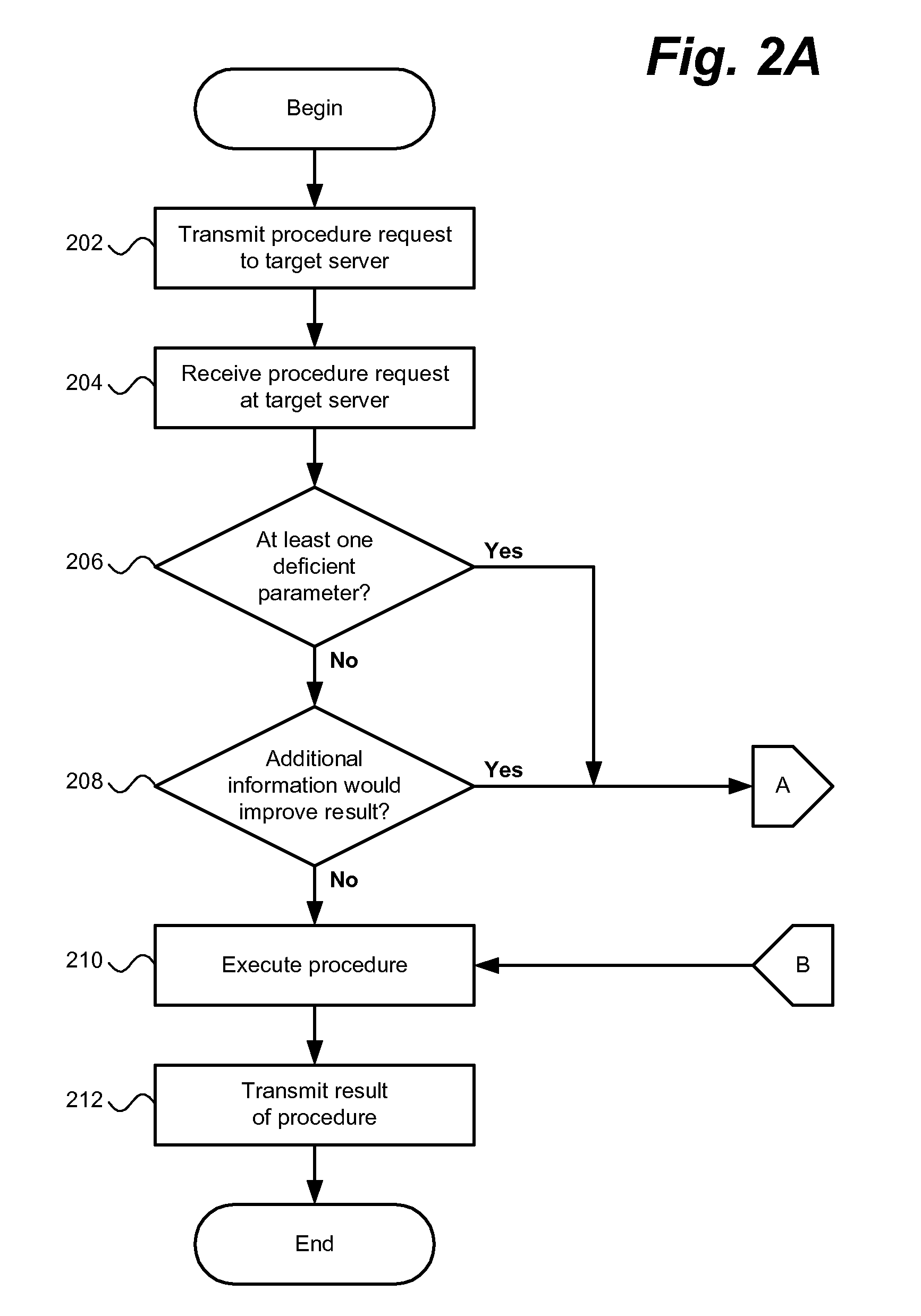

System and method for flexible and deferred service configuration

InactiveUS20090125920A1Not easy to make mistakesSpecific program execution arrangementsProcedure requestedService configuration

A method, system and computer program product for flexible service configuration. In one embodiment, the method includes receiving a procedure request to perform a procedure at a target server, detecting by the target server at least one deficient parameter in the procedure request, suspending processing of the procedure request, sending a request by the target server for additional information from a middleware system to correct the at least one deficient parameter in the procedure request, and resuming the procedure request upon receiving the additional information.

Owner:IBM CORP +1

Image processing apparatus, image processing method, and computer- readable recording medium storing image processing program for generating color tone correction parameter

ActiveUS8610950B2Reduce unevennessDigitally marking record carriersVisual presentation using printersImaging processingProcedure requested

An image processing apparatus is disclosed that includes a printing procedure request portion configured to request printing of color tone image data in a state where a patch row is arranged in a direction almost parallel with a main scanning direction; an image data obtaining portion configured to obtain scanned color tone data, showing scanned value of the patch row, from a scanning portion configured to optically scan the patch row; and a parameter generating portion configured to generate a color tone correction parameter for correcting color tone value of photoconductive image data by comparing the scanned color tone data and the color tone image data.

