Method for processing center frame of equal height triangle sleeve barrel structure and triangle sleeve barrel

A processing method and the technology of the center rest, which are applied in metal processing equipment, manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, etc. problems, to achieve the effect of ensuring stability, dynamic rigidity, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

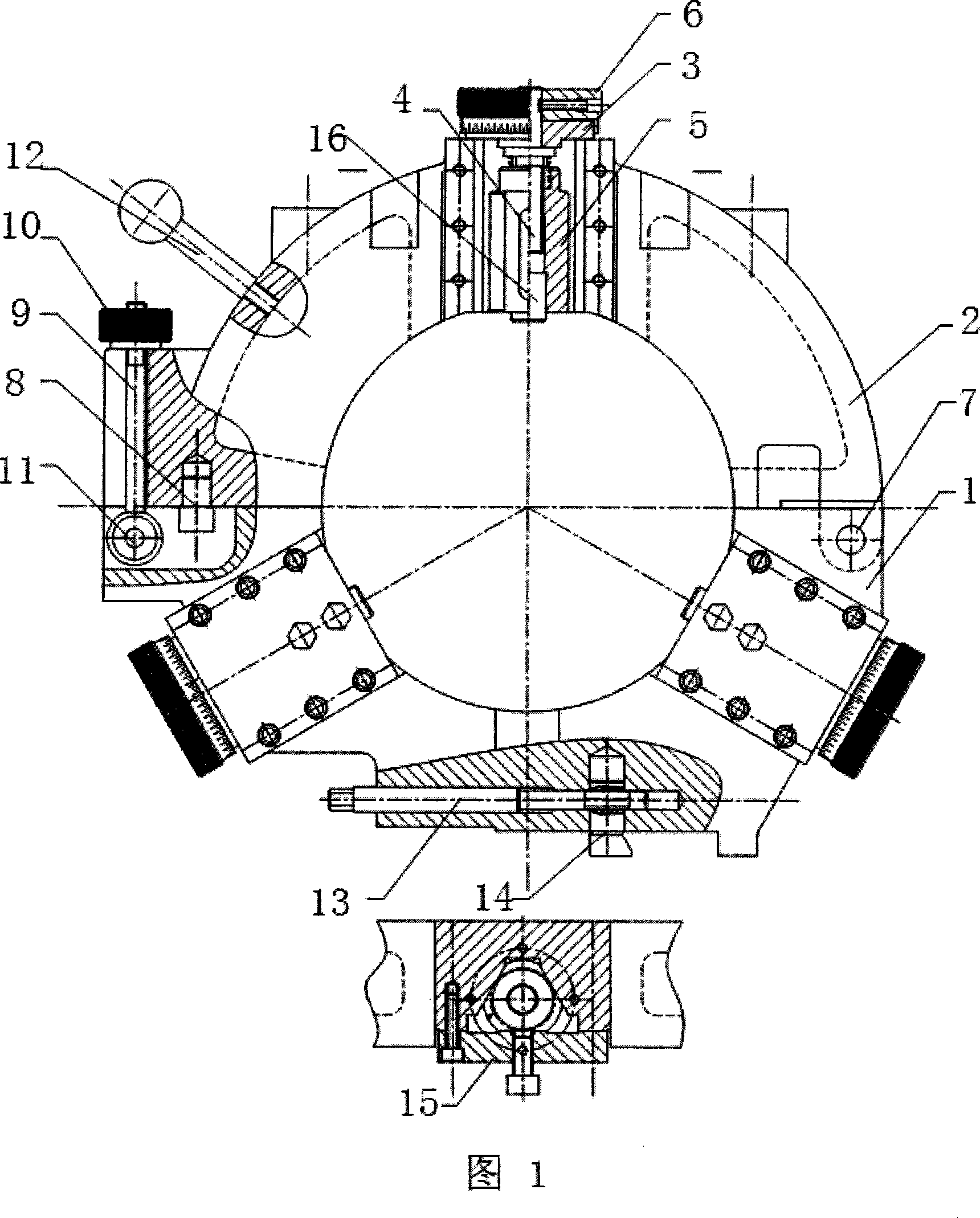

[0028] Embodiment 1: As shown in Figure 1, a precision center frame with a triangular sleeve structure of equal height, including: a center frame base 1, a center frame upper body 2, a flange plate 3, a lead screw 4, a triangular sleeve 5, Hand wheel 6, shaft 7, positioning pin 8, pull rod 9, lock nut 10, pin shaft 11, handle 12, eccentric tight rod 13, tight block 14, gland 15, top column 16,

[0029] The base 1 of the center frame and the upper body 2 of the center frame are equipped with three groups of equal-height triangular sleeve 5 mechanisms, which are distributed at 120° to each other. The triangular sleeve 5 coordinates with the center frame base 1 and the center frame upper body 2 respectively with three corresponding 60° grooves scraped into position, and is pressed by three glands 15 respectively. The three flanges 3 fixed on the base 1 of the center frame and the upper body 2 of the center frame can realize the radial positioning of the three sets of micrometer s...

