Paperboard cutting machine and paperboard pushing mechanism thereof

A push mechanism and cutting machine technology, applied in the direction of sending objects, separating objects, separating piles, etc., can solve problems affecting production efficiency, low work efficiency, and potential safety hazards, so as to improve cutting accuracy, improve automation, and eliminate The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

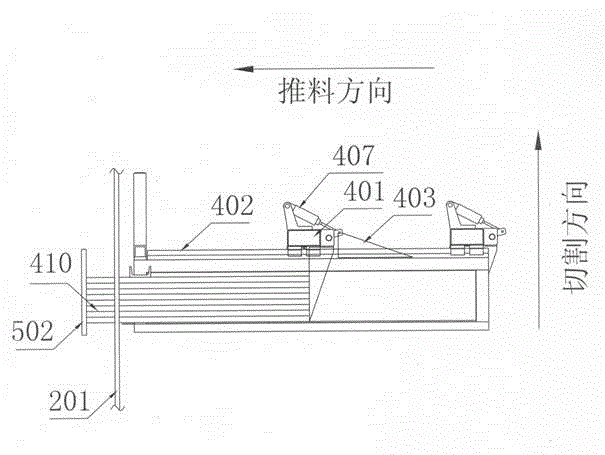

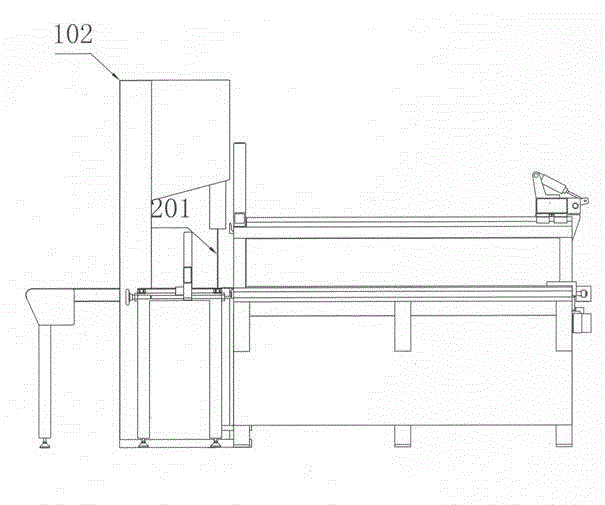

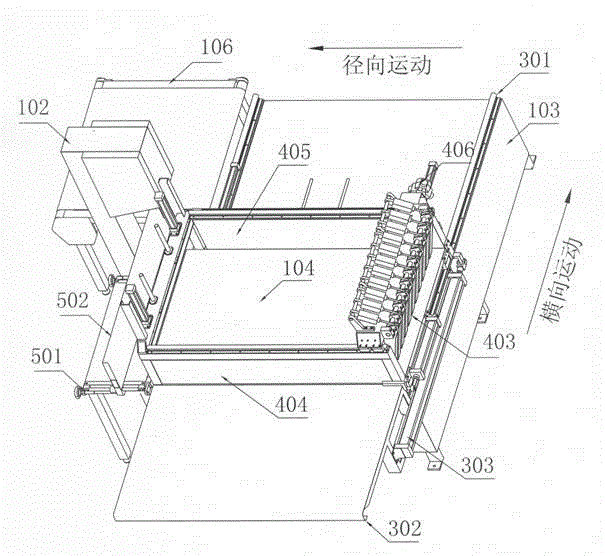

[0019] The relevant details and working principle of the embodiment of the utility model are described below in conjunction with the accompanying drawings.

[0020] A cardboard cutting machine includes a cutting device 102, a cutting platform 103 and a gauge device, the cutting device includes a cutting knife 201, the gauge device includes a gauge plate 502, and the cutting knife is arranged on the gauge Between the board and the cutting platform, the cutting knife is a disc knife or a belt knife with cutting functions on both sides. In order to prevent incomplete cutting of the cardboard, the cardboard will collide with the cutting knife when the feeding bin returns horizontally, which will cause cutting The damage of the cutting knife of the device will seriously damage the cutting device. The disc knife or the belt knife with cutting function on both sides will well avoid this problem. The cutting platform is provided with a feed bin 104 of a laterally reciprocating movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com