Remover composition for photoresist of semiconductor device

A technology of composition and removal agent, used in semiconductor/solid-state device manufacturing, optics, instruments, etc.

Active Publication Date: 2011-04-13

DONGJIN SEMICHEM CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

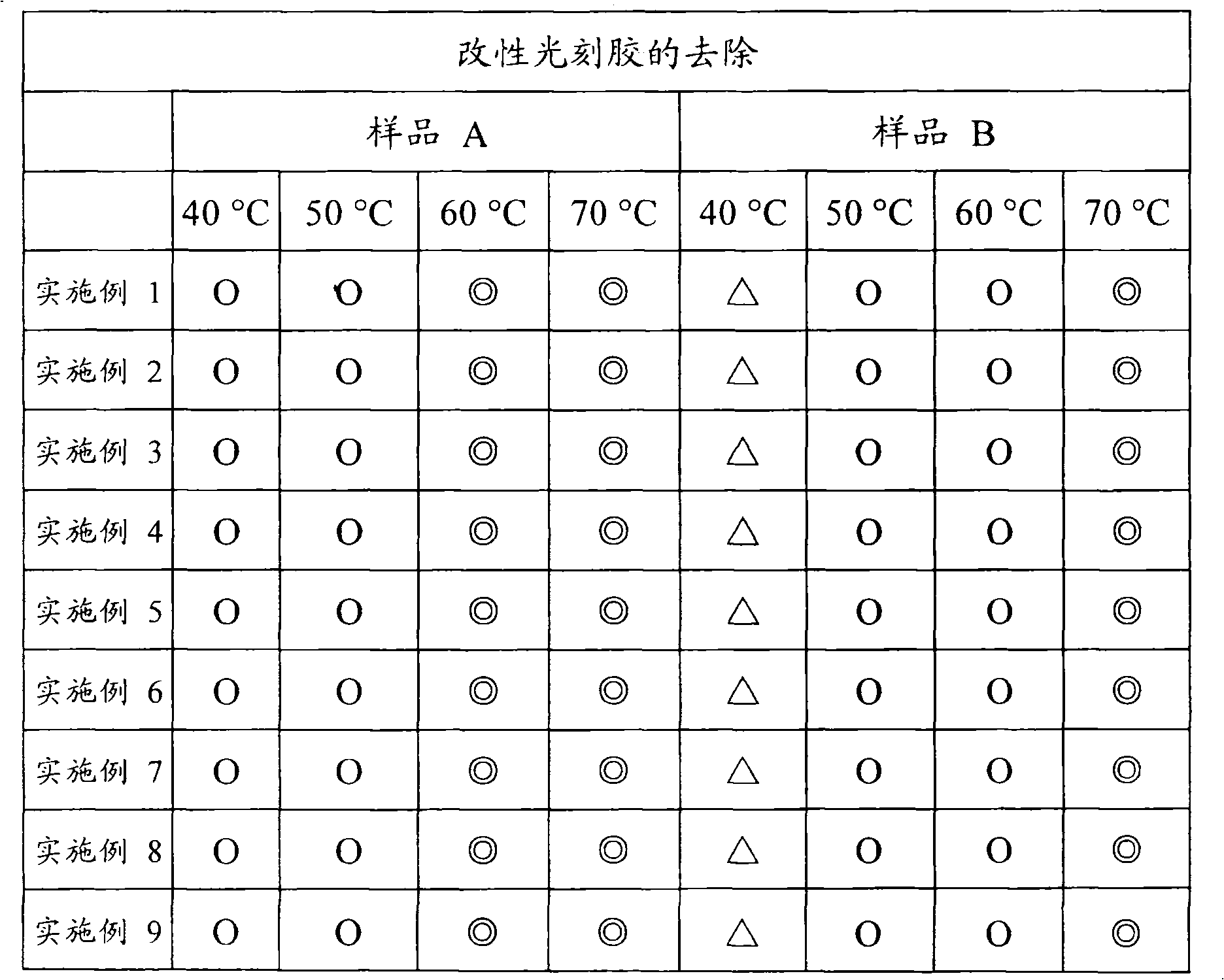

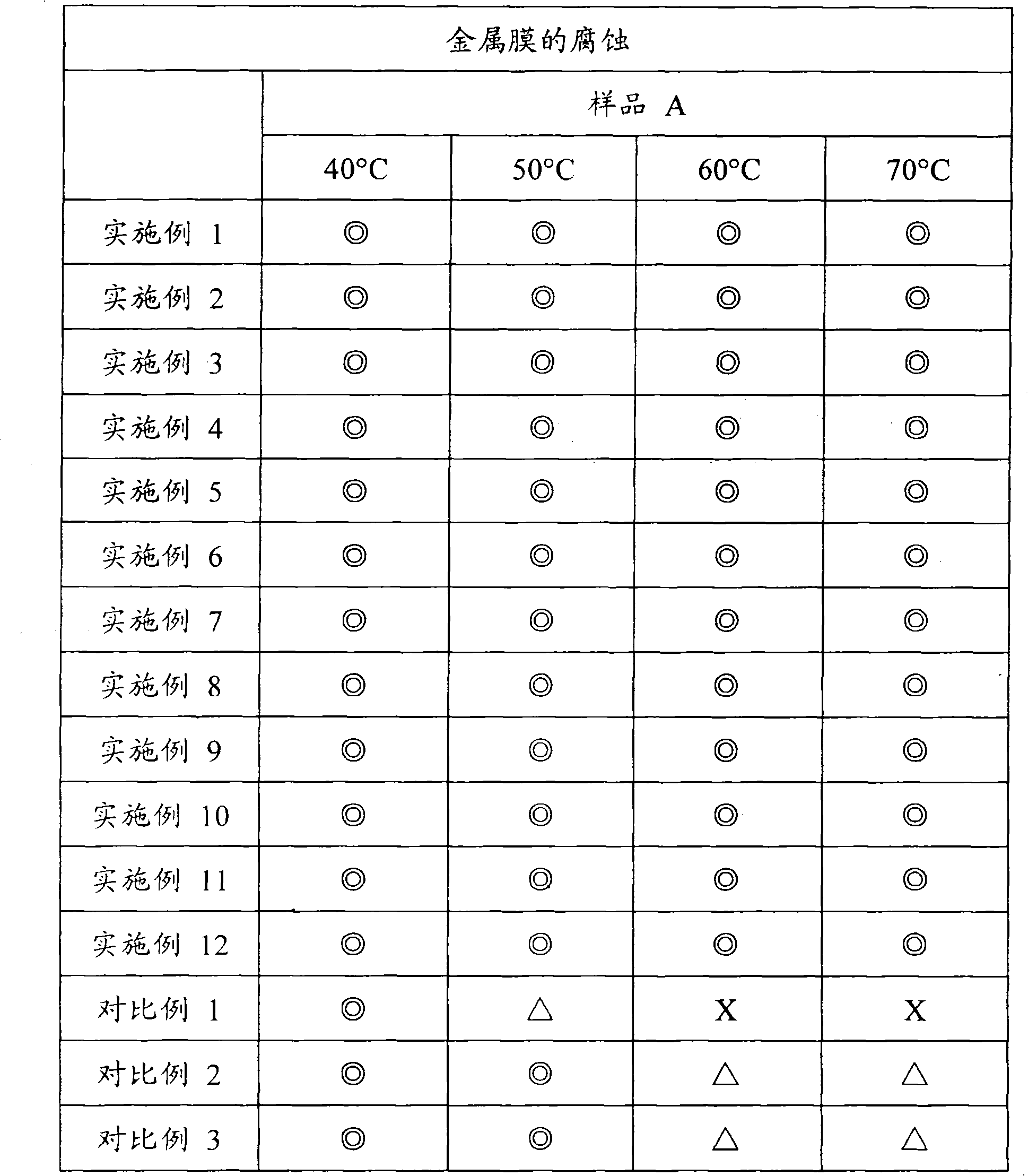

Embodiment 1~12 and comparative example 1~3

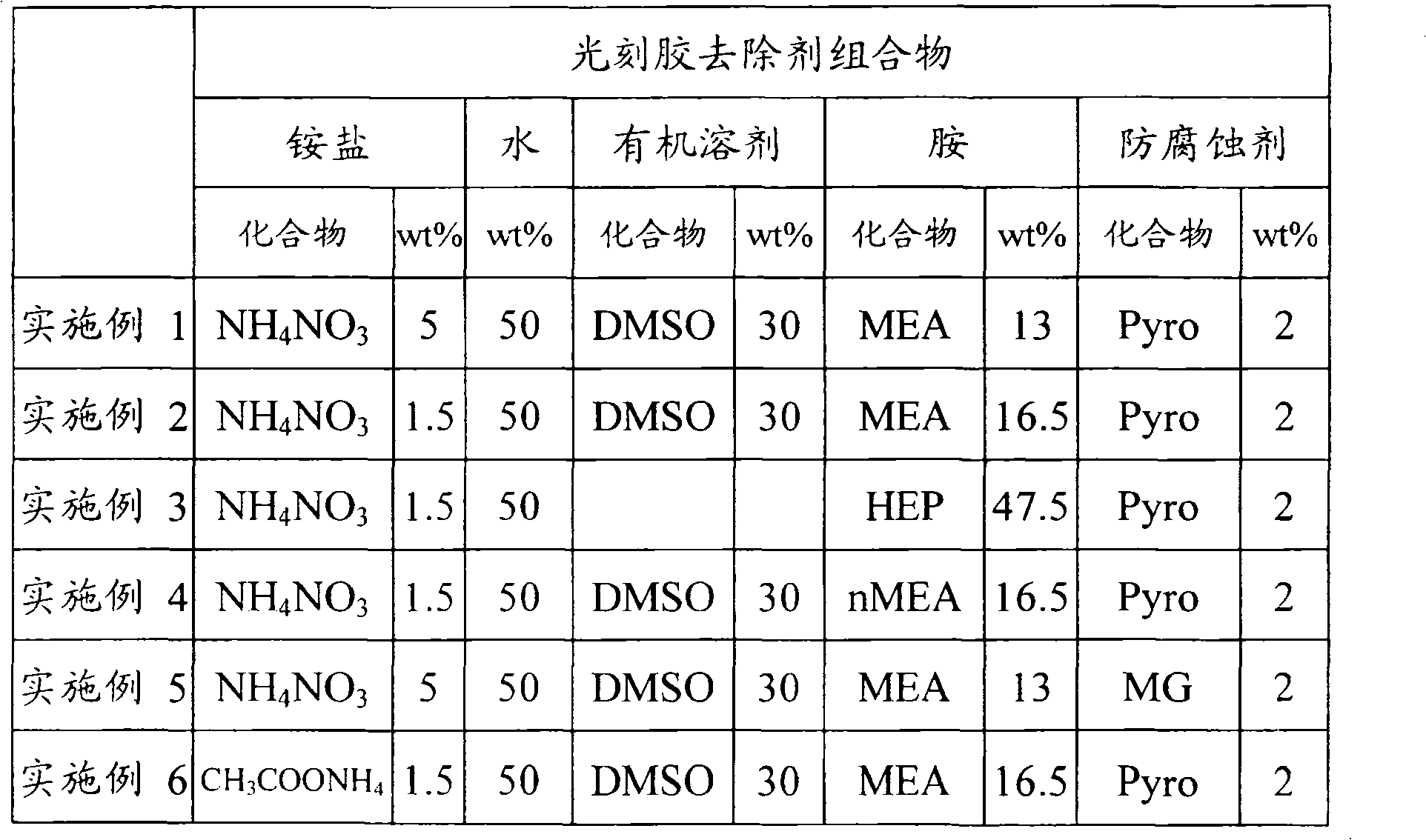

[0038] Photoresist remover compositions were prepared at the compositions and levels given in Table 1 below.

[0039] [Table 1]

[0040]

[0041] [0041]

[0042] (HEP: hydroxyethylpiperazine, Pyro: pyrocatechol, MG: methyl gallate, MEA: monoethanolamine, nMEA: N-methylethanolamine, HDA: hydroxylamine)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a photoresist remover composition used in the manufacturing