Fiber highly cool to touch

It is an excellent technology with cold feeling on contact. It is used in the field of grey fabrics, clothing materials and undershirts, and can solve problems such as bad hand feel or skin touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

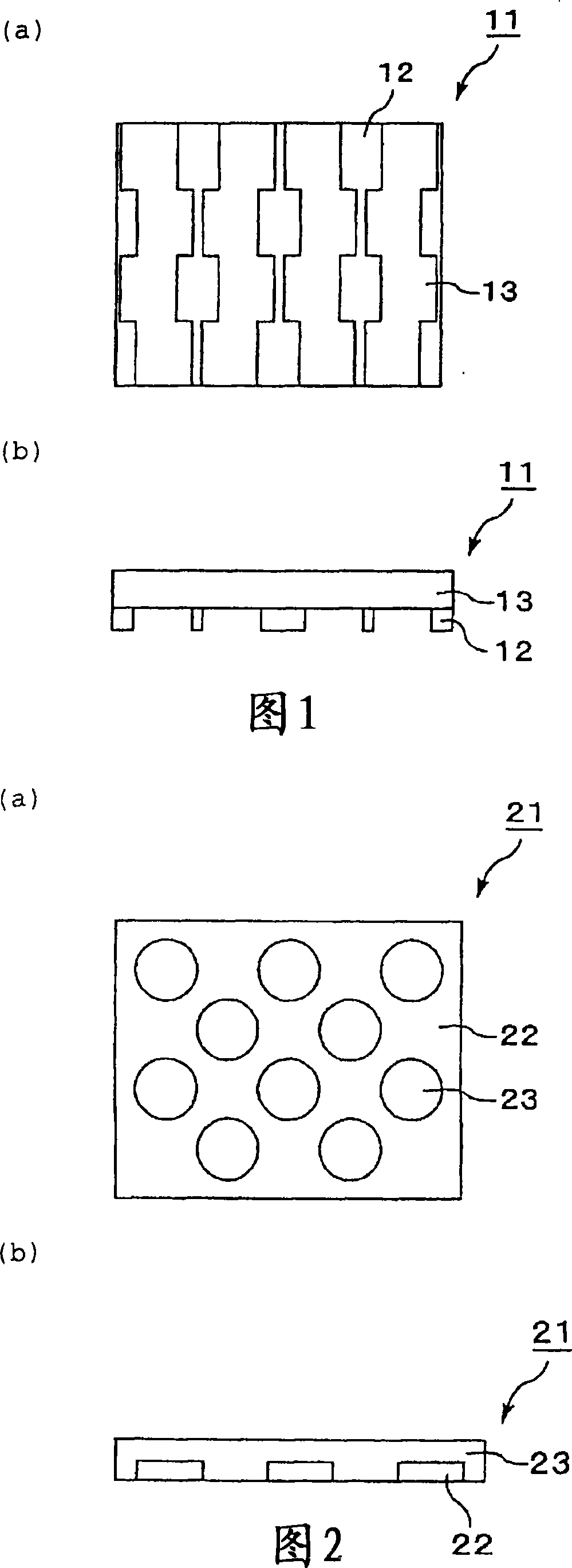

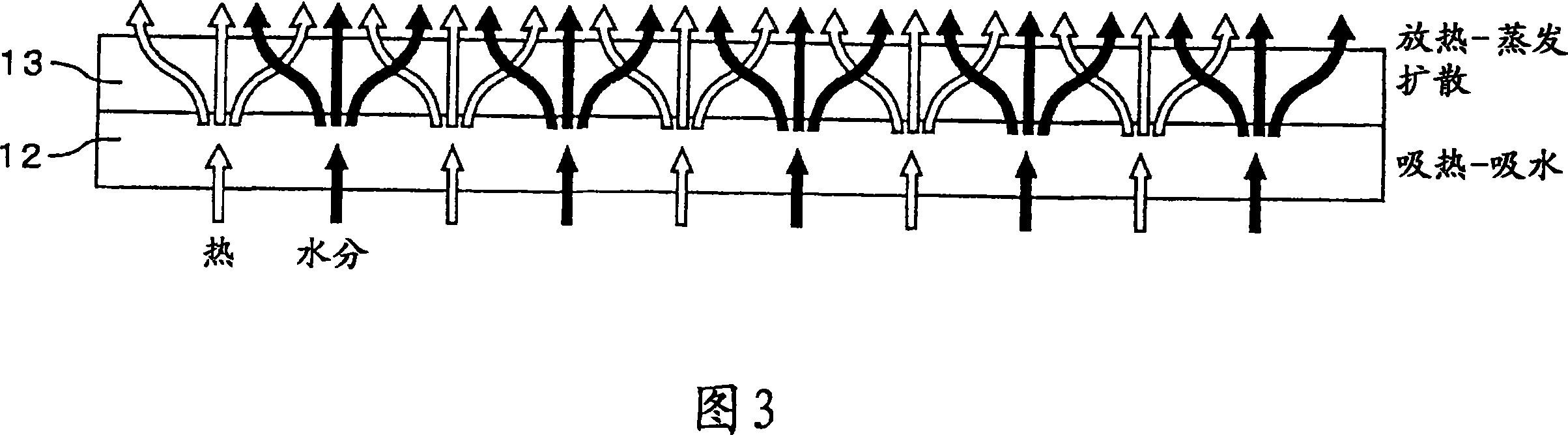

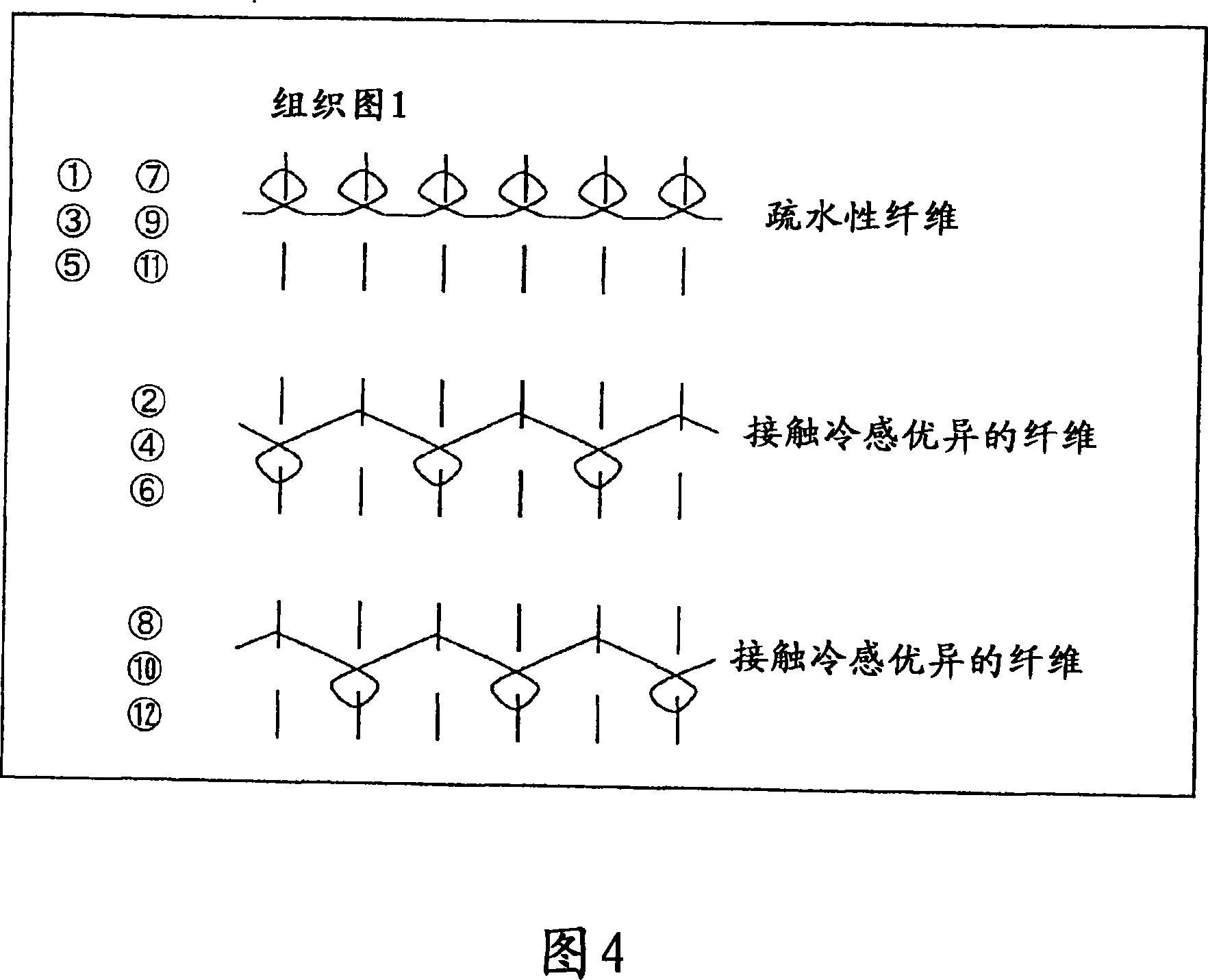

Image

Examples

Embodiment 1

[0118] With respect to 98% by weight of a polyether block amide copolymer (manufactured by Arkema, "Pebax 1041SA01") which is a thermoplastic polyamide-based elastomer, titanium oxide (manufactured by Sakai Chemical Industry Co., Ltd., "D918") was added, with an average particle diameter of 0.26 μm ) after 2% by weight, melt-mixing, and using a pelletizer to obtain resin pellets.

[0119]Next, the obtained resin pellets were spun by a melt spinning method to obtain a raw yarn. Gray cloth is produced by weaving using the obtained raw yarn.

Embodiment 2

[0121] In addition to making the addition amount of polyether block amide copolymer (manufactured by Arkema, "Pebax 1041SA01") 96% by weight, the addition amount of titanium oxide (manufactured by Sakai Chemical Industry Co., Ltd., "D918", average particle diameter 0.26 μm) was Gray fabrics were obtained in the same manner as in Example 1 except for 4% by weight.

Embodiment 3

[0123] Except that the addition amount of polyether block amide copolymer (manufactured by Arkema, "Pebax1041SA01") was 94% by weight, the addition amount of titanium oxide (manufactured by Sakai Chemical Industry Co., Ltd., "D918", average particle diameter 0.26 μm) was 6 Gray fabrics were obtained in the same manner as in Example 1 except for weight %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com