Owner:RICOH KK

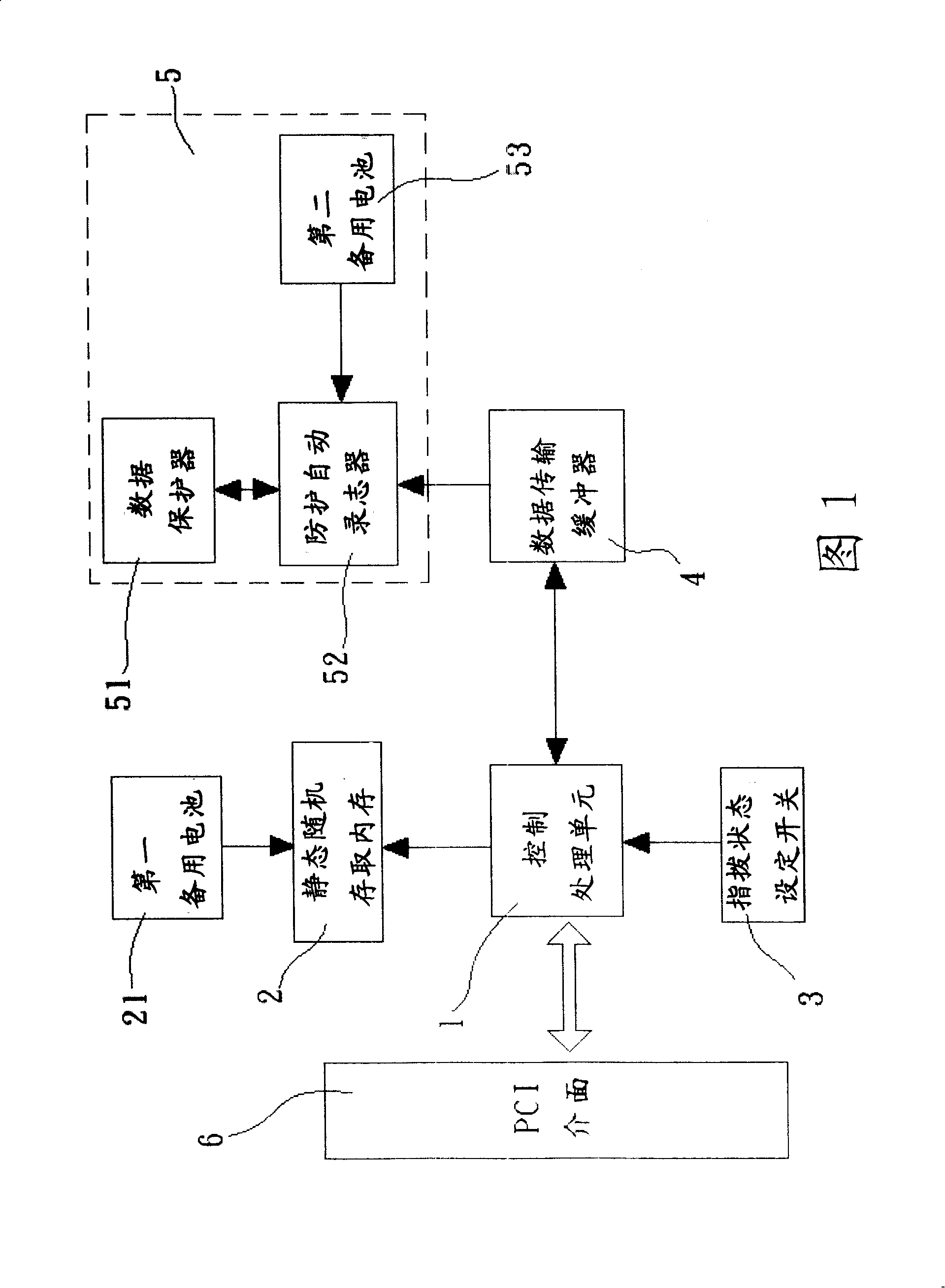

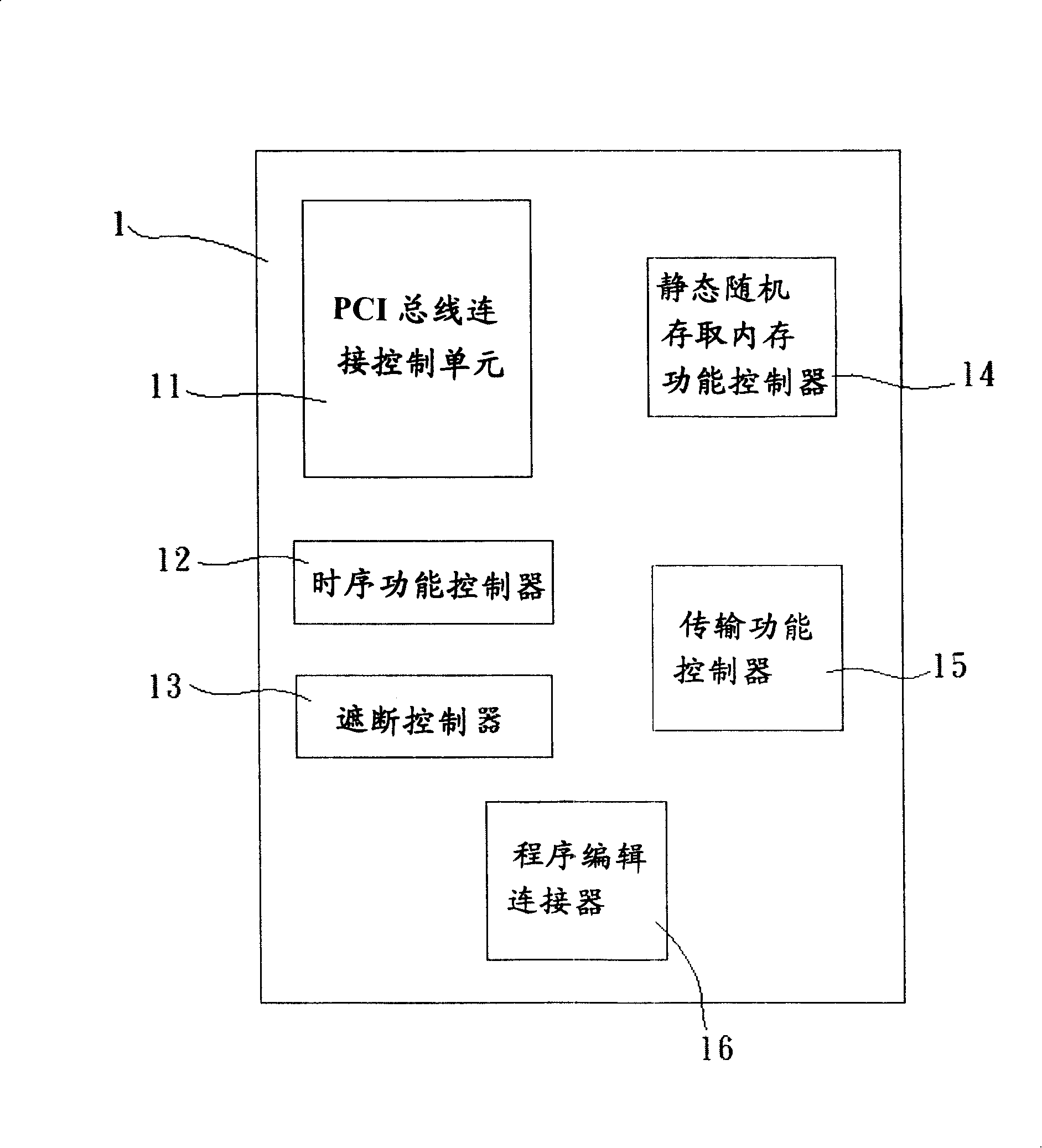

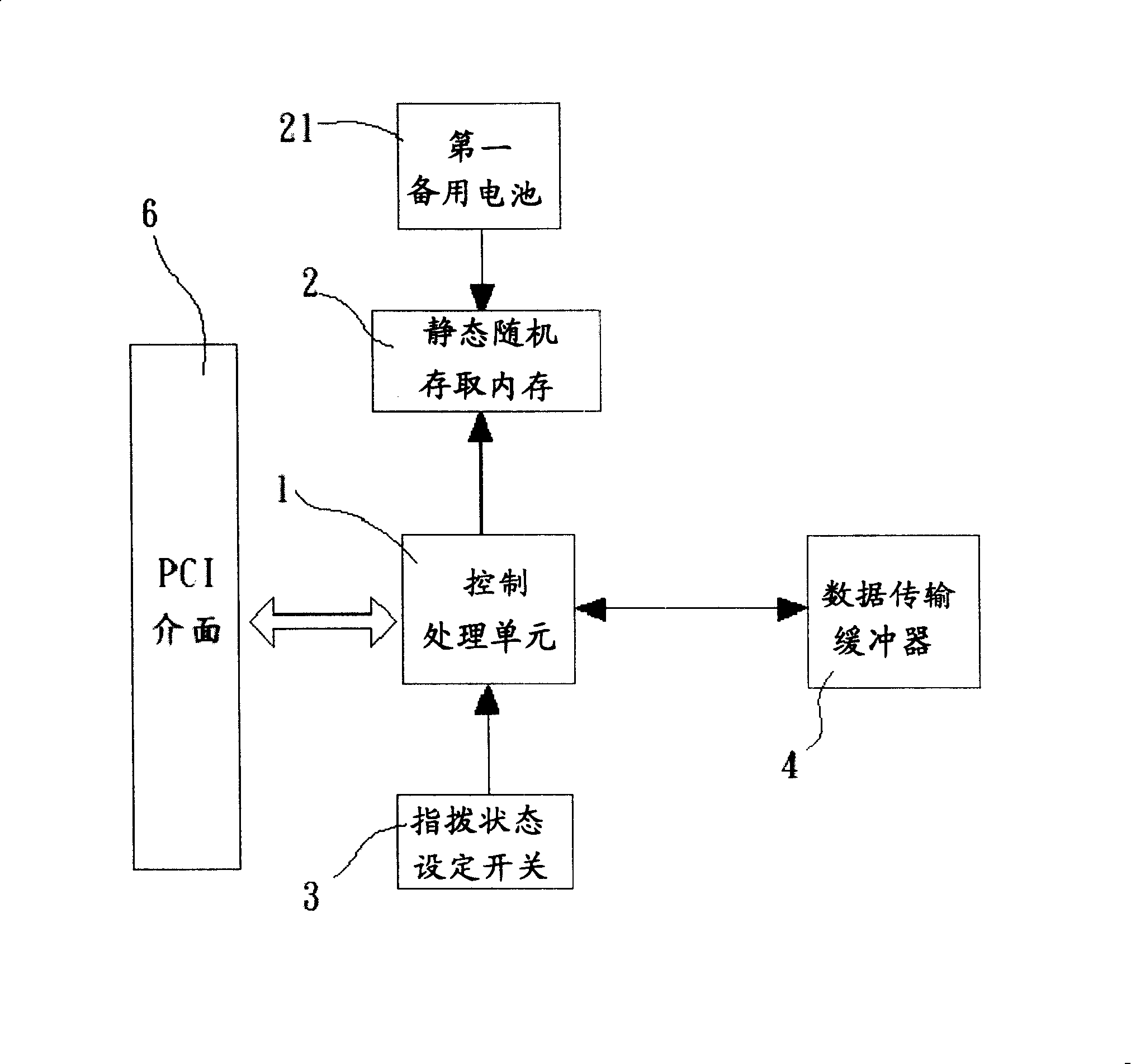

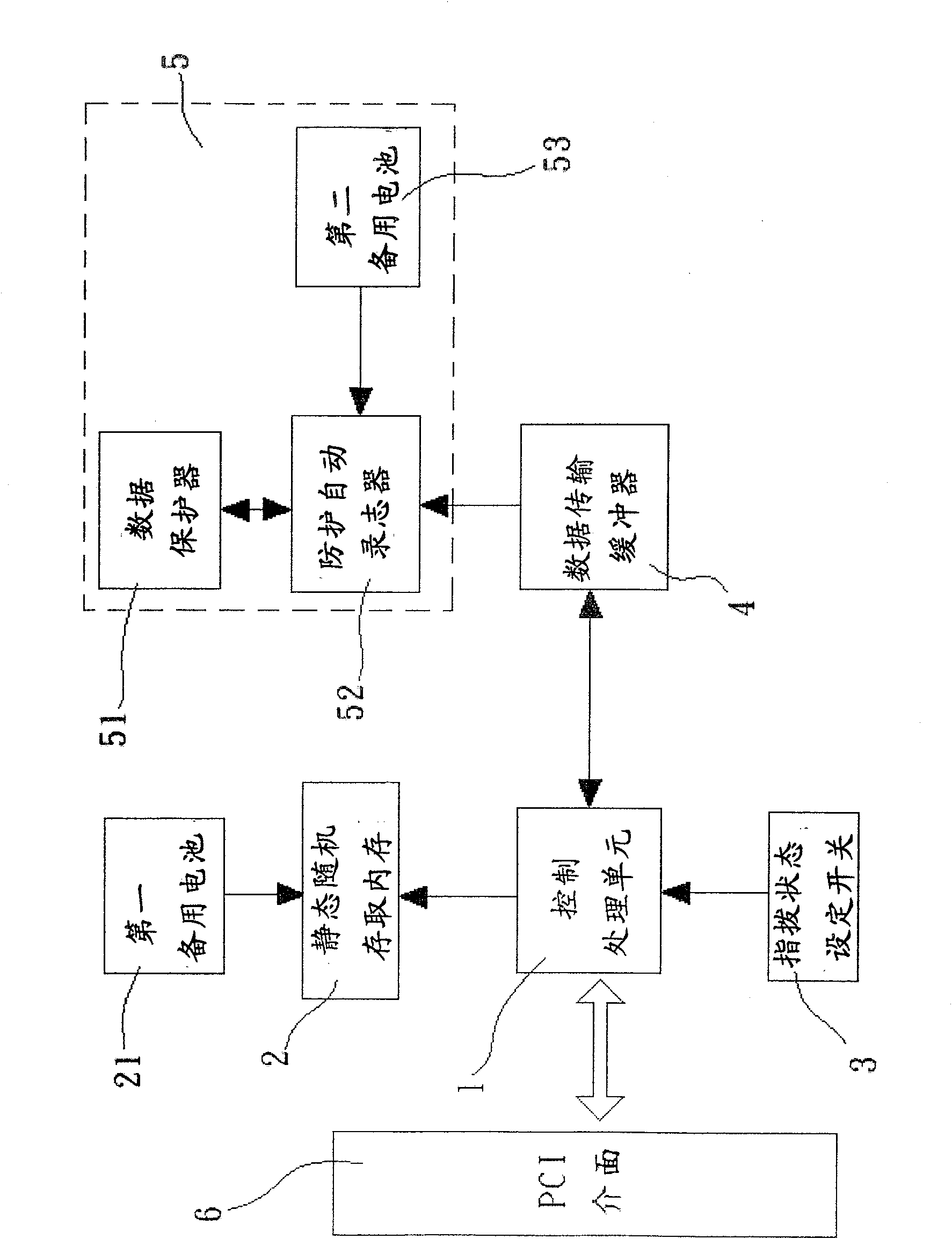

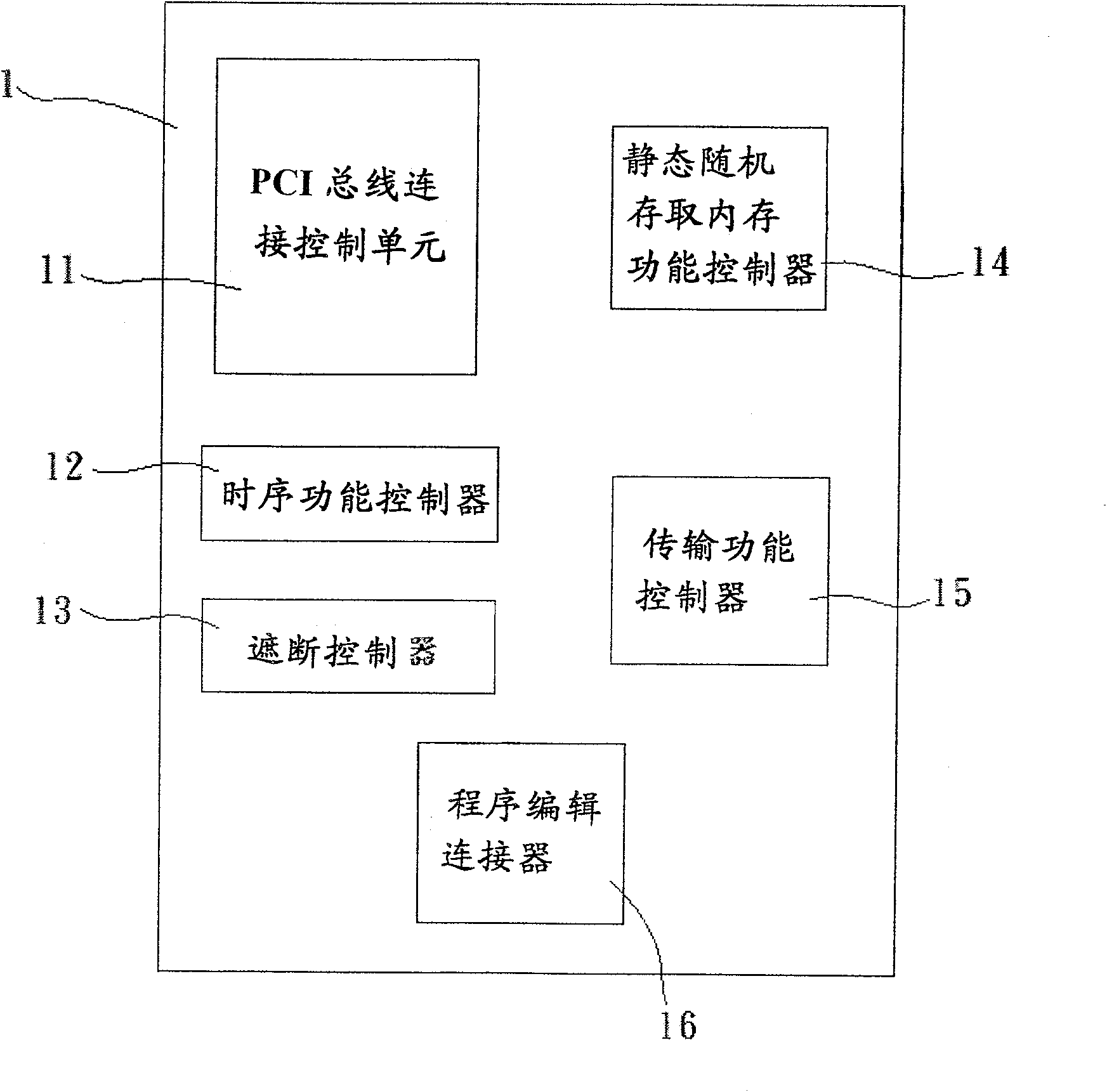

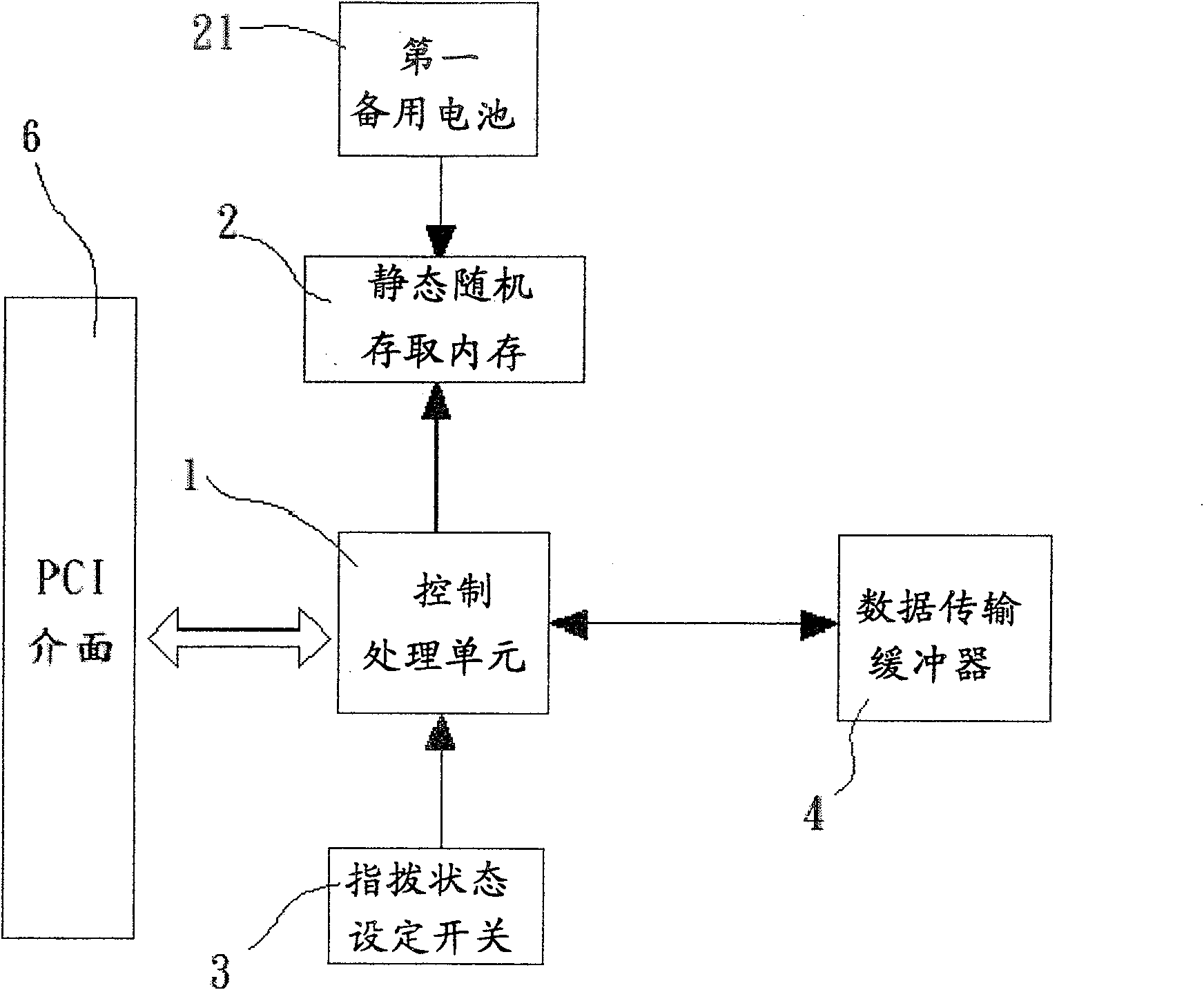

Multi-point universal transmission control interface arrangement

InactiveCN101221545AControl operating hoursElectric digital data processingStatic random-access memoryGate array

The invention discloses a multi-point general-purpose input / output (GPIO) control interface device which comprises a control and processing unit, a static random access memory (SRAM), a setting switch for dip state, a general-purpose output port and a general-purpose input port which correspond to a data transmission buffer. The invention is used to be arranged in a computer system or a host of a game machine; the control and processing unit is used to control at least one peripheral function device connected with a hardware operation timer, an interruption controller, SRAM access and I / O transmission according to program editing and setting of different use requirements by an operation function controller constructed by a field programmable logic gate array (FPGA) , further to control the periphery of the computer system or the host of the game machine; and the needed data is stored into the static random access memory (SRAM).

