Light temperature-keeping combined wall

A wall and lightweight technology, applied to walls, building components, buildings, etc., can solve problems such as unfavorable on-site construction, poor thermal insulation performance, and poor impact resistance, so as to improve construction efficiency, improve thermal insulation performance, and increase the use of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

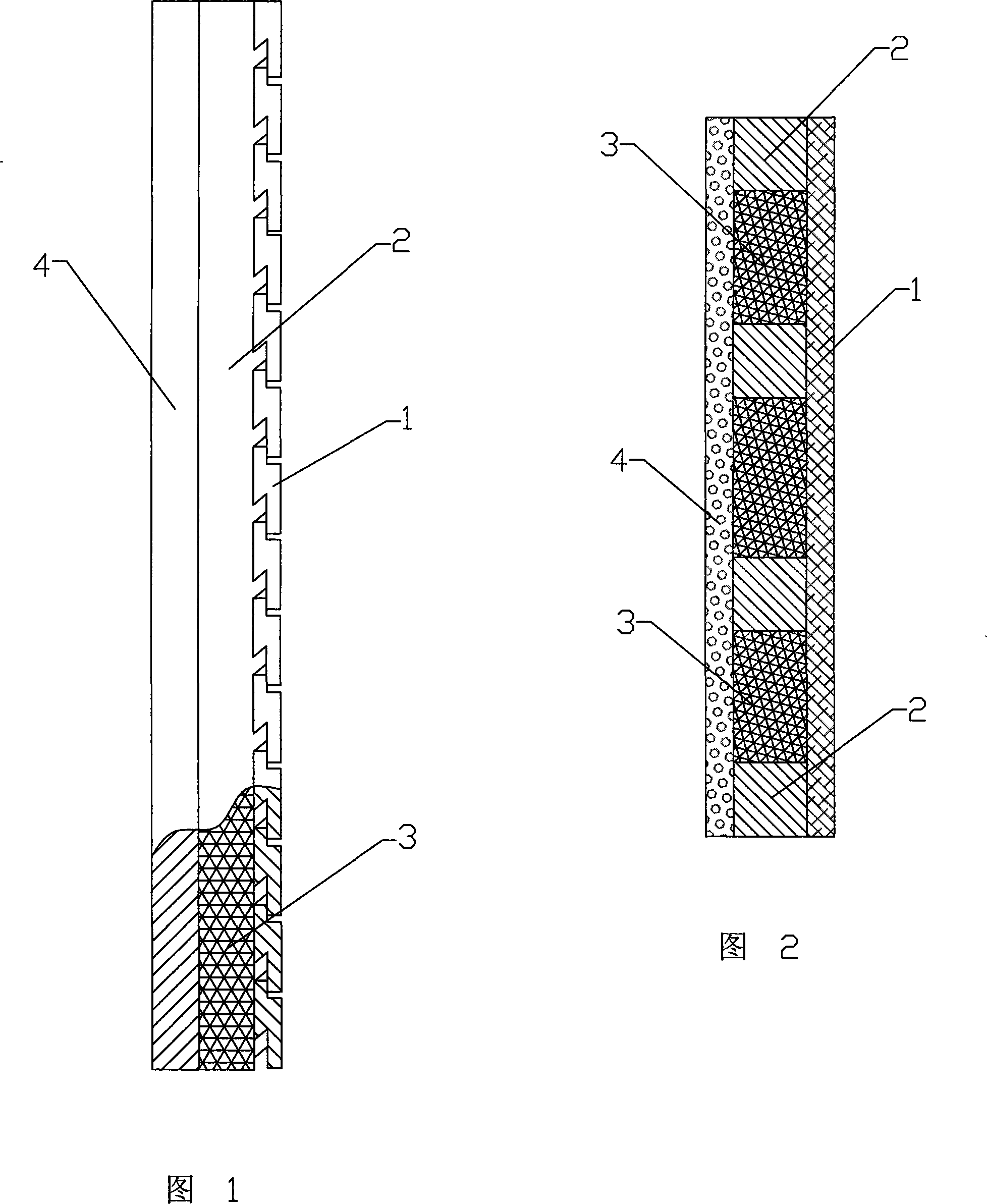

[0025] Embodiment 1, as shown in Figure 1, a light-weight thermal insulation composite wall, including several hanging columns 2 and concrete hanging boards 1 installed on the hanging columns 2, the hanging columns 2 are opposite to the concrete hanging boards 1 One side is provided with a cement foam decorative board 4, and an insulating layer 3 composed of a cement polystyrene particle grouting pouring layer is provided between the cement foam decorative board 4 and the concrete hanging board 1, as shown in Figure 2, the described The thermal insulation layer 3 is filled in the cavity formed by the adjacent hanging columns 2, the concrete hanging board 1 and the foamed cement decorative board 4, the thickness of the concrete hanging board 1 is 4cm, and the hanging column 2 and the insulation The thickness of the layer 3 is 10 cm, and the thickness of the cement foam decorative board 4 is 3 cm.

