Down-hole water warehouse coal slurry digging device

A technology for coal slime and excavation, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. It can solve the problems of inconvenience and general products, etc., to expand the scope of application and facilitate operation. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

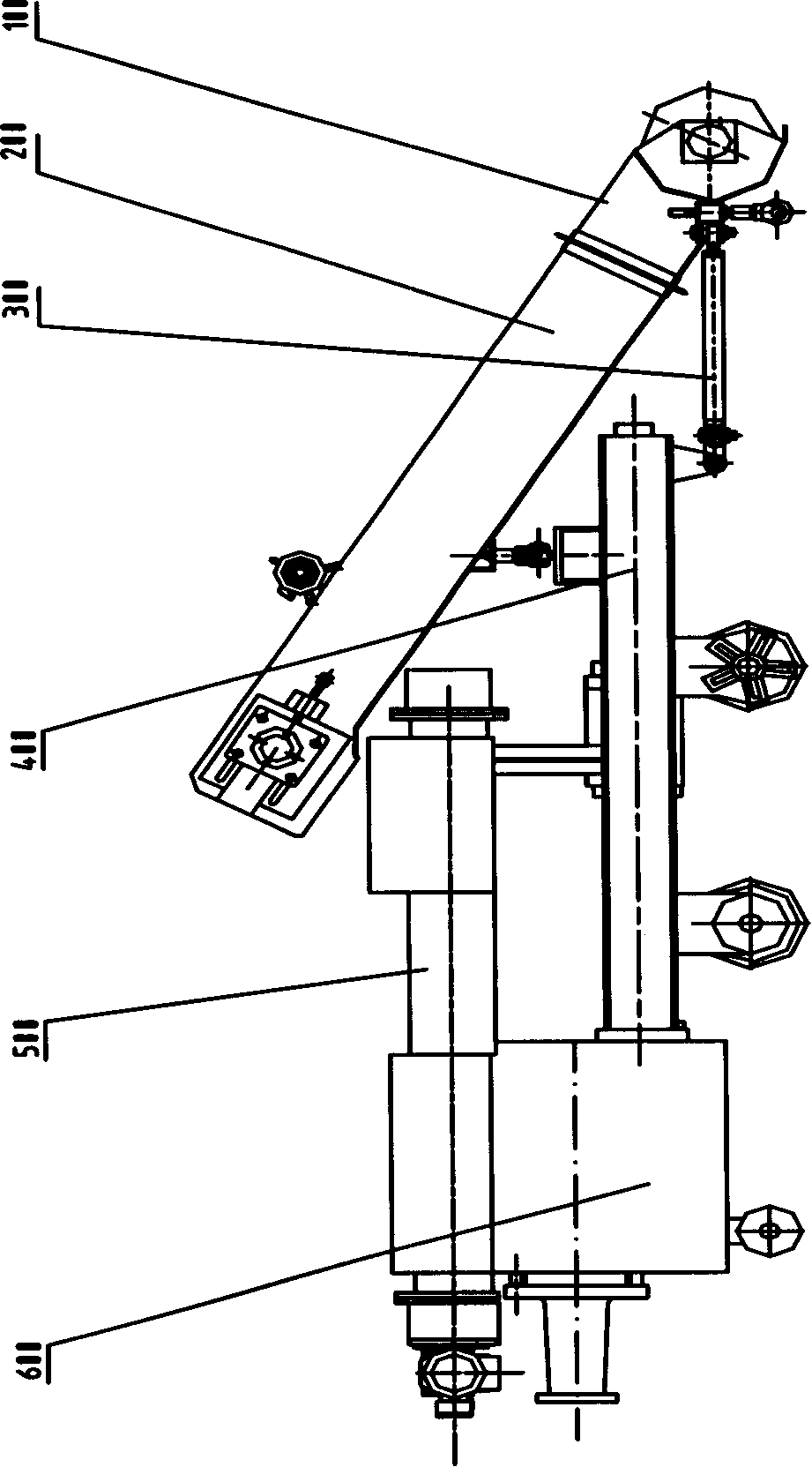

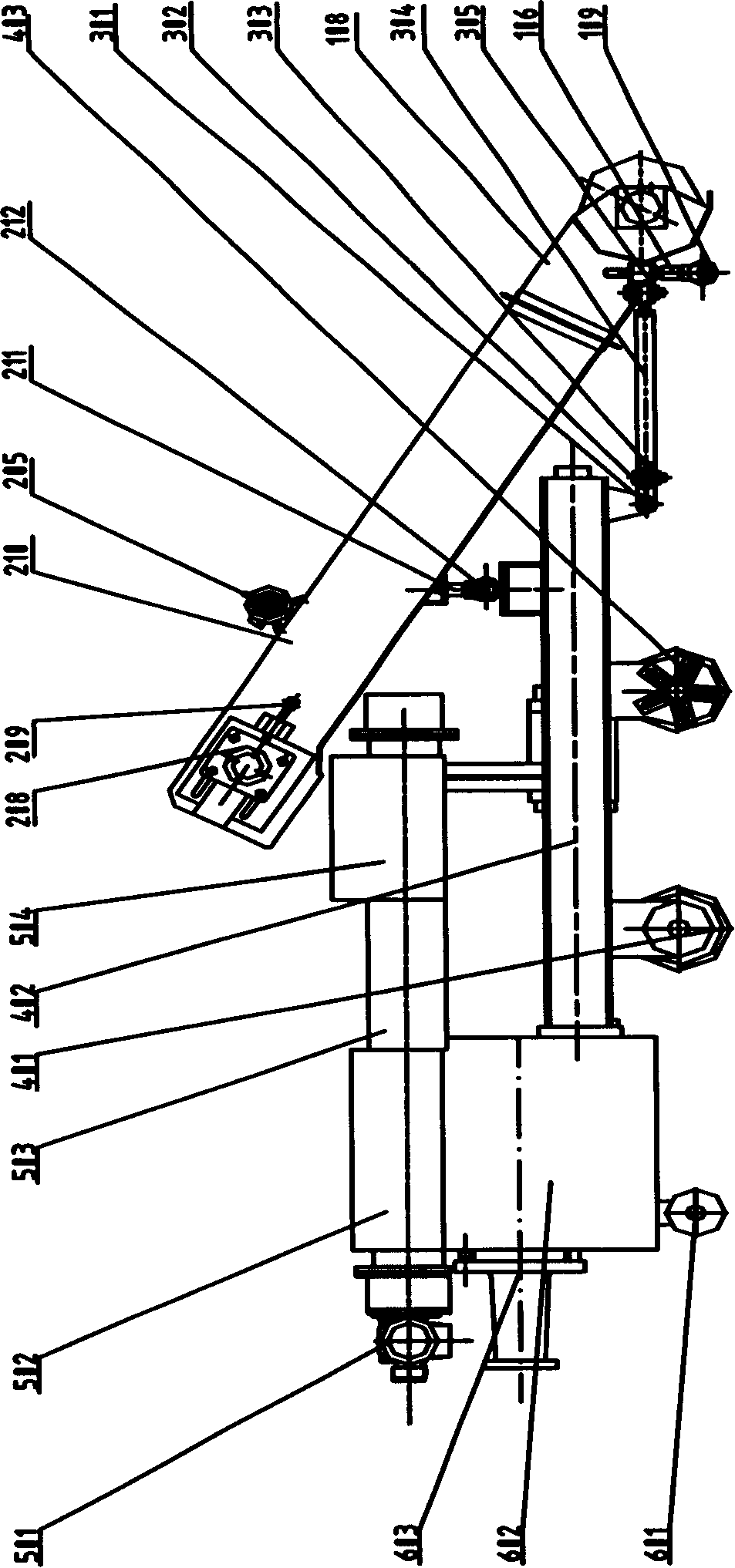

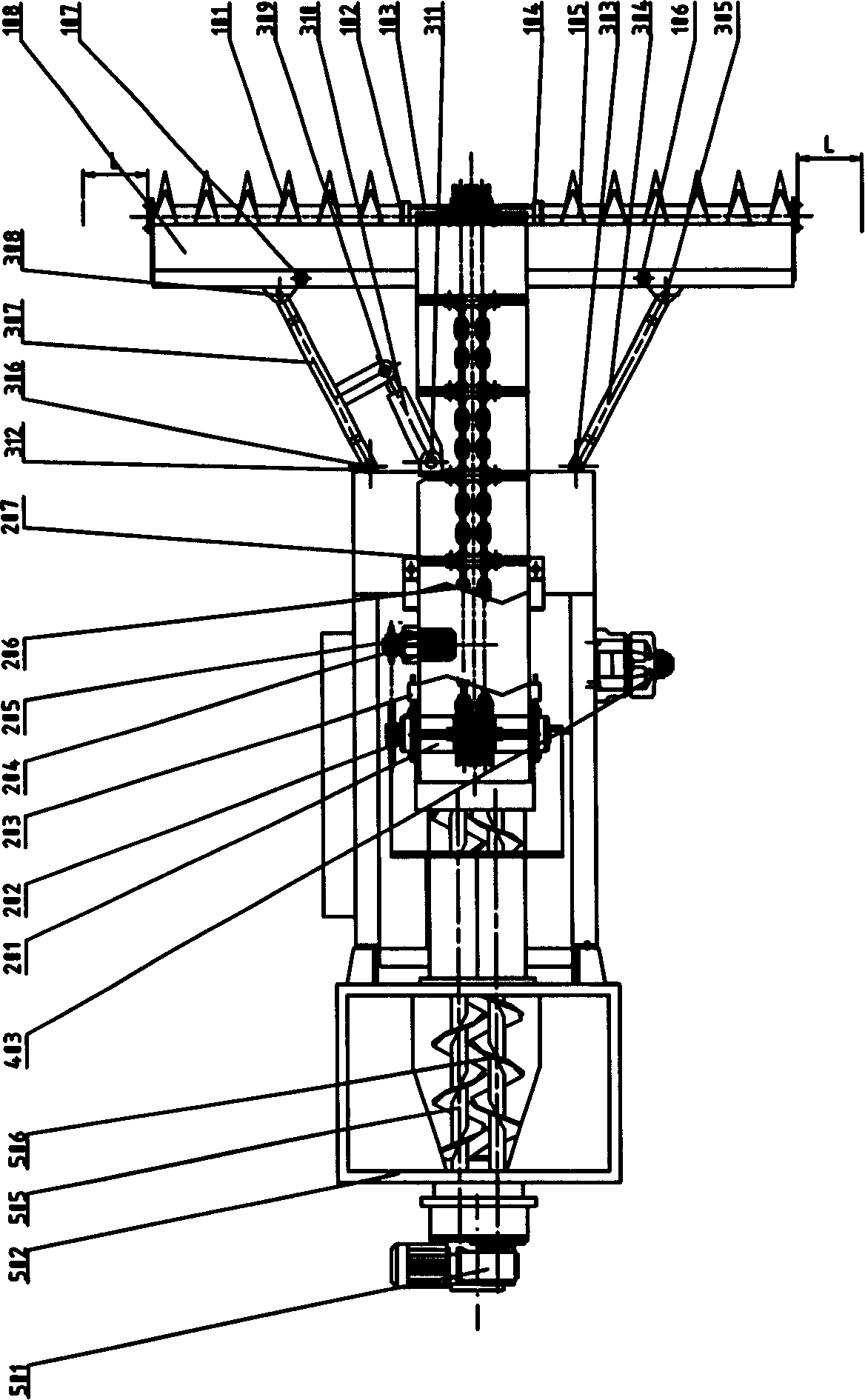

[0060] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the underground water bin coal slime dredging device that proposes according to the present invention, its specific implementation, structure , features and their effects are described in detail below.

[0061] figure 1 Among them, an underground water bin coal slime dredging device integrating coal slime excavation, coal slime aggregate, coal slime conveying, mixing and pumping. 400, conveying screw 500, concentrated material pump 600 and other parts. Wherein, the dredging screw 100 is located in front of the whole device, and the screw blade of the dredging screw 100 adopts a shaftless screw. One end of the conveyor scraper 200 is integrated with the middle part of the dredging screw 100, and the other end is located above the feed inlet of the conveyor screw 500....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com