Owner:ACROSSER TECH

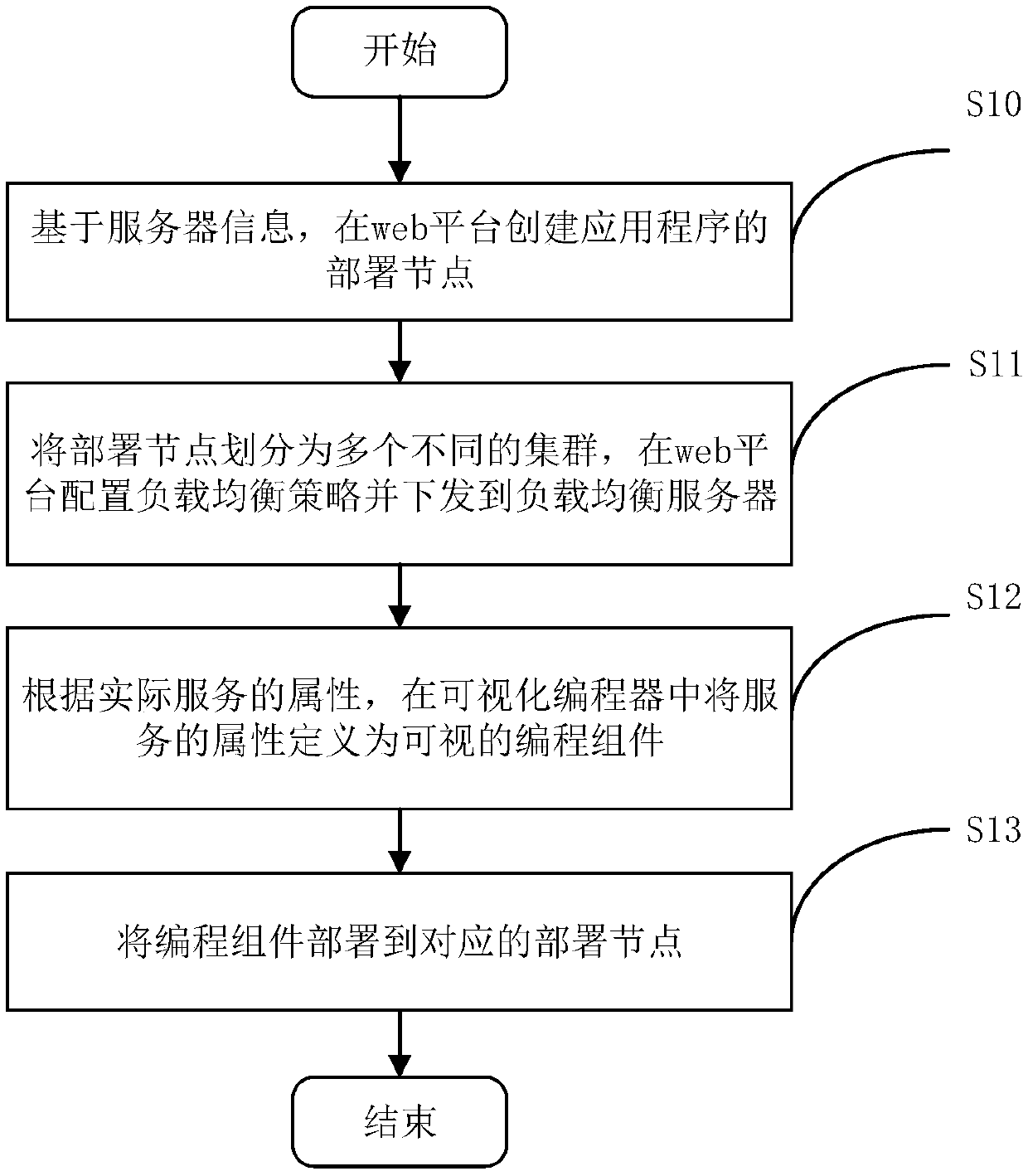

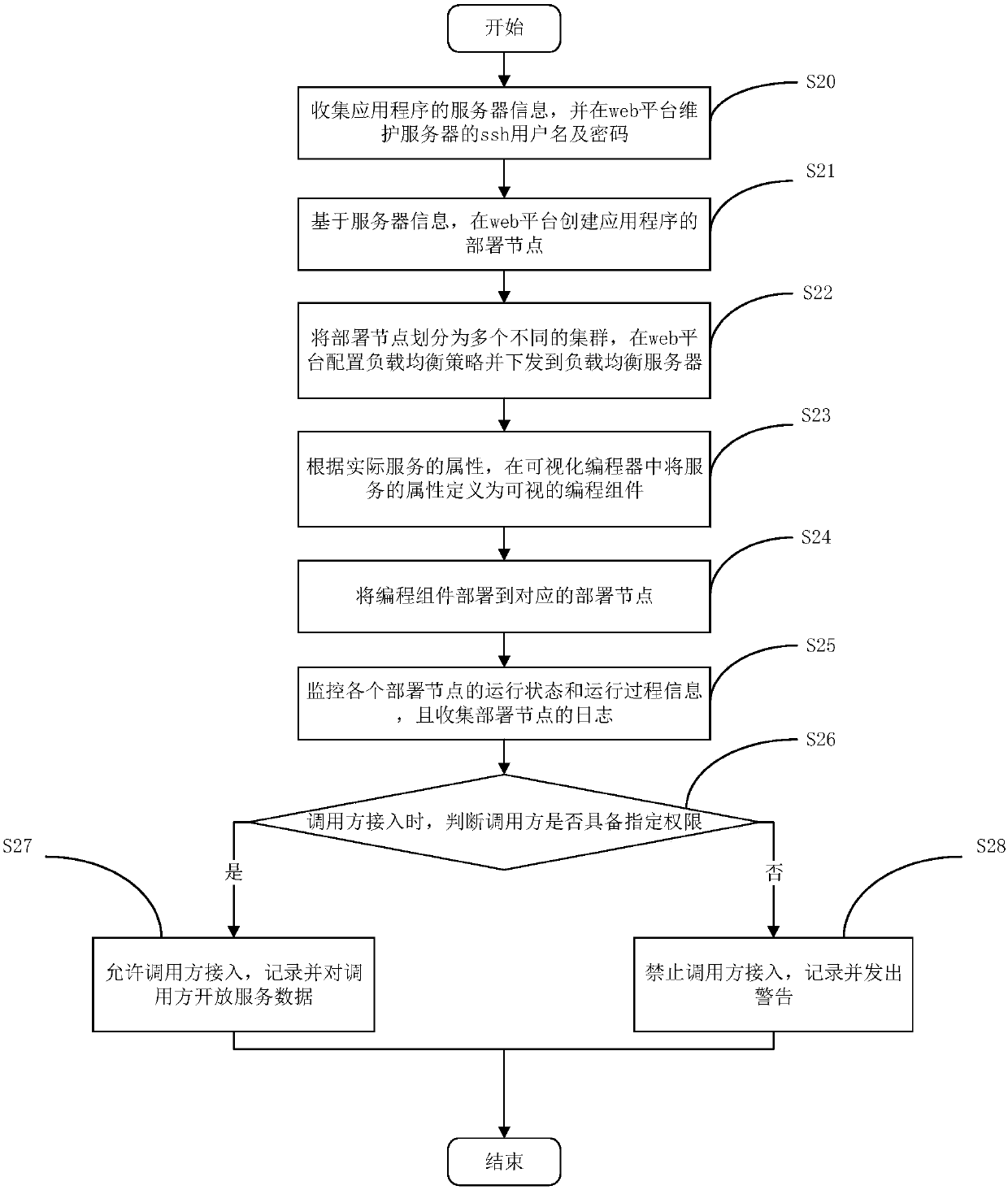

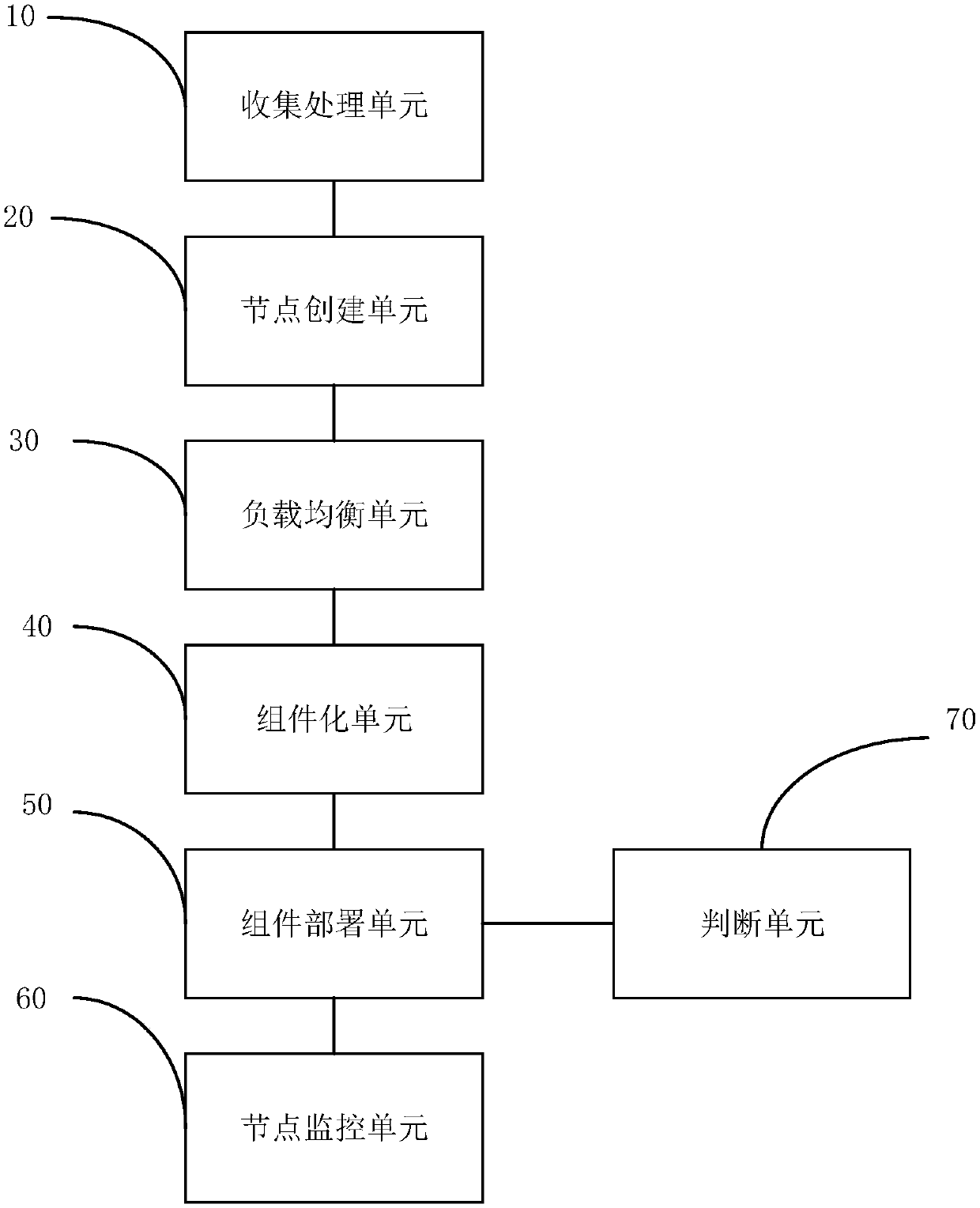

Modularize enterprise bus integration method and device

The invention discloses a modularize enterprise bus integration method and device. The method comprises the following steps that disposition nodes of applications are created in a web platform based on server information; the disposition nodes are divided into different clusters, and a load balancing strategy is configured in the web platform and issued to a load balancing server; according to attribute of a practical service, the service attribute is defined as a visual programming assembly in a visual programming device; and the programming assembly is disposed in the corresponding disposition node. A target service can be designed easily in the web management platform; a program satisfying the requirement can be designed via the visual programmer and issued to the disposition node by one click, and the workload and difficulty of disposition are both reduced; load balancing is set to improve the stability and availability of the service and reduce influence of a single-point fault onuse; the disposition nodes are monitored, and a problem can be located and solved timely; and access authentication is set to ensure the safety of data storage, transmission and access.