Embodiment 2

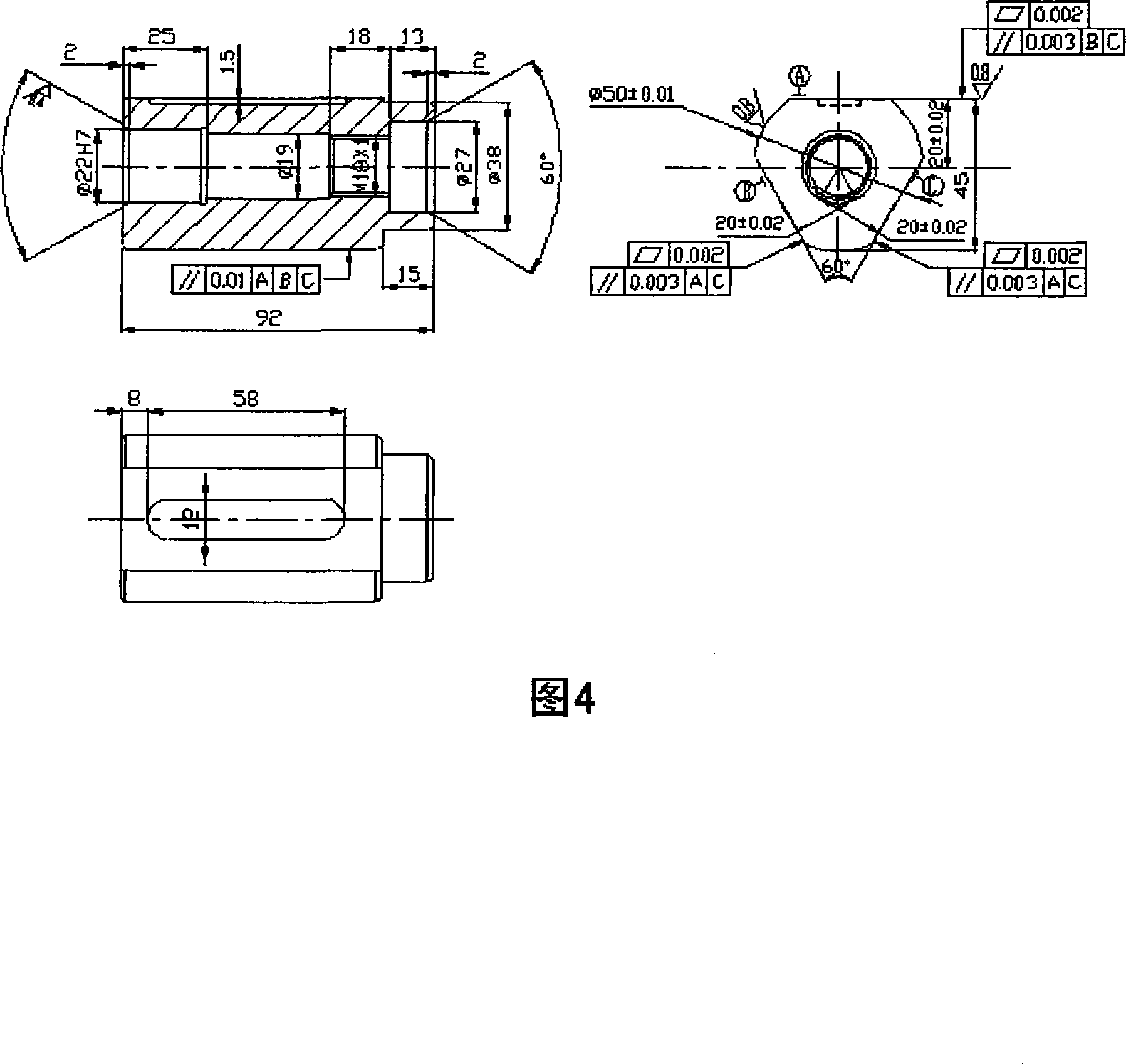

[0030] Embodiment 2: a kind of processing method of contour triangular sleeve, containing step is:

