Full automatic tunneling machine

A roadheader and fully automatic technology, which is applied in the direction of slitting machinery, earth square drilling, etc., can solve the problems of increasing the danger of coal miners, high labor intensity, and high physical exertion, so as to eliminate danger and ensure safe production and work. high efficiency effect

Inactive Publication Date: 2010-09-08

SANY HEAVY EQUIP

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the harsh working environment in the mine and high physical exertion, manual operation makes coal miners bear greater labor intensity, and also increases the danger of coal miners operating underground

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

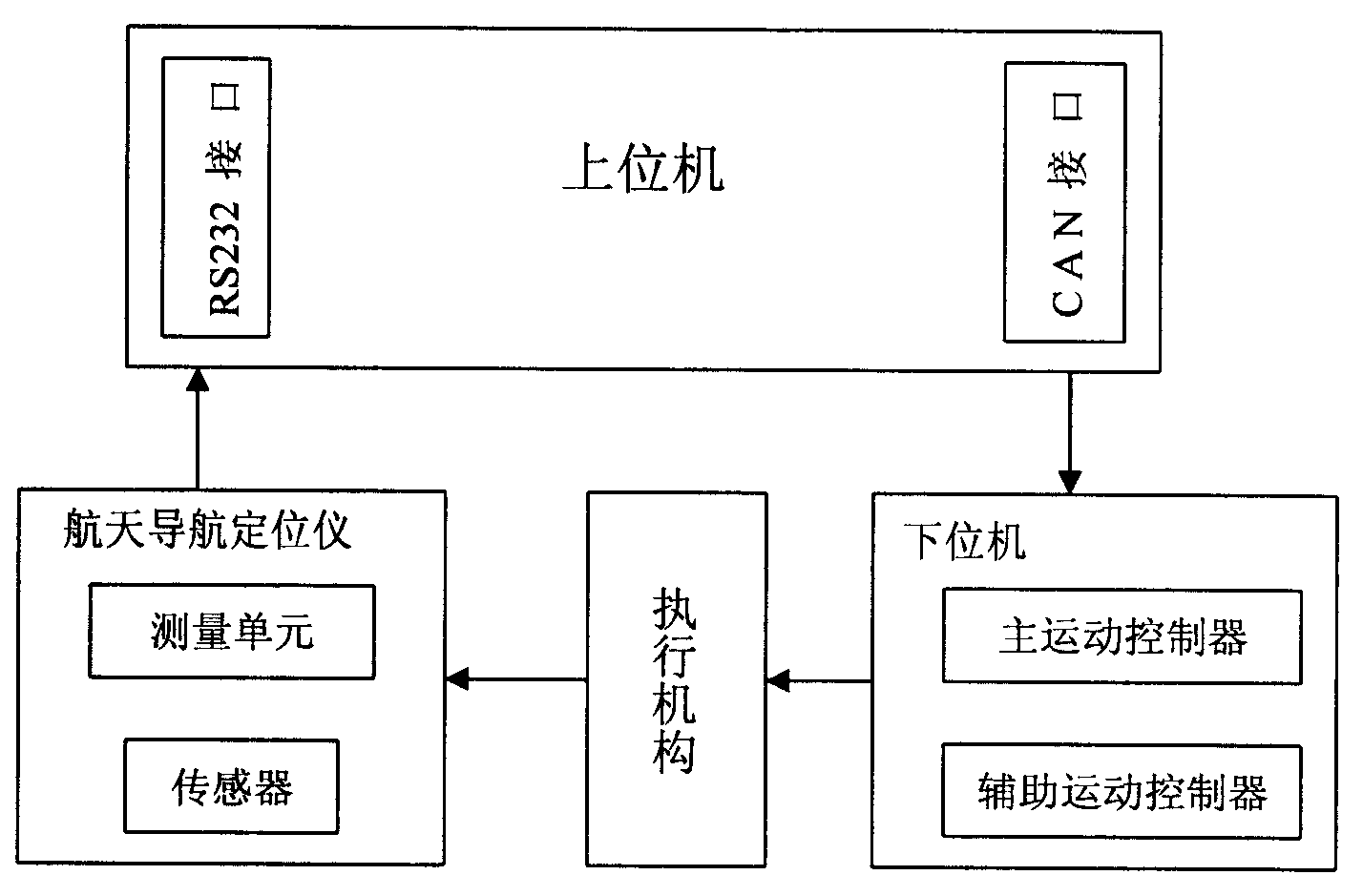

The invention discloses a full-automatic boring machine. A space navigating and positioning instrument can communicate with an upper computer through a RS-232 interface, can transfer the feature extraction value of the boring machine and the navigating calculation value to the upper computer for data feature fusing, and can detect the absolute position coordinate of the boring machine in the inertial space in real time. The upper computer communicates with a lower computer through a CAN-BUS transmission interface, can transfer the control data to the lower computer by which the practicing position of the boring machine is controlled, and then the automatic finding function can be realized. The lower computer takes two motion controllers as the core being the control part. The motion controllers can conduct real-time control by an implementing mechanism on the boring machine and a cutting head according to the ground measurement data pre-stored in the upper computer, the local data provided by the space navigating and positioning instrument, the automatically generated gridding data of the mining plane of the current position of the boring machine, and the current position of the boring machine and the cutting head, and then the automatic mining of the automatic boring machine can be realized.

Description

technical field The invention relates to coal mine roadheader equipment, in particular to a full-automatic roadhead control system. It can realize fully automatic excavation operation, can reduce the influence of human factors, and make the excavation roadway more accurate. Background technique At present, the general roadheader is fed manually by coal miners to control the equipment to complete the tunneling task. However, due to the harsh working environment in the mine and high physical exertion, manual operation makes coal miners bear greater labor intensity, and also increases the danger of coal miners operating underground. Therefore, there is a great need for a fully automatic tunneling operation machine to improve work efficiency and reduce the labor intensity of the operator. Contents of the invention In order to overcome the above disadvantages, the object of the present invention is to provide a fully automatic tunneling machine with high working efficiency a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21C35/24

Inventor 吴佳梁梁坚毅李勇王志刚李恩龙陈锷王智永李铁宁

Owner SANY HEAVY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com