Plate heat exchanger composite corrugated plate bind

A plate heat exchanger and corrugated plate technology, applied in the field of large-channel composite corrugated plates, can solve the problems of poor heat transfer performance, high flow resistance, and unsatisfactory stiffness, etc., achieve low flow resistance, reduce flow resistance, and be easy to process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

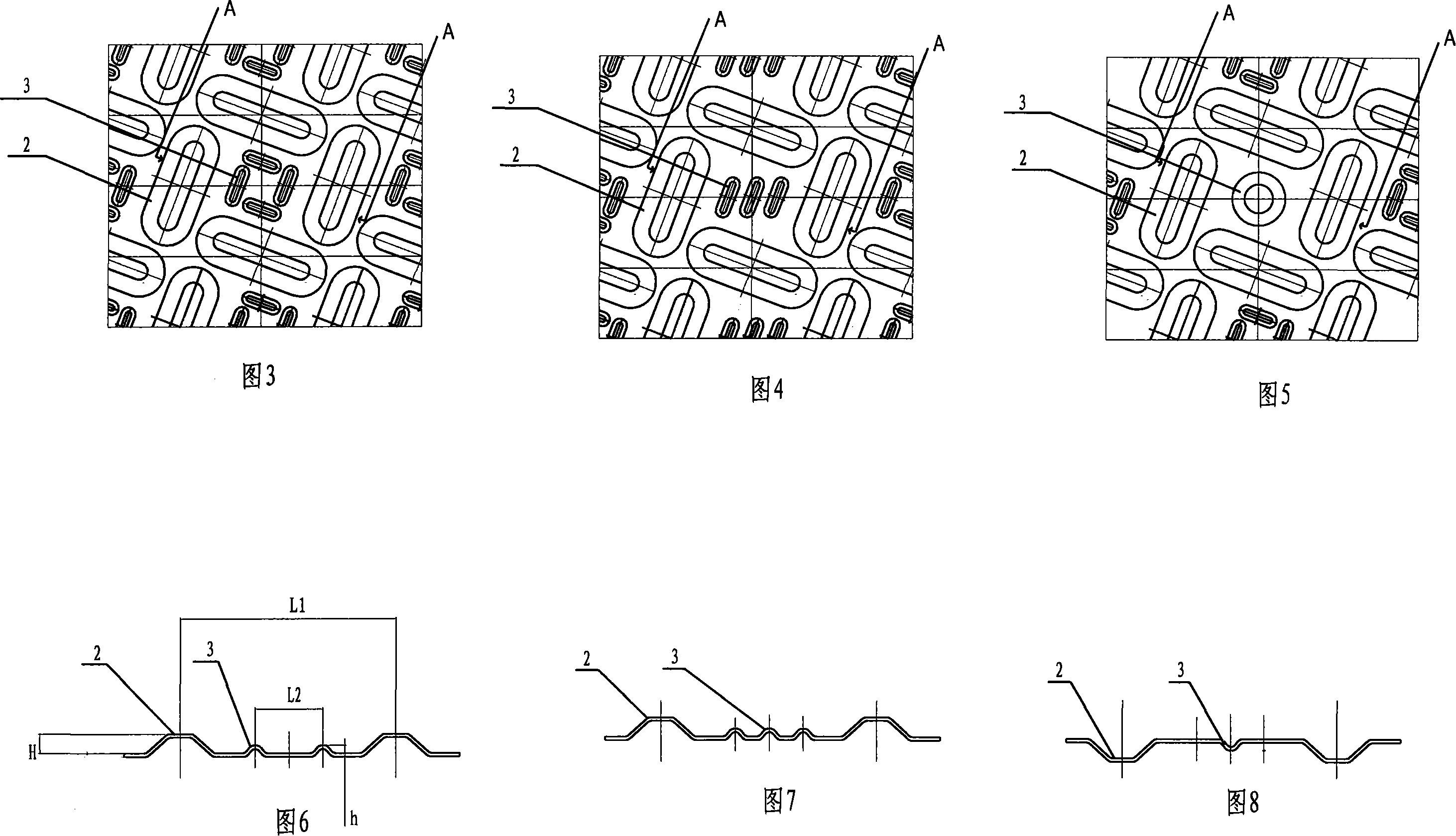

[0017] The specific technical solution of the present invention is: it punches two inner and outer layers of corrugations with different heights and shapes on the flat plate, and the outer corrugations have higher wave height and larger wave distance. The convex ribs of the peripheral corrugation also serve as the supporting function between the plates. The wave height of the inner corrugation is small, which mainly plays the role of disturbing the flow and improving the heat transfer.