[0026] The thermal insulation layer can also be made of one of cement perlite gr...

Embodiment 2

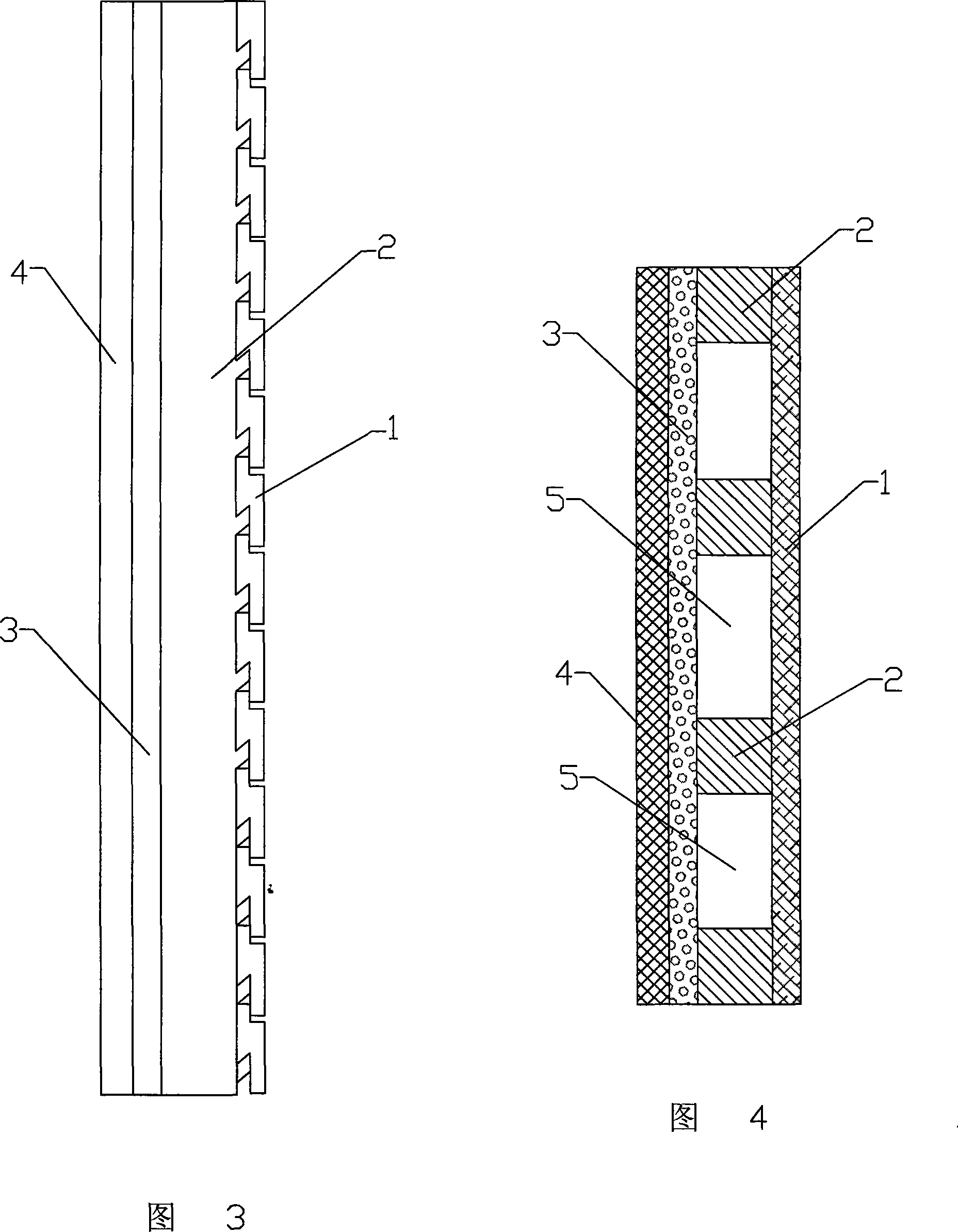

[0027] Embodiment 2, as shown in Figure 3, a light-weight thermal insulation composite wall, including several hanging columns 2 and concrete hanging boards 1 installed on the hanging columns 2, the hanging columns 2 are opposite to the concrete hanging boards 1 One side is provided with a cement foam decorative board 4, and an insulating layer 3 made of glass wool board is arranged between the cement foam decorative board 4 and the concrete hanging board 1, as shown in Fig. 4, the described insulating layer 3 is arranged on Between the cement foam decorative board 4 and the hanging column 2, a cavity 5 is formed between the hanging column 2, the concrete hanging plate 1 and the insulation layer 3,

[0028] The insulation layer can also be made of polystyrene board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com