Film-forming apparatus, matching unit, and impedance control method

A film-forming device and film-forming technology, which are used in semiconductor/solid-state device manufacturing, packaging, containers, etc., can solve the problems of insufficient film-forming time, unsatisfactory film quality, and uneven film quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

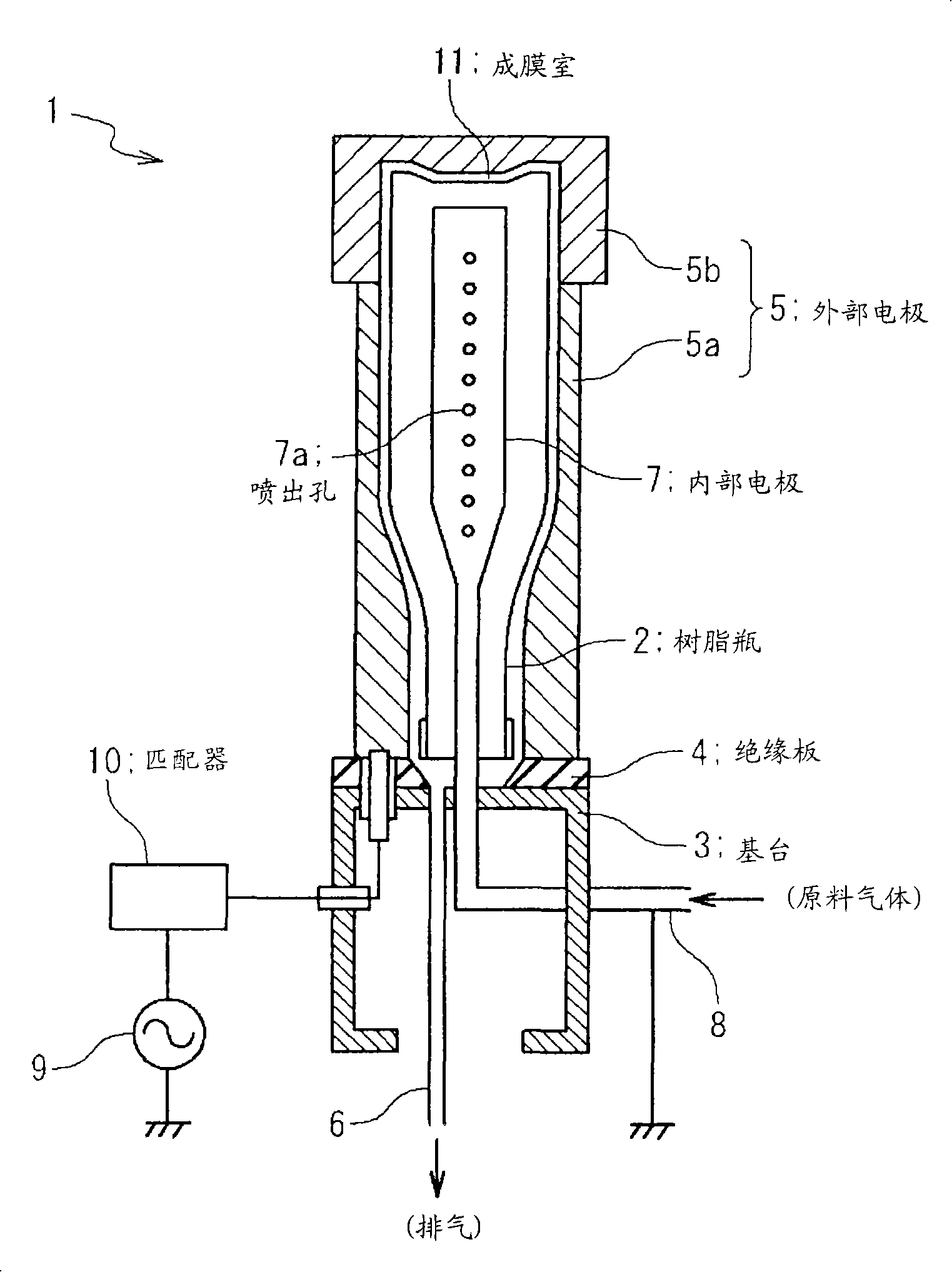

[0041] Hereinafter, an embodiment of the film forming apparatus of the present invention will be described in detail with reference to the drawings. The film forming apparatus of this embodiment, such as figure 1 Shown is a resin bottle coating device 1 for forming a DLC (diamond like carbon) film on the inner surface of a resin bottle 2 (such as a PET (polyethyleneterephthalate) bottle). The DLC film is an anti-permeation film for preventing oxygen and carbon dioxide gas from permeating the resin bottle 2 undesirably. Most of the resin bottles 2 are slightly permeable to oxygen and carbon dioxide gas, and the formation of a permeation prevention film is very important for maintaining the quality of beverages, medicines, and other liquids contained in the resin bottles 2 .

