Metal hot extrusion formability judging method

A technology of extrusion forming and judging methods, which is applied in the direction of testing metals, testing the ductility of materials, and material inspection products, and can solve problems affecting the optimization and formulation of metal extrusion production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

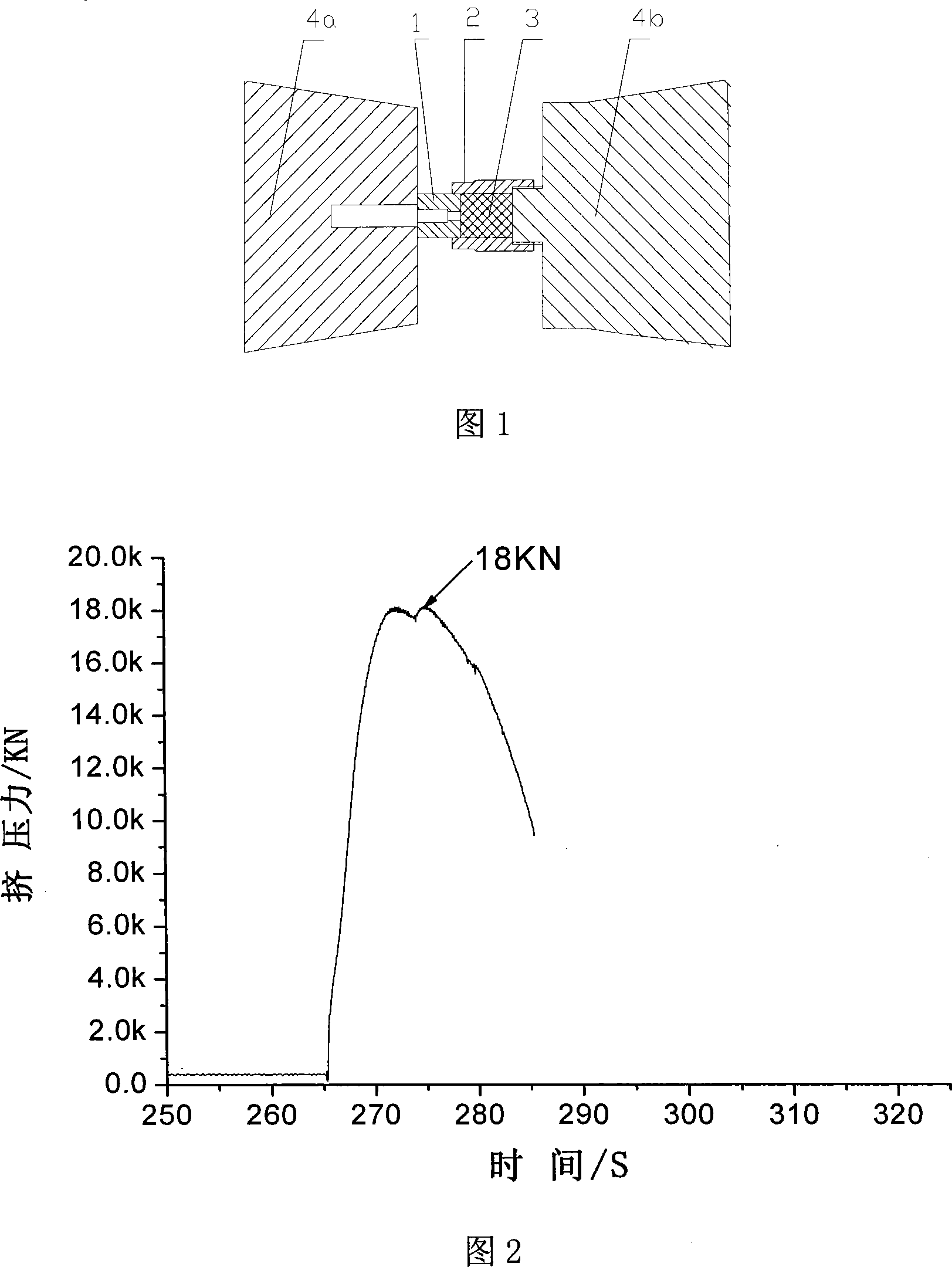

[0022] Referring to Fig. 1, the simulation test extrusion device used in the present invention is a reverse extrusion simulation deformation device, the extrusion cylinder 2 of the device is screwed on the right support seat 4b, and the alloy sample 3 (φ10 × 12mm round bar) is placed After entering the extrusion cylinder 2, one end of the extrusion die 1 is inserted into the extrusion cylinder 2 to form a sliding fit, and the other end is against the left support seat 4a. The center of the extrusion die 1 is provided with an axial extrusion deformation through hole. The compression deformation through hole is opposite to the channel on the left support seat 4a. A certain pressure is applied through the left and right support seats to ensure that the extrusion die 1 and the extrusion cylinder 2 are centered. Before the extrusion die 1 is put into the extrusion cylinder 2, it is necessary to apply graphite paste on both ends of the extrusion die 1 as a lubricant, and paste graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com