Substrate transfer-machine and substrate take-in box thereof

A technology for transferring machines and substrates, which is applied in the direction of conveyor objects, packaged object types, special packaged objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

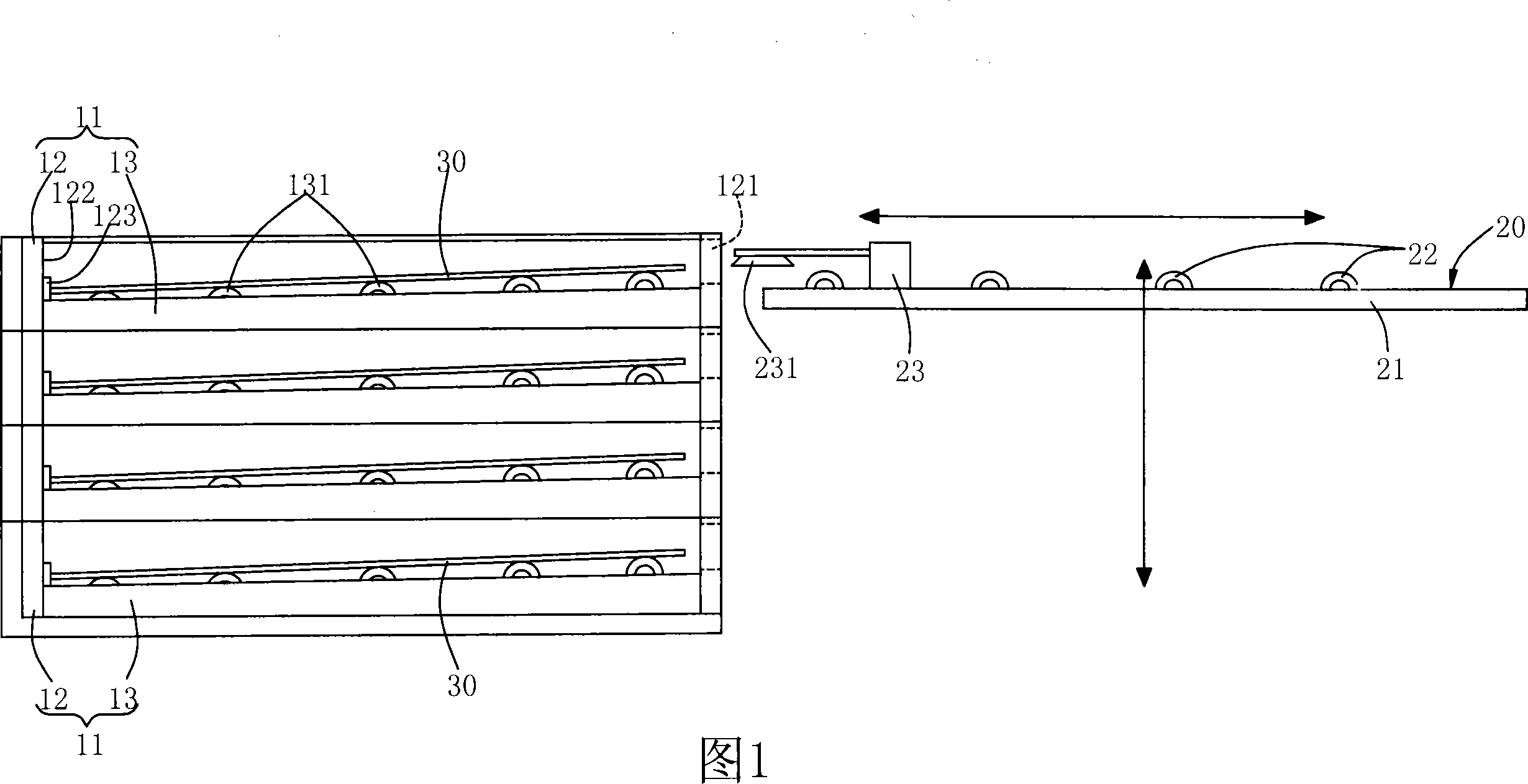

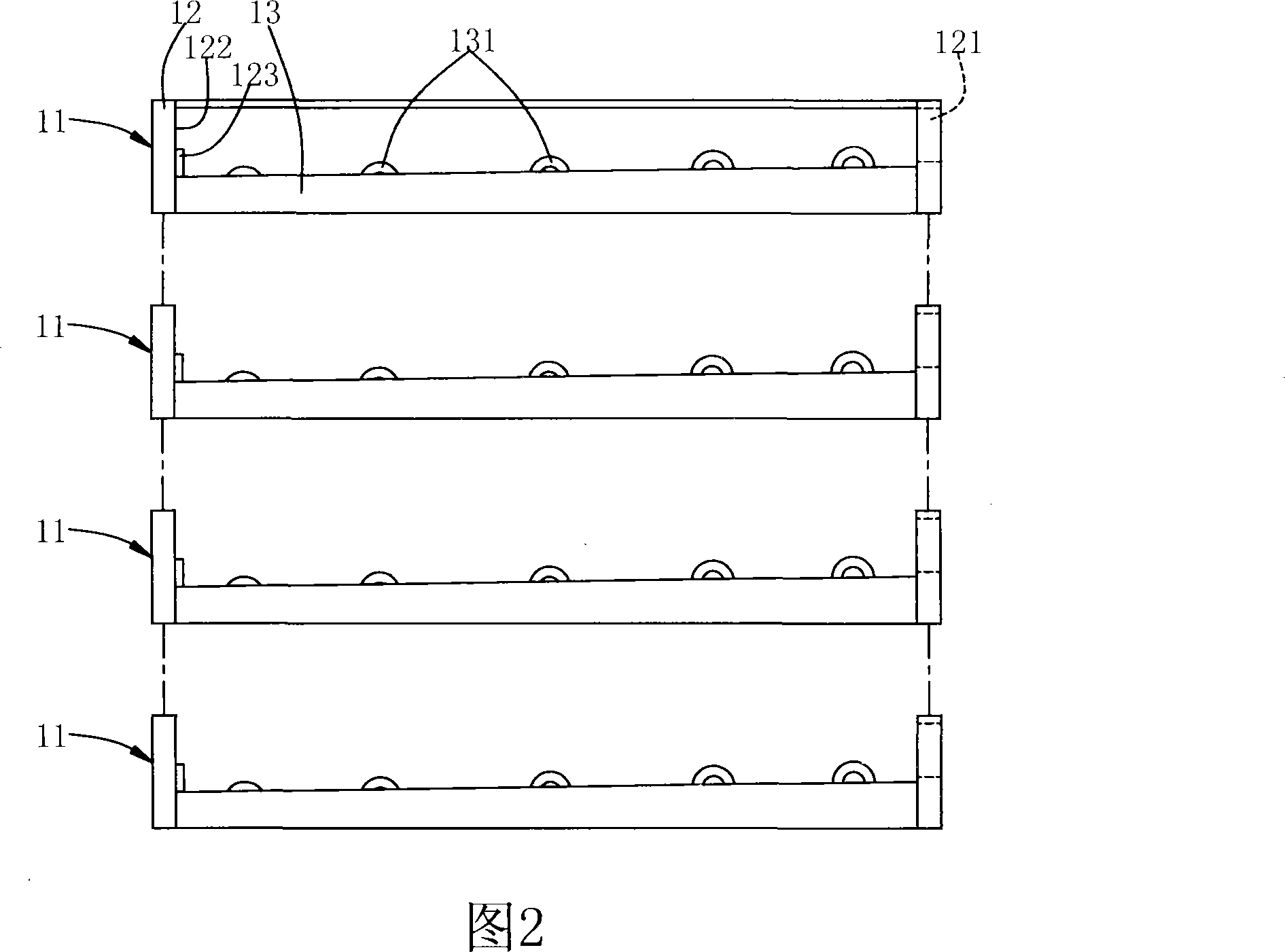

[0038] Please refer to FIG. 1 and FIG. 2 , which is a substrate transfer machine provided by the first embodiment of the present invention, which is suitable for storing or transferring substrates 30 . The substrate 30 may be, but not limited to, a glass