Owner:GUANGDONG ESHORE TECH

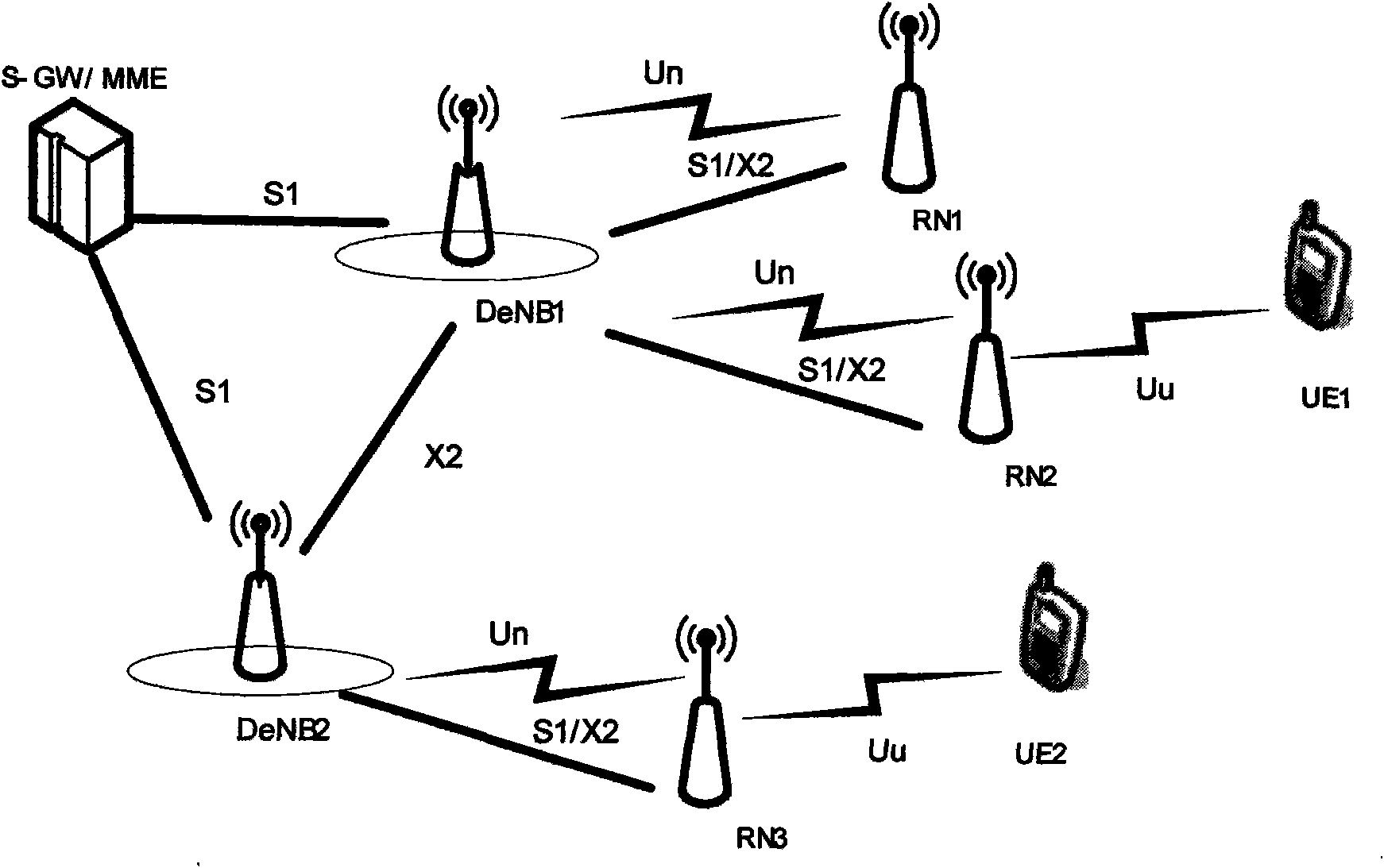

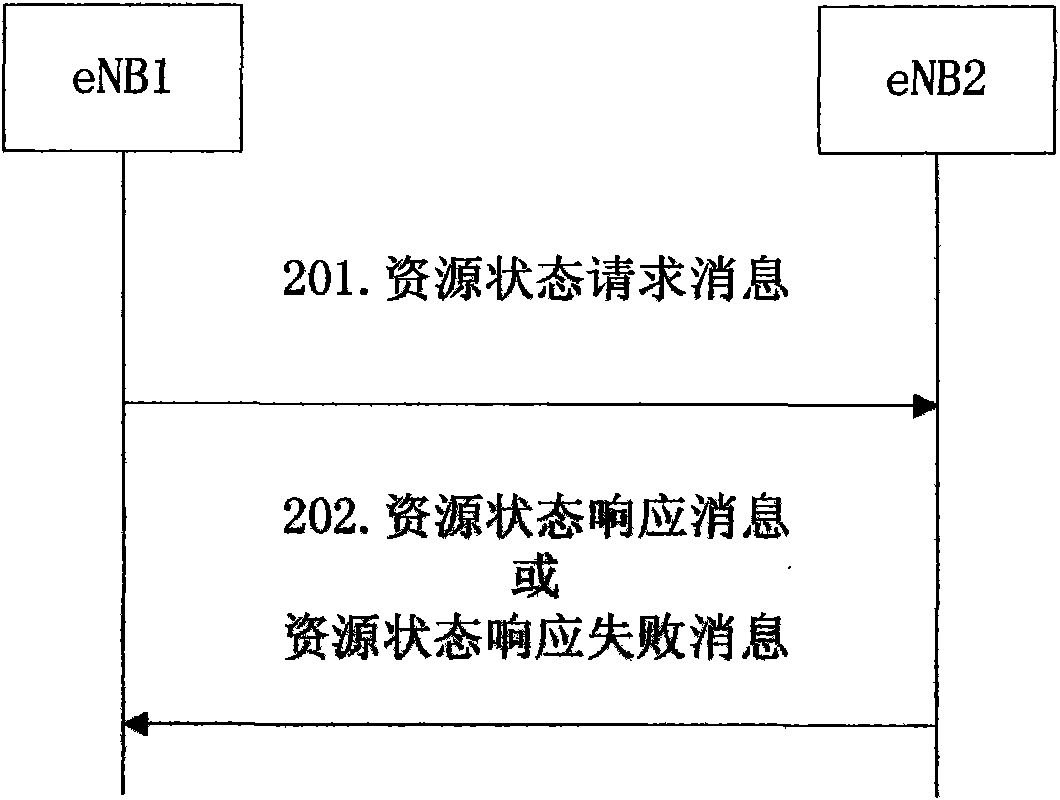

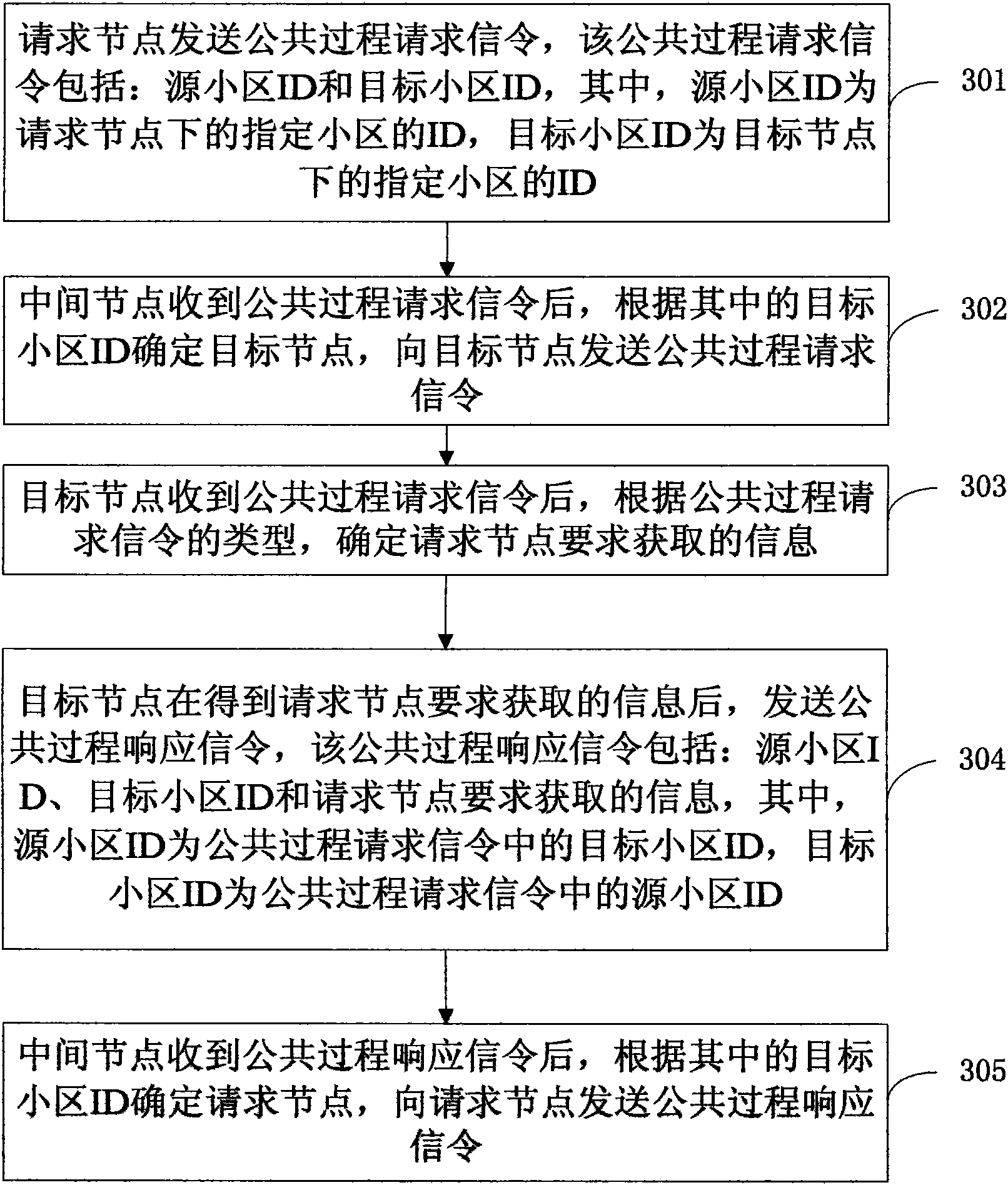

Method for transmitting public procedure information in long term evolution augmentation system and system thereof

The invention discloses a method for transmitting public procedure information in a long term evolution augmentation system and a system thereof. The method comprises the following steps: a request node sends a public procedure request signaling comprising a source cell ID and a target cell ID, wherein the source cell ID and the target cell ID are respectively the appointed cell ID for the request node and the target node; an intermediate node determines the target node according to the target cell ID and transmits the signaling to the target node; the target node determines the information required by the request node according to the type of the public procedure request signaling, sends a responding signaling containing the source cell ID, the target cell ID and the corresponding information after obtaining the corresponding information, wherein the source cell ID and the target cell ID are respectively the target cell ID and source cell ID of the request signaling; and the middle node determines the request node according to the target cell ID and transmits the signaling to the request node. By using the technical scheme of the invention, the intermediate node can determine the destination route of the request signaling and a response signaling, and transmits the route to the destination.

