Electric spring operation machine for switch device

A technology of electric springs and switchgear, which is applied to the power device inside the switch, electric switch, high-voltage/high-current switch, etc. It can solve the problems of non-parallel between plates, troublesome adjustment, improper adjustment, etc., and achieve high corner accuracy and transmission The effect of less loss and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

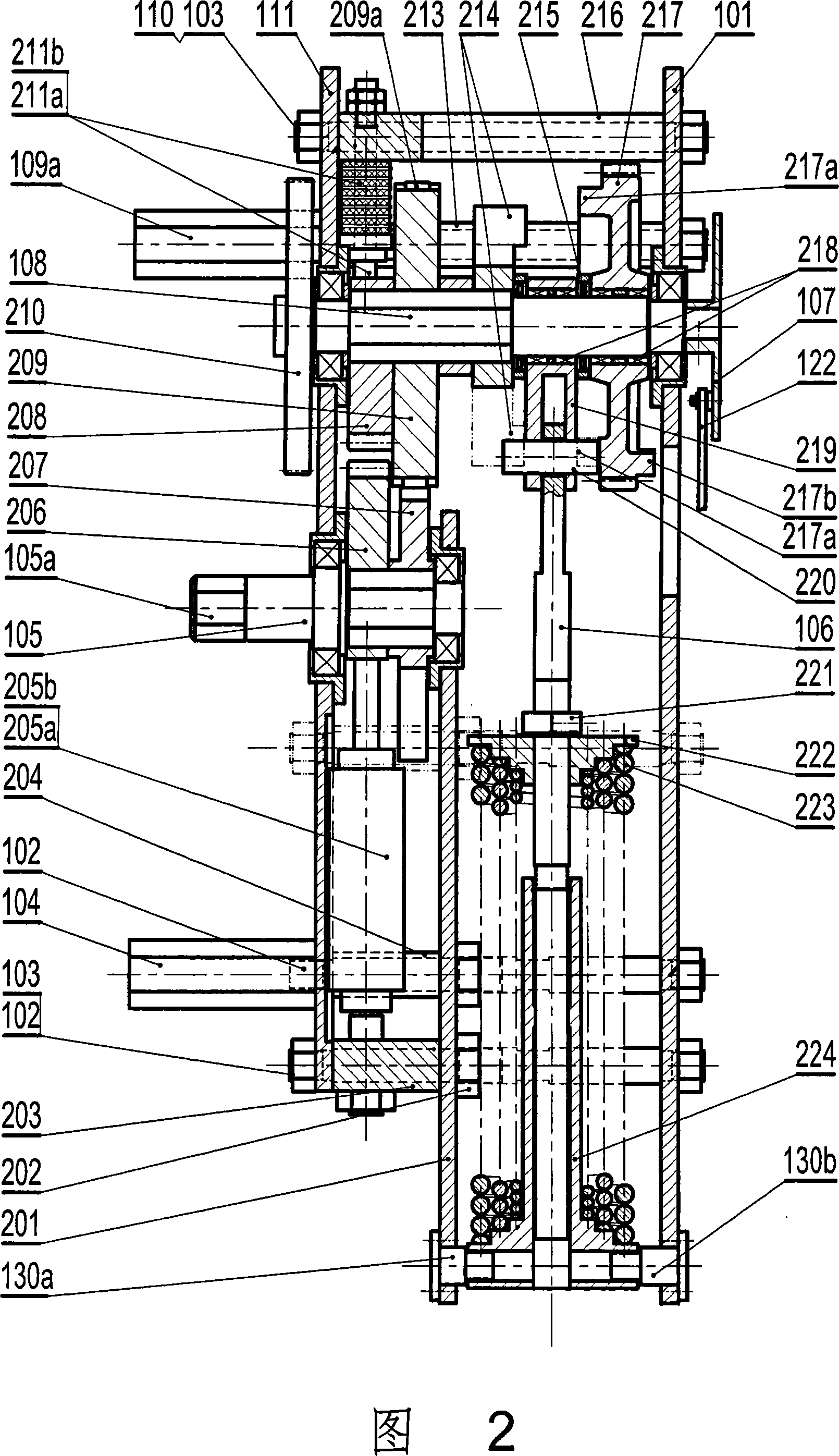

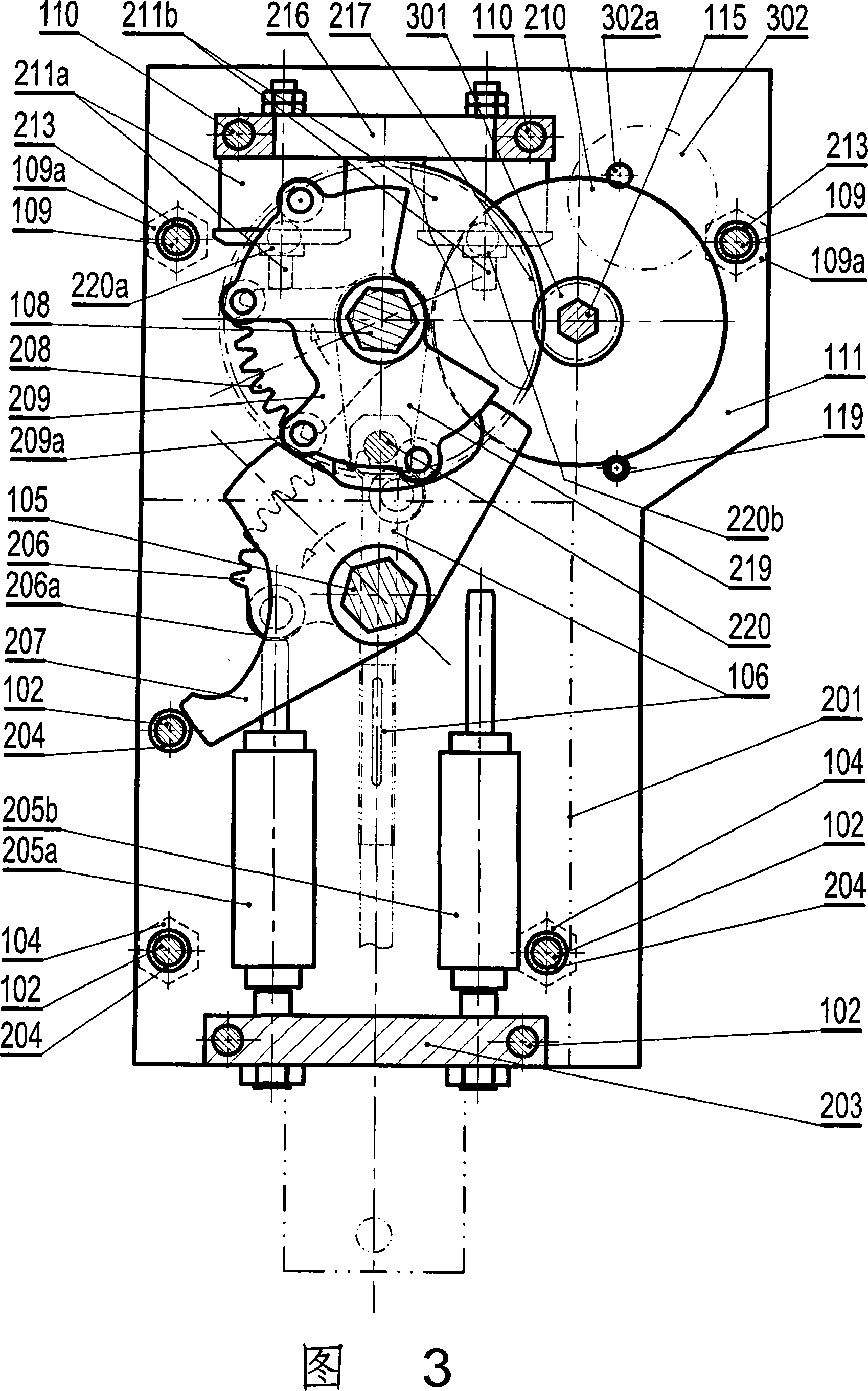

[0027] Embodiment 1 The steering direction of the output shaft of the mechanism is: clockwise when the brake is closed, and counterclockwise when the brake is opened.

