Coal mine tunnel initating machine

A coal mine roadway and power transmission mechanism technology, applied in the direction of cutting machinery, slitting machinery, driving devices, etc., can solve the problems of not being able to adapt to roadway transportation and transfer of working faces, inconvenient disassembly and reorganization, and large material consumption, so as to save manpower , compact structure and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

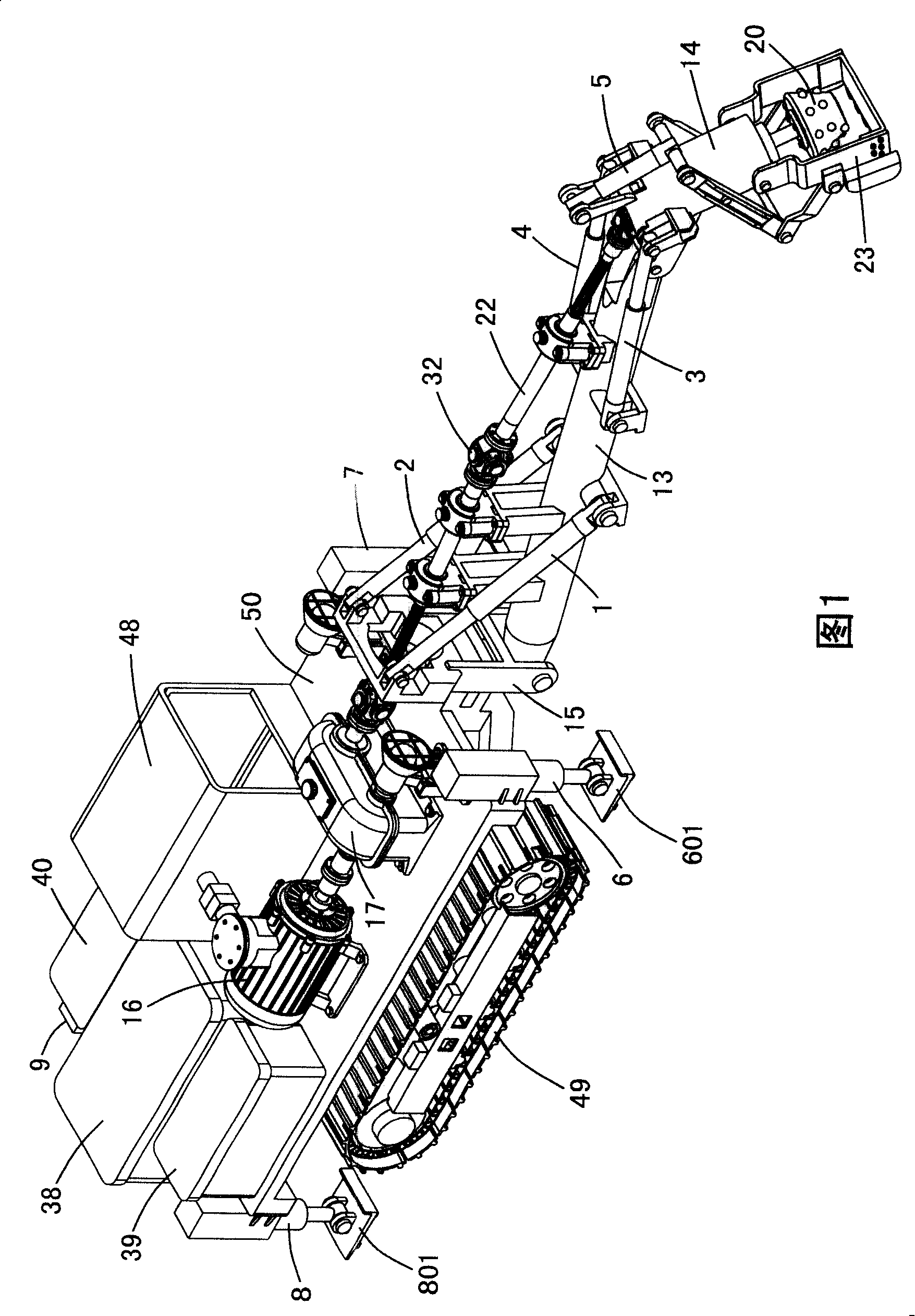

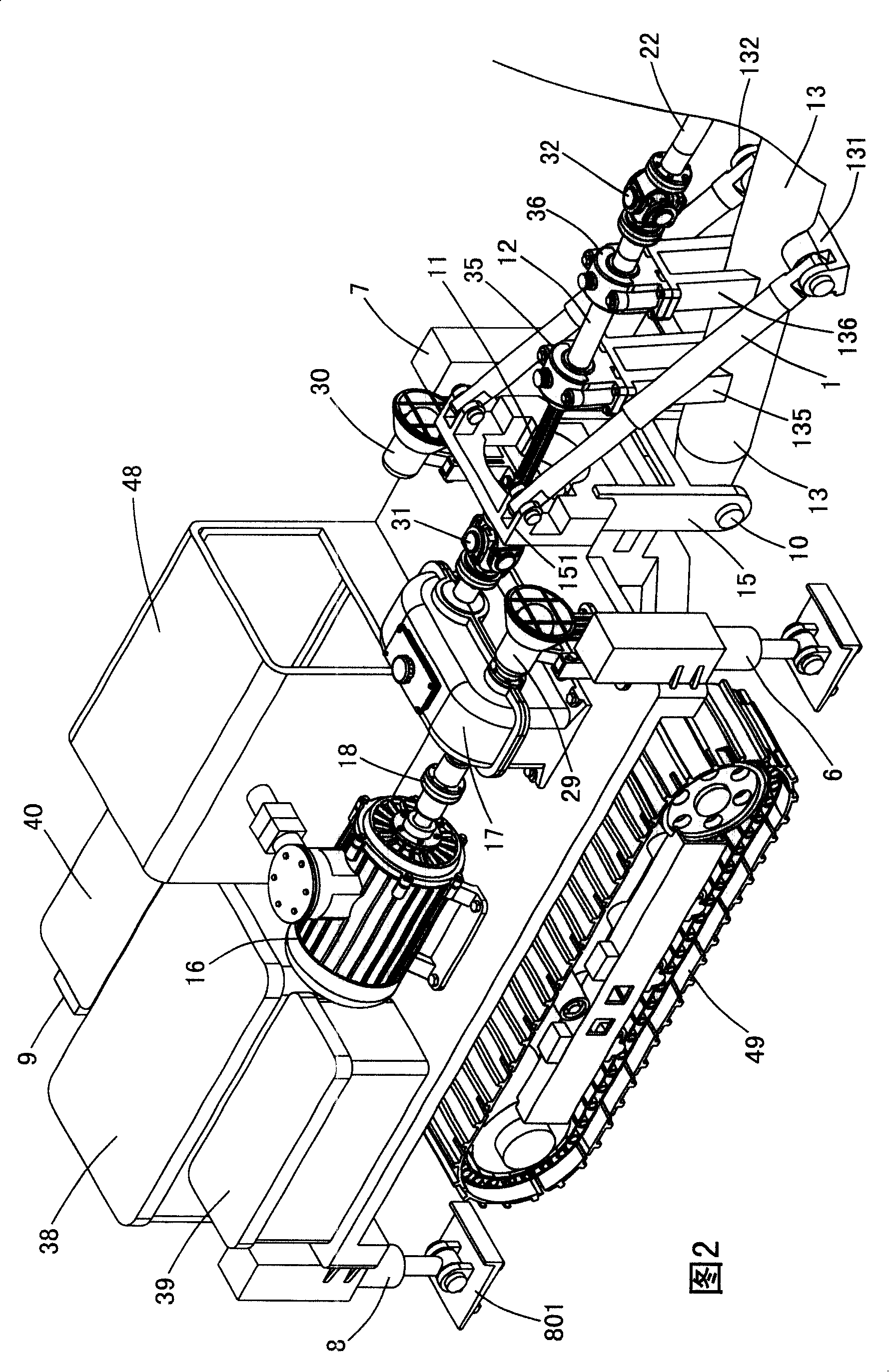

