Numerically-controlled forging hydraulic press capable of realizing workpiece automatic centering

A technology for automatic centering and hydraulic presses, applied in the field of hydraulic presses, can solve problems such as difficulty in ensuring medium precision, unsafety, and impact on production efficiency, and achieve the effects of improving production efficiency, high comprehensive performance, improving the overall automation level and industry productivity level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

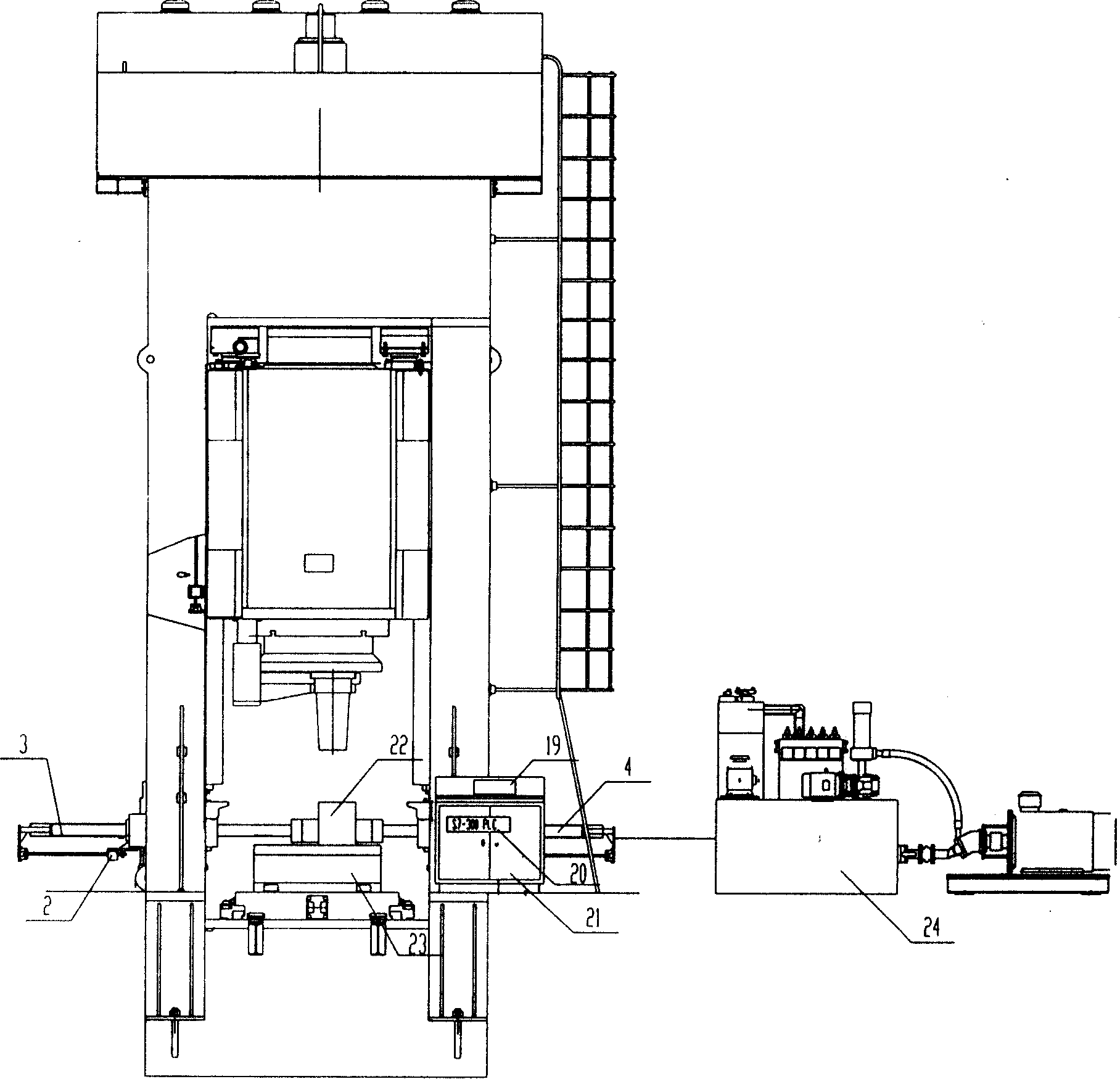

