Infrared temperature measurement online self-calibrating equipment and method thereof

An infrared temperature measurement and self-calibration technology, applied in the field of infrared temperature measurement devices and their calibration, can solve the problems of waste of resources, low work efficiency, poor device packaging, etc., to improve measurement accuracy, improve work efficiency, and reduce the amount of calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

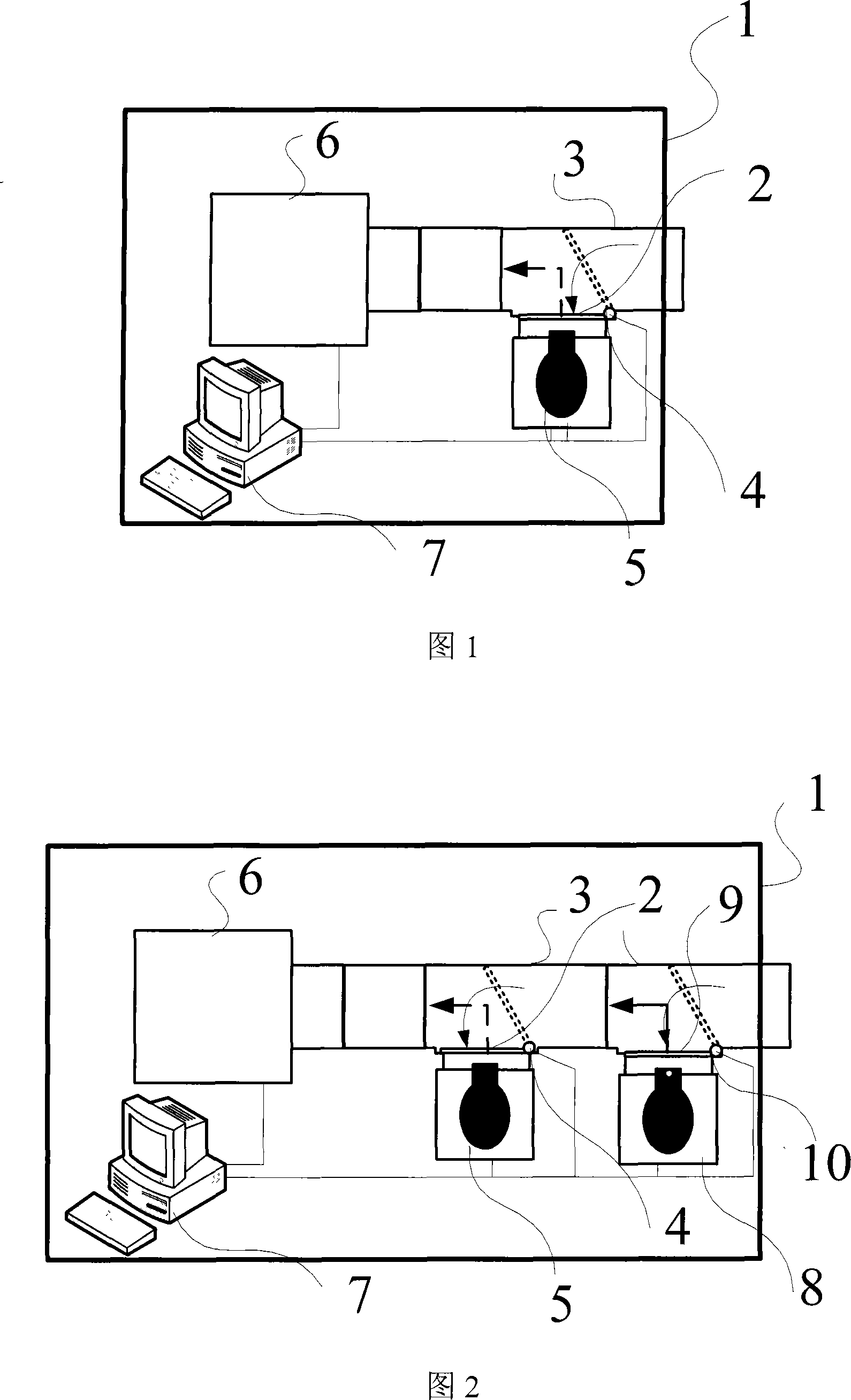

[0026] As shown in Figure 1, the device consists of a black body 5, a mirror 2, a rotation axis 4, an infrared camera 6, a square lens barrel 3, and a computer 7 assembled in the same housing 1. The infrared camera 6, the built-in black body 5, And the mirror 2 is electrically connected to the computer 7 through a data cable, the rotation axis 4 is located on a frame of the square lens barrel 3, and the rotation axis 4 of the mirror 2 is controlled to rotate through the instructions of the computer 7 to maintain the constant temperature of the black body 5 and process the infrared Camera 6 data.

[0027] The method and process of using the above device to perform infrared temperature measurement online self-calibration is:

[0028] (1) When the infrared temperature measuring device is in the working state of temperature measurement, the position of the reflector 2 just connects the optical path between the measured object and the infrared camera 6 and at the same time blocks the o...

Embodiment 2

[0033] As shown in Figure 2, the device consists of two black bodies 5, 8, two mirrors 2, 9, two rotating shafts 4 and 10, an infrared camera 6, a square lens barrel 3, and a computer 7 assembled in the same housing 1. Among them, two or more built-in black bodies and reflectors can be set, as long as the set temperatures of the two or more built-in black bodies are not equal.

[0034] Blackbody 5 and 8 have different set temperatures. Blackbody 5 is a lower temperature blackbody with a set temperature of 30°C, and blackbody 8 is a higher temperature blackbody with a set temperature of 50°C. The infrared camera 6, the built-in black bodies 5 and 8, and the mirrors 4 and 10 are electrically connected to the computer 7 through a data cable. The rotating shafts 4, 10 are located on the frame of the lens barrel 3, and the mirrors 2 and 9 are controlled by the instructions of the computer 7 The rotating shafts 4 and 10 rotate to maintain the constant temperature of the black bodies 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com