substrate of a liquid crystal display panel. The substrate transfer machine in this embodiment includes a plurality of substrate storage boxes 11 and a take-out device 20 . Each substrate storage box 11 is formed by stacking each other up and down, and the substrate storage boxes 11 can be disassembled one by one for cleaning. In other embodiments of the present invention, only a single substrate storage box 11 may be provided to store and retrieve the substrate 30 .

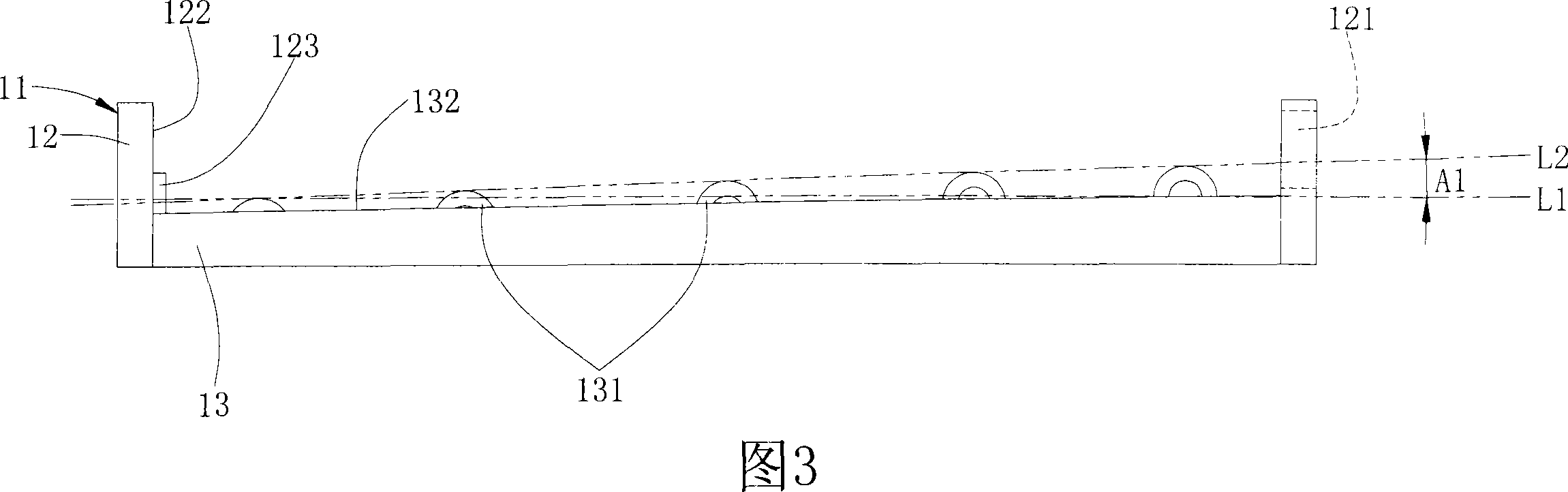

[0039]Please refer to Figure 3, Figure 4 and Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com