Agitating fan assembly structure of circular furnace cavity micro-wave oven

A component structure and microwave technology, applied in the field of microwave ovens, can solve the problems of ineffective concentration, microwave dispersion, poor heating uniformity, etc., and achieve the effects of good heating effect, good heating uniformity, and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the drawings and examples.

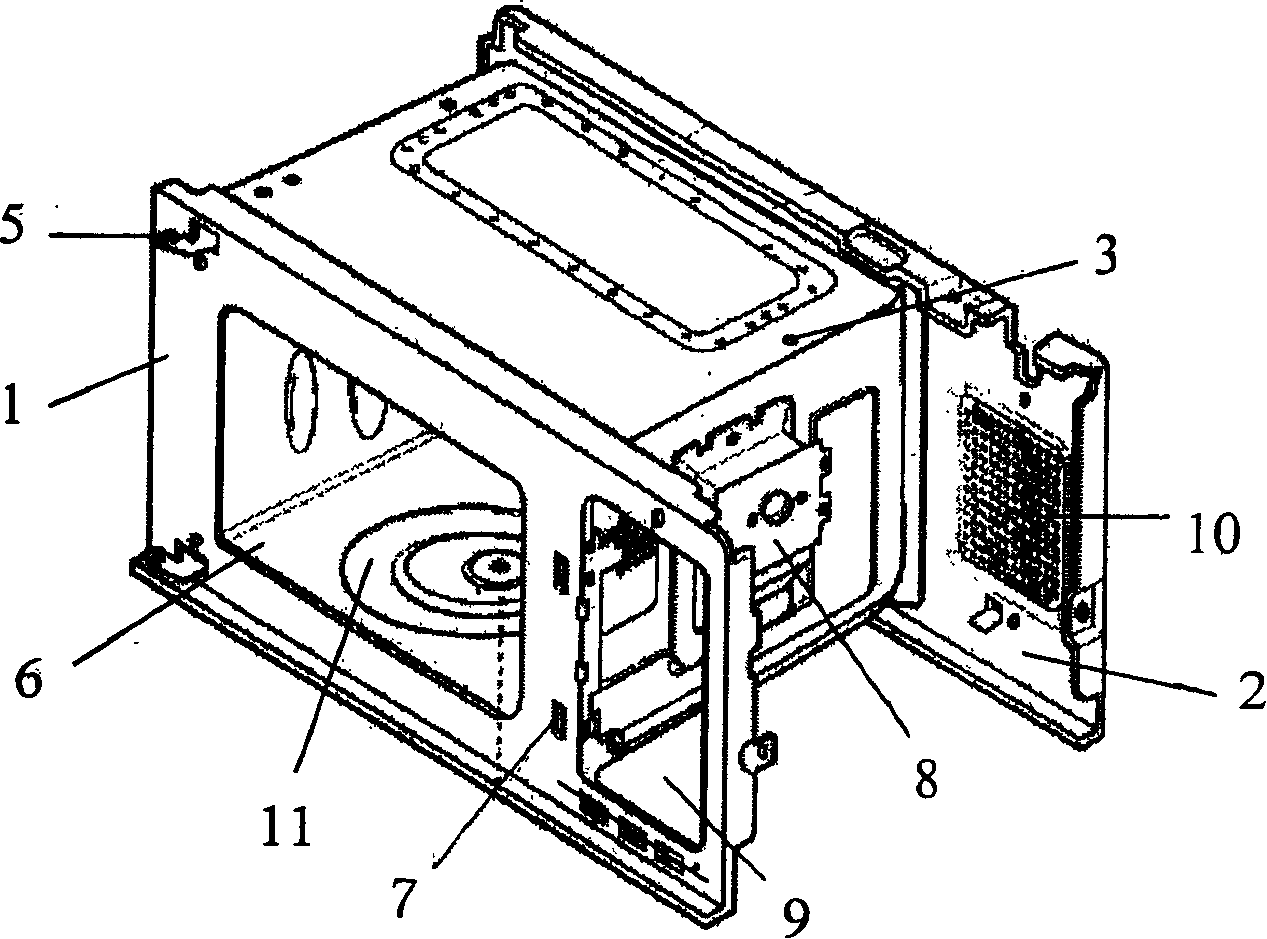

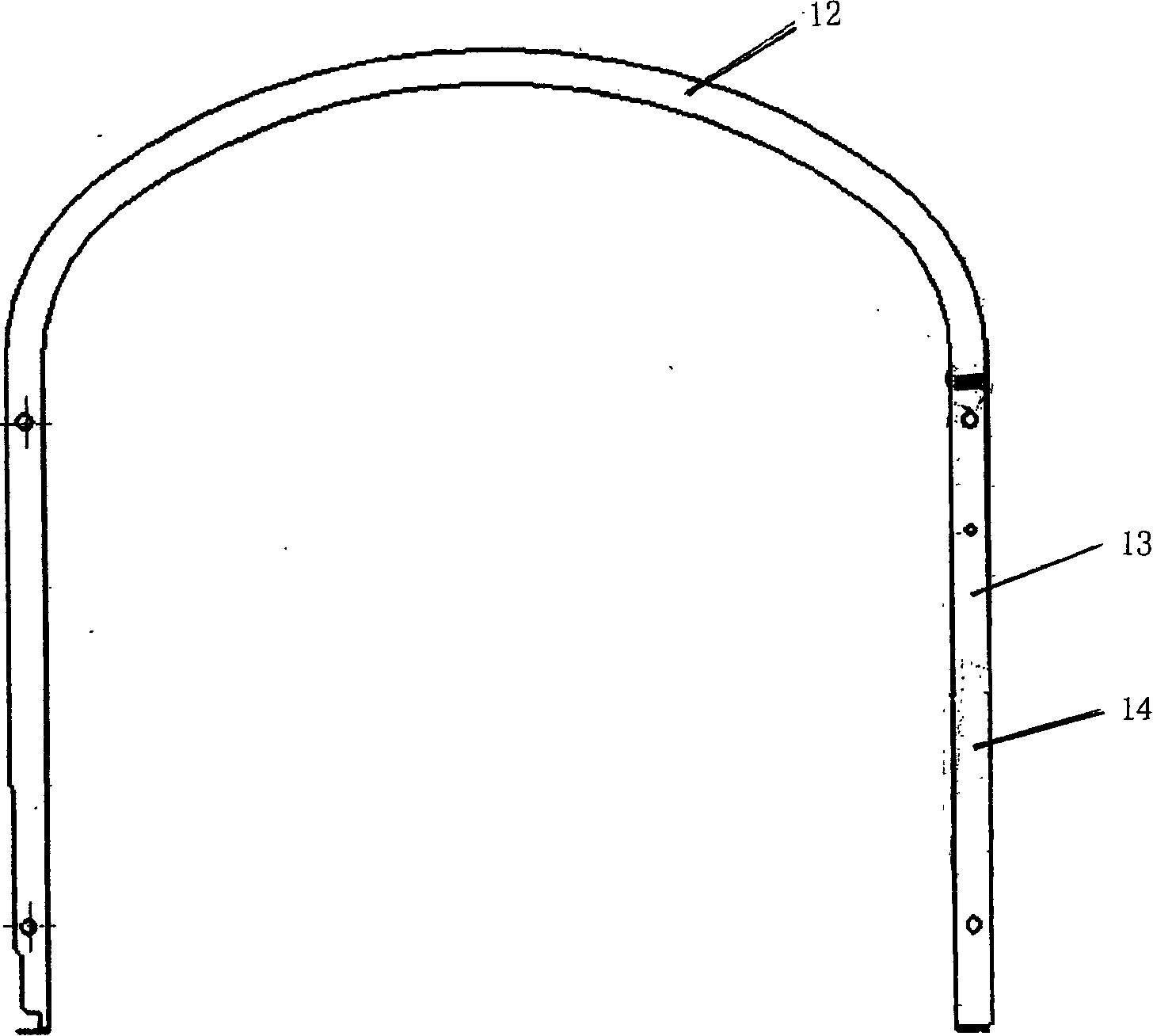

