Method and device for testing railway by laser and device thereof

A technology of laser detection and track, which is applied in the direction of using optical devices, active optical measuring devices, measuring devices, etc., can solve the problems of many intermediate links, low precision, and troublesome detection, and achieve the improvement of measurement accuracy, error avoidance, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

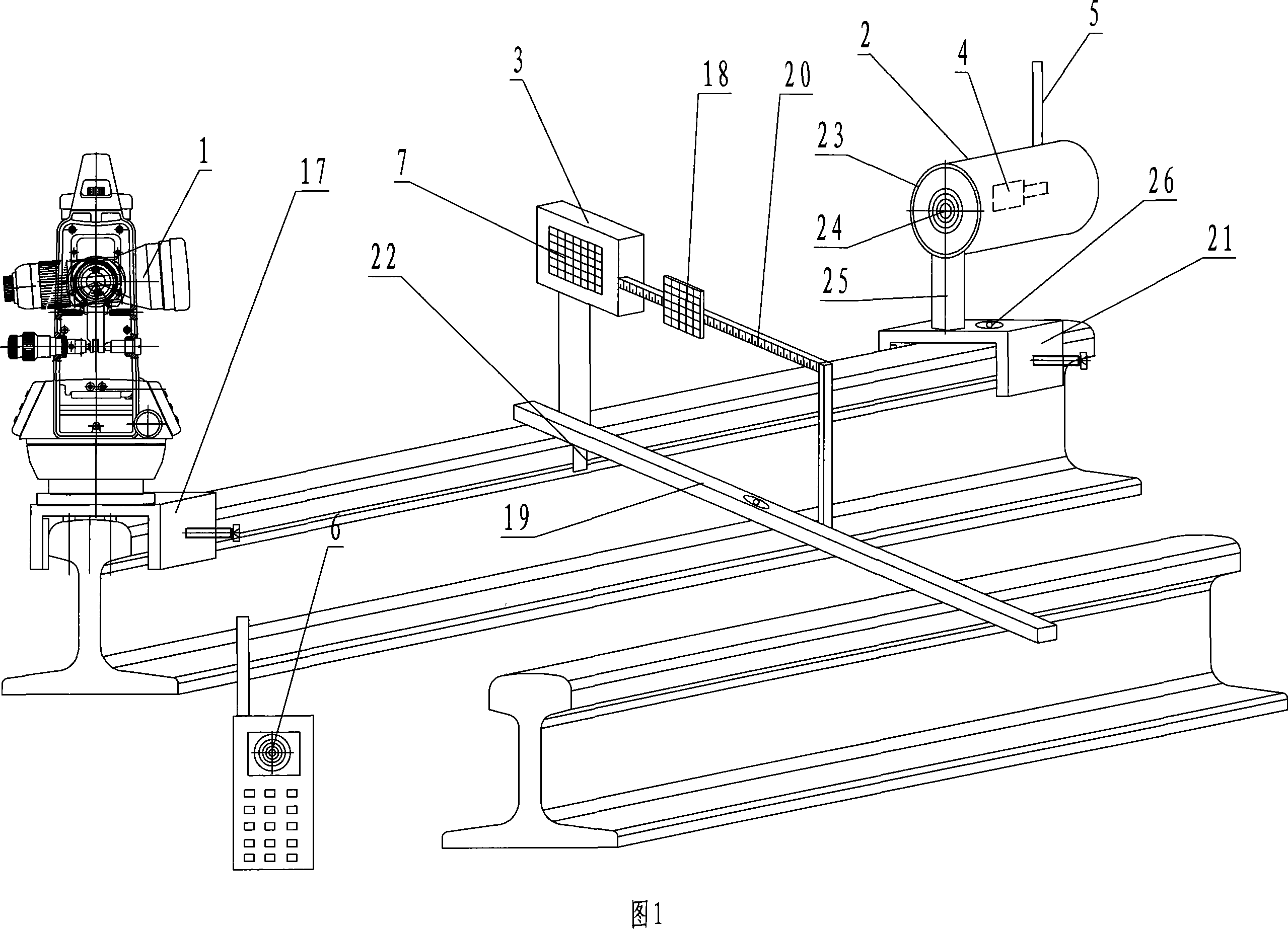

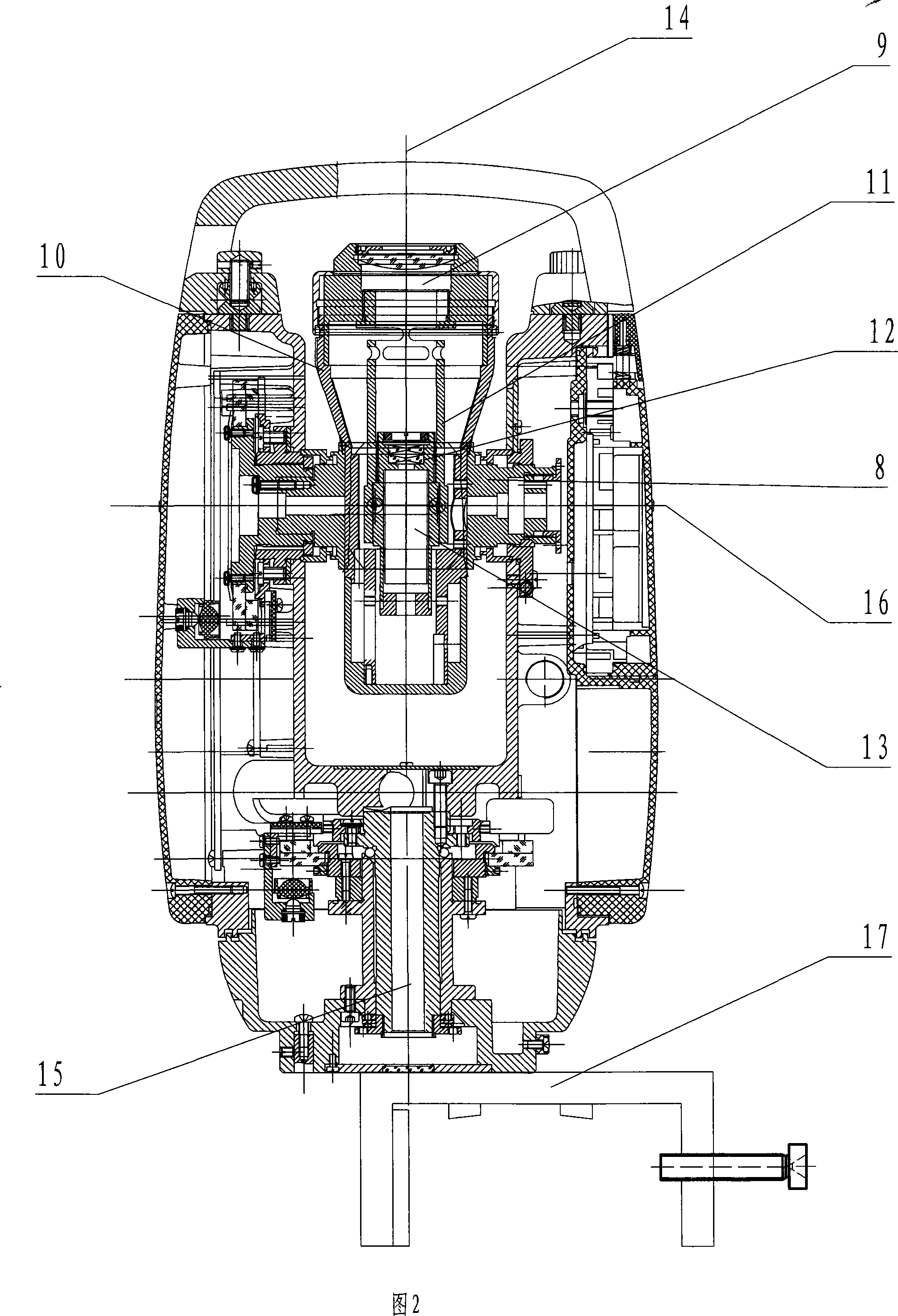

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail: as shown in Figure 1. It is composed of a laser transmitter 1, a positioning receiving light target 2, a measuring target 3 and an image wireless receiving device 6. A camera device 4 and a camera transmitting device 5 are installed in the positioning receiving light target. The camera device adopts a CCD or CMOS camera, and the laser emitter The device adopts a laser theodolite with a spatial phase modulator. As shown in Figure 2, the laser theodolite adopts a laser theodolite with a spatial phase modulator. It consists of a base, an adjustment system, an operating system, a display system, a shell and a handle, and A laser emitter 9 is installed vertically on the longitudinal axis of rotation 8, a spatial phase modulator 11 is installed in the laser emitter housing 10, a laser 13 is fixed at the end of the spatial phase modulator close to the lens group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com