Balance system with inhibition structure

A balance and bearing technology, applied in the field of balance systems, can solve the problems of increasing the rolling torque measurement error, the rolling torque signal distortion, and the limited improvement of the rolling torque measurement accuracy, so as to reduce interference and improve the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

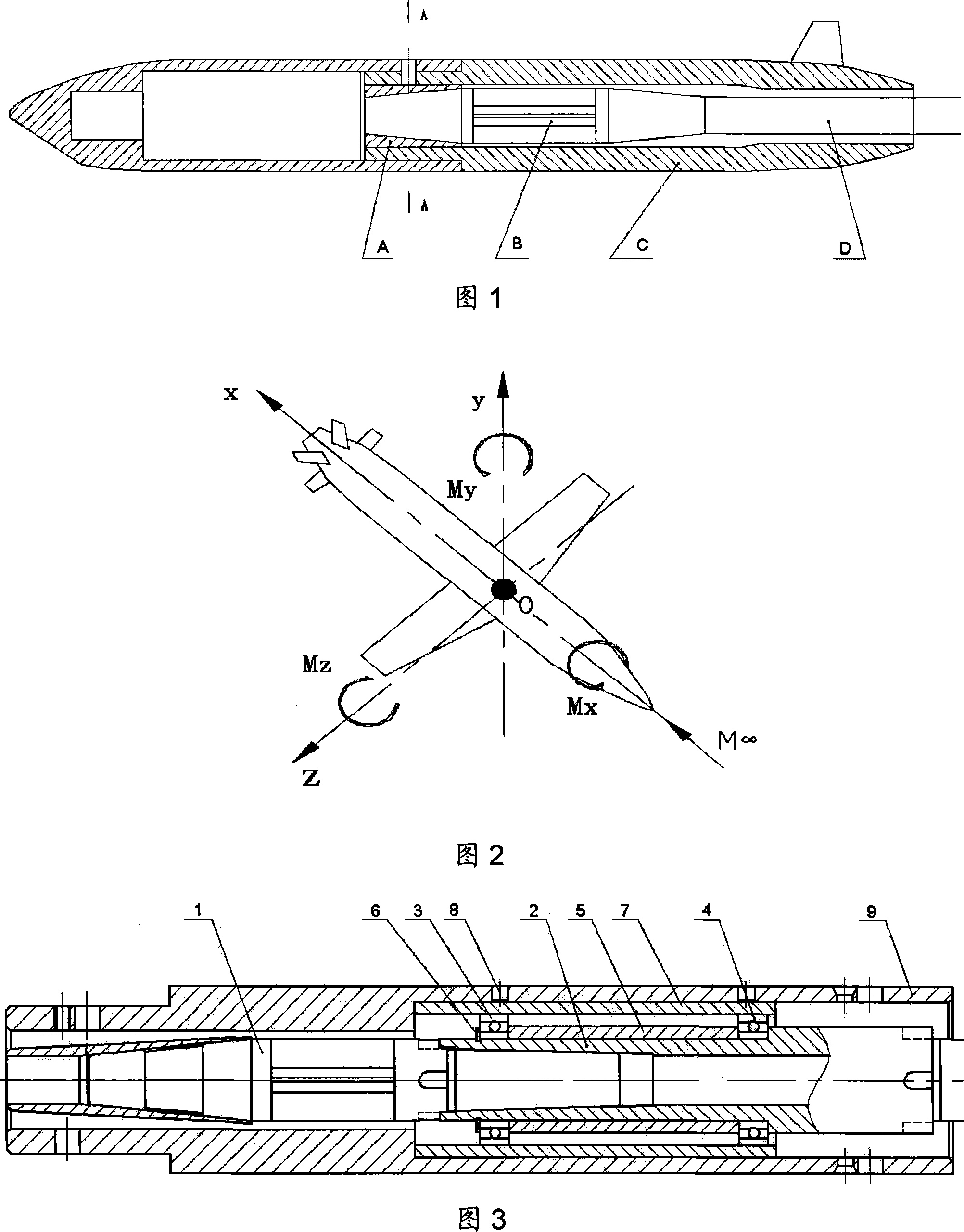

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0012] As shown in Figure 3, the present invention includes a six-component internal strain balance 1, a small inner ring shaft 2, a first deep groove ball bearing 3, a second deep groove ball bearing 4, a sleeve 5, a collar 6 and a bearing outer casing 7 , the front end of the small shaft 2 of the inner ring is connected with the rear cone of the six-component internal strain balance 1 through a 1:5 cone fit, and the rear end of the small shaft 2 of the inner ring is connected with the scimitar frame of the wind tunnel through the balance rod; A deep groove ball bearing 3, a second deep groove ball bearing 4 are mechanically matched with the inner ring small shaft 2, and a sleeve is installed between the first deep groove ball bearing 3 and the second deep groove ball bearing 4 on the inner ring small shaft 2 , its purpose is to fix the front a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com