Musical instrument packing box structure and preparing method thereof

A manufacturing method and technology for packaging boxes, which are applied in chemical instruments and methods, packaging, wrapping paper, etc., can solve the problems of being difficult to carry, not pressure-resistant, and complicated in process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

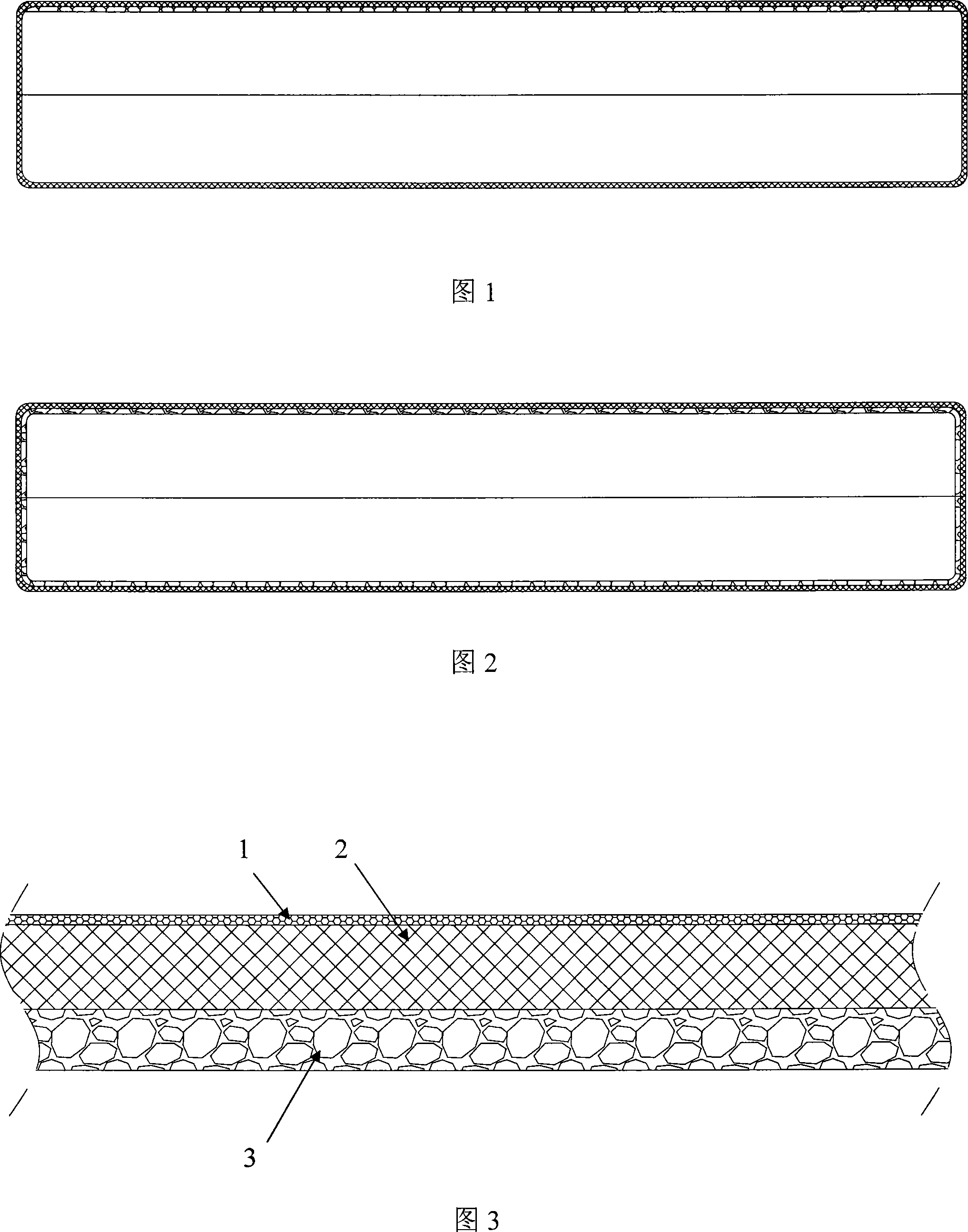

[0017] As shown in Figure 1, Figure 2 and Figure 3, the musical instrument packaging box structure of the present invention includes a musical instrument packaging box shell 2 made of rubber or PE, and Oxford cloth or PVC is adhered to the outer surface of the shell Cloth 1, a fiberglass layer 3 is adhered to the part to be reinforced on the inner surface of the casing of the musical instrument packaging box.

[0018] The above-mentioned manufacturing method of the musical instrument packaging box of the present invention is completed by the following steps:

[0019] 1) Make the outer casing of the musical instrument packaging box with Oxford cloth and elastic glue;

[0020] 2) Make at least one layer of fiberglass reinforcement layer on the part to be reinforced on the inner surface of the outer shell of the prepared musical instrument packaging box.

[0021] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com