Straight line shock device

An impact device and straight line technology, applied in the field of impact devices, can solve problems such as increasing instantaneous speed, consumption, and increasing the power of impact tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

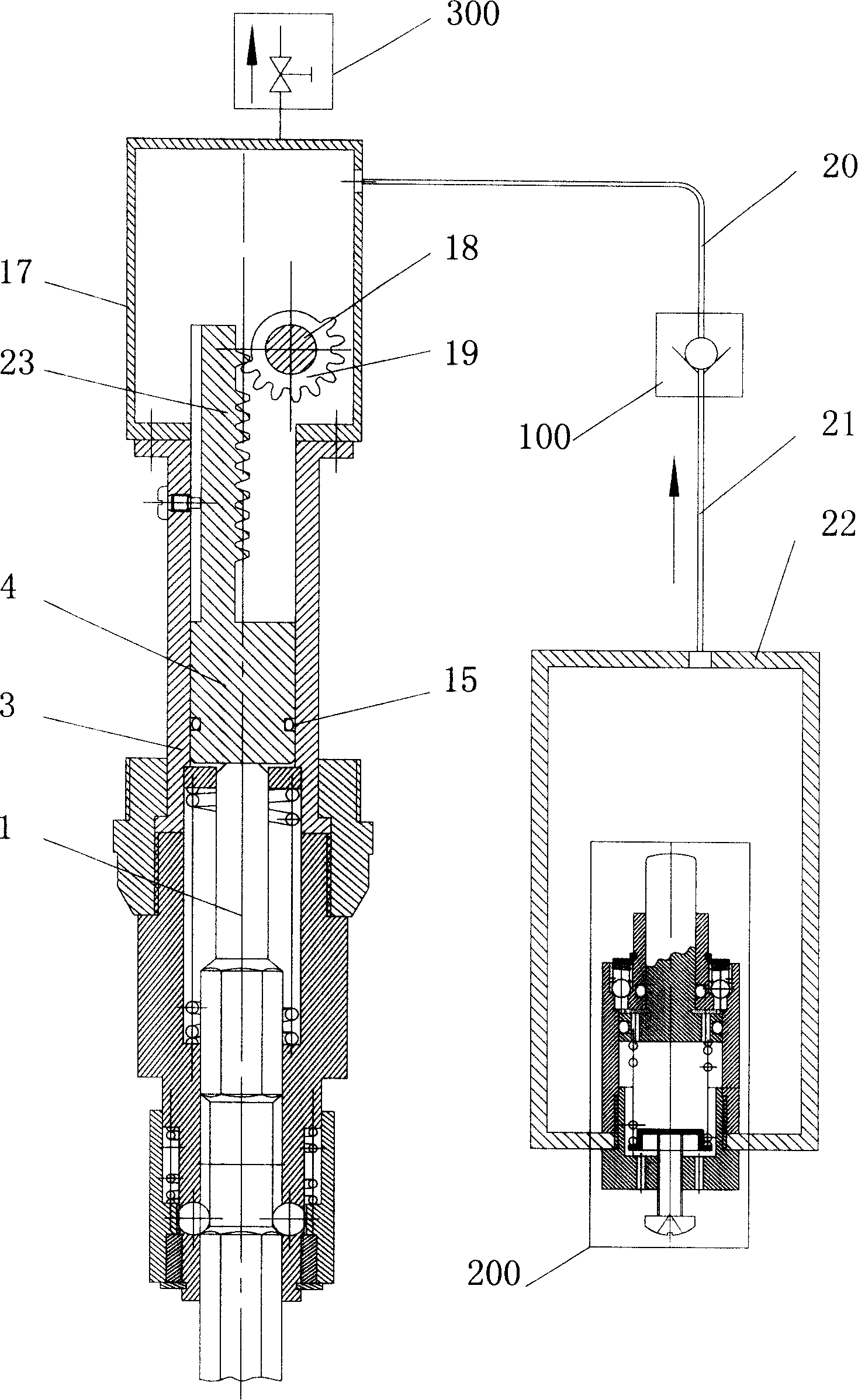

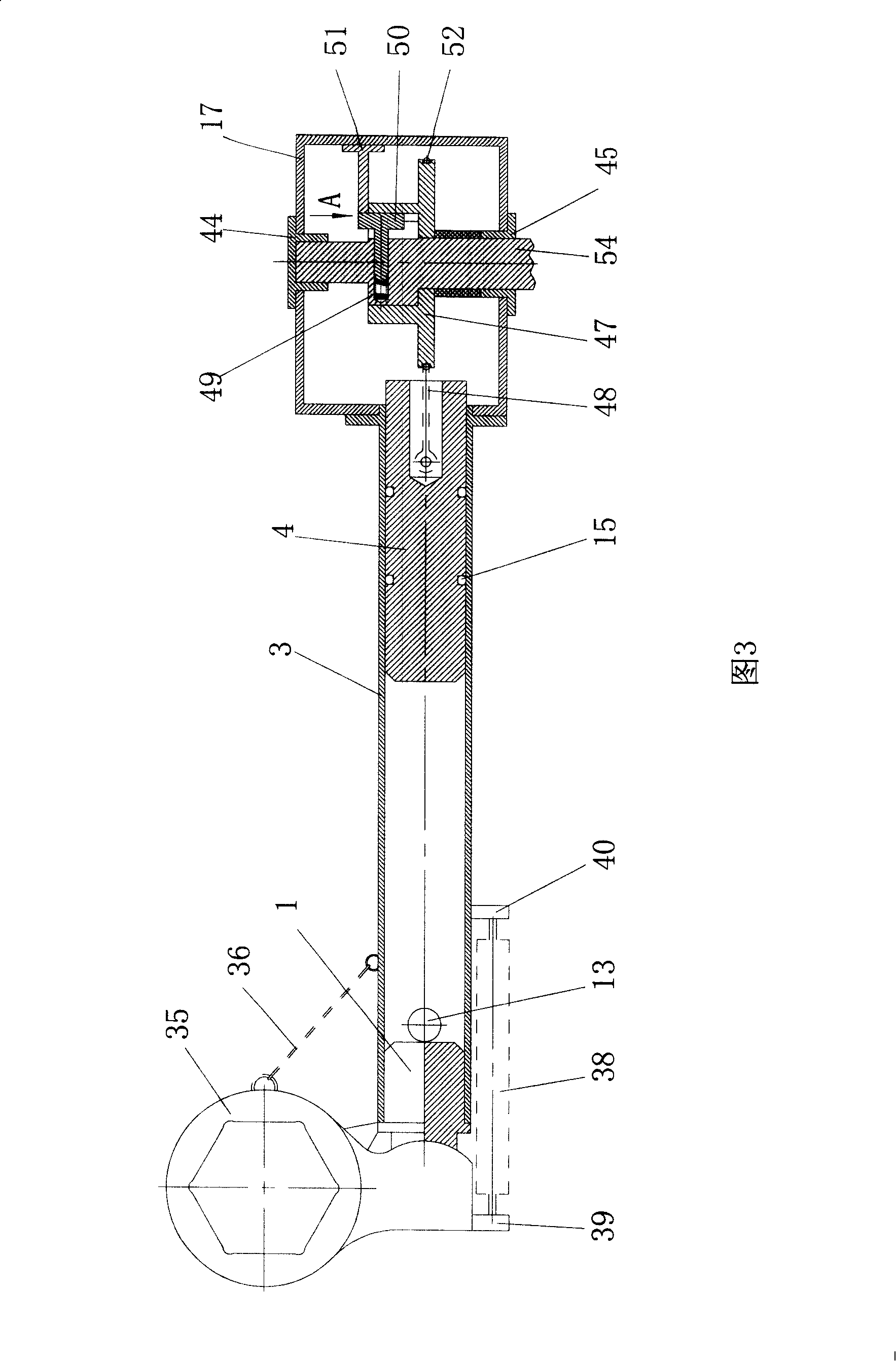

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] figure 1 Shown is a schematic structural view of applying an embodiment of the present invention to an electric (pneumatic) pick. Wherein, the lifting and disengaging mechanism is composed of a crankshaft 11 connected to the power system and capable of rotating under the action of the power system, and a bellcrank pin 6 fixed to the crankshaft 11. The impact piston 4 is provided with grooves 406 in the axial and circumferential directions. The groove 406 is L-shaped; the bellcrank pin 6 is embedded in the groove 406, and the part embedded in the groove 406 is made into a rod shape, and its cross-section is arcuate or the shape of the remaining part after the circle is excised by an arcuate portion, as shown in the figure 4. The accumulator includes an elastic element 10 and a gland 8. The gland 8 and the impact piston 4 are located at both ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com