Device using vacuum to rapidly regulate particulate material dampening

A granular material, fast vacuum technology, applied in the application, grain processing, grain milling and other directions, can solve the problems of increasing processing procedures and production costs, slow water mist immersion into grain, unsatisfactory infiltration effect, etc. effect, energy consumption reduction, power reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

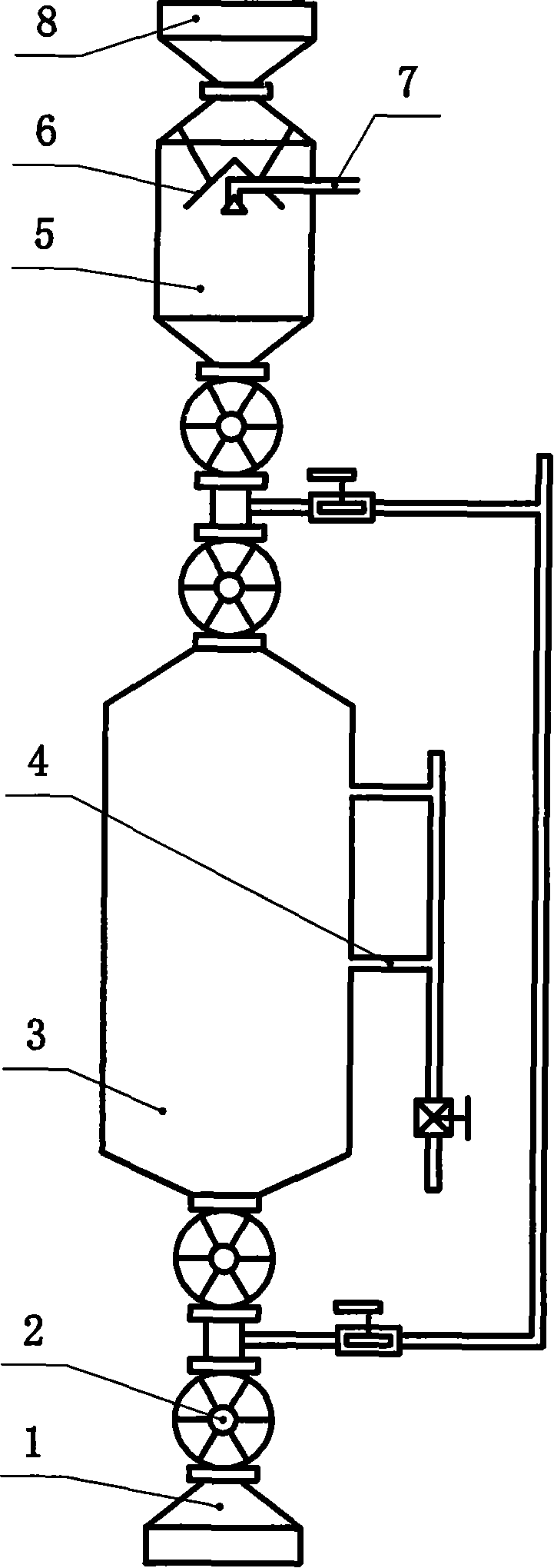

[0020] Embodiment one: see figure 1 , in the figure, the upper and lower ends of the hollow silo 3, which is a device for quickly adjusting the impingement of granular materials by vacuum, are respectively installed in series with two high-tightness airlocks 2 (the rotating speed of all high-airtightness airlocks The same), the middle connection housing of two high airtight airlocks 2 installed in series is provided with a vacuum tube, and the uppermost high airtight airlock 2 is connected to the housing 5 of the grain spraying water mechanism. The lower end is connected, the upper end of the casing 5 of the grain spraying water mechanism is connected with the lower end of the grain inlet section 8, the lowermost air-tight air sealer 2 is connected with the upper end of the grain outlet section 1, and the body wall of the hollow silo 3 A vacuum tube 4 is arranged on it.