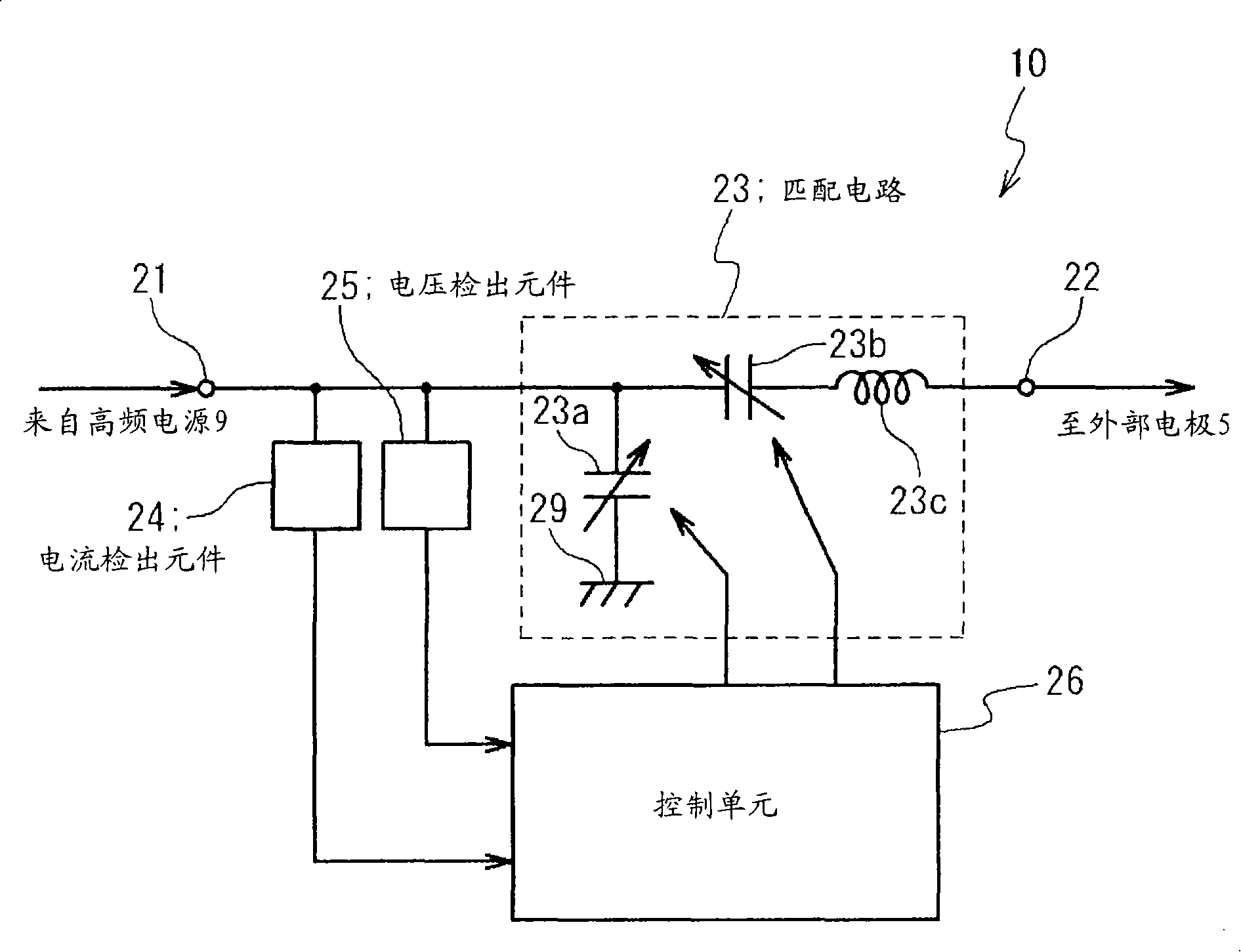

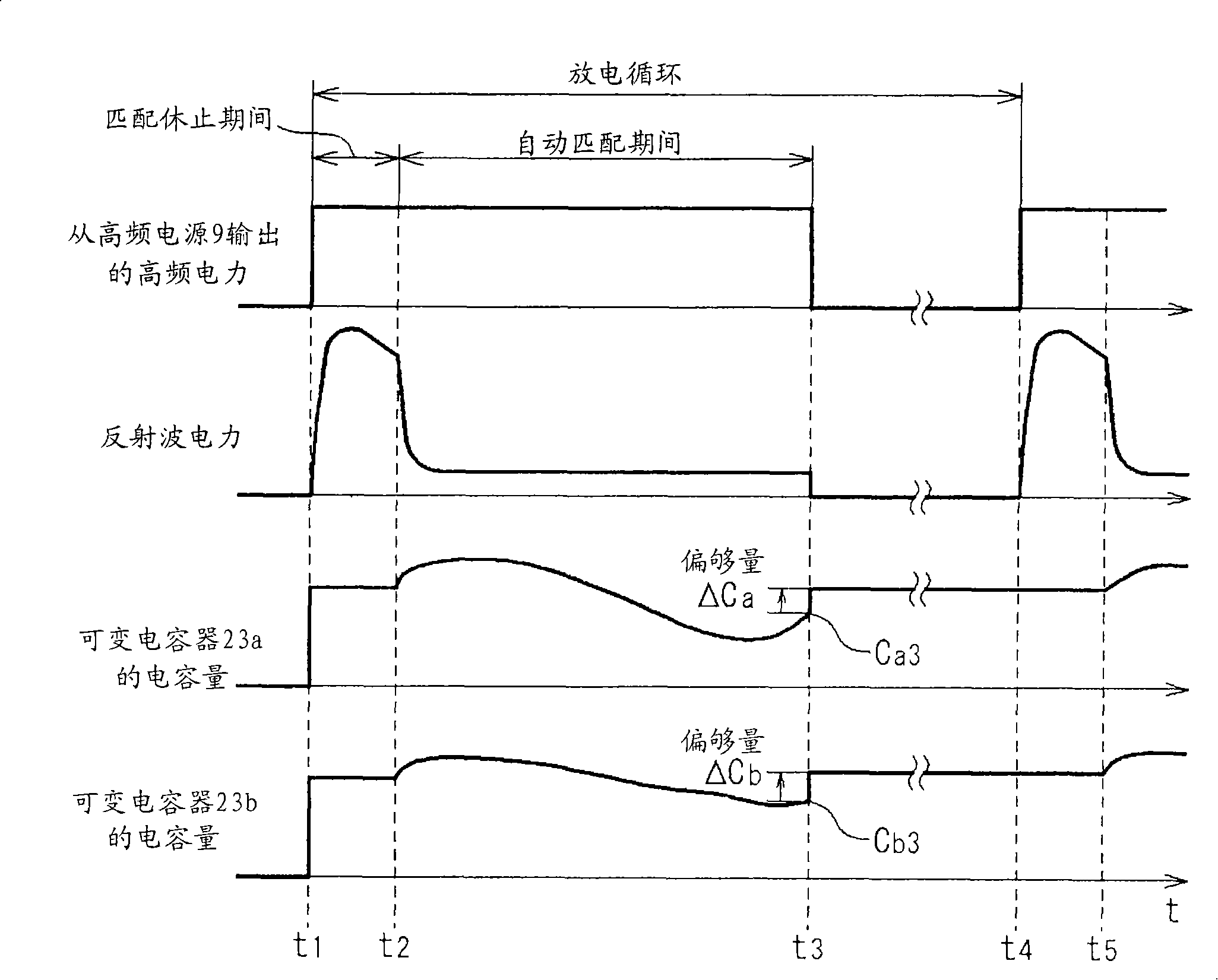

[0042] The resin bottle coating device 1 includes: a base 3 , an insulating plate 4 , an external electrode 5 , an exhaust pipe 6 , an internal electrode 7 , a raw material gas supply pipe 8 , a high-freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com