Automatic vertical quartz tube cleaning machine and cleaning technique thereof

A quartz tube and cleaning machine technology, applied in the field of cleaning, can solve problems such as insecurity, multiple processes, and fragility of back and forth handling, and achieve the effects of improving cleanliness, coherent processes, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

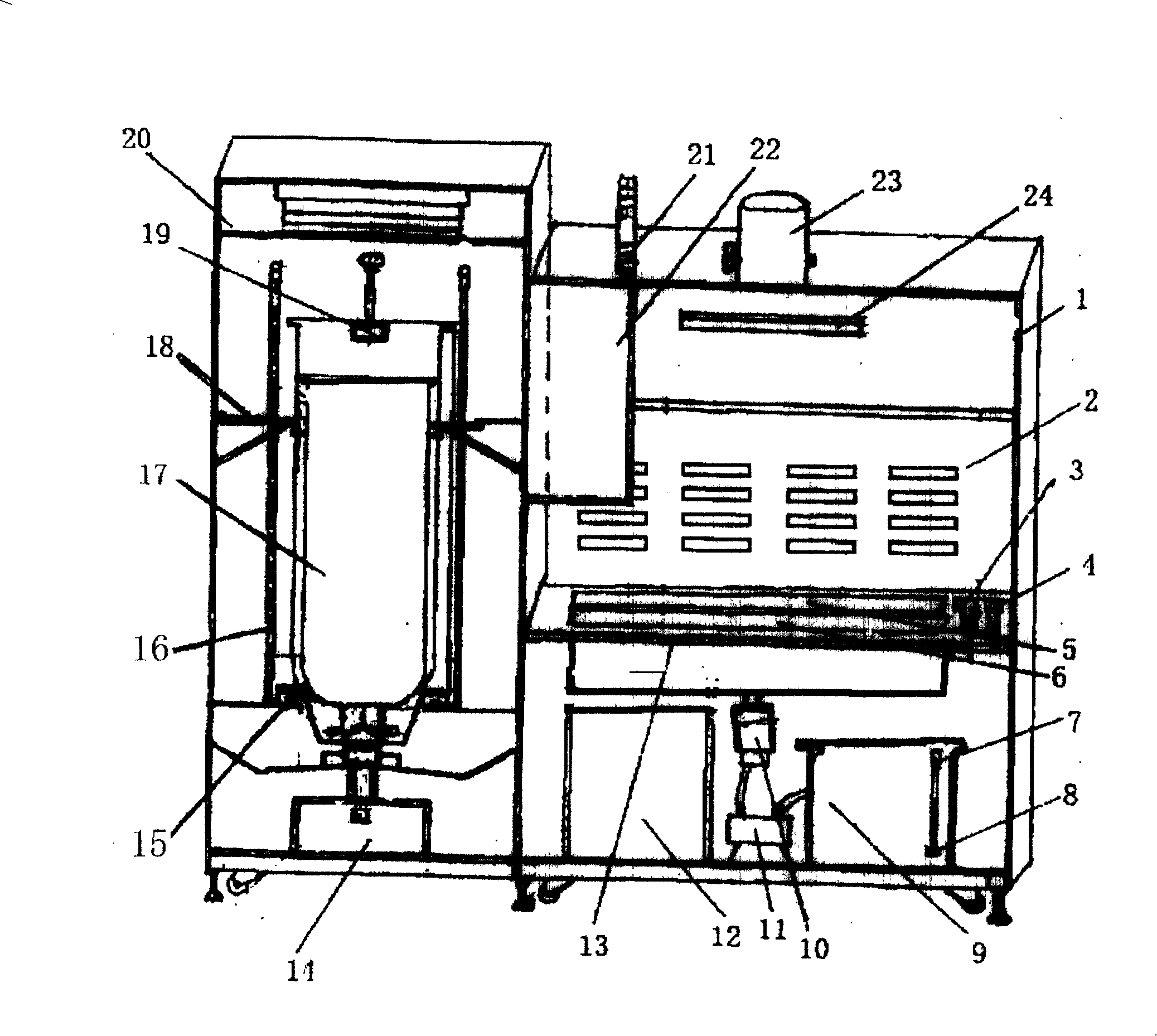

[0018] The invention provides an automatic vertical quartz tube (bell jar) cleaning machine and a cleaning process thereof. The automatic vertical quartz tube cleaning machine is composed of a horizontal cleaning cabinet and a vertical quartz cleaning cabinet. On the working table 13 of the horizontal parts cleaning cabinet 1, the pickling tank 5 and the water washing tank 6 are embedded on the table 13. There are also liquids, spray guns 3 and gas spray guns 4, and the liquid spray guns 3 are used for spraying water or acid. A certain pressure of water or acid sprays the inner and outer walls of the quartz tube, and the dirt attached to the inner and outer walls of the tube is washed by the pressure water and easily falls off, and then dehydrated. Residual acid and water liquid film spraying and drying shorten the drying time. The liquid storage tank 9 and the heating tank 12 are placed under the table top 13. The lower liquid level alarm 8 and the liquid level alarm 7 are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com