Polarizing body preparation method and polarizing sheet preparation method

A photon, aluminum ion technology, applied in optics, polarizing elements, nonlinear optics, etc., can solve the problem of reducing the optical properties of polarized photons, achieve good optical properties, increase the width and extension ratio, and reduce the film thickness.

Inactive Publication Date: 2008-04-30

DAXON TECH INC

View PDF1 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional production process using boric acid as a cross-linking agent, although the film thickness of the PVA film can be reduced by changing the m

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

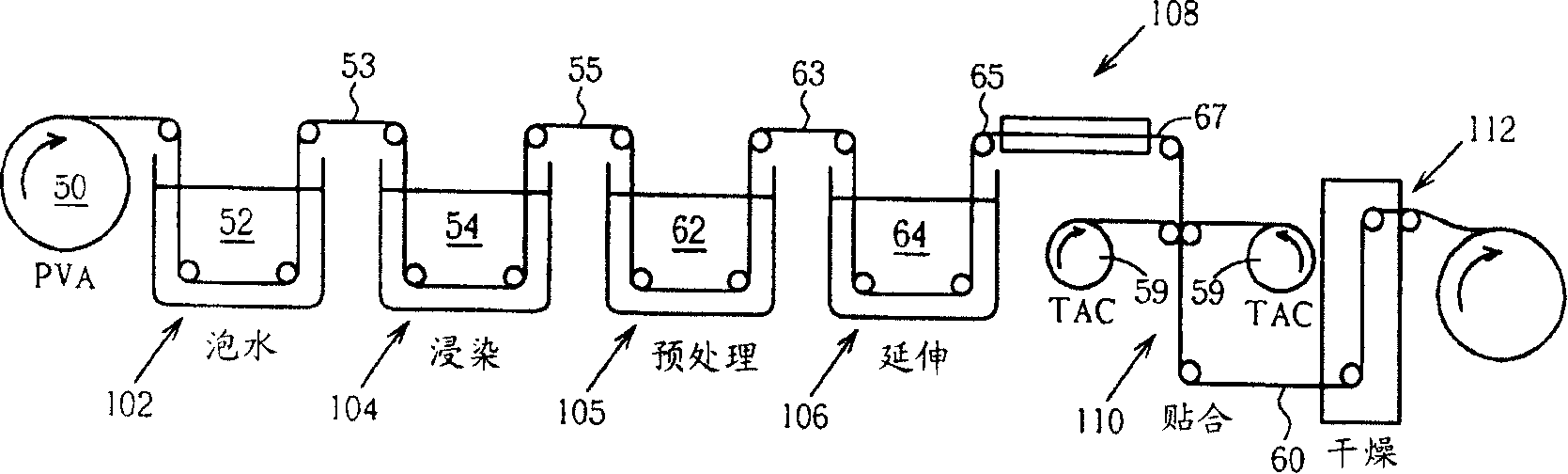

Login to View More Abstract

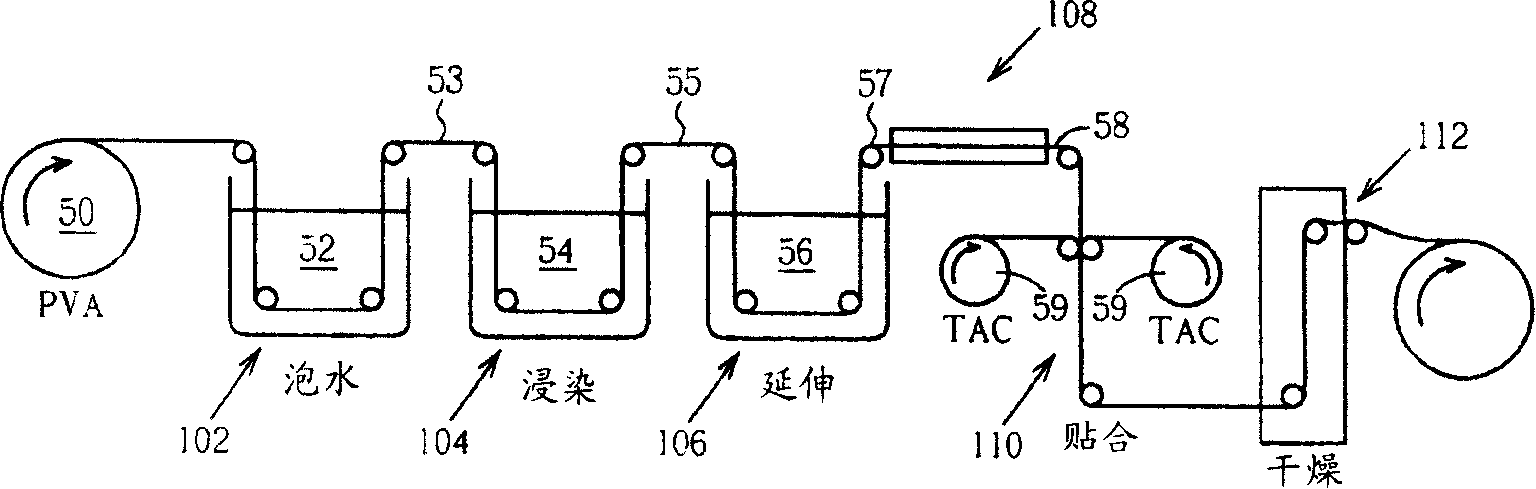

The invention relates to a manufacture method of partial photon, and the method comprises the steps as follows: a polyvinyl alcohol (PVA) film is provided. The PVA film is soaked in staining solution to carry through a soaking and staining process. The PVA film is soaked in a first solution to carry through a pretreatment. The PVA film after the pretreatment is soaked in a second solution, simultaneously, the PVA film is extended. The first solution includes dicarboxylic acid and catalyst which can catalyze the reaction of the dicarboxylic acid and the surface of the PVA film. No boric acid is included. The second solution includes boric acid.