Owner:NEW POSTCOM EQUIP

Systems and methods for improving an in-trail procedures request

Owner:HONEYWELL INT INC

System, method, and computer-readable medium for authentication center-initiated authentication procedures for a mobile station attached with an IP-femtocell system

ActiveUS8547859B2Error preventionFrequency-division multiplex detailsProcedure requestedMobile station

A system, method, and computer readable medium that facilitate authentication center-initiated authentication procedures for a mobile station attached with a femtocell system are provided. A femtocell system may generate a registration identification of a mobile station from one or more mobile station authentication parameters. A convergence server located in a core network receives an authentication procedure request from an authentication center for the mobile station attached with the femtocell system and generates an authentication procedure request message that includes the registration identification assigned to the mobile station. The convergence server then transmits the authentication procedure request message to the femtocell system and receives a response to the authentication procedure request message from the femtocell system. The authentication procedure request may comprise a unique challenge, a shared secret data update procedure, or a call history count update procedure.

Owner:RED HAT

Method of automatically configuring a home base station router

The present invention provides a method of automatically configuring a base station router. The method includes modifying a transmission power for a pilot signal transmitted by the base station router. The modification of the transmission power is determined based upon a frequency of mobility-related procedure requests received by the base station router.

Owner:ALCATEL-LUCENT USA INC

A kind of tobacco processing production method

ActiveCN104921284BRealize flexible connectionFlexible combinationTobacco preparationTobacco treatmentProcedure requestedMaterial supply

The invention relates to the technical field of tobacco, and discloses a tobacco processing production system. The tobacco processing production system comprises a loosening and conditioning processing module, a conditioning and charging processing module, a leaf tobacco cutting processing module, a cut leaf tobacco drying processing module, a blending and perfuming processing module, a burley tobacco processing module, and movable leaf storage cabinets. The movable leaf storage cabinets connected with the six processing modules freely to achieve arbitrary permutation and combination of the processing modules, wherein the loosening and conditioning module or the conditioning and charging processing module is arranged at the first place. The invention further provides a tobacco processing method. The movable leaf storage cabinets connected with the six processing modules arbitrarily, material supply, discharging and storage of each module are achieved through the movable leaf storage cabinets, the movable leaf storage cabinets can be pulled to any designated position as needed, and therefore whole-line flexible connection is achieved through the movable leaf storage cabinets. The processing modules do not need to be moved, flexible combination of production procedures can be achieved, and the requirement for manufacturing special cigarettes or some cigarettes with the special production procedure request can be met.

Owner:CHINA TOBACCO GUANGDONG IND

Multi-point universal transmission control interface arrangement

InactiveCN100559363CControl operating hoursElectric digital data processingStatic random-access memoryProcedure requested

The present invention is a multi-point general transmission (GPIO) control interface device, including: a control processing unit, a static random access memory (SRAM), a thumb state setting switch and a data transmission buffer corresponding to the general output entrance Composition, used to install in a computer system or a game machine host, using the aforementioned control processing unit to construct an operational function controller constructed from a Field Programmable Logic Gate Array (FPGA), edit and set programs according to different usage requirements , to control the hardware operation timer, interrupt controller, SRAM access and I / O transmission at least one peripheral function device interfaced with it, and control the peripheral of the computer system or the game machine host, and store the required data in The aforementioned static random access memory (SRAM).

