Heat conductive electrical-insulation polymeric material and heat-dissipating substrate including same

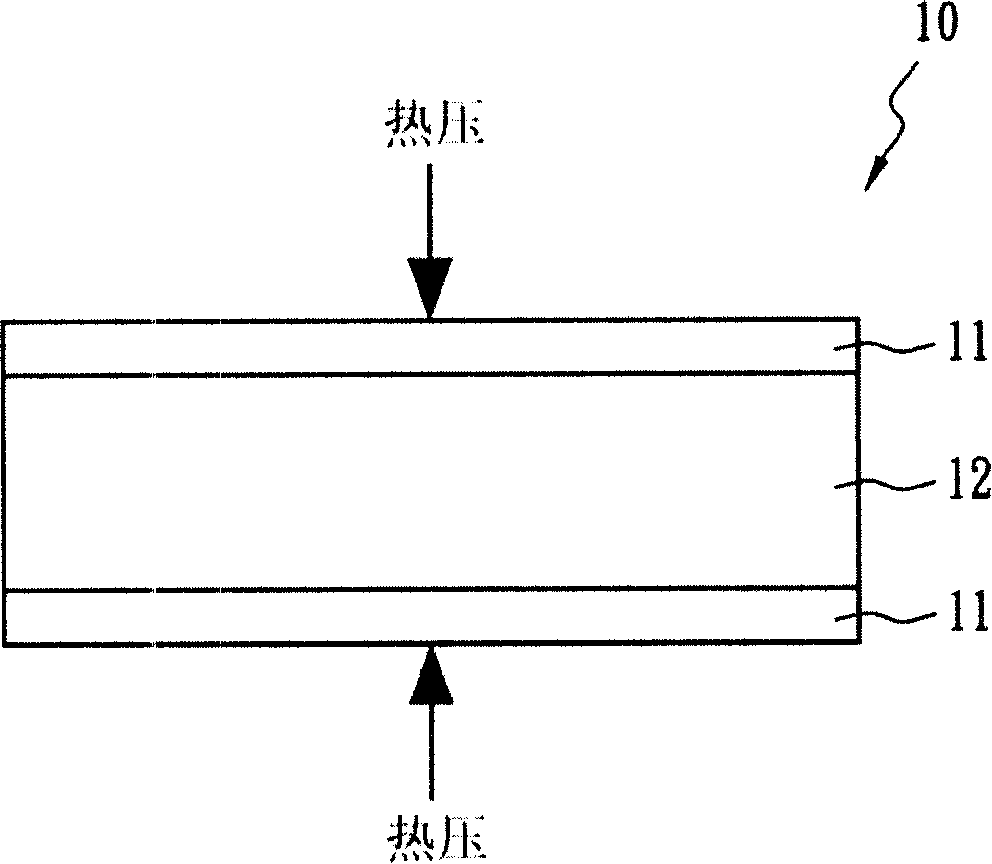

A technology of polymer materials and heat-dissipating substrates, applied in layered products, chemical instruments and methods, cooling/ventilation/heating transformation, etc., can solve problems affecting heat dissipation efficiency of heat-dissipating substrates 10, uneven distribution of conductive fillers, and difficult storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