Description

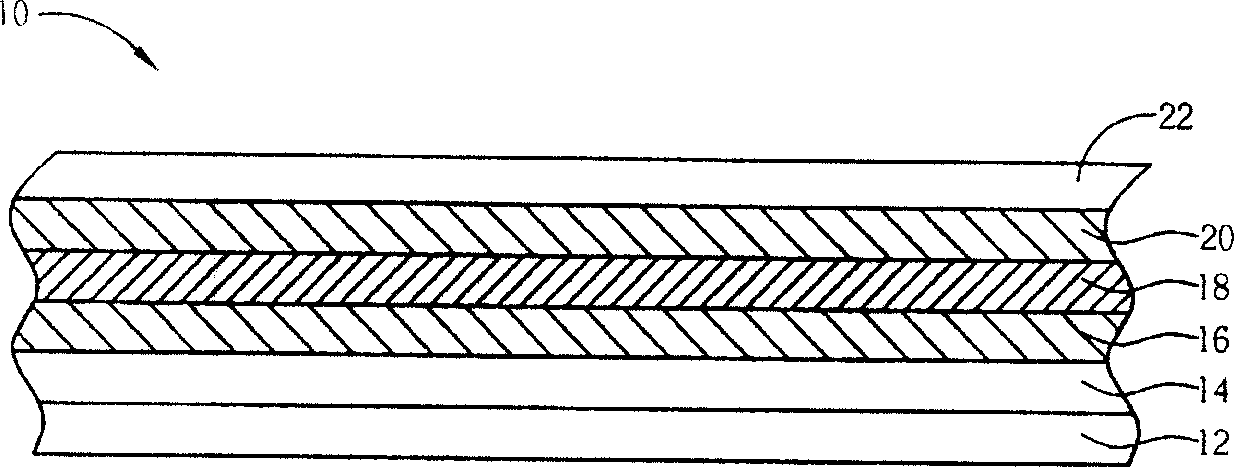

technical field [0001] The invention relates to a method for preparing polarizers, in particular to a method for manufacturing polarizers used in polarizers of liquid crystal displays. Background technique [0002] In the liquid crystal display, the polarizer is one of the indispensable components. Its purpose is to polarize the originally non-polarized light and convert it into polarized light. Therefore, the liquid crystal display can use this polarized light, plus The twisting characteristics of the liquid crystal molecules themselves are used to control the passage of light and the presentation of color signals. In recent years, as liquid crystal display components are widely used in various electronic devices such as word processors, computer screens, mobile phones or LCD TVs, and even large outdoor display billboards, vehicles, aircraft, and navigation instruments And satellites, etc. Therefore, the demand for polarizers is also increasing. [0003] The cross-section...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02B5/30G02F1/1335

Inventor 蔡政欣傅从能

Owner DAXON TECH INC

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com