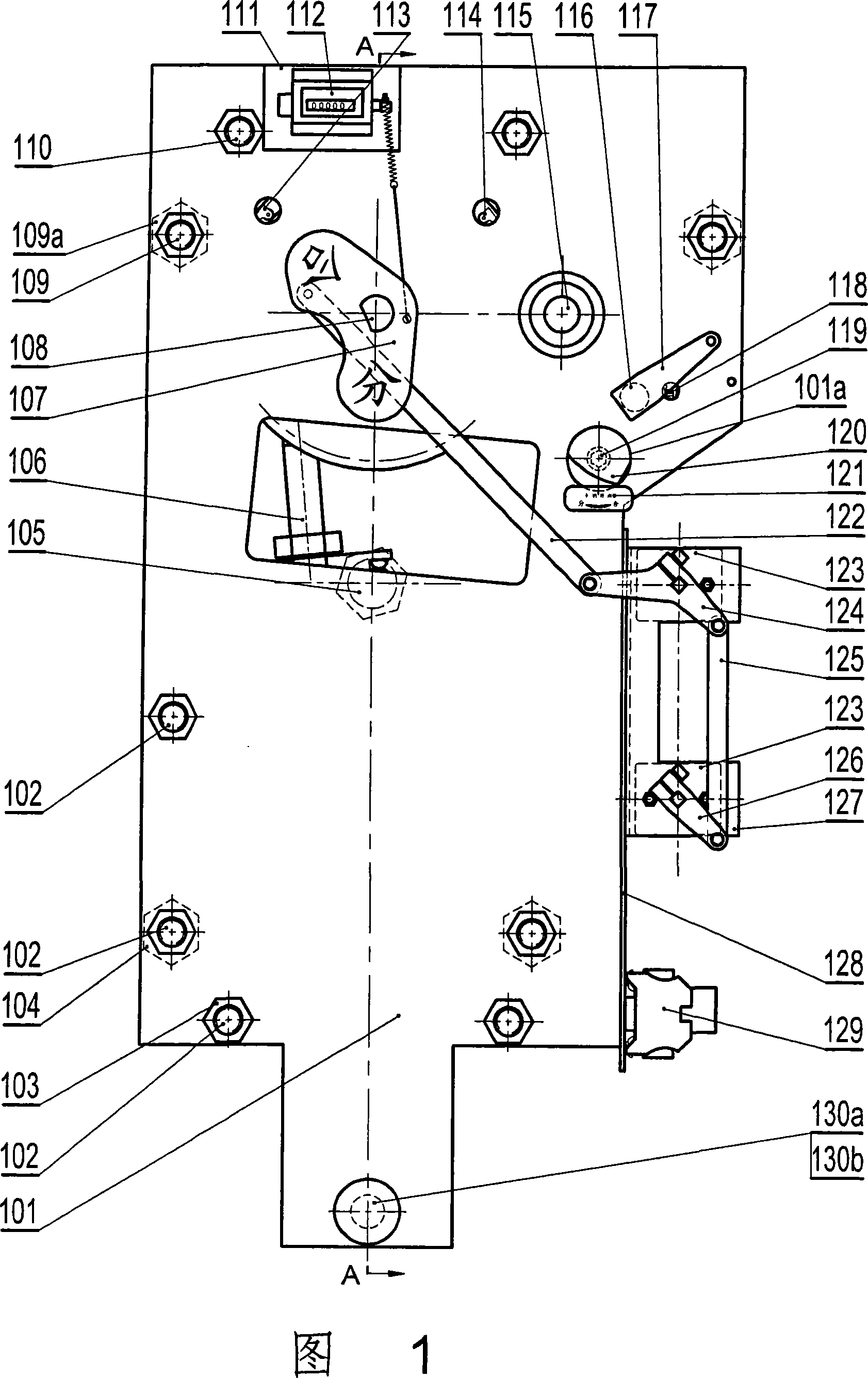

[0028]As shown in Figure 1, the mechanism main shaft 108 protrudes from the flat shaft end of the panel, and an indicator plate 107 is fixed on which the dividing and closing signs are housed. When the opening (or closing) gate is in place, the opening (or closing) sign is aligned with the observation window on the mechanism box, and it can be clearly observed from the outside of the box that the machine is in the opening (or closing) gate position. When the pin installed on the indicator board is in the opening (or closing) action, the two auxiliary switches 123 are driven to switch through the connecting plate 122, the lever 124, the connecting plate 125, and the crank arm 126, and the auxiliary switch is connected to the contact of the control circuit. When the opening (or closing) fast-action main shaft tur...

Embodiment 2

[0040] The output shaft of the mechanism in embodiment 2 is turned counterclockwise when closing, and clockwise when opening. The opening and closing speeds of the switch operated by the mechanism in embodiment 2 and the required operating work and operating torque are different from those in embodiment 1.

[0041] The structure, connection mode, action principle and action process of each part of the mechanism in embodiment 2 are the same as those in embodiment 1, so no further detailed description is required. Embodiment 2 has some differences from Embodiment 1 as follows.

[0042] In order to meet the requirements of greater operating power, operating torque and lower opening and closing speeds, Embodiment 2 has the following changes compared with Embodiment 1: the total spring force of the springs actually installed in Embodiment 2 is larger; the mechanism output The hexagon of the output end 105a of the shaft 105 is larger and extends out of the bottom plate shorter (sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com