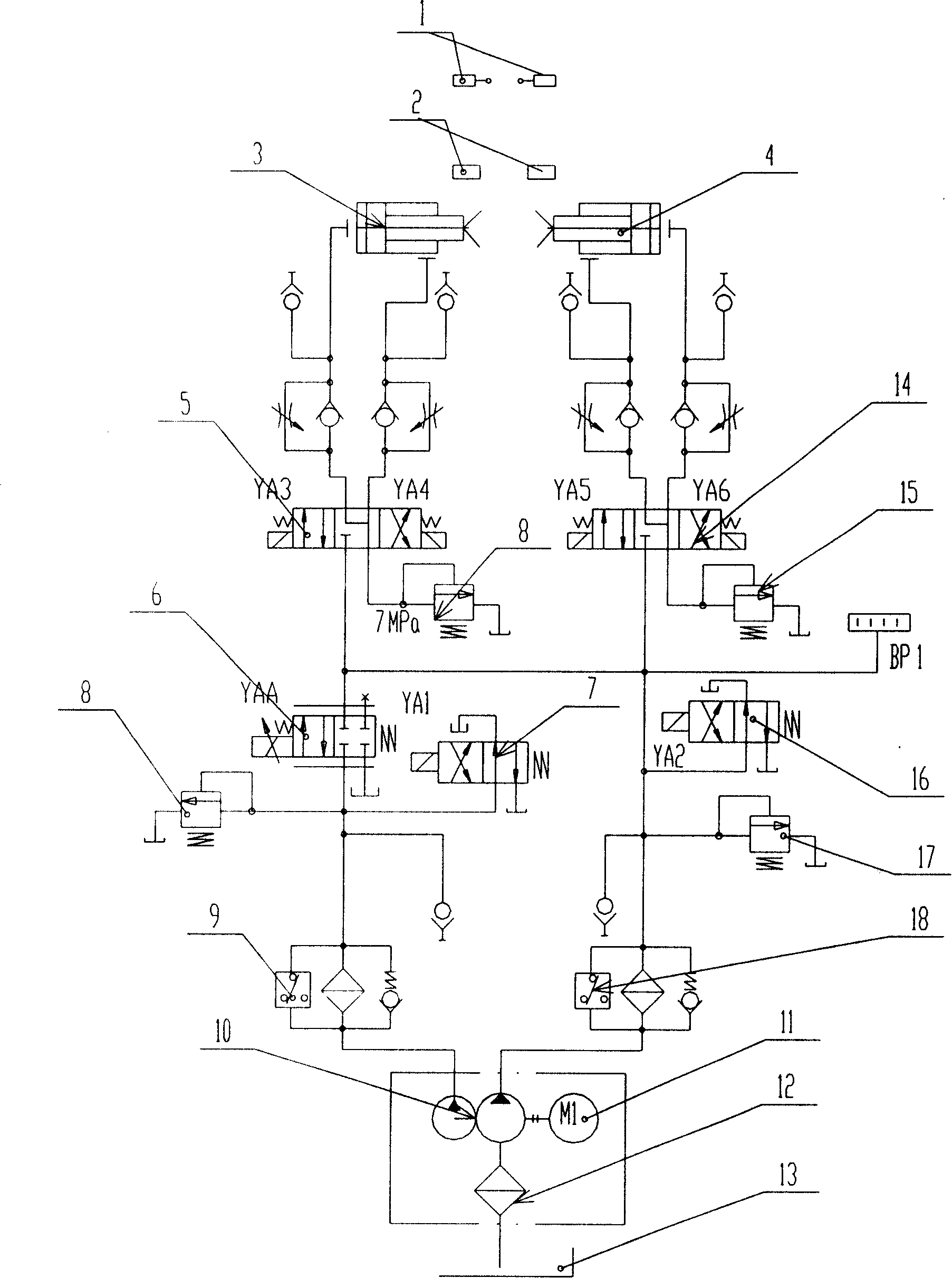

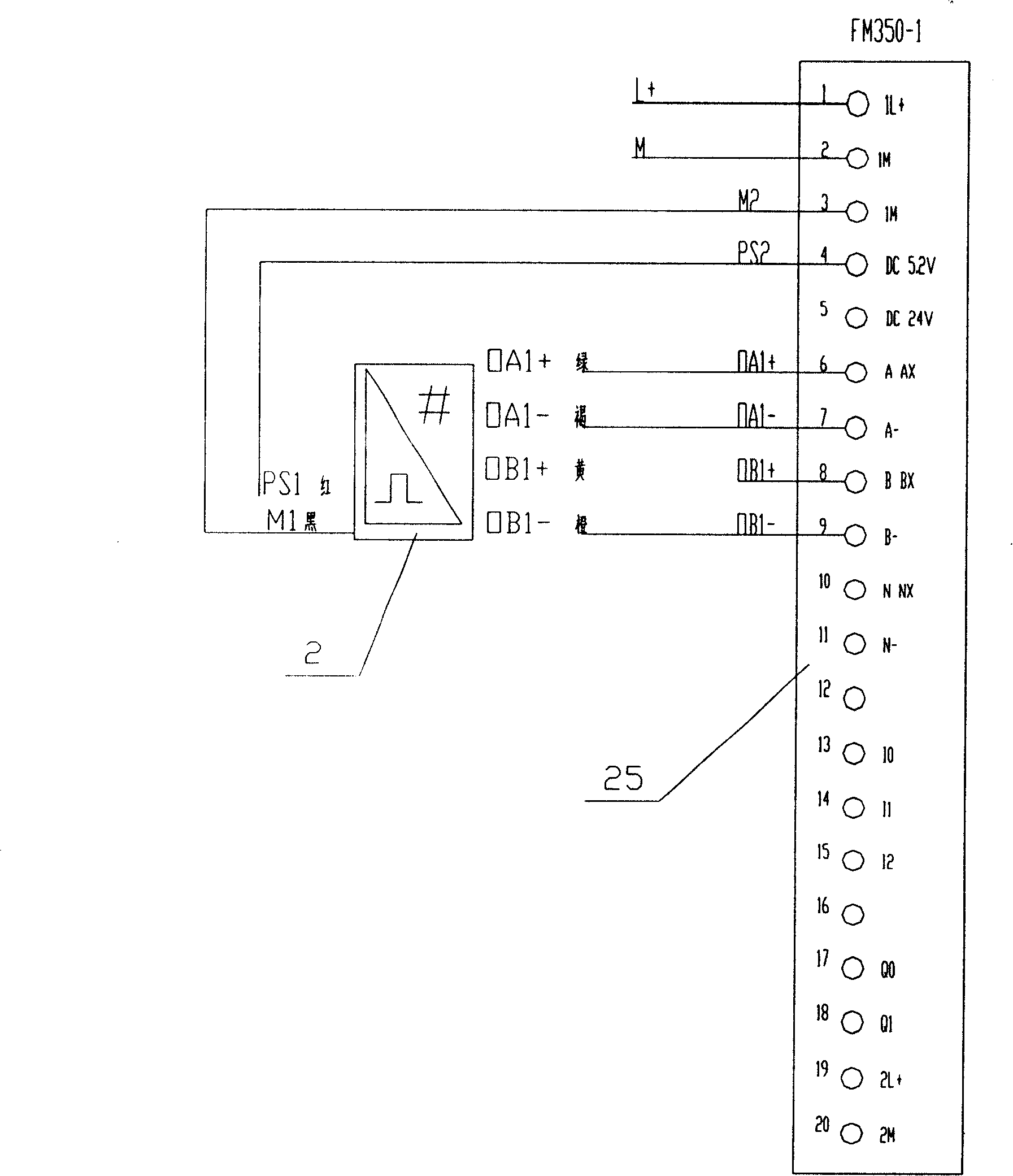

[0027] Reference attached figure 1 , figure 2 with image 3 .

[0028] The CNC forging hydraulic press that can realize the automatic centering of the workpiece, including the hydraulic frame, the movable beam, the worktable 23, the touch screen 19, the PLC controller 20 and the power mechanism 24, the controller controls the power mechanism to drive the hydraulic frame, the movable beam, and the PLC controller 20 The touch screen 19 is connected through the PROFIBUS-DP bus to realize data exchange. The touch screen 19 displays program data and screen images. A workpiece centering cylinder is installed on the worktable 23, and the centering cylinder is divided into a left centering cylinder 3 and a right centering cylinder 4. The left centering cylinder 3 is equipped with a rotary encoder 2, and the right centering cylinder is equipped with a rotary encoder. The rotary encoder is connected to the PLC controller 20 through the counting module. The left centering cylinder and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com