Apparatus for precisely controlling wire distribution distance

A technology of precise control and wiring, applied in microstructure devices, piezoelectric/electrostrictive/magnetostrictive devices, membrane technology, etc., can solve the problems of high production cost, high wiring cost, and cost increase, and achieve low cost , Easy to operate, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

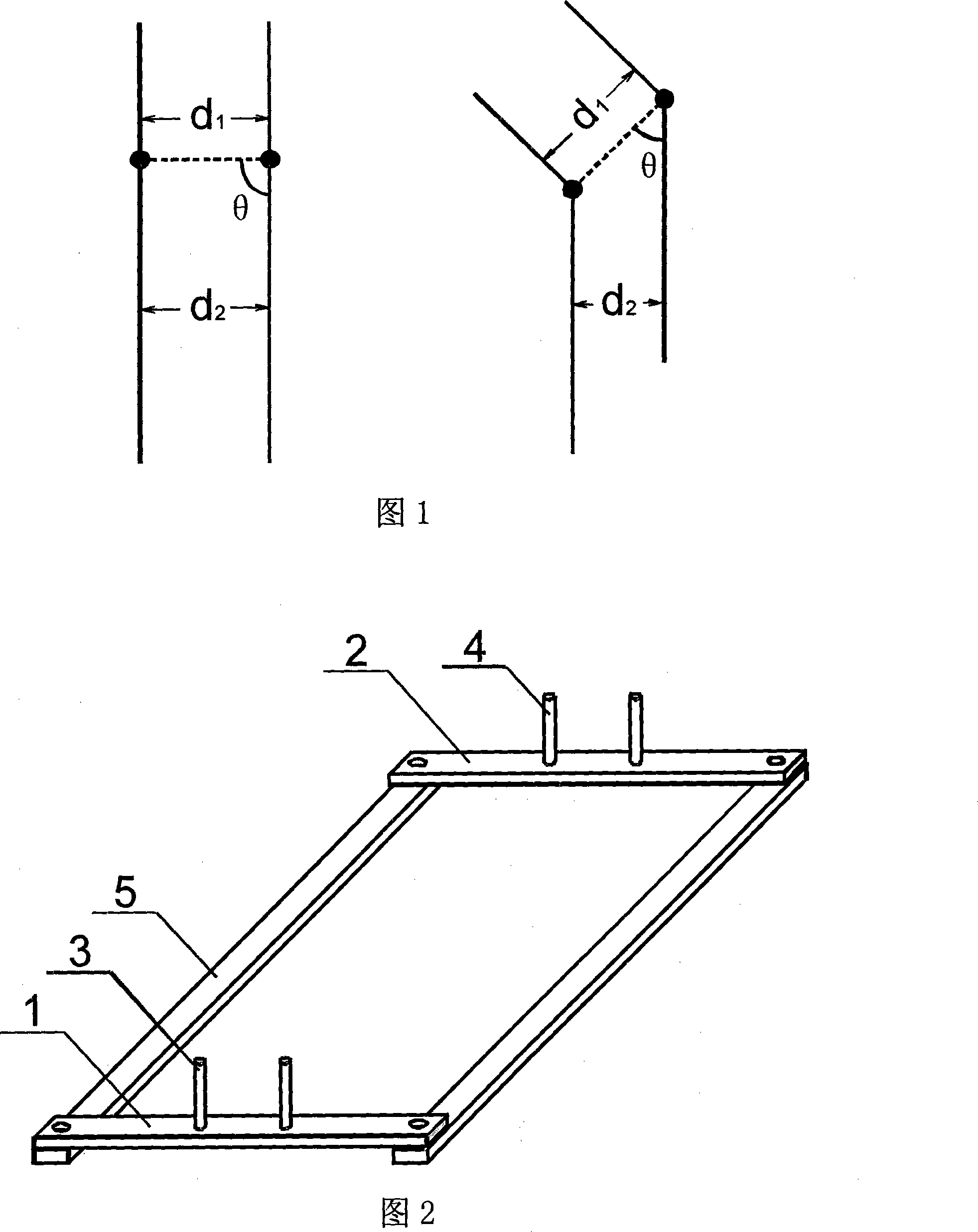

[0030] As shown in Figure 2: the device is a two-line spacing control device, consisting of two strip-shaped wiring pillows (wiring pillow A 1 and wiring pillow B 2) and two straight rods 5 to form a parallelogram frame, each wiring pillow is respectively The wiring comb (wiring comb A 3 and wiring comb B 4) is composed of two cylinders, and the distance between the cylinders of each wiring comb is equal. This device enables high-precision control of the spacing between two parallel lines. In the microscopic observation environment, the minimum distance between two lines can be controlled at the submicron level.