Owner:ACROSSER TECH

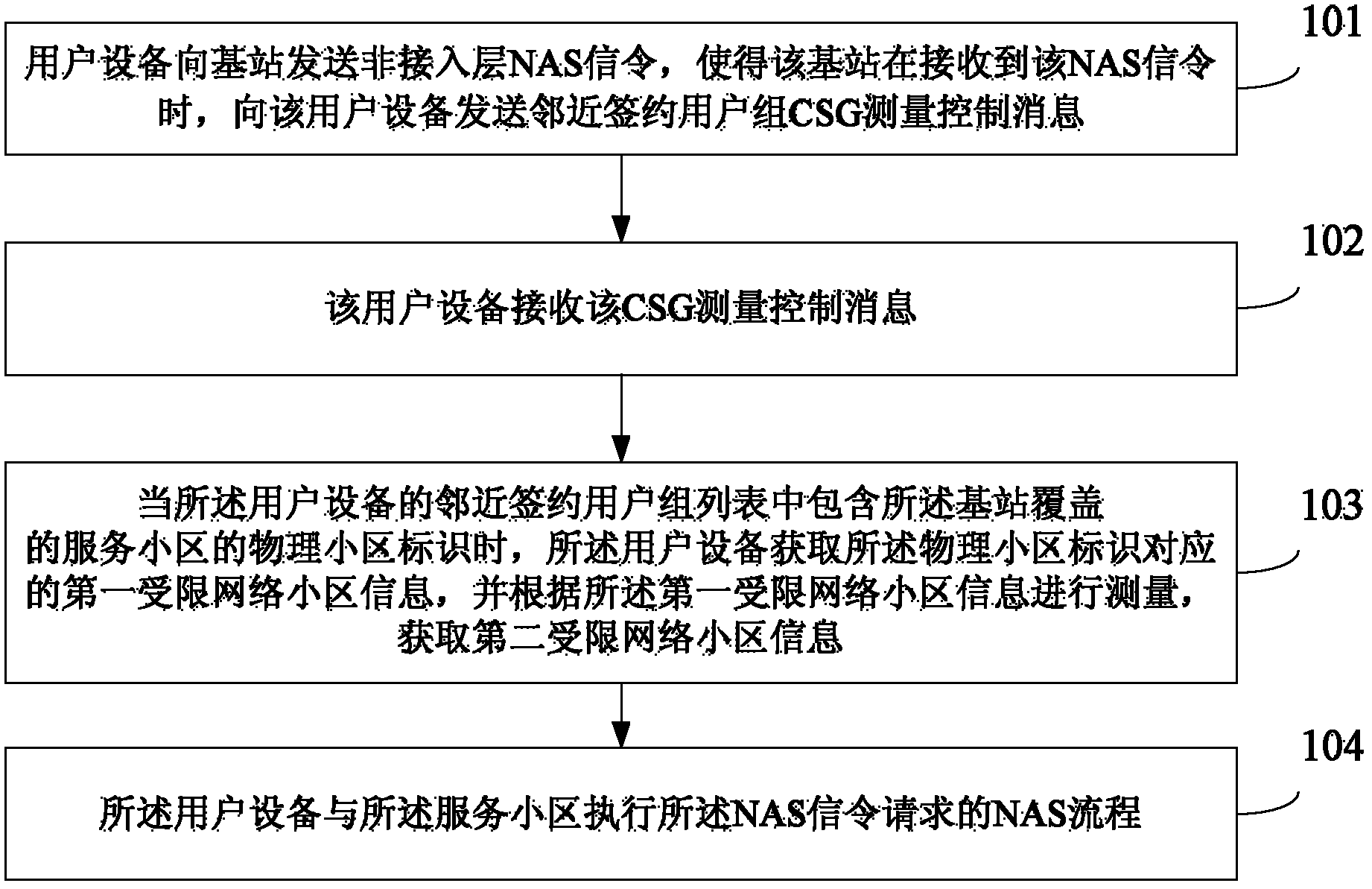

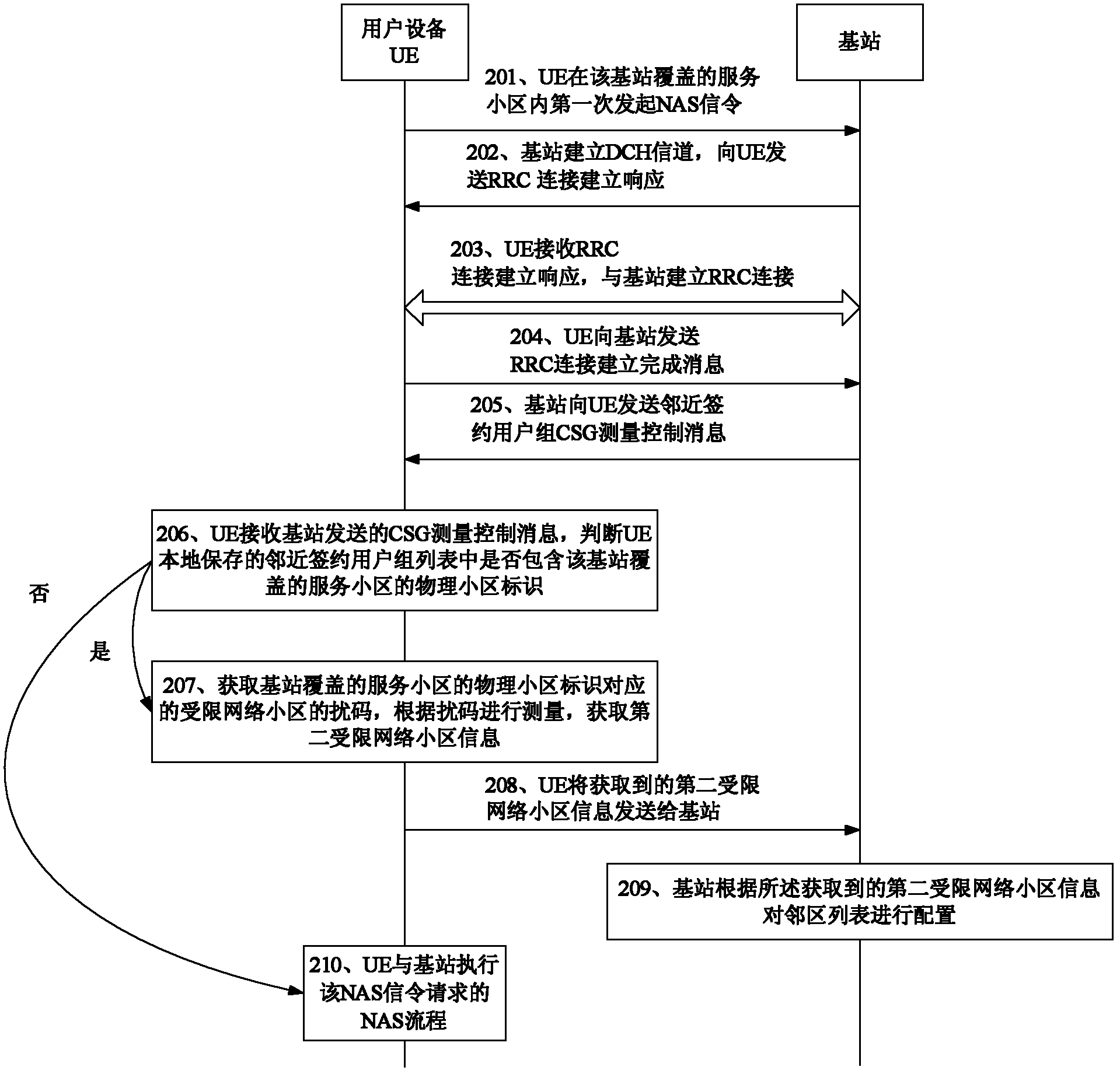

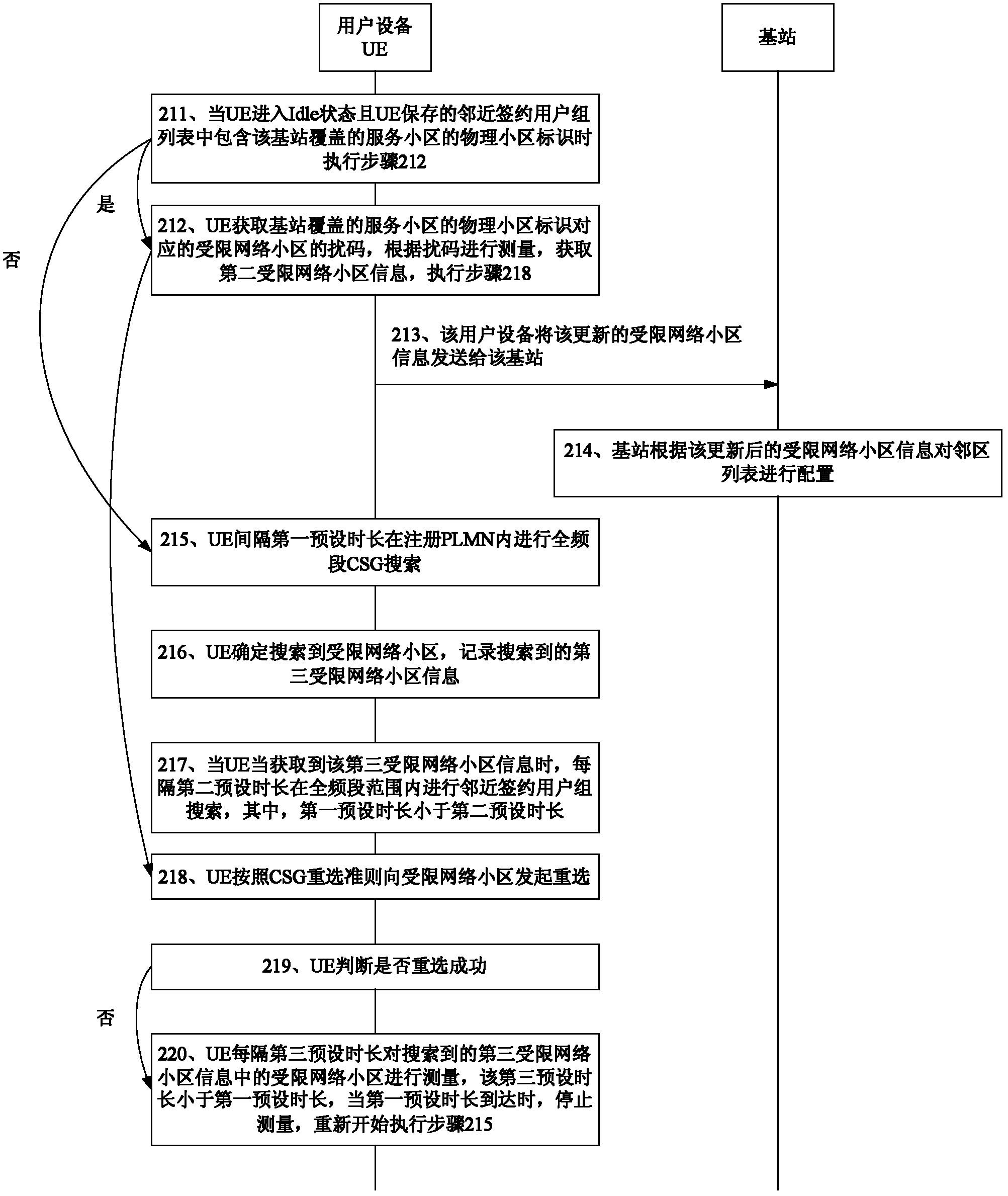

Measurement method, user device, and eNB for limited network cell

ActiveCN102696253BIncrease access rateEnsure normal communicationAssess restrictionProcedure requestedClosed subscriber groups