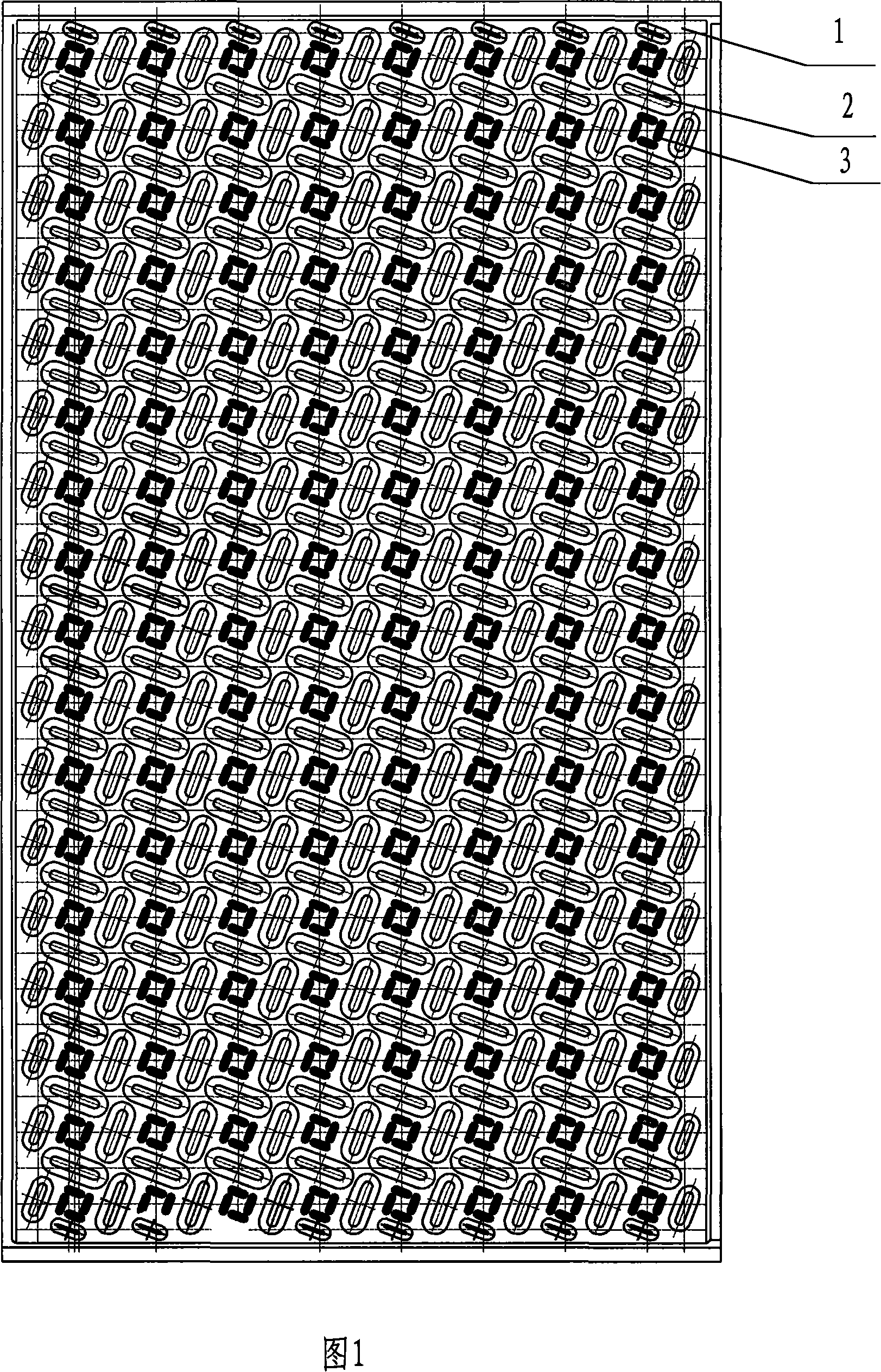

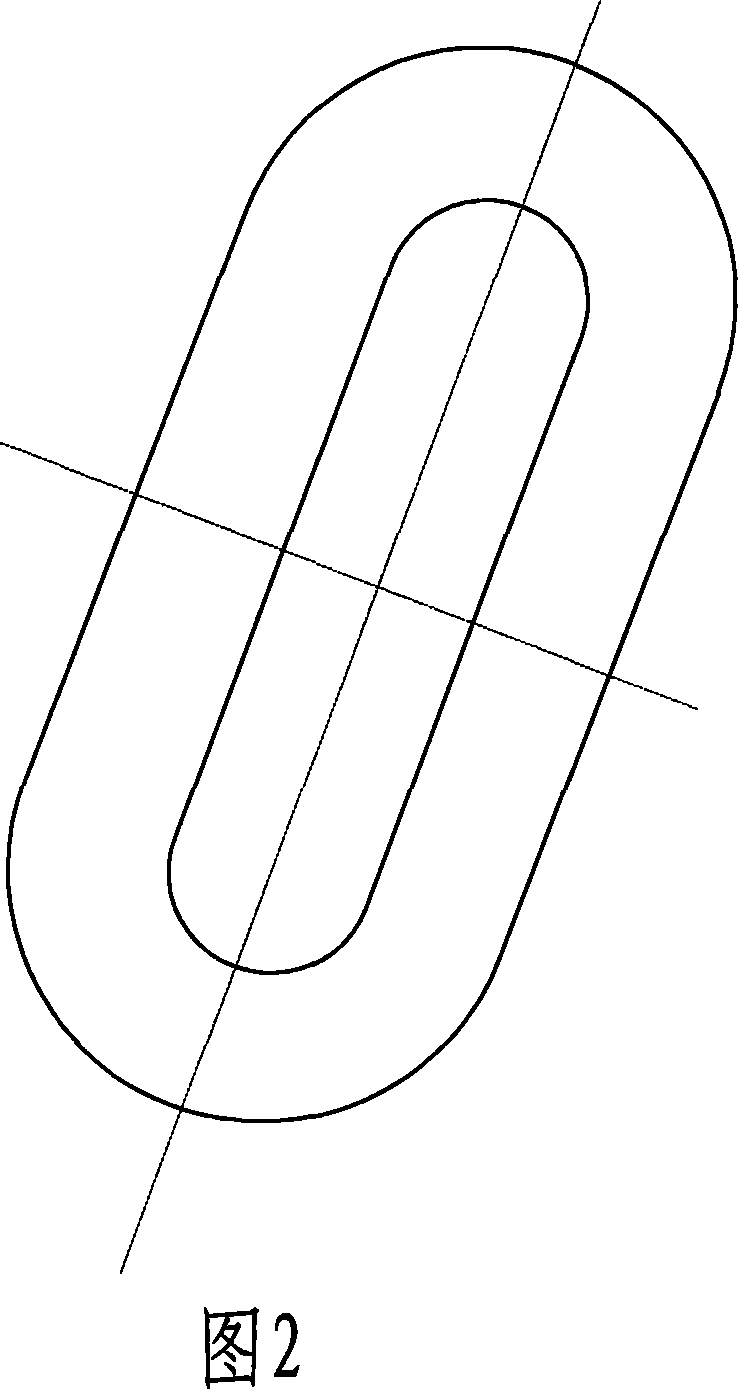

[0018] The plane of many rectangular composite corrugations punched into a matrix on a flat plate is shown in Figure 1; the composite corrugations are composed of two inner and outer layers of corrugations 2,3. The waveform of the outer single wave 2 is shown in Figure 2. The corrugations 2 are arranged in pairs, and the longitudinal axes of the two pairs of corrugations 2 form a rectangle. Horizontal corrugations arranged in a rectangle are raised, vertical corrugations are recessed, or vic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com