Double-power driven single-wing fixed-wing aircraft

A dual-power drive, fixed-wing technology, applied in the field of fixed-wing aircraft, can solve the problems of low aircraft safety performance, short aircraft endurance, no engine group, etc., and achieve the effect of shortening take-off distance, increasing endurance time, and improving power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

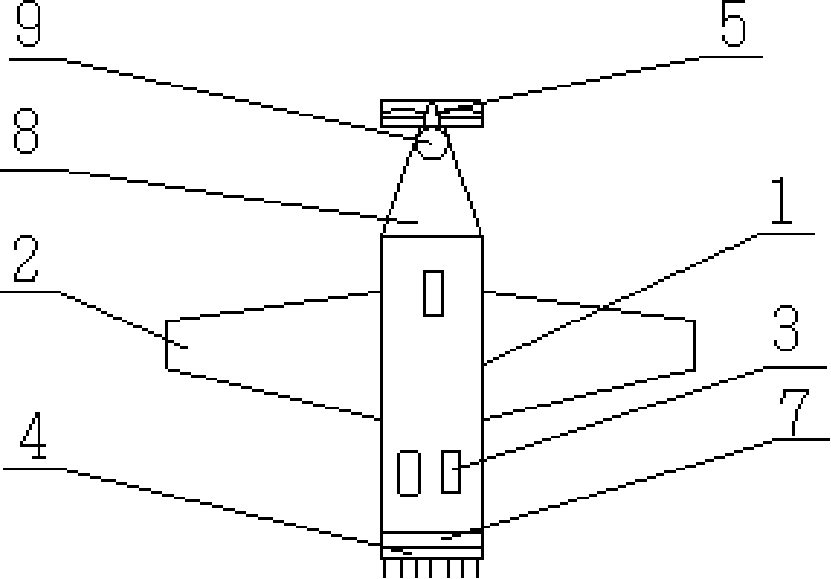

[0022] Embodiment 1 of the present invention: the present invention is as figure 1 Shown, it comprises the fuselage 1 of existing aircraft, the wing 2 that is connected on the fuselage 1 and the landing gear 3 that is connected under the fuselage 1, turbo thrust engine 4 and propeller engine are installed on the aircraft, its common or Constitute power system of the present invention respectively, and adopt the mode of pulling forward and pushing back to provide power for fixed-wing aircraft; Existing electric pitch variable mechanism 9 is installed on propeller engine, and it can make the blade of propeller engine move in the direction of turbine thrust engine 4. Be in the feathering position when working independently, that is, the blade chord (the connection between the leading edge and the trailing edge of the blade is called the blade chord) is parallel to the fuselage, so as to reduce the resistance of the present invention when flying The propeller engine can use a pull...

Embodiment 2

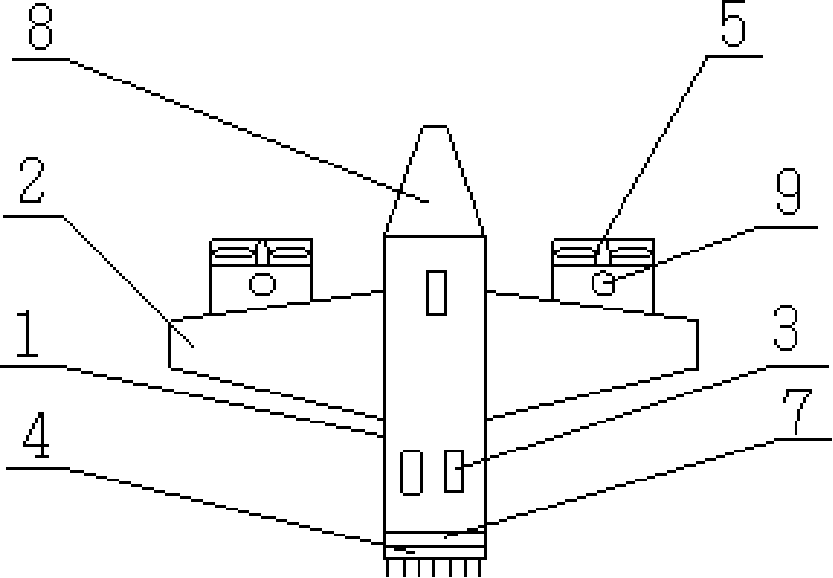

[0024] Embodiment 2 of the present invention: the present invention is as figure 2 Shown, it comprises the fuselage 1 of existing aircraft, the wing 2 that is connected on the fuselage 1 and the landing gear 3 that is connected under the fuselage 1, turbo thrust engine 4 and propeller engine are installed on the aircraft, its common or Constitute power system of the present invention respectively, and adopt the mode of pulling forward and pushing back to provide power for fixed-wing aircraft; Existing electric pitch variable mechanism 9 is installed on propeller engine, and it can make the blade of propeller engine move in the direction of turbine thrust engine 4. Be in the feathering position when working independently, that is, the blade chord (the connection between the leading edge and the trailing edge of the blade is called the blade chord) is parallel to the fuselage, so as to reduce the resistance of the present invention when flying The propeller engine can use the p...

Embodiment 3

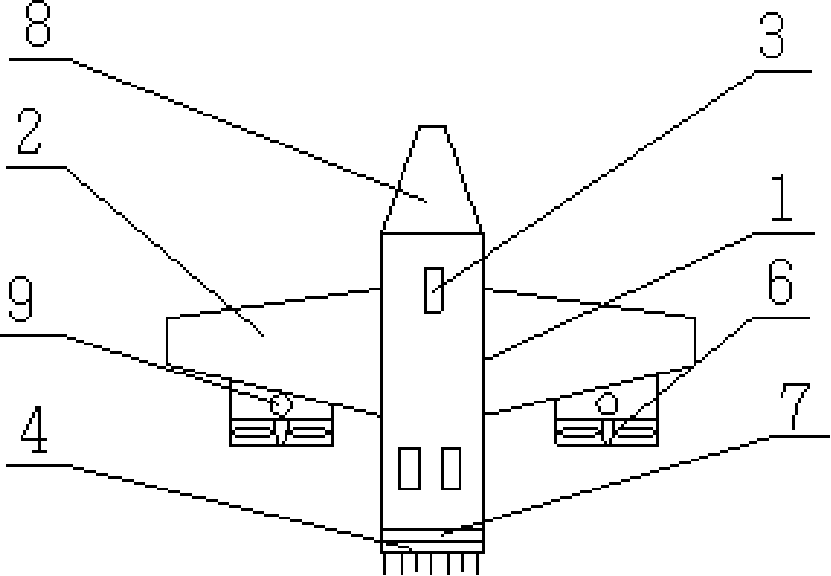

[0026] Embodiment 3 of the present invention: the present invention is as image 3 Shown, it comprises the fuselage 1 of existing aircraft, the wing 2 that is connected on the fuselage 1 and the landing gear 3 that is connected under the fuselage 1, turbo thrust engine 4 and propeller engine are installed on the aircraft, its common or Constitute power system of the present invention respectively, and adopt the mode of pulling forward and pushing back to provide power for fixed-wing aircraft; Existing electric pitch variable mechanism 9 is installed on propeller engine, and it can make the blade of propeller engine move in the direction of turbine thrust engine 4. Be in the feathering position when working independently, that is, the blade chord (the connection between the leading edge and the trailing edge of the blade is called the blade chord) is parallel to the fuselage, so as to reduce the resistance of the present invention when flying The propeller engine can use the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com