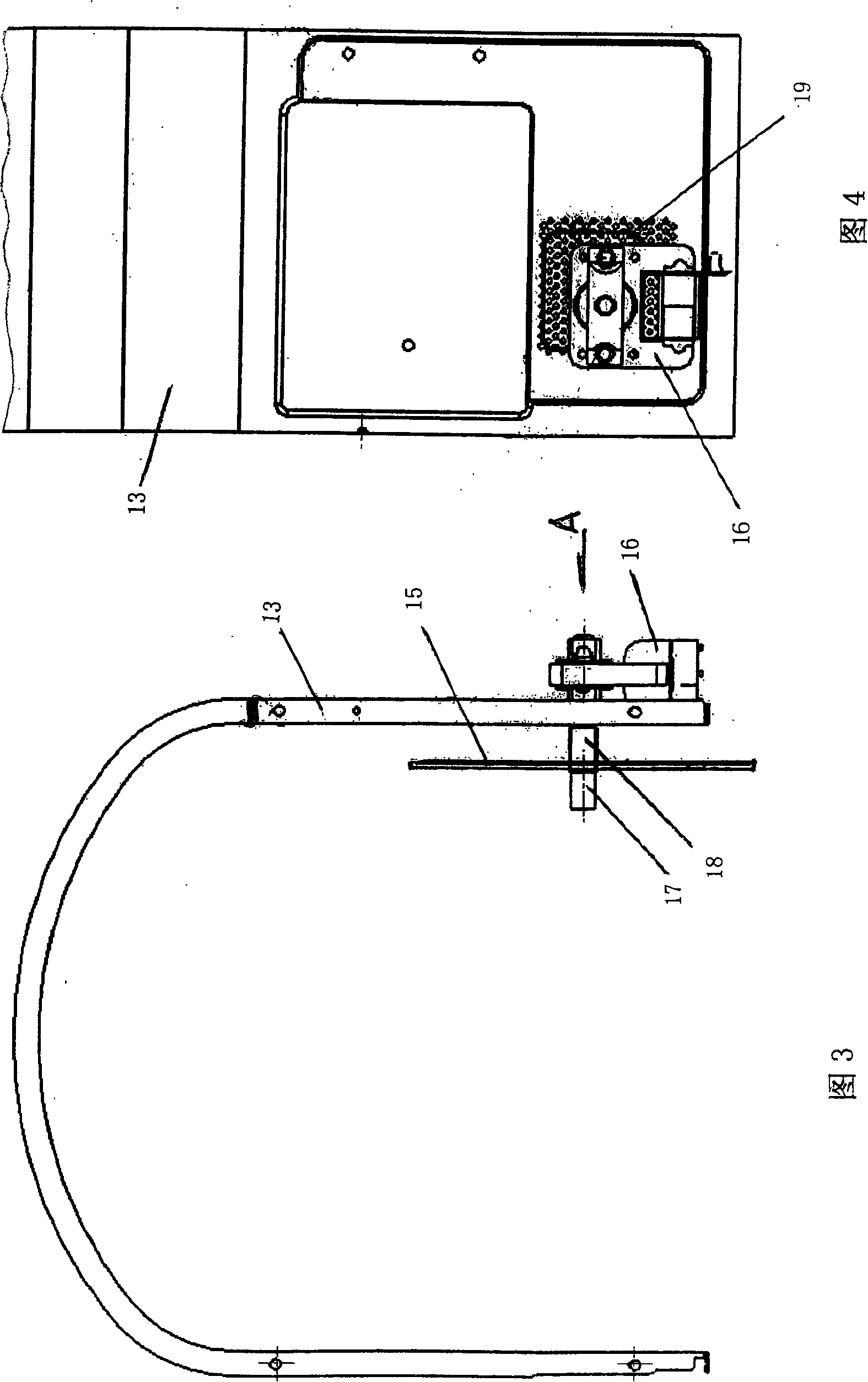

[0032] The structure of the stirring fan assembly of the round cavity microwave oven of the present invention is as shown in the figure, figure 1 It is a three-dimensional view of the structure of the glass turntable microwave oven after removing the shell.

[0033] Such as figure 1 As shown, the hexahedral rectangular box of the microwave oven is surrounded by a front panel 1, a rear panel 2, side panels, a top panel, a bottom panel (not shown), and a hinge shaft 5 connected to the oven door (not shown) in front of the front panel. The furnace cavity 6 is formed. Heat-resistant glass (not shown) that prevents microwave penetration is provided in the middle of the furnace door (not shown), and the other side of the furnace door is provided with a door handle (not shown) that is convenient for opening and closing the furnace cavity 6. The provided striker pin (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com