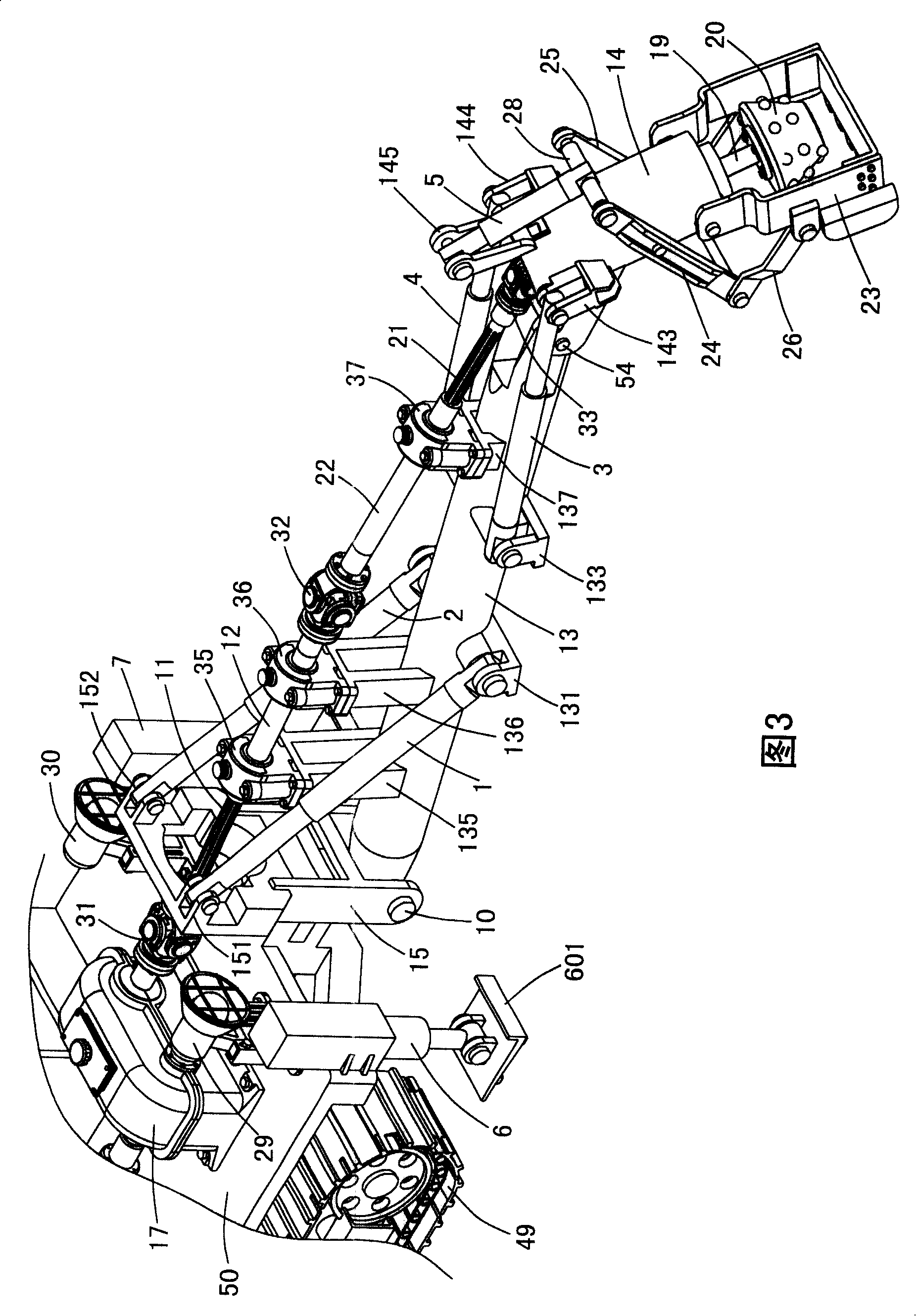

[0038] Labels in the figure:

[0039] 1. The first hydraulic cylinder 2. The second hydraulic cylinder 3. The third hydraulic cylinder

[0040] 4. Fourth hydraulic cylinder 5. Fifth hydraulic cylinder

[0041] 6. Sixth hydraulic cylinder 601. Leg 7. Seventh hydraulic cylinder 701. Leg

[0042] 8. Eighth hydraulic cylinder 801. Leg 9. Ninth hydraulic cylinder 901. Leg

[0043] 10. Shaft 11. First guide shaft 12. First guide sleeve

[0044] 13. Boom 131. Shaft seat 132. Shaft seat

[0045] 135. Support platform 136. Support platform 137. Support platform

[0046] 14. Small arm 143. Shaft seat 144. Shaft seat 145. Shaft seat

[0047] 15. Bracket 151. Shaft seat 152. Shaft seat

[0048] 16. Explosion-proof motor 17. Reducer 18. Flange coupling

[0049] 19. Transmission shaft 191. Bearing 192. Connecting flange

[0050] 20. Crushing head 21. Second guide shaft 22. Second guide bushing

[0051] 23. Rake bucket 231. Rake shovel 232. Guard plate 233. Guard plate

[0052] 24....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com