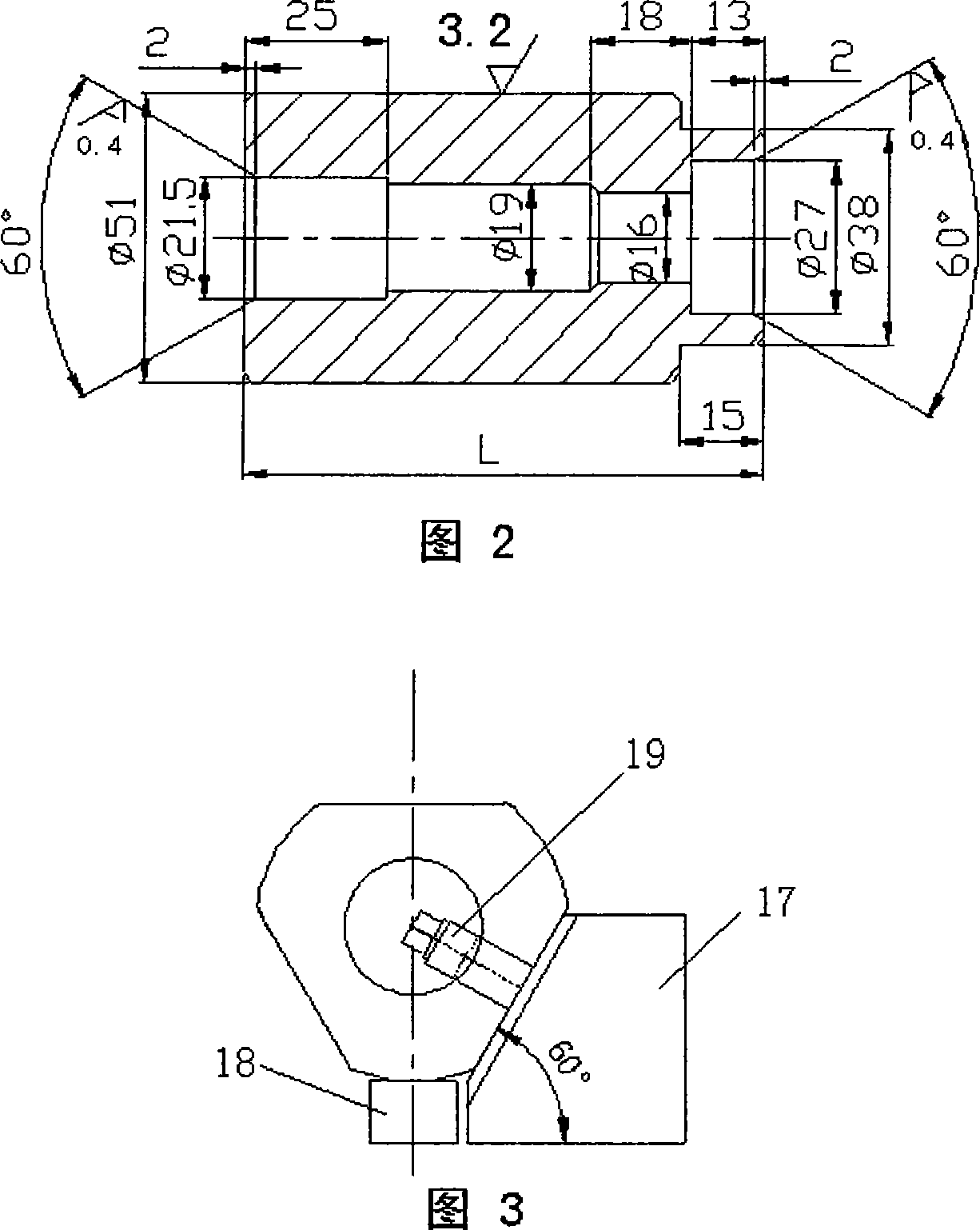

[0031] (1) Design and manufacture of debugging rods: as shown in Figure 2, except for the A, B, and C surfaces with an included angle of 60°, the other debugging rods are exactly the same as in Figure 4, as shown in the figure: the center of both ends The hole must be carefully drilled, and it should be ring-shaped in contact with the front and rear tops of the cylindrical grinder without gaps. Otherwise, the roundness and cylindricity of the outer circle can not meet the requirements.

[0032] (2) Trial grinding with a debugging rod, and adjust the cylindrical grinding machine to be used: use the debugging rod with a well-ground center hole to grind the outer circle on the cylindrical grinding machine to be used, and adjust the machine tool to make the roundness of the outer circle to be ground Both the cylindricity and cylindricity meet the requirements of less than 1 μm. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com