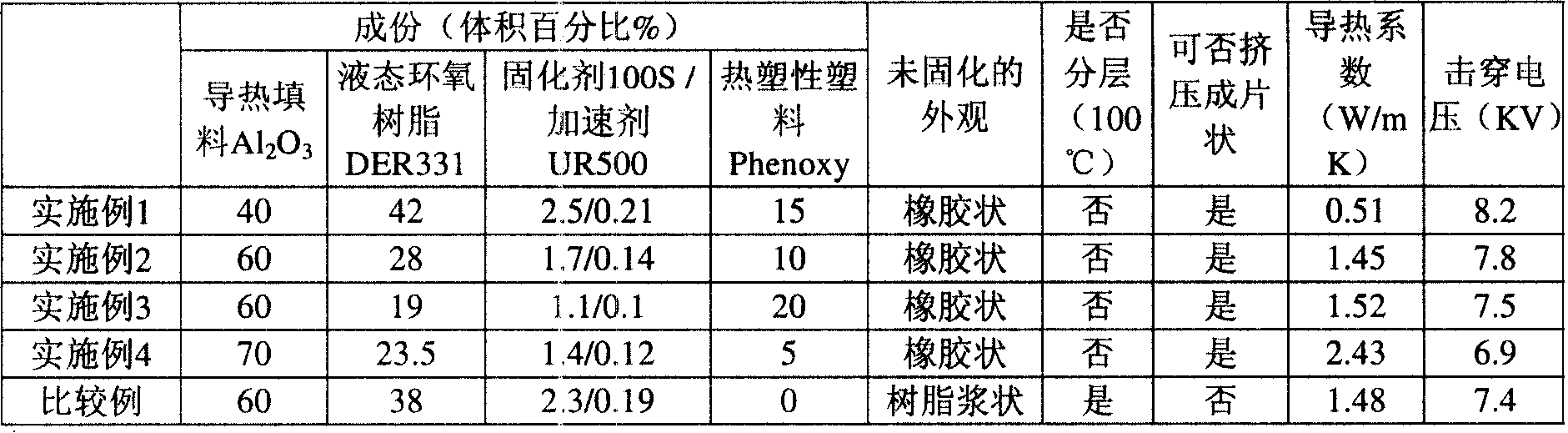

[0011] The thermally conductive and electrically insulating polymer material of the present invention comprises a polymer component with an interpenetrating network structure, a curing agent and a thermally conductive filler. The polymer component includes thermoplastic and thermosetting epoxy resin, and the thermosetting epoxy resin accounts for 10% to 75% of the polymer component in terms of volume percentage. The curing agent is used to cure the thermosetting epoxy resin at a curing temperature. The thermally conductive filler is evenly dispersed in the polymer component, and accounts for 40% to 70% of the thermally conductive and electrically insulating polymer material in volume percentage. Wherein the thermal conductivity of the thermally conductive and electrically insulating polymer material is greater than 0.5W / mK.

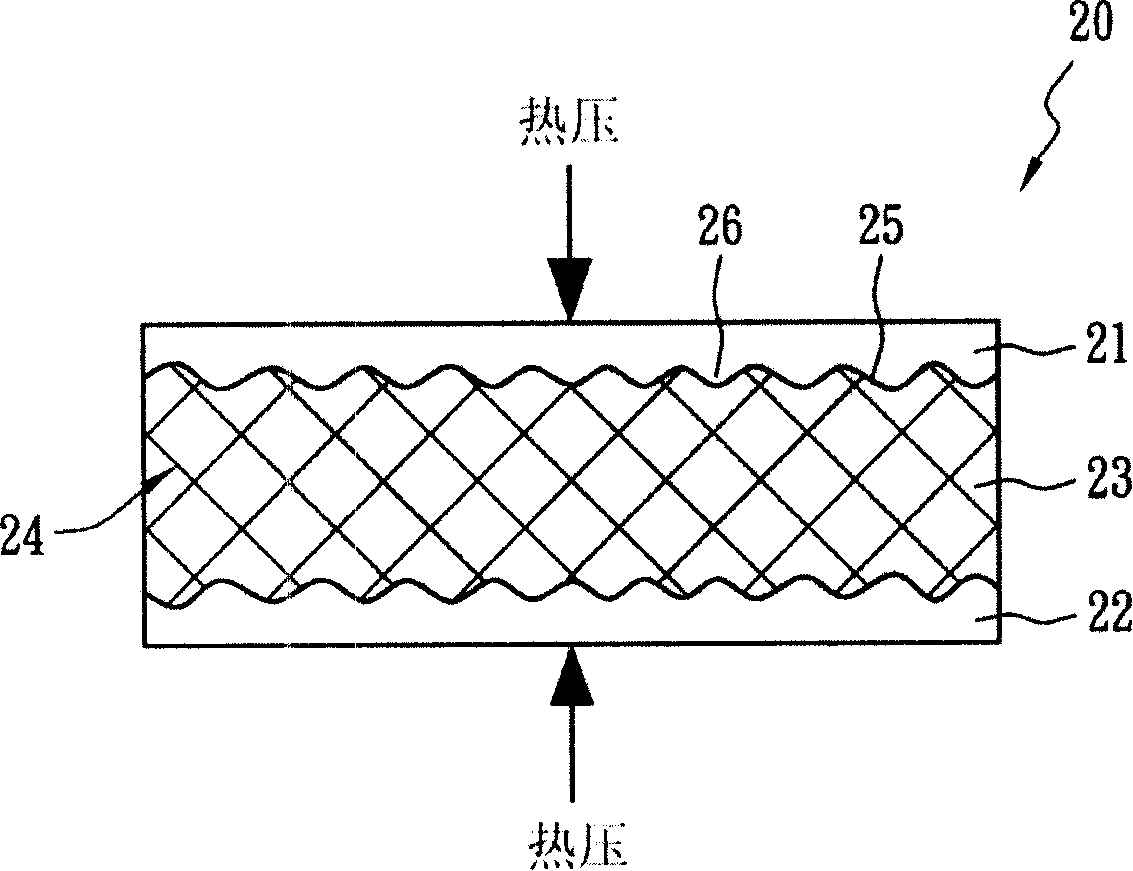

[0012] figure 2 It is a schematic diagram of the heat dissipation substrate 20 of the present invention, including a first metal layer 21 , a second m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com