Owner:HUAWEI TECH CO LTD

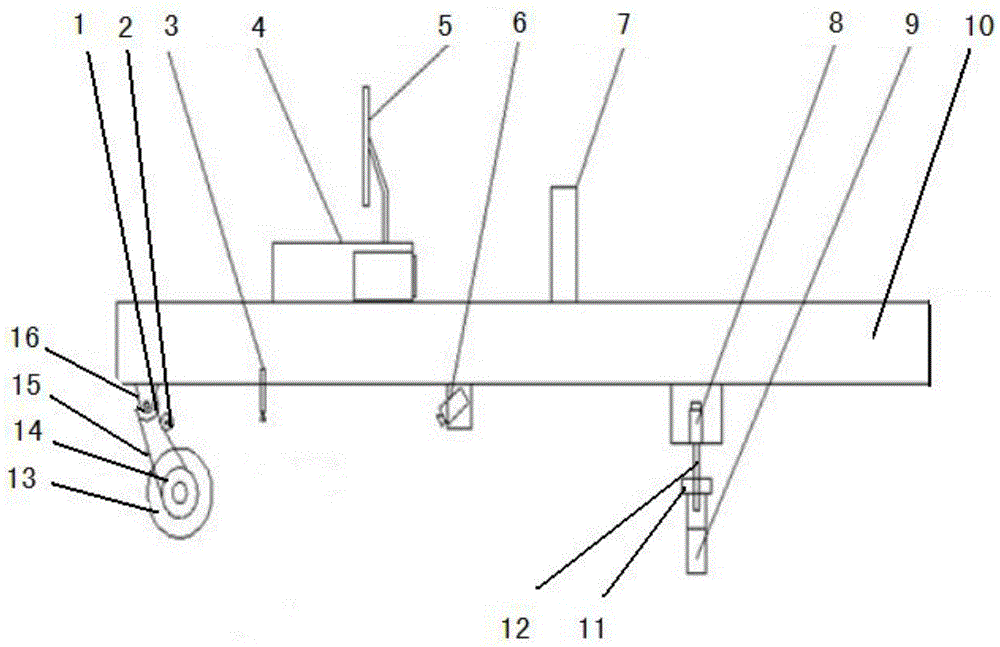

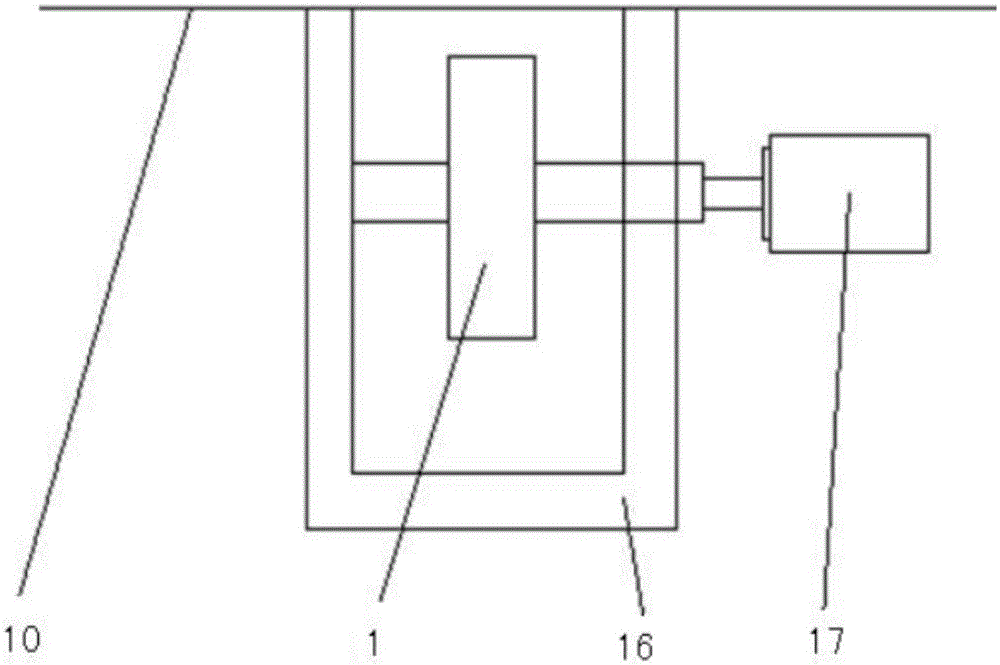

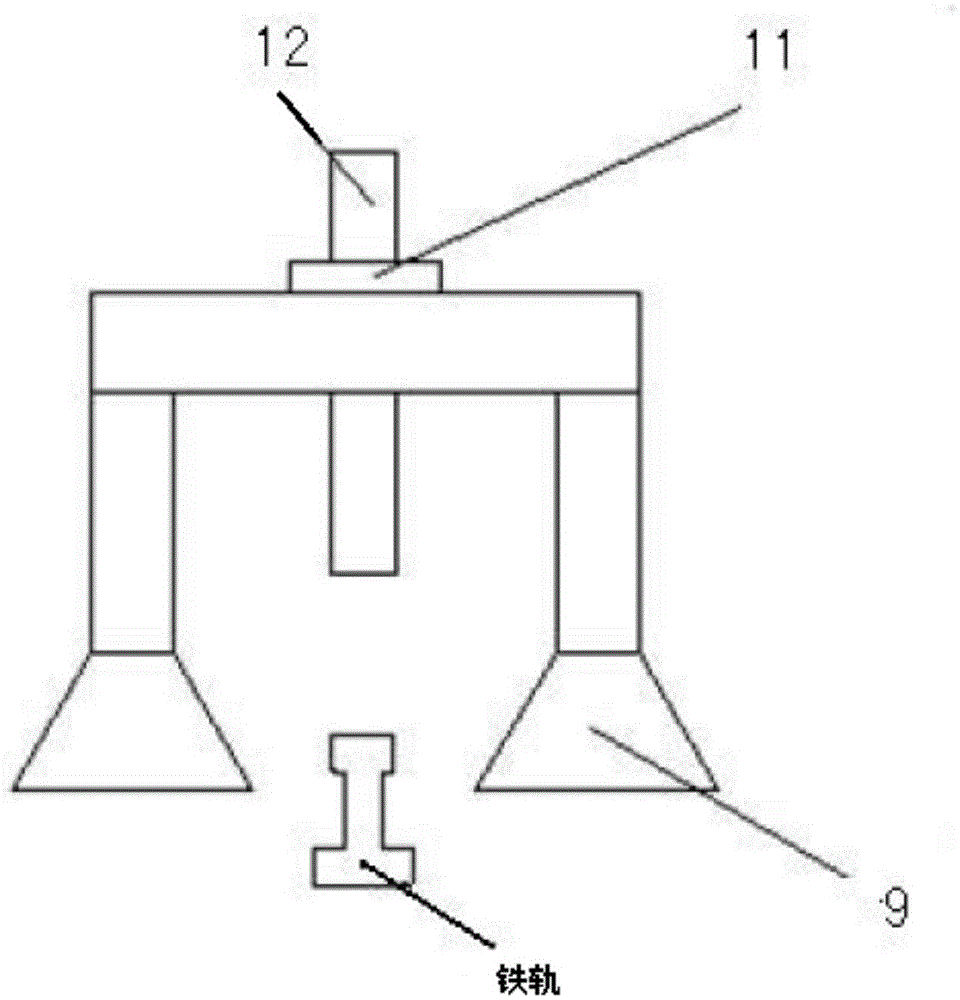

An accurate obstacle avoidance linkage control system for the dust suction port of a track road cleaning vehicle

Owner:国家电投集团远达环保装备制造有限公司

Method and arrangement for provision of security relevant services via a security module of a franking machine

ActiveUS8682801B2Improve overall utilizationGood utilization of security-related (and therewith economical) possibilityMemory loss protectionUnauthorized memory use protectionSafety firstProcedure requested

In a method and an arrangement for provision of at least one secured service via a security module of a franking machine for at least one procedure for data processing that is executed in a data processing device that can be connected with the franking machine, the procedure requests a secured first service from the security module in a request step; and the security module provides the first service in a provision step subsequent to the request step. The security module verifies an authorization to request the first service via the procedure in a verification step preceding the provision step.

Owner:FRANCOTYP POSTALIA

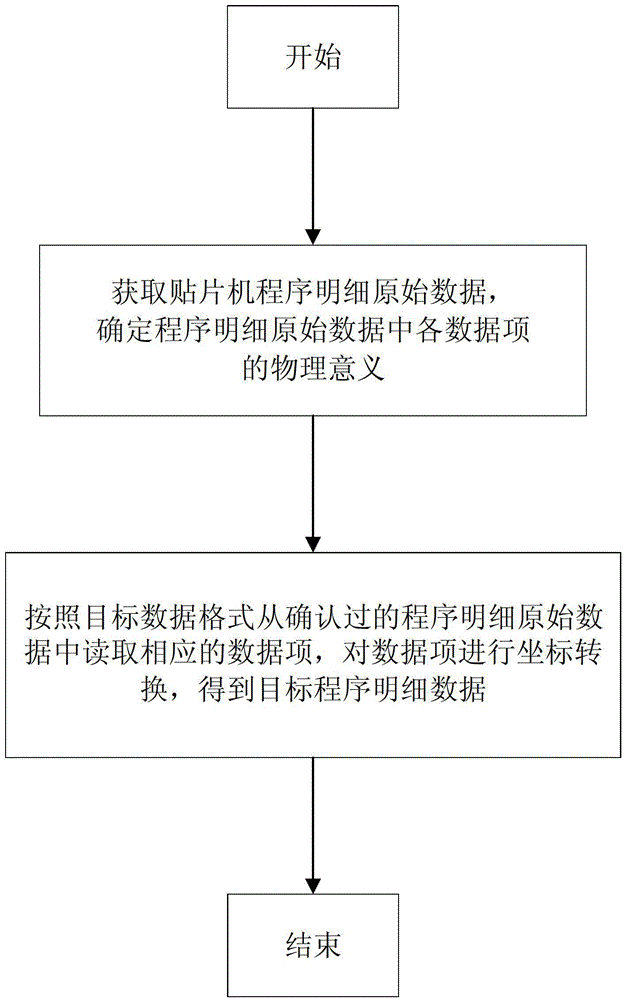

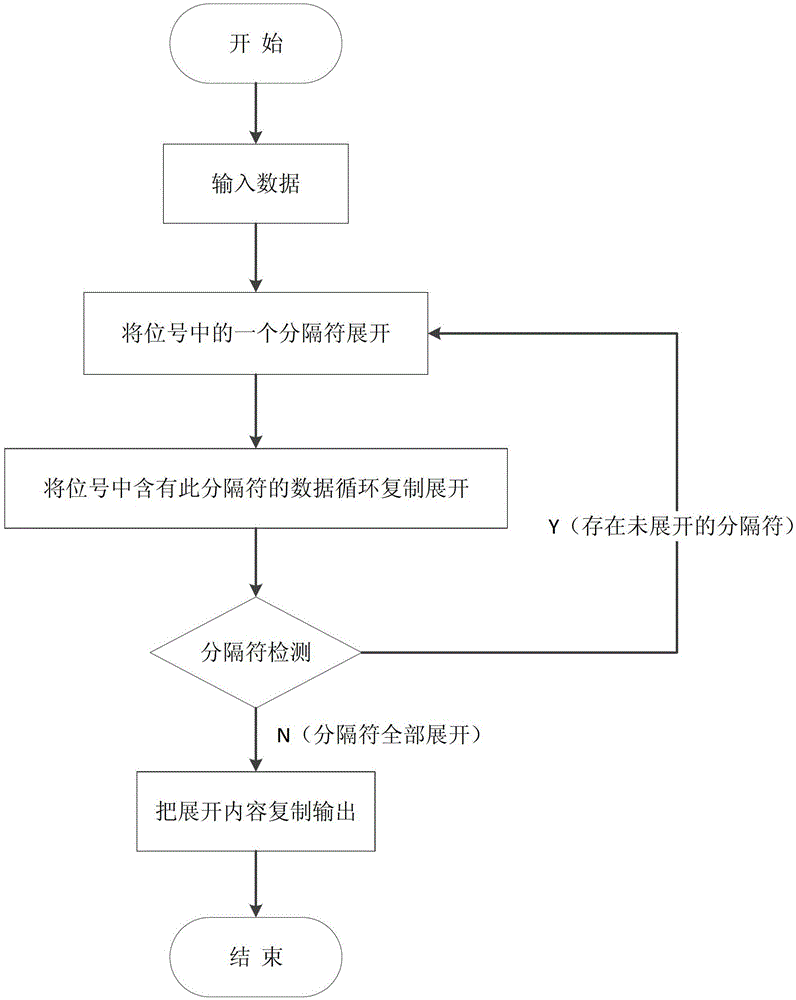

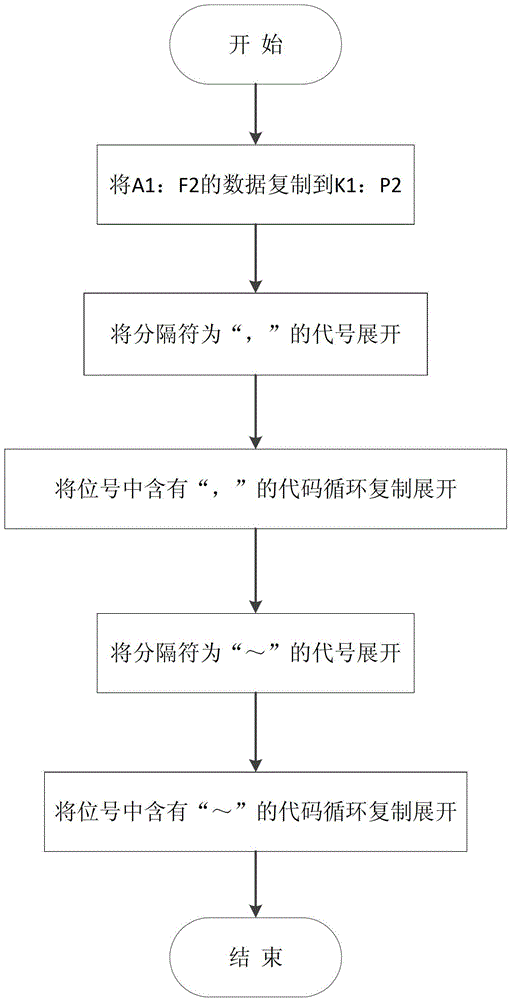

A Coordinate Transformation Method of Mounter Program

InactiveCN103377050BFully utilizeReduce preparation timeSpecific program execution arrangementsOriginal dataProcedure requested

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com