Hollow hammer hole bottom strong suction apparatus

The technology of a suction device and a down-the-hole hammer is applied in percussion drilling, reciprocating drilling rigs, drilling equipment and methods, etc., and can solve problems such as loss of drilled ore samples with reduced diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

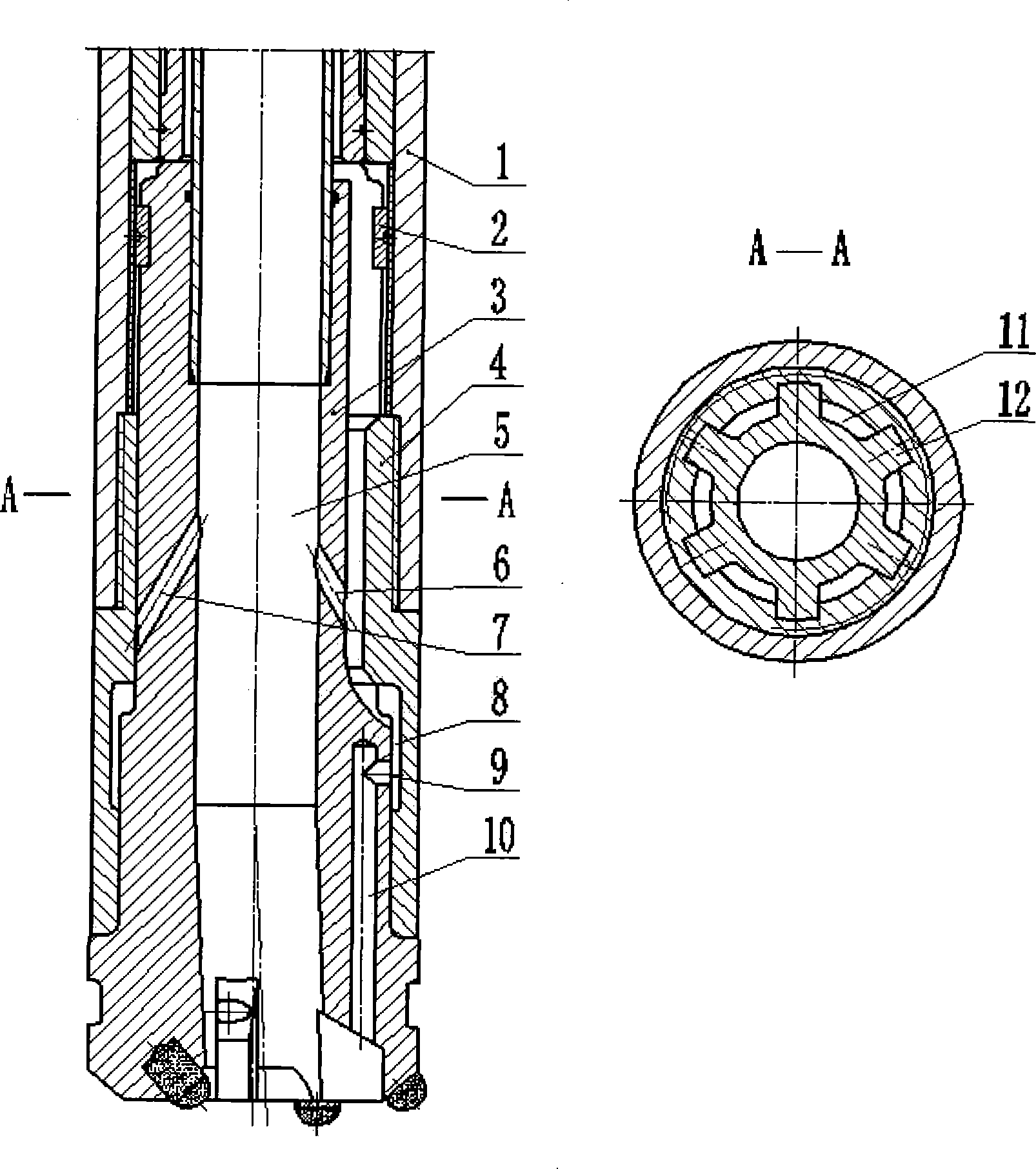

[0013] Below in conjunction with accompanying drawing and example, the present invention is described in further detail:

[0014] The outer cylinder 1 of the down-the-hole hammer is connected with the lower joint 4 through a screw, the inner wall of the lower part of the lower joint 4 is provided with a ring groove 8, the lower section of the reverse circulation drill bit 3 is provided with a meridian hole 9 and communicates with the bottom nozzle hole 10, and the middle part of the reverse circulation drill bit 3 is provided with a radial hole 9. There are drill spline grooves 11 and drill splines 12. There are more than 2 normally open inner spray holes 6 at the bottom of the drill bit spline groove 11, and more than 2 spare inner spray holes 7 are arranged on the top of the drill bit spline 12. The hole 6 and the spare inner spray hole 7 communicate with the central channel 5 .

[0015] The angle between the axis of the normally open inner spray hole 6 and the axis of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com