process of semiconductor devices. The remover composition of the present invention, which comprises an ammonium salt, a water-soluble organic amine and water, can effectively remove the photoresist film hardened and modified by hard baking, dry etching, wet etching, ashing and / or ion implantation and the photoresist film modified by the metallic byproduct etched from the metallic film under the photoresist film in a short period time, either at high temperature or low temperature, while minimizing corrosion of the metal wiring under the photoresist film.

Description

technical field [0001] The invention relates to a photoresist remover composition for removing photoresist during the preparation of semiconductor devices such as integrated circuits (ICs), large scale integrated circuits (LSIs), very large scale integrated circuits (VLSIs) etc. . Background technique [0002] Generally, the manufacturing process of a semiconductor device includes a conductive film pattern forming step in which a photoresist pattern is formed on a conductive film existing on a surface of a semiconductor substrate, and a portion of the conductive film not covered by the photoresist is removed by etching. In the cleaning process after the patterning of the conductive film, a photoresist remover should be used to remove the photoresist pattern used as a mask during the patterning process from the conductive film. In the recent fabrication of semiconductor devices, the etching of the conductive film for patterning of the conductive film is mainly performed by d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G03F7/42

CPCG03F7/426G03F7/425H01L21/31133G03F7/42

Inventor 金柄郁尹锡壹金圣培郑宗铉

Owner DONGJIN SEMICHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com