Industry intelligent camera

A smart camera and industrial technology, applied in TV, color TV parts, electrical components, etc., can solve the problems that cannot meet the needs of product quality inspection, difficult new product inspection, single function, etc., and achieve low manufacturing cost and strong versatility sex, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

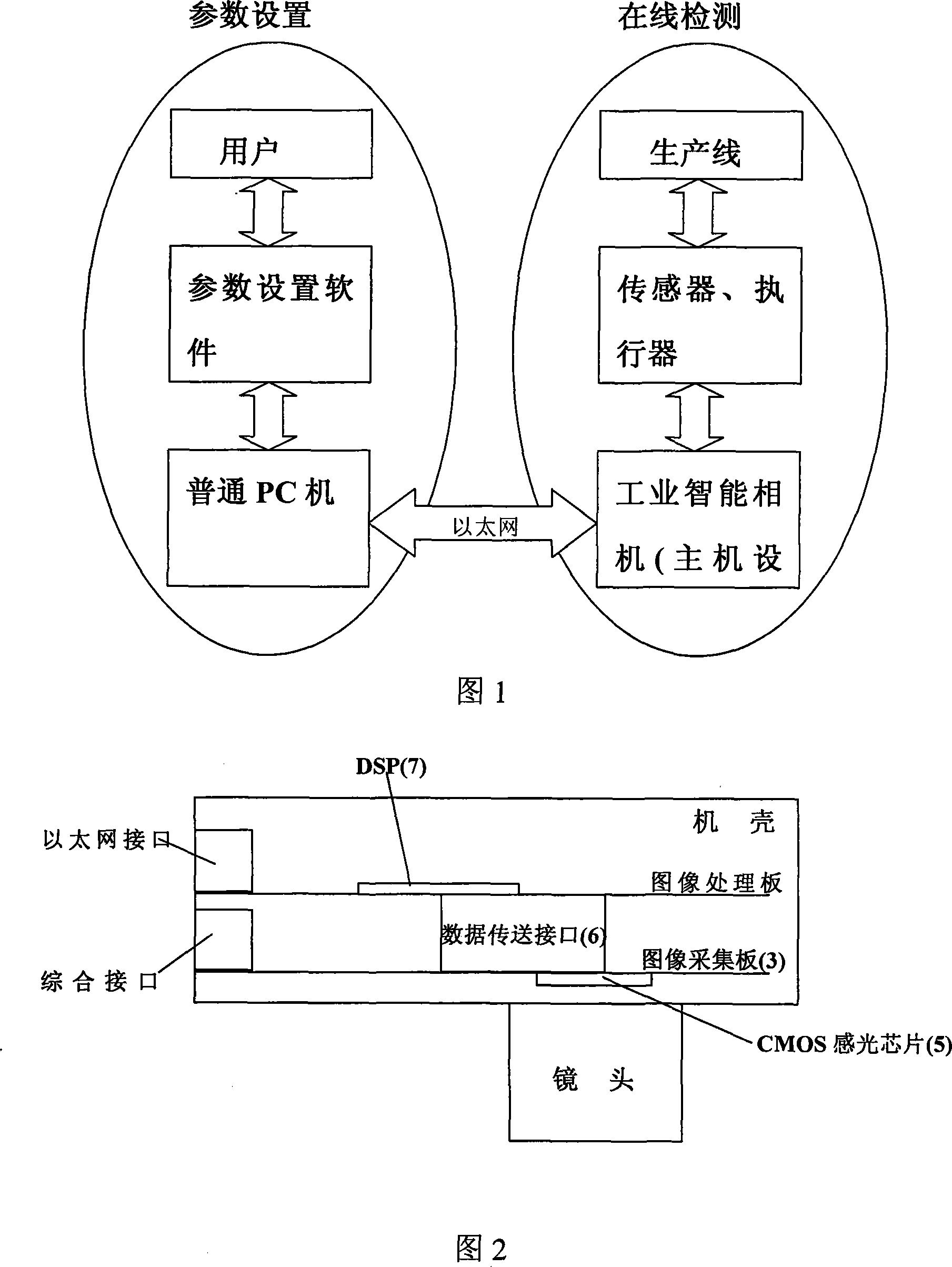

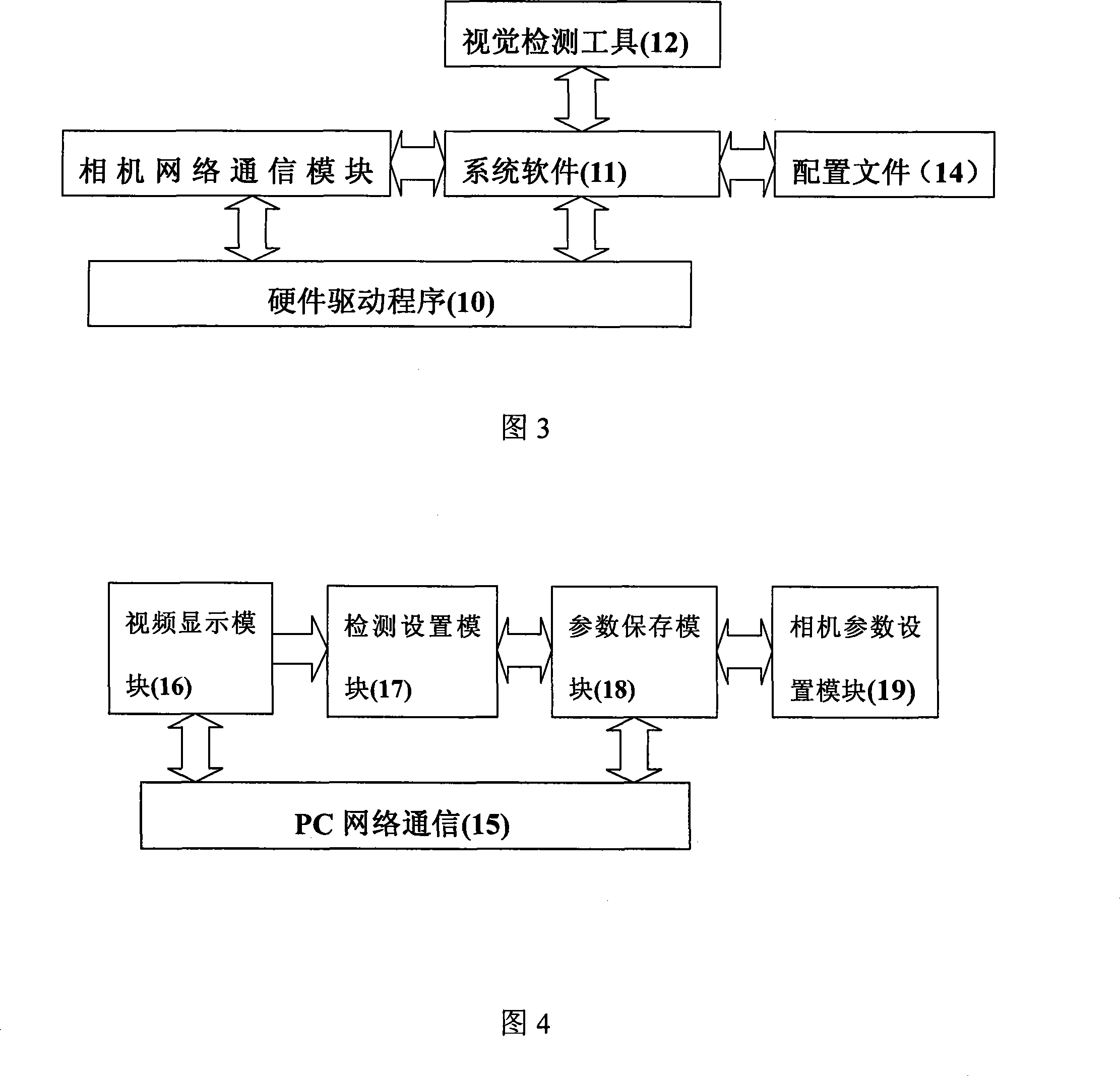

[0018] The structural block diagram of the industrial smart camera of the present invention is shown in Fig. 1, and the industrial smart camera includes a host device and a set of parameter setting software. The hardware part of the host device includes an image acquisition board and an image processing board; the software part of the host device includes two parts: system software and a visual inspection tool. The parameter setting software runs on the PC.

[0019] The host equipment of the industrial smart camera is installed on the production line, and the cooperation of sensors and actuators constitutes a machine vision online detection system. Before use, the user can use the parameter setting software running on the PC to connect to the host device via Ethernet to set various parameters of the host device. After the setting is completed, the host device can run independently.

[0020] There is a lens interface under the casing of the host device, and a standard CS-type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com