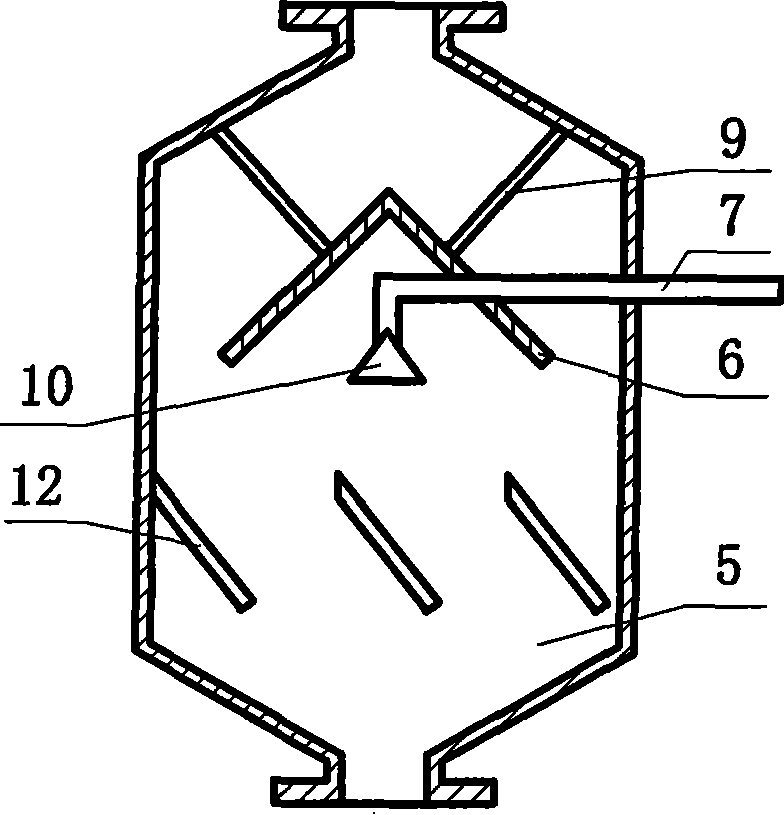

[0021] The grain spraying mechanism includes a housing 5, a feeder 6 and a water mist nozzle 10, the feed...

Embodiment 2

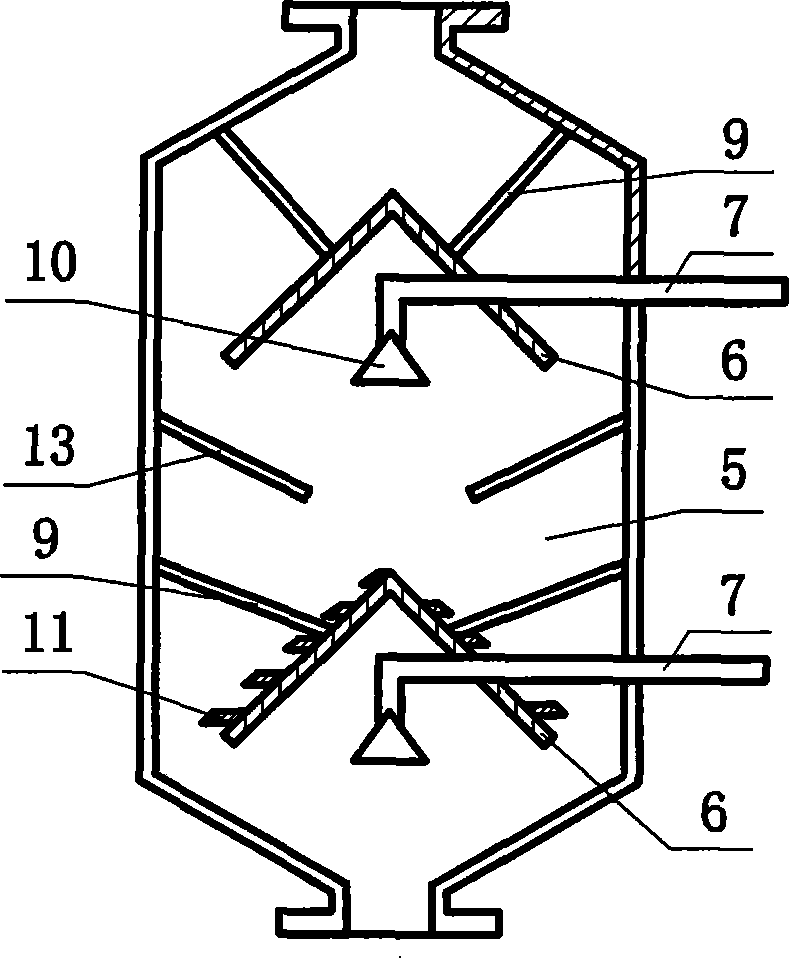

[0025] Embodiment two: this embodiment is basically the same as embodiment one, and the similarities will not be repeated. The difference is that the secondary swirl plate is multilayer (can be two layers, three layers, or four layers) layer or more), and the upper and lower adjacent secondary swirl plates have the same or opposite swirl direction, so that the grain will generate multiple swirls to improve the water landing effect.

Embodiment 3

[0026] Embodiment three: see image 3 , the numbers in the figure are the same as those in Embodiment 1, and the representative meanings are the same, and the same parts will not be repeated. The difference is that: the distributor 6 and the water mist nozzle 7 are two layers (it can also be more than two layers, depending on the housing 5 and the degree of water impingement of the granular material), and the inner wall of the housing between the adjacent distributor 6 and the water mist nozzle 7 is provided with a deflector 13, which is convenient for the material to flow to the center and be used by the next The feeder spins. The outer surface of the distributor 6 is provided with a swirl plate 11 (it can be arranged on the upper surface of a distributor 6, or it can be arranged on the upper surface of all the distributors 6, and of course it can not be provided, it can be determined according to the needs, no Enumerate one by one), the grain is evenly rotated and dropped, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com