Kitchen garbage pathogenic bacteria high-temperature inactivation technology

A kitchen waste and inactivation technology, applied in waste disinfection or sterilization methods, heating, irradiation and other directions, can solve the problems of unfavorable landfill, incineration, composting, pyrolysis, and high water content of kitchen waste, reaching Conducive to high temperature heat transfer, rapid temperature rise and strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

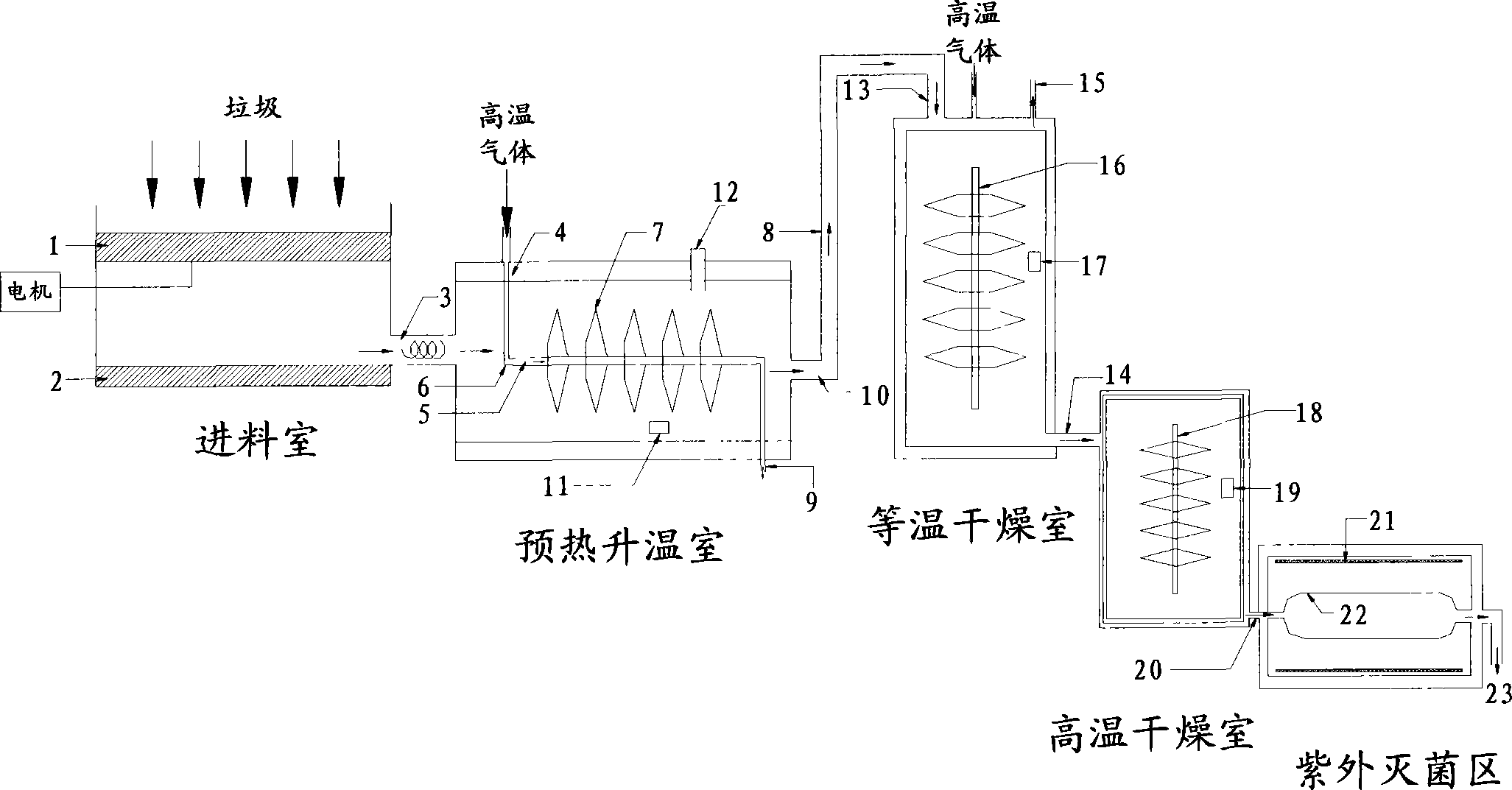

[0014] An application example of the device and method is described with reference to FIG. 1 . Xining Qinghai Jieshen Food Waste Disposal Industry Co., Ltd. has established a 60 tons / day harmful bacteria inactivation drying sterilizer based on this technology.

[0015] Through compression, crushing, and dehydration, the particle size of the food waste particles is kept at 0.1-10mm, and the humidity is less than 60%. Then the treated food waste is sent to the feeding port, and then passes through the preheating room, isothermal drying room, High-temperature heating chamber and ultraviolet inactivation chamber are used to inactivate harmful bacteria with high-temperature ultraviolet rays. After entering the preheating room, the temperature of the food waste is raised to 120 °C at 7 °C per minute, and then kept for 15 minutes; in the isothermal drying room, the temperature is maintained at 120 °C, and the food waste stays for 30 minutes under the agitation of the spiral stirrer; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com