A attemperation system of highlight weld mark-free plastic mould

A temperature control system and plastic mold technology, applied in the direction of temperature control using electric methods, can solve the problems of inability to alternately heat and cool the mold, mold temperature mismatch, inaccurate mold temperature control, etc., and achieve a large heating and cooling range , Good product performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

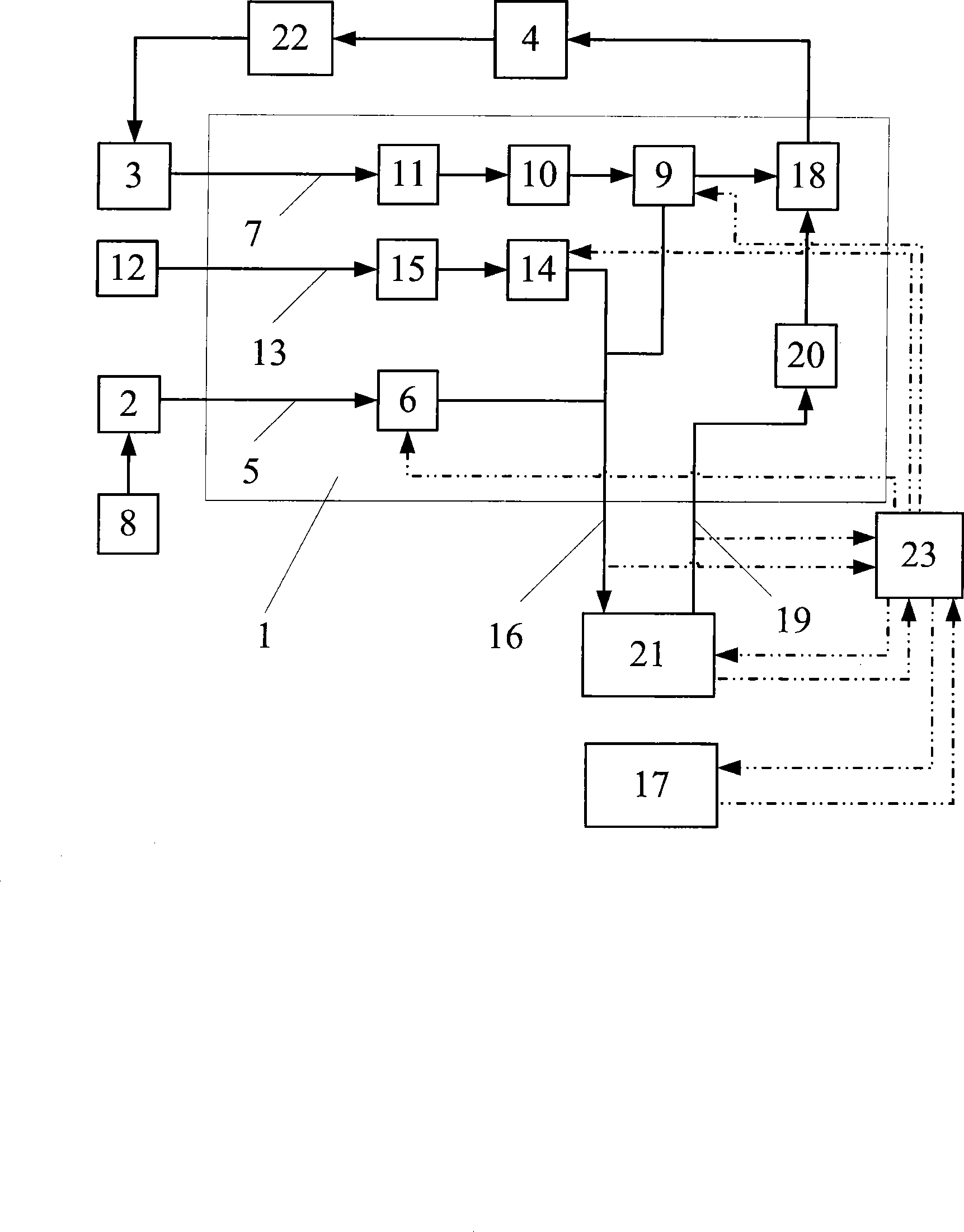

[0020] As shown in the accompanying drawings (the solid line with the arrow in the accompanying drawing is the pipeline, and the dotted line with the arrow is the control signal), the temperature control system of the present invention mainly includes a temperature controller 1, a heating boiler 2, a cooling tower 3, Water tank 4 , air compressor 12 and control unit 23 . The temperature controller 1 is provided with a steam pipeline 5 , a cooling water pipeline 7 , a compressed air pipeline 13 , a mixer 18 , a mold ejection pipeline 19 and a mold inlet pipeline 16 . The mold ejection pipeline 19 and the cooling water pipeline 7 are all connected with the inlet of the mixer 18, and the outlet of the mixer 18 is connected with the water tank 4. The steam pipeline 5 , the cooling water pipeline 7 and the compressed air pipeline 13 are all connected with the mold feeding pipeline 16 . A steam control valve 6 is connected to the steam pipeline 5 . A cooling water control valve 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com