Method for regulating mechanical property of polyethylene terephthalate/polyolefin mixture by using magnetic field

A technology of polyethylene terephthalate and ethylene phthalate is applied in the field of regulating the mechanical properties of polyethylene terephthalate/polyolefin blend materials, and can solve the problem of directional regular arrangement Difficulties and other problems to achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Comparative example

[0032] 1) PET was dried at 150°C for 6 hours to remove moisture; polypropylene, polypropylene grafted with maleic anhydride, antioxidant 1010 and antioxidant 168 were dried at 100°C for 3 hours.

[0033]2) According to PP 87% (mass percentage, the same below), PET 10%, maleic anhydride grafted polypropylene 3%, and antioxidant 1010 (accounting for 0.3% of polypropylene), auxiliary antioxidant 168 (accounting for poly 0.2% of propylene) ingredients.

[0034] 3) After the material is pre-mixed, it is extruded by a twin-screw extruder, and then drawn into pellets. The temperature of each section of the extruder from the hopper to the die is set to 130°C, 220°C, 270°C, 275°C, 265°C, 260°C, 255°C, 250°C, 245°C, 240°C, 238°C, and the main screw speed is 60r / min.

[0035] 4) The obtained blend pellets were dried in an oven at 100°C for 4 hours.

[0036] 5) Put the dried blend pellets into the material cavity of the plunger extrusion device, ...

Embodiment 2

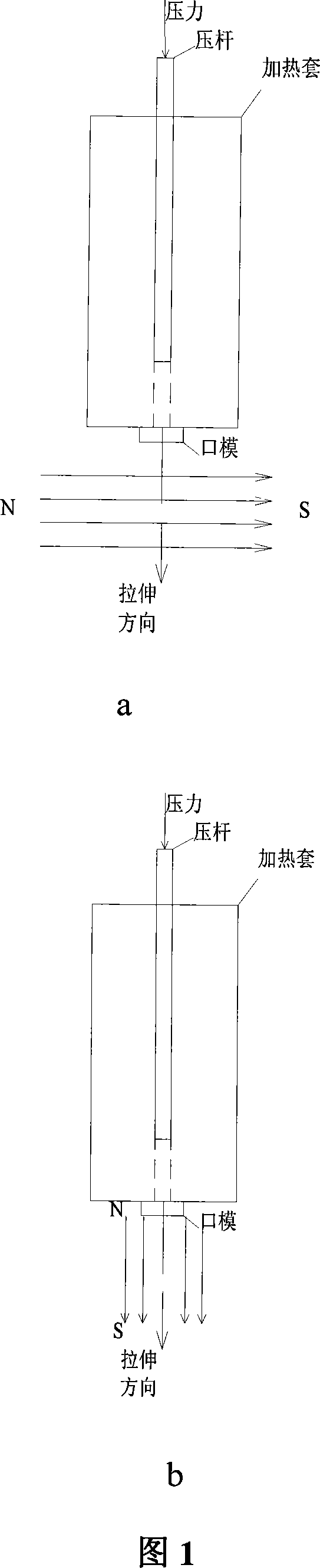

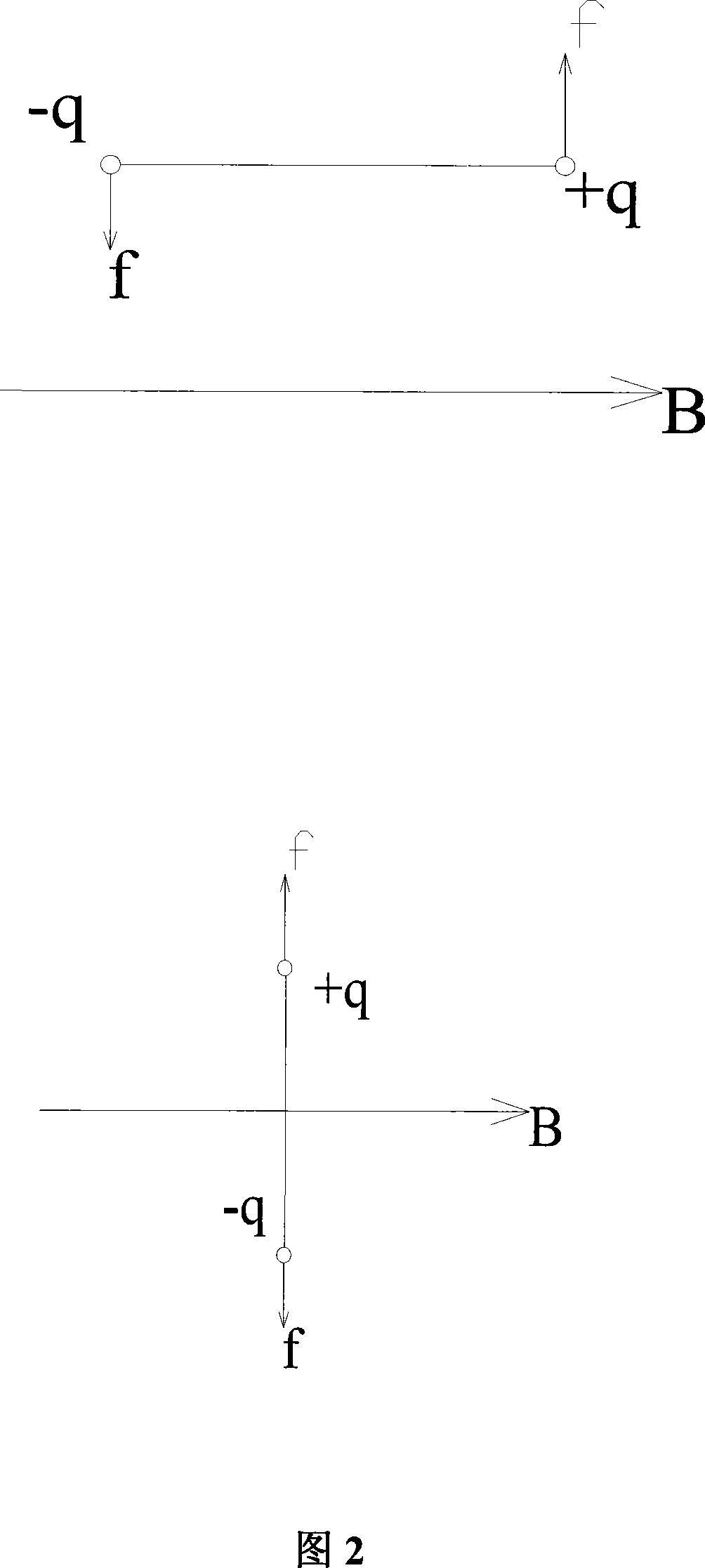

[0040] A set of rubidium-iron-boron permanent magnets is set at the die of the plunger extrusion device. The blend melt comes out of the die and enters the magnetic field for cooling (see Figure 1). The magnitude of the magnetic field is 0.7T. The direction of extension is parallel. Others are the same as in Example 1.

Embodiment 3

[0042] The direction of the magnetic field is perpendicular to the stretching direction, and the others are the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com