Pallet for conveying monolithic plate

A single-piece board and pallet technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large conflict impact of pallet 101, damage to workpiece 112, damage to workpiece 112, etc., so as to reduce costs and restrain individual components. The effect of increasing the number, eliminating position shift and breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

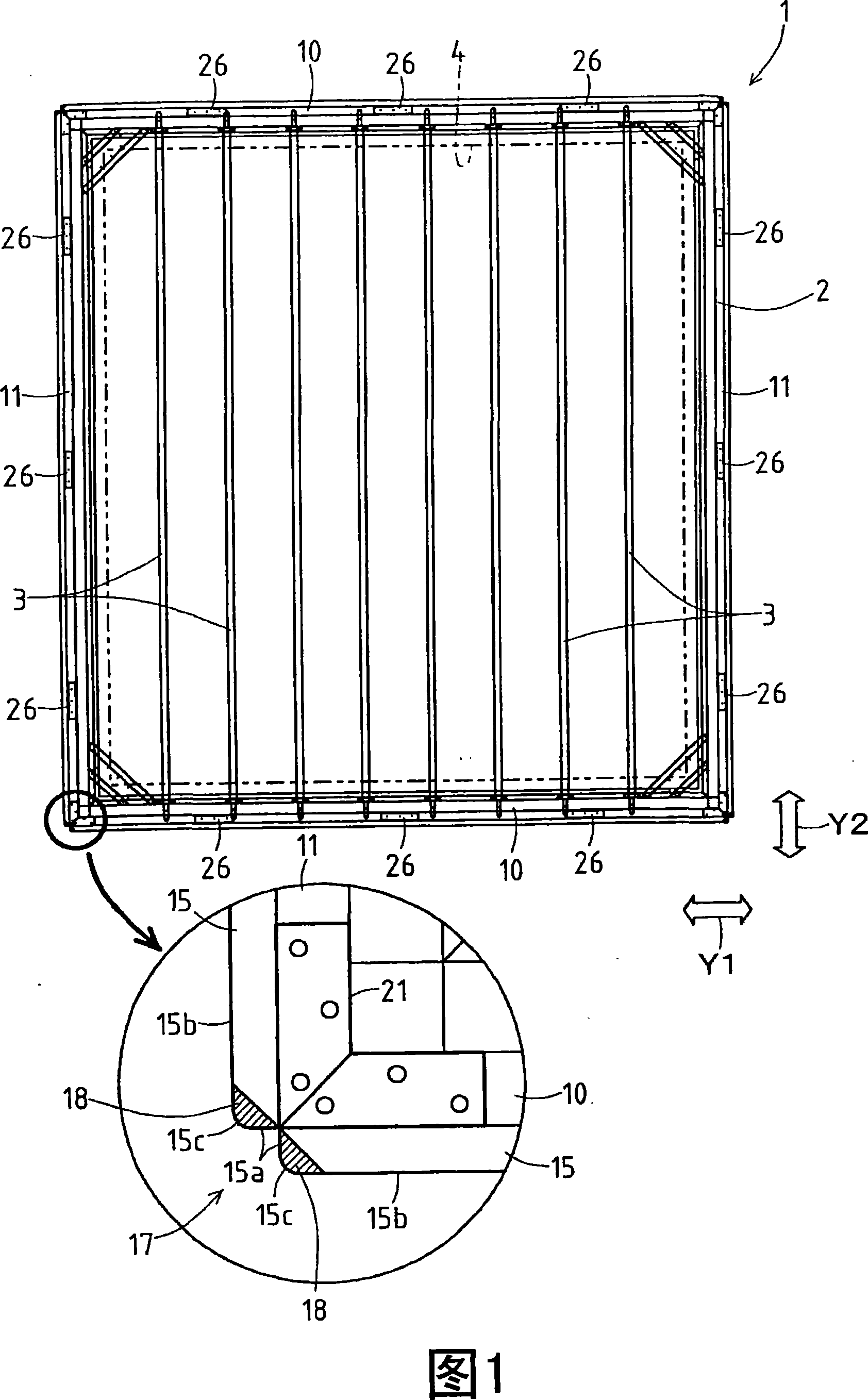

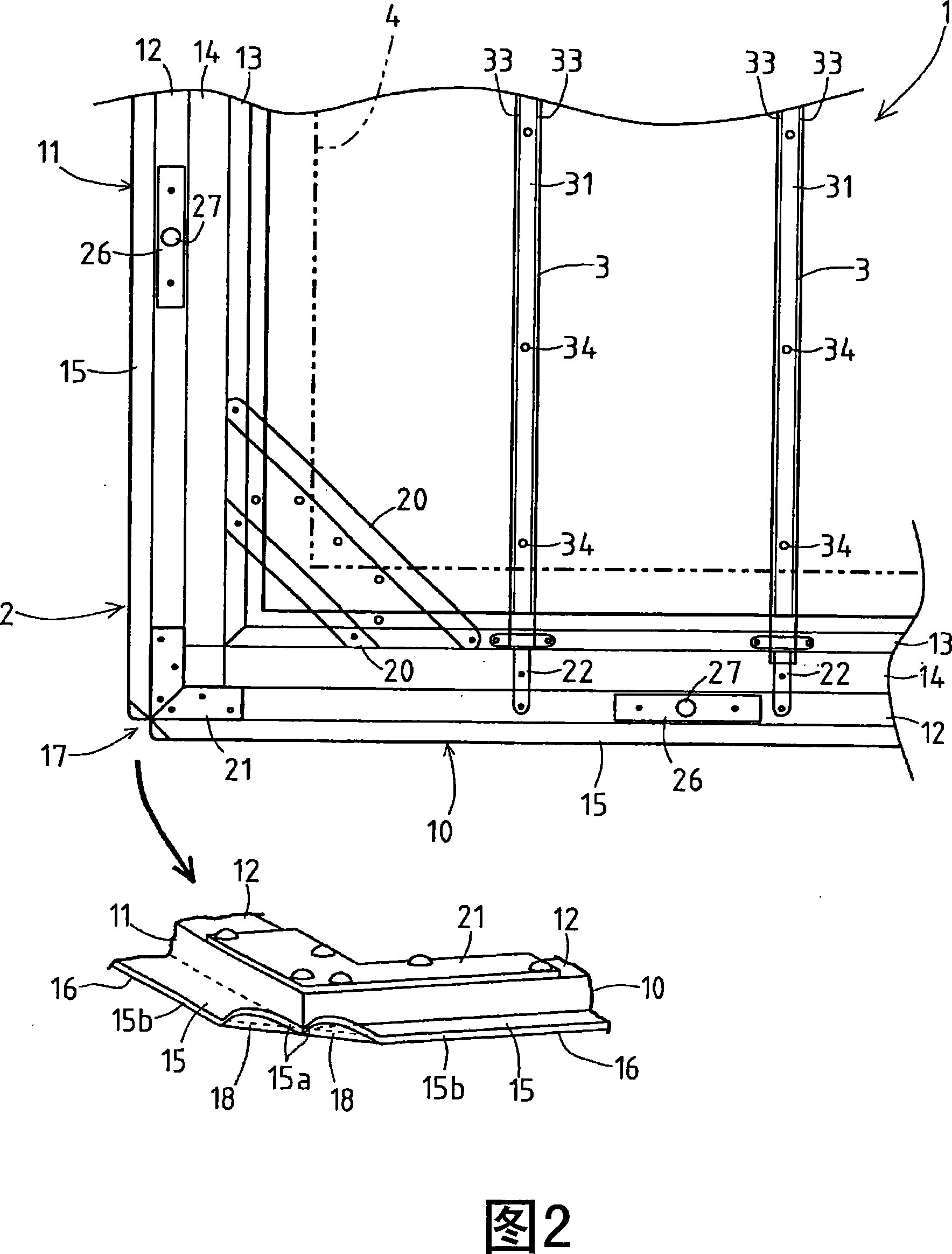

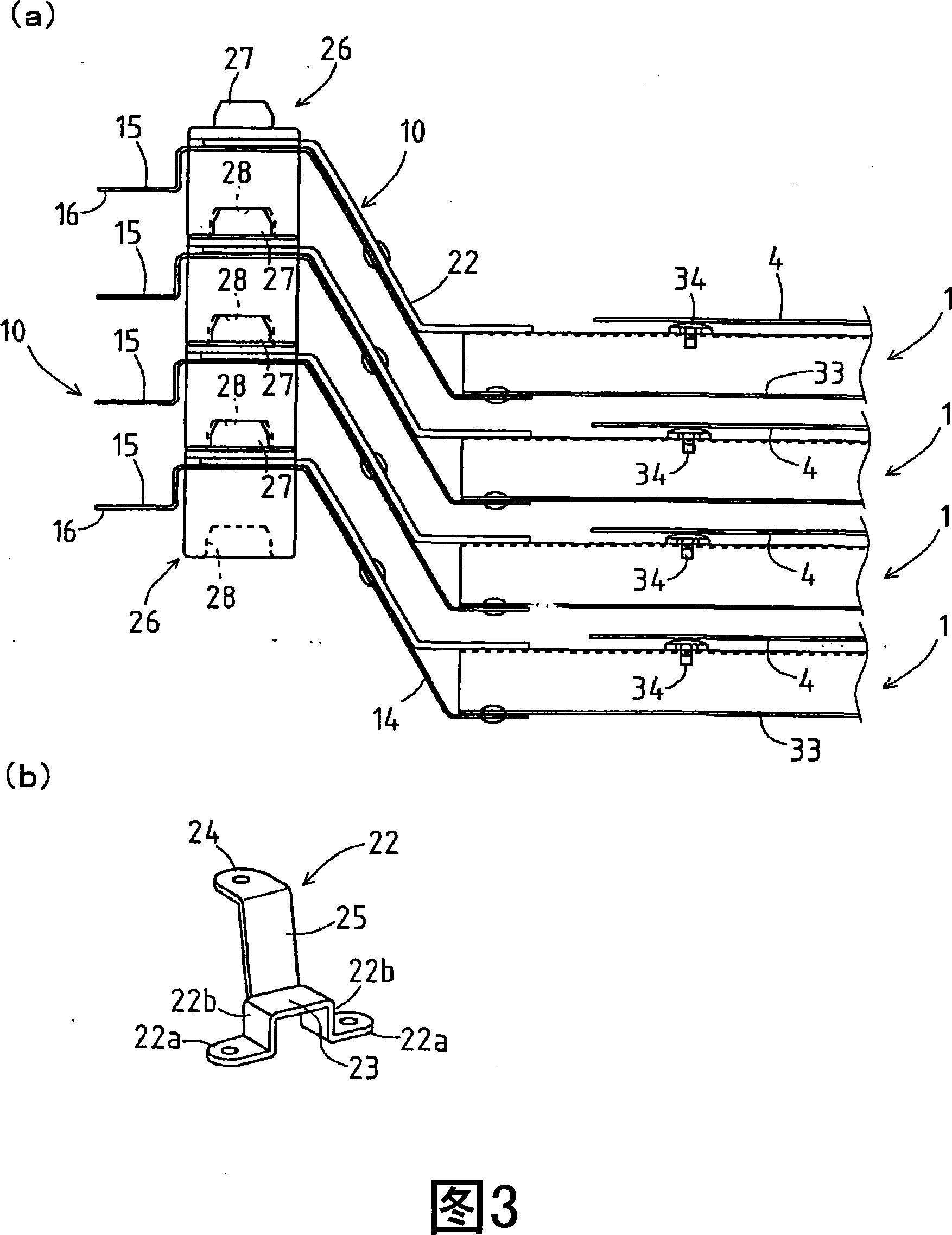

[0026] Hereinafter, embodiment of the tray for sheet|seat board conveyance which concerns on this invention is demonstrated, referring drawings. Fig. 1 is a plan view showing the overall structure of the single-sheet conveying tray of the present invention, Fig. 2 is an enlarged view of important parts, Fig. 3 is a view showing a state in which trays are stacked, and Figs. 4 to 6 show roller conveyance. A diagram of the conveying state of the single-piece board conveying tray of the machine. In addition, in FIG. 1 , the following is specified: the direction indicated by the arrow Y1 is the front-rear direction, and the direction (arrow Y2 ) orthogonal to this direction is the left-right direction.

[0027] As shown in FIG. 1 , a pallet (hereinafter referred to simply as "tray") 1 for conveying single-piece boards has a hollow quadrangular frame-shaped outer frame 2 and a plurality of (in this paper) erected between the left and right sides of the outer frame 2. In the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com