Decelerator for control motor

A reducer and step technology, applied in the field of precision reducers, can solve the problems of fast wear, long working time, reduced gear efficiency, etc., and achieve the effects of high transmission efficiency, long service life and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

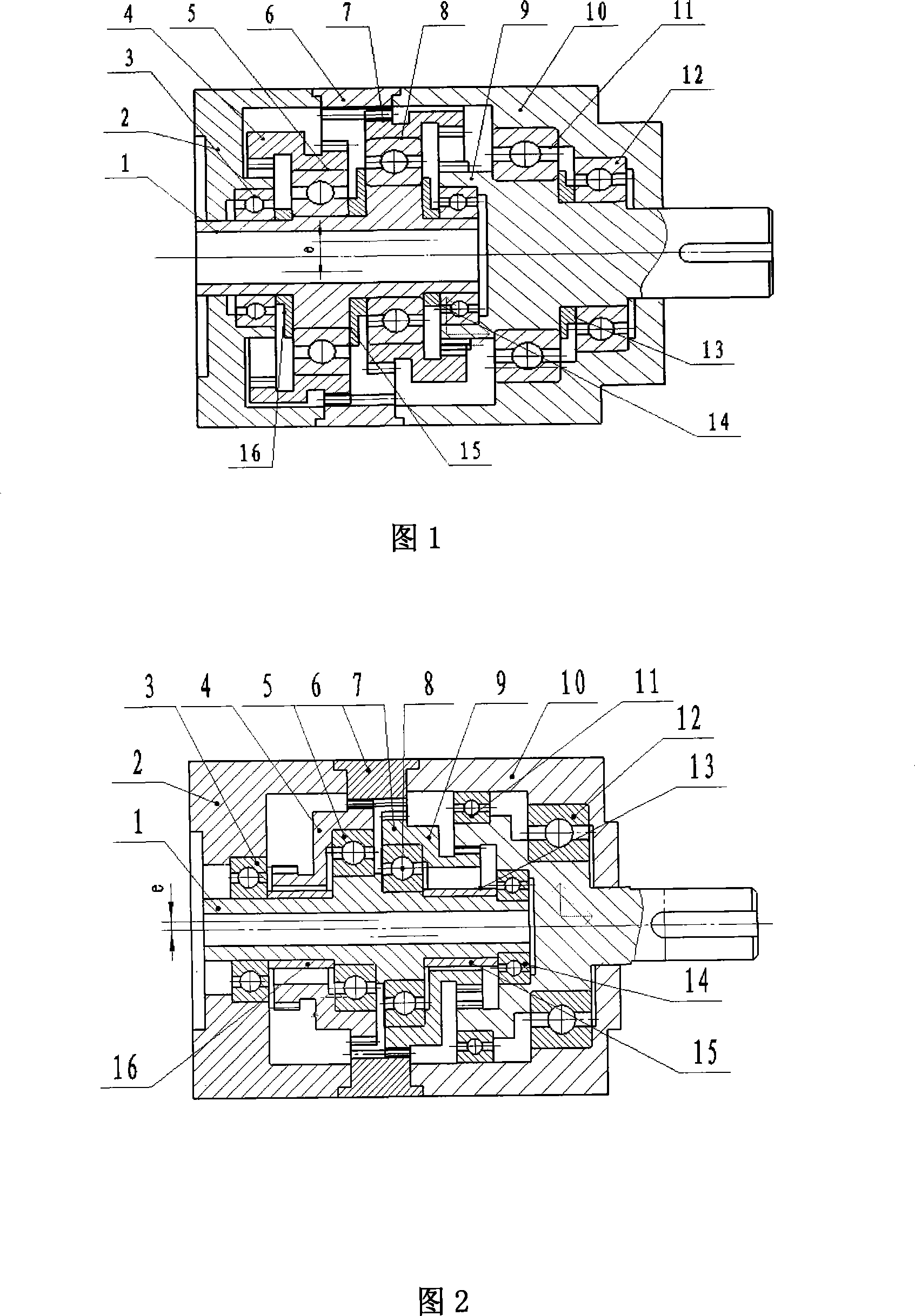

[0014] Embodiment 1: as shown in Figure 1, a kind of speed reducer for controlling motor is made up of input shaft 1, stepped planetary gear 4,7 (stepped planetary gear 4,7 are all made up of an external gear and internal gear), internal gear 6 , output shaft 9, right housing 10, left housing 2, support bearings 3, 14 of input shaft 1, support bearings 5, 8 of two stepped planetary gears 4, 7, and support bearings 11, 12 of output shaft 9 constitute. Among the figure, 13,15,16 all are retaining rings.

[0015] The input shaft 1 is supported by the first support bearing 3 and the second support bearing 14 respectively in the inner hole of the left housing 2 and the left end of the output shaft 9. There are two pairs of eccentric circles with a circumferential difference of 180° in the middle of the input shaft 1. The third support bearing 5 and the fourth support bearing 8 are installed on the circle, the inner hole of the stepped planetary gear 4 is sleeved on the outer ring ...

Embodiment 2

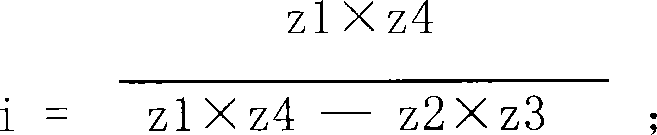

[0020] Embodiment 2: The difference from the first structure is that the teeth on the two-step planetary gears 4 and 7 are all external teeth, and the left end of the output shaft 9 has a ring of internal teeth, and the rest of the structure is the same as the first structure.

[0021] As shown in Figure 2: the reducer mainly includes an input shaft 1, a first stepped planetary gear 4, a second stepped planetary gear 7, an internal gear 6 and an output shaft 9, as well as a first support bearing 3 for supporting the input shaft 1 and The second support bearing 14 is used to support the third support bearing 5 and the fourth support bearing 8 of the two-step planetary gears 4 and 7 , and the fifth support bearing 11 and the sixth support bearing 12 are used to support the output shaft 9 . Among the figure, 2 is the right housing, 10 is the left housing, and 13 is a retaining ring.

[0022] The input shaft 1 is supported by the first support bearing 3 and the second bearing 14 r...

Embodiment 3

[0028] Embodiment 3: Figures are omitted, the two-stage planetary gears are both external gears, and the modulus difference between the first-stage and second-stage gears in the meshing of two-stage internal and external gears is 0.25, such as 1.25 for the first stage and 1.5 for the second stage , by adjusting the displacement coefficient x to ensure that the center distance between the two pairs of gears is e.

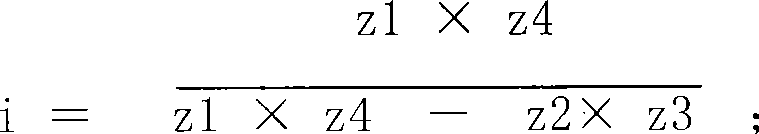

[0029] transmission ratio i = z 1 × z 4 z 1 × z 4 - z 2 × z 3 ; zi and z3 are the external teeth of the stepped planetary gear, z2 is the internal tooth of the internal gear 6; z4 is the internal tooth fixed on the output shaft.

[0030] z1=z3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com