Embodiment 2

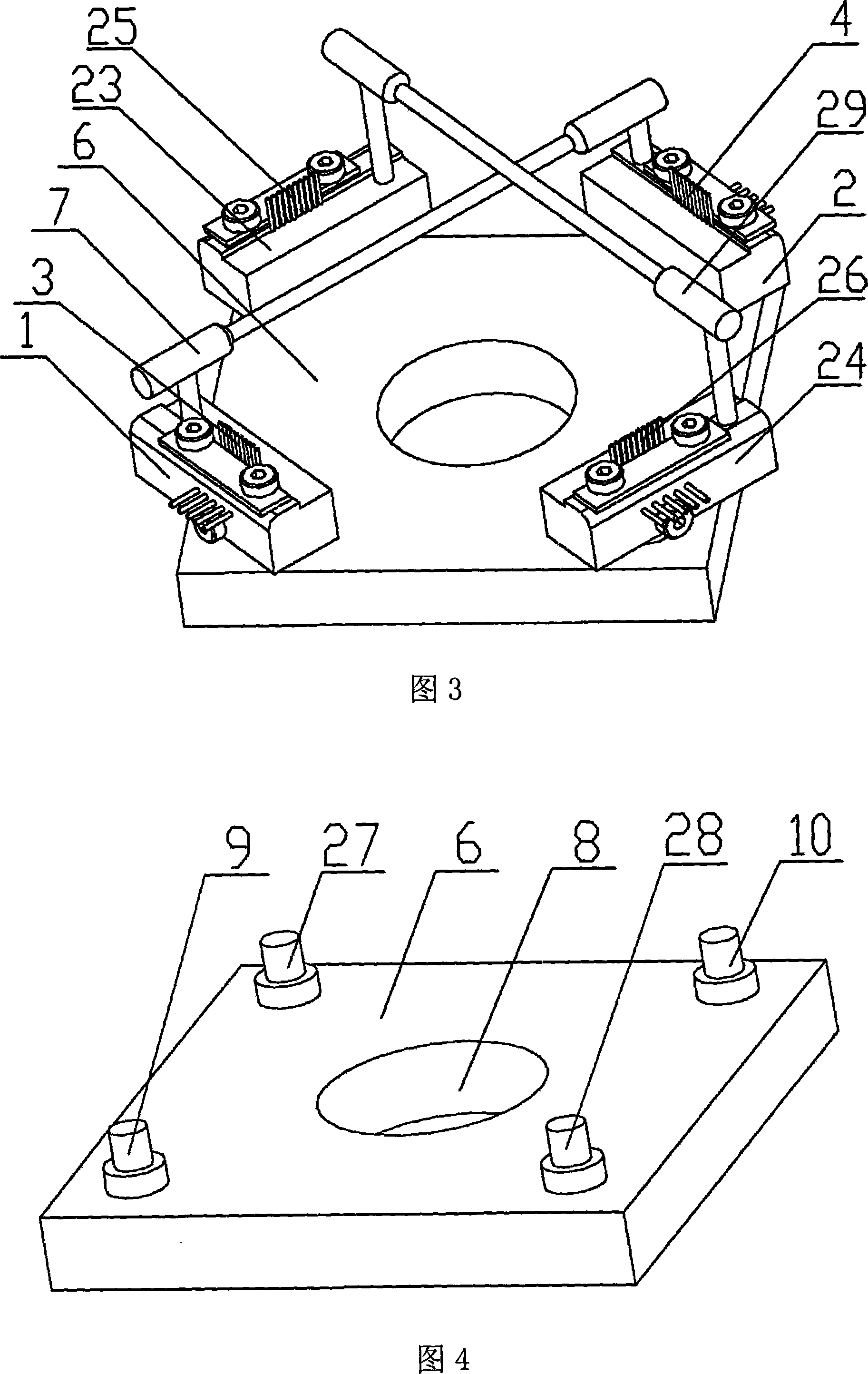

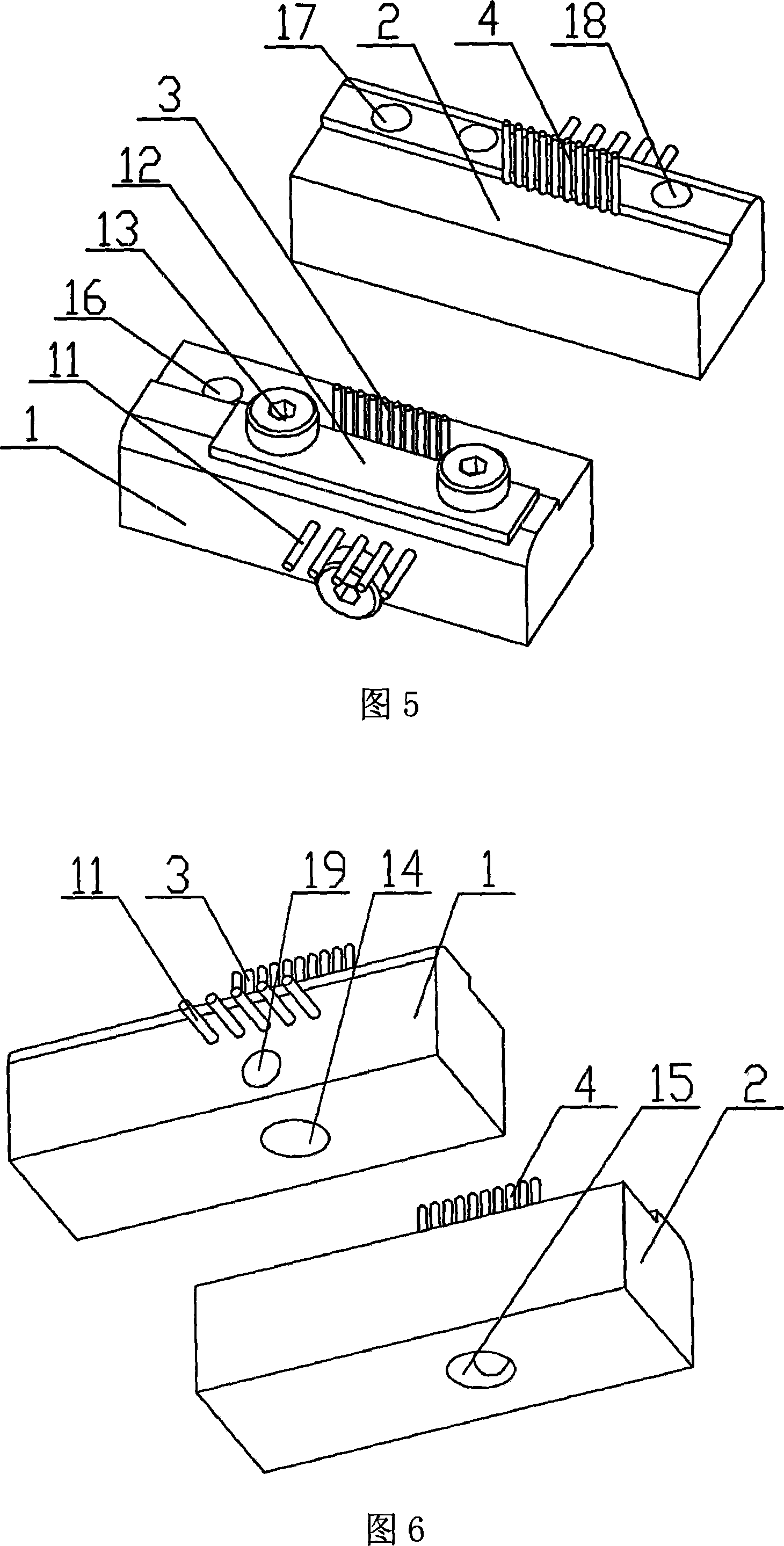

[0032] As shown in Figures 3 to 9: the device is an orthogonal wiring spacing control device, which consists of two pairs of opposing wiring pillows (wiring pillow A 1 and wiring pillow B 2, wiring pillow C 23 and wiring pillow D 24), two Composition of wiring combs (wiring comb A 3 and wiring comb B 4, wiring comb C 25 and wiring comb D 26), base 6, connecting rod (connecting rod 7 and second connecting rod 29), and form two parallelogram frames . Base 6 is equipped with operating hole 8 and two pairs of rotating shafts (rotating shaft first 9 and rotating shaft second 10, rotating shaft third 27 and rotating shaft D 28). The operation hole 8 is located at the center of the base 6, and the two connecting lines between the two pairs of rotating shafts are orthogonal to each other. The wiring comb is composed of ten cylinders with a diameter of 0.63 mm and a center distance of 1 mm. Each wiring comb is fixed on the top of the corresponding wiring pillow.

[0033] One group of...

Embodiment 3

[0037] As shown in Figures 10 to 12: the device is a wiring array spacing control device with variable wiring length, consisting of wiring pillows (wiring pillow A 1 and wiring pillow B 2), wiring combs (wiring comb A 3 and wiring comb B 4 ), straight bar 5, connecting rod 20, slide block 21 and wiring board 22 constitute. The wiring pillow is strip-shaped, and two straight bars 5, a connecting rod 20 and the wiring pillow B 2 form a parallelogram frame. A slide block 21 is provided on the straight bar 5 and can slide freely along the straight bar 5. The two slide blocks 21 are movably connected with the wiring pillow armor 1, and the two wiring pillows are parallel to each other. The two wiring combs are composed of ten wiring posts arranged at equal intervals. There are small holes on the wiring pillow to fix the wiring combs. The wiring board 22 runs through the wiring combs.

[0038] When wiring, the effective length of the wiring can be